In situ gelifying powder

A technology of powder and pectin, which can be used in powder delivery, chemical preservation of meat/fish, drug combination, etc., and can solve problems such as shortening gelation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0267] Example 1 - Preparation of liquid composition

[0268] 1A) Aqueous composition (free of inorganic salts)

[0269] 1a) Preparation of sodium alginate solution

[0270] 53.6 mg of sodium alginate (whose mannuraldehyde residue content is 65% by weight relative to the total weight of sodium alginate) (FMC Biopolymer) was added to 21.4 ml of distilled water, and the solution was left under stirring for about 10 minutes.

[0271] 1b) Preparation of sodium alginate and pectin aqueous composition

[0272] To the sodium alginate solution prepared as described in a) was added 53.6 mg of amidated pectin (with a degree of amidation (DA) of 18% to 23% and a degree of methoxylation (DM) of 27% to 32%) (Herbstreith & Fox), the resulting solution was left under stirring for 15 minutes.

[0273] 1c) Preparation of colloidal chitosan solution

[0274] 8.9 mg of chitosan (with a molecular weight of 50000 to 150000 DA) (Sigma Aldrich) was added to 3.6 ml of a 0.1 M HCl solution in dist...

Embodiment 2

[0292] Example 2 - Preparation of the composition in powder form

[0293] 2A) Preparation of Compositions in Submicron Powder Form

[0294] Samples of each liquid composition obtained in Examples 1b (comparison), 1d and 1e (invention), respectively, were maintained under continuous agitation and dried with the aid of a Nano Spray Dryer B-90 instrument (BuchiLaboratoriums-Tecnik, Flawil , Switzerland) through nano-spray drying technology for atomization process. The inlet temperature in the atomizer for composition 1b (comparative) was 90°C, whereas for the particular composition 1d or 1e (invention) it was 50°C, ie advantageously lower.

[0295] The remaining process parameters were the same for both the comparative and inventive compositions, as follows:

[0296] - atomizer feed rate 9.5ml / min;

[0297] - The diameter of the atomizing nozzle is 4.0 microns;

[0298] - Incoming air flow 100L / min;

[0299] - a pressure of 38 mbar in the drying chamber;

[0300] - Relative...

Embodiment 3

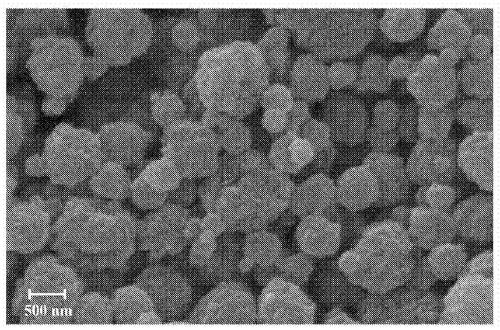

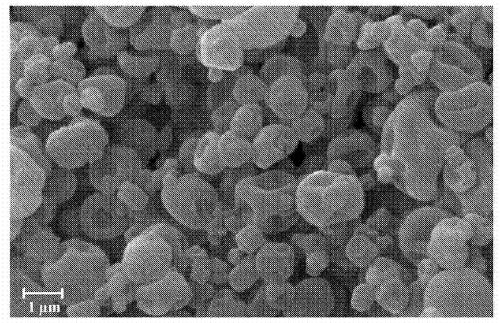

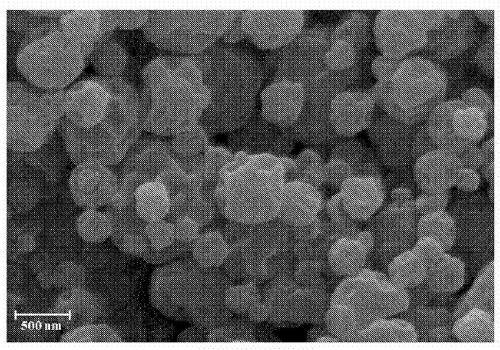

[0326] Example 3 - Morphological analysis of the composition of the invention in powder form

[0327] Nanospray as described in Example 2A or 2B and the Compositions (2d1) and (2d2) in powder form according to the invention prepared by the micro-spray drying technique were analyzed. The powder particles were coated with 200A thick gold patina by means of a LEICA EMSCD005 metallizer. Analysis was performed at 20 KeV. At least 20 SEM images were obtained for each individual sample to verify the morphological uniformity of the particles.

[0328] like Figure 1A As shown in SEM analysis, the particles of the submicron-scale powder (2d1) have spherical shape and high surface roughness, which makes the particles easy to contact with liquid.

[0329] like Figure 1B As shown in the SEM analysis, the particles of the micron-sized powder (2d2) have a generally spherical shape and their surface roughness is lower than that of the sub-micron-sized powder (2d1).

[0330] Composition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com