Extruding, filtering and stirring device for feeding end of micro-jet equipment and cleaning mode

A feed end and agitator technology, which is applied in the field of extrusion, filtration, stirring and cleaning devices, can solve the problems of time-consuming and labor-intensive, no collision, no design device, etc., and achieves saving manpower and material resources, novel structure, and satisfying aseptic requirements. production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing, and the structure and principle of this device are very clear to those skilled in the art. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

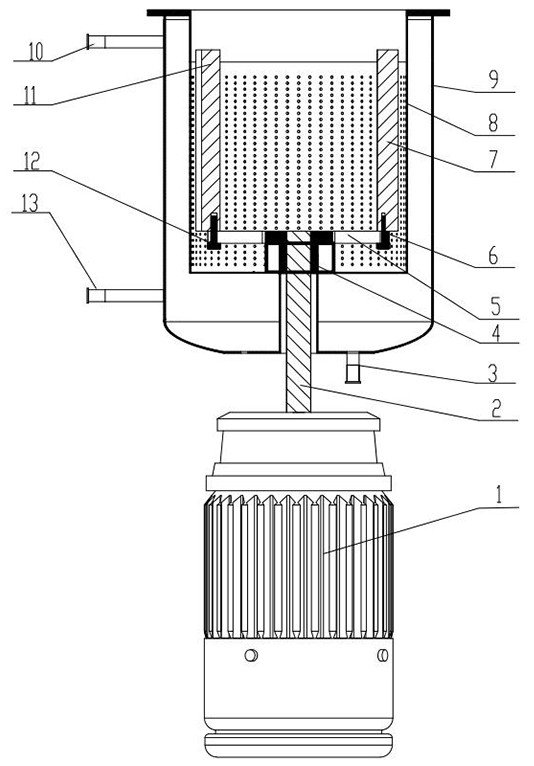

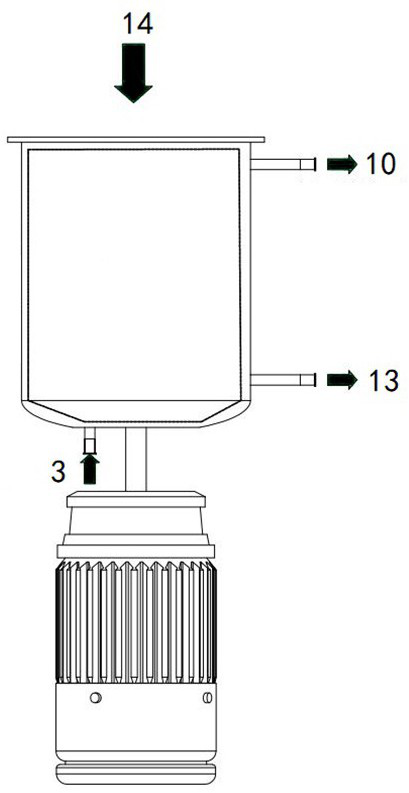

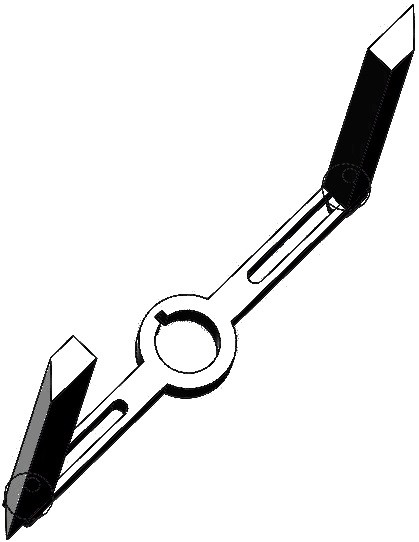

[0026] see figure 1 Generally speaking, at the feeding end of the micro-fluidic equipment, there are generally charging barrels and filtering barrels, and the filtering barrel is located inside the charging barrel. The extruding filter agitator is arranged inside the filter barrel, and mainly includes a combined transmission part composed of a first scissors-face scraper, a second scissors-face scraper, a sliding connecting rod, and a rotating central shaft.

[0027] As shown in the figure, a motor is connected under the extruding filter agitator, and the motor is connected with the rotating neutral ash. The motor is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com