Cross-linked plugging agent stimulated by high density brine and preparing method thereof

a plugging agent and high density brine technology, applied in the field of oilfield chemistry, can solve the problems of increasing the cost, increasing the requirement, and high cost during well completion and workover, and achieves the effects of good pumpability, effective protection of the reservoir, and viscosity of the plugging agen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

[0042]A cross-linked plugging agent stimulated by high density brine for temporary blockage comprises the mixture of main agent of 70 wt %, gelling agent of 5 wt %-8 wt % and pure water. The experiment temperature is 120° C. The gelation time and a gelation strength are shown in the below table 2.

TABLE 2gelation time and a gelation strength in embodiment 1Gelling agentAging time / gel strength codecontent Wt %Initial2 h4 h12 h1 D3 D5 D7 D9 D12 D5ADGGGGGGGG7ADGGGGGGGG8ADGGGGGGGG

[0043]As shown in Table 2, the gelation time is within 2-4 hours; the final forming strength is G; no syneresis happens within 12 days.

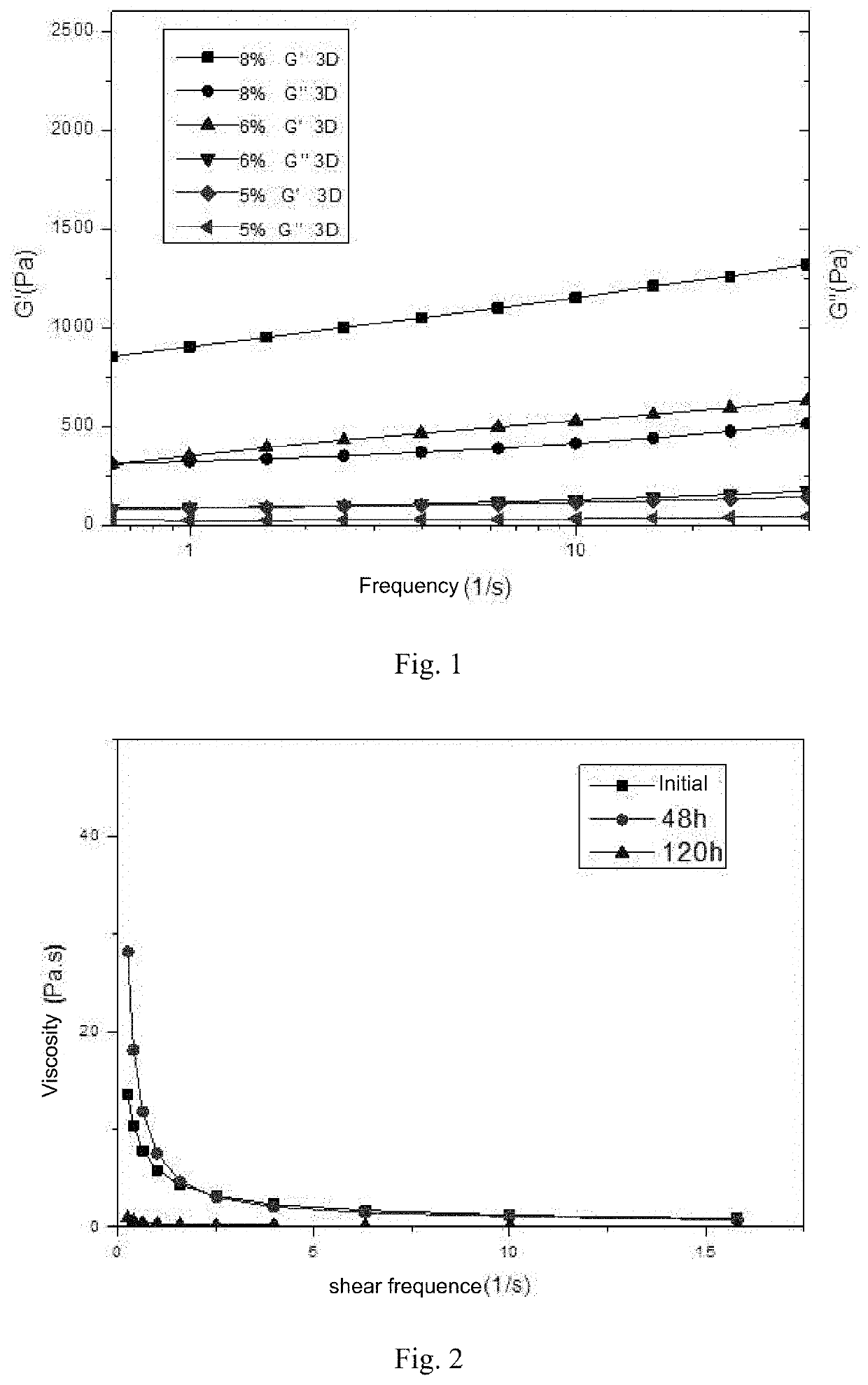

[0044]As shown in FIG. 1, the values of elastic modulus and loss modulus of various gelling agent content after aging for three days prove that the strength of the plugging agent is able to be adjusted by adjusting the gelling agent content.

embodiment 2

[0045]A cross-linked plugging agent stimulated by high density brine for protection of reservoir near perforations comprises main agent of 70 wt %, gelling agent of 1.5 wt %-3 wt % and pure water. The experiment temperature is 160° C. The gelation time and a gelation strength are shown in the below Table 3.

