Dealcoholization type storage-resistant RTV electronic coating glue and preparation method thereof

A storage-resistant and dealcoholized technology, used in adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of poor storage stability, strong copper corrosion, strong odor, etc., and achieve excellent weather resistance, