A kind of preparation method of nano metal oxide

A nano-metal and oxide technology, which is applied in the dye manufacturing process and the field of nano-inorganic compound photocatalytic materials, can solve problems that affect implementation and promotion, unstable production process, and increase production costs, so as to improve synthesis efficiency and reduce short condensation Gel time, the effect of accelerating synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

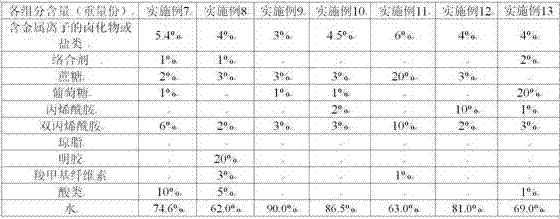

Examples

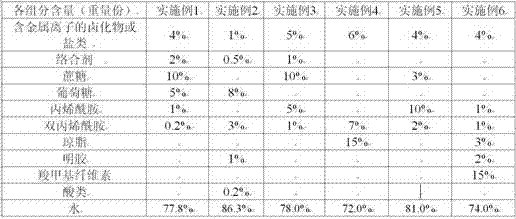

Embodiment 1

[0036] Under normal temperature and pressure, according to the component ratio specified in Table 1, 4% aluminum nitrate (Al(NO 3 ) 3 ), 2% complexing agent citric acid, 10% sucrose, 5% glucose, 1% acrylamide, 0.2% bisacrylamide were dissolved in water and stirred to form a uniform solution. In this embodiment, the inorganic salt aluminum nitrate is selected as the aluminum ion provider, and citric acid is selected as the complexing agent. Pour the stirred solution into a container, put 60 The Co-γ irradiation field is irradiated with 5 kGy to 25 kGy to synthesize the initial hydrogel. The synthesized hydrogel was put into a drying oven and dried at 120°C for 24 hours to become a xerogel. Grind the xerogel into powder using a ball mill. Afterwards, put the powdered gel into a sintering furnace and sinter at a temperature range of 1200°C for 3 to 5 hours to obtain nano-Al 2 o 3 particles.

Embodiment 2

[0038] The gel synthesis steps, drying, grinding, and sintering methods in this example are the same as in Example 1, but the raw material components, component weight percentages, radiation sources for gel synthesis, radiation doses, and sintering temperatures are different. In this embodiment, the halides or salts containing metal ions are Y(NO 3 ) 3 ·6H 2 O and Mn(CH 3 COO) 2 4H 2 O, used as yttrium and manganese ion donors respectively, Y(NO 3 ) 3 ·6H 2 O and Mn(CH 3 COO) 2 4H 2 O weight ratio is 0.78:1; Select tartaric acid as complexing agent; Acids are nitric acid; 60 Co-γ-ray irradiation 5 kGy ~ 60 kGy, sintering furnace temperature is 800 ℃, sintering for 3 ~ 5 hours, and finally synthesized nanometer YMn 2 o 5 particles.

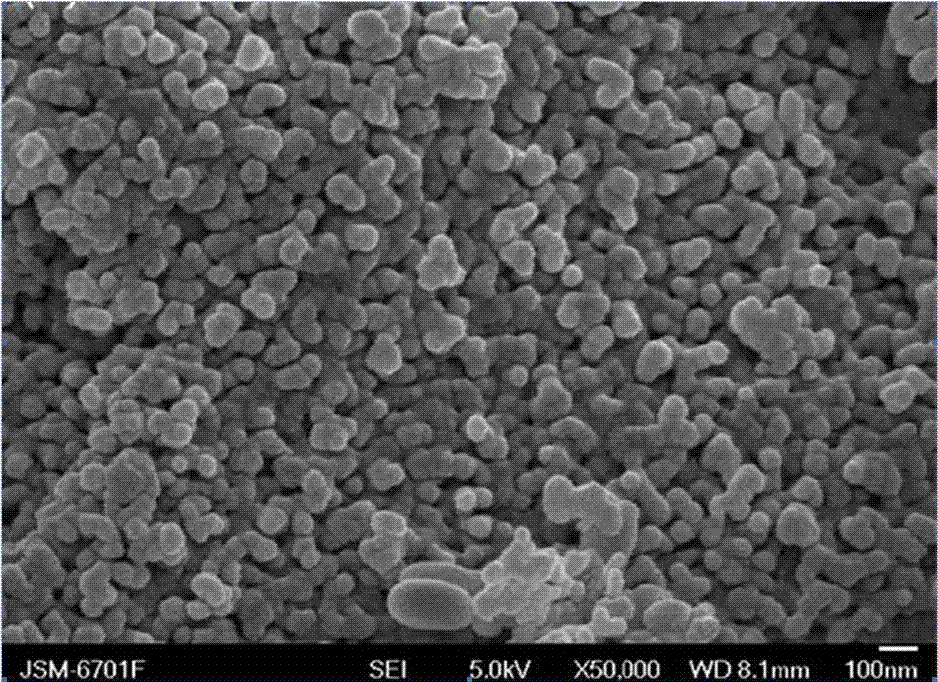

[0039] figure 1 It is the photo of this embodiment, which is the nanometer Ymn synthesized by this embodiment 2 o 5 Electron micrograph of the particles.

Embodiment 3

[0041] The gel synthesis steps, drying, grinding, and sintering methods in this example are the same as in Example 1, but the raw material components, component weight percentages, radiation sources for gel synthesis, radiation doses, and sintering temperatures are different. In this embodiment, the halides or salts containing metal ions are cobalt chloride (CoCl 2 ) and aluminum nitrite (Al(NO 2 ) 3 ), providing cobalt and aluminum ions respectively, the weight ratio of cobalt chloride and aluminum nitrite is 0.40:1; 60 Co-γ-ray irradiation 5 kGy ~ 35 kGy, the temperature range of sintering furnace is 300 ℃ ~ 600 ℃, sintering for 3 ~ 5 hours, and finally synthesize nano CoAl 2 o 4 particles, the nanoparticles can be used as excellent dyes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com