TABLE 3gelation time and a gelation strength in embodiment 2Gelling agentAging time / gel strength codecontent Wt %Initial4 h8 h1 D2 D3 D4 D1.5ABDDDDAsyneresis2ABDDDDDsyneresis2.5ABEEEEEsyneresis3ABEEEEE

[0046]As shown in table 3, the gelation time is within 4-8 hours; the final forming strength is D or E; syneresis and degradation occur on the third day; the plugging agent degrades to solid-free and low viscosity fluid 48 hours after syneresis begins.

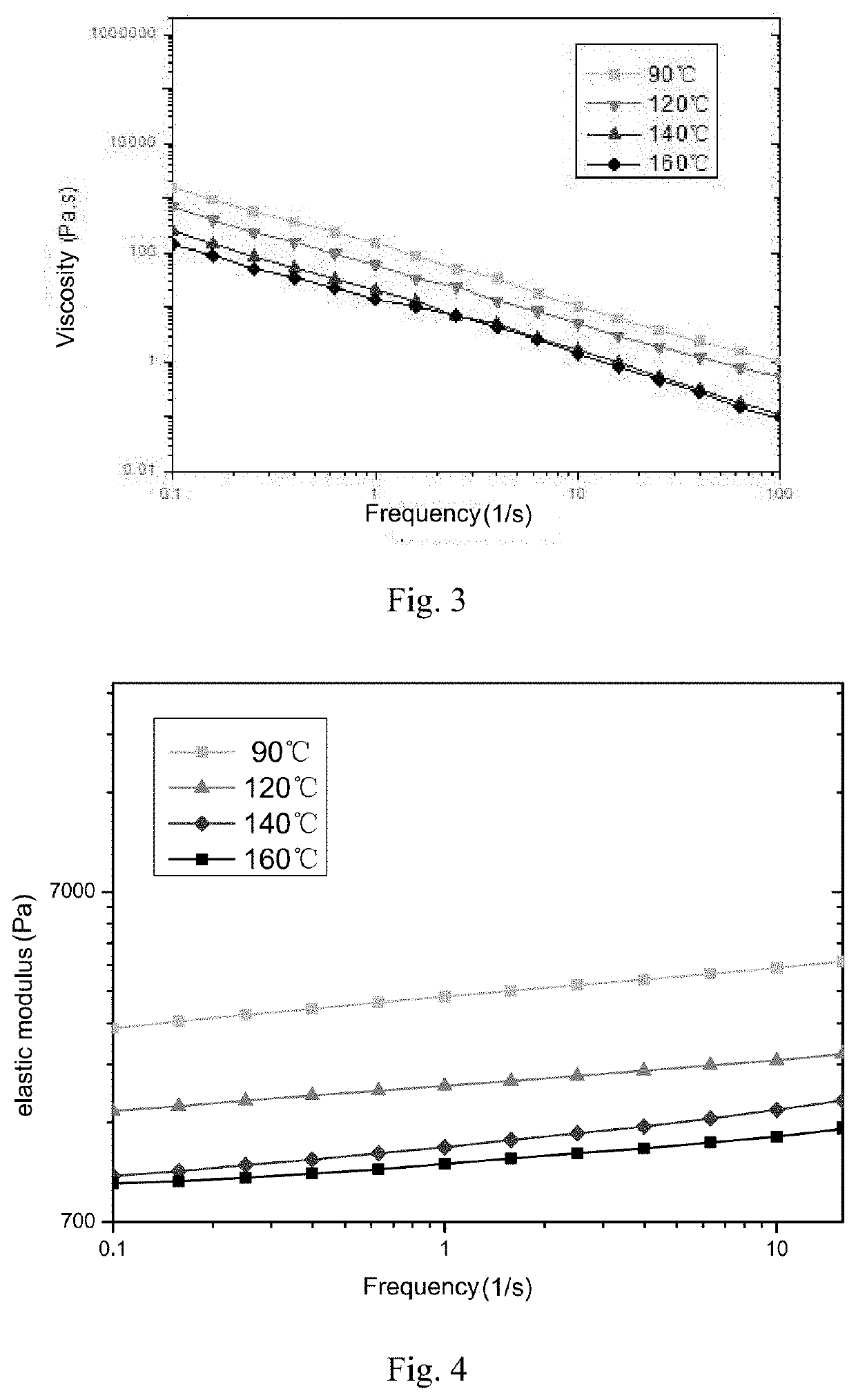

[0047]As shown in FIG. 2, the viscosity and shear force curve of the plugging agent with 2 wt % of gelling agent content at the initial time, after two days and after five days illustrates the viscosity of the plugging agent at the init...

embodiment 3

[0048]A cross-linked plugging agent stimulated by high density brine for temporary blockage comprises main agent of 70 wt %, gelling agent of 6 wt %-8 wt % and pure water. The experiment temperature is 90° C. The gelation time and a gelation strength are shown in the below table 4.

TABLE 4gelation time and a gelation strength in embodiment 3Gelling agentAging time / gel strength codecontent Wt %Initial2 h4 h12 h1 D3 D5 D7 D9 D12 D6ADFFFFFFFF7ADFGGGGGGG8ADGHHHHHHH

[0049]As shown in table 4, the gelation time is within 2-4 hours; the final forming strength is F, G or H; no syneresis happens within 7 days. The plugging agent is able to be applied in temporary blockage and water plugging when different gel strength is required.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com