Cutter for electrical adhesive tape

A technology of electrical tape and cutter, which is applied in the directions of sending objects, thin material handling, transportation and packaging, etc., can solve the problems of troublesome operation, troublesome cutting process of electrical tape, inconvenient to turn around, and inconvenient to take and place tools, so as to achieve a reasonable structure. , Easy to carry and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further specifically described below through embodiments and in conjunction with the accompanying drawings.

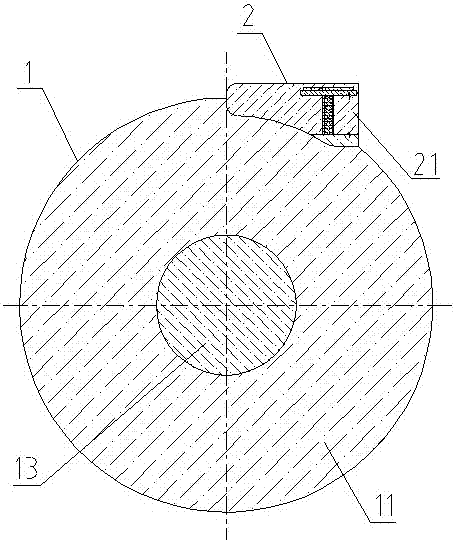

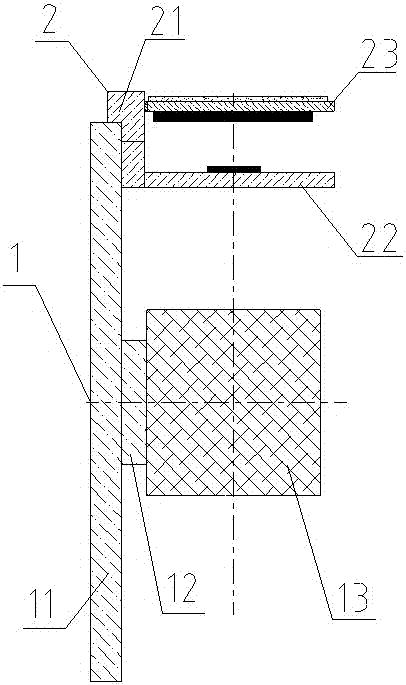

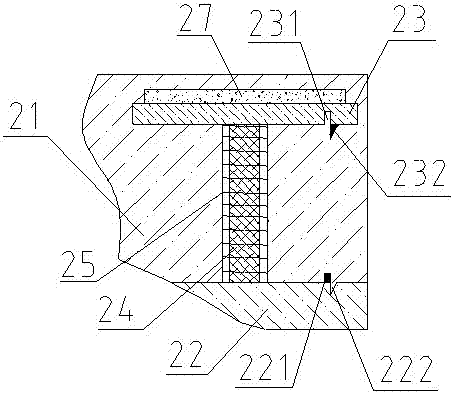

[0020] Such as figure 1 , figure 2 , image 3 , Figure 4 Shown: a cutter for electrical tapes, including a tape holder 1 and a cutting device 2, the tape holder 1 includes a baffle 11, a connecting shaft 12 and a drum 13, the baffle 11 is circular, The connecting shaft 12 is arranged at the center of the inner surface of the baffle plate 11, and is fixed and vertically connected with the baffle plate 11. The rotating cylinder 13 is a cylindrical structure with one end open, and the rotating cylinder 13 is sheathed on the baffle plate 11. The outer side of the connecting shaft 12 is rotationally connected with the connecting shaft 12; the cutting device 2 includes a fixed plate 21, a bottom plate 22 and a cutting plate 23, the fixed plate 21 is fixedly welded to the inner surface of the baffle plate 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com