Mixed coating lithium battery diaphragm and preparation method thereof

A lithium battery diaphragm and coating technology, which is applied in the direction of secondary batteries, battery pack components, circuits, etc., to achieve the effects of favorable battery capacity retention, easy absorption, and good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

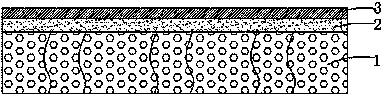

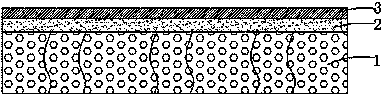

[0031] Such as figure 1 Shown, a kind of lithium battery diaphragm of mixed coating, base film 1 and the coating layer 2 that is coated on one side of base film constitute, the upper surface of coating layer is coated with the coating layer 3 of PMMA / PVDF, described The thickness of the coating layer 2 is 1-2um, and the thickness of the coating layer 3 of the PMMA / PVDF is 0.3-1.8um;

[0032] The coating layer 2 is composed of the following parts by mass: 20 parts of alumina micropowder, 40 parts of aluminum hydroxide micropowder, 2 parts of adhesive, 1 part of cosolvent, 1 part of emulsifier, 2 parts of pore forming agent, 0.5 parts of ethylene oxide dispersant and 20 parts of water;

[0033] The coating layer 3 of PMMA / PVDF consists of the following parts by mass: 20 parts of ceramic powder, 20 parts of PVDF powder, 20 parts of PMMA powder, 1 part of coupling agent, 2 parts of dispersant, 5 parts of wetting agent, 2 parts of defoamer, 2 parts of co-solvent, 1 part of emulsi...

Embodiment 2

[0041] Such as figure 1 Shown, a kind of lithium battery diaphragm of mixed coating, base film 1 and the coating layer 2 that is coated on one side of base film constitute, the upper surface of coating layer is coated with the coating layer 3 of PMMA / PVDF, described The thickness of the coating layer 2 is 1-2um, and the thickness of the coating layer 3 of the PMMA / PVDF is 0.3-1.8um;

[0042] The coating layer 2 is composed of the following parts by mass: 22 parts of alumina micropowder, 45 parts of aluminum hydroxide micropowder, 3 parts of adhesive, 2 parts of cosolvent, 1.5 parts of emulsifier, 4 parts of pore-forming agent, poly 1 part of ethylene oxide dispersant and 22 parts of water;

[0043] The coating layer 3 of PMMA / PVDF consists of the following parts by mass: 25 parts of ceramic powder, 22 parts of PVDF powder, 22 parts of PMMA powder, 1.3 parts of coupling agent, 4 parts of dispersant, 6 parts of wetting agent, 3 parts of defoamer, 3 parts of co-solvent, 1.2 parts...

Embodiment 3

[0051] Such as figure 1 Shown, a kind of lithium battery diaphragm of mixed coating, base film 1 and the coating layer 2 that is coated on one side of base film constitute, the upper surface of coating layer is coated with the coating layer 3 of PMMA / PVDF, described The thickness of the coating layer 2 is 1-2um, and the thickness of the coating layer 3 of the PMMA / PVDF is 0.3-1.8um;

[0052] The coating layer 2 is composed of the following parts by mass: 25 parts of alumina micropowder, 50 parts of aluminum hydroxide micropowder, 3 parts of adhesive, 2 parts of cosolvent, 2 parts of emulsifier, 4 parts of pore-forming agent, poly 1 part of ethylene oxide dispersant and 25 parts of water;

[0053] The coating layer 3 of PMMA / PVDF consists of the following parts by mass: 30 parts of ceramic powder, 25 parts of PVDF powder, 25 parts of PMMA powder, 107 parts of coupling agent, 6 parts of dispersant, 7 parts of wetting agent, 4 parts of defoamer, 4 parts of co-solvent, 1.6 parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com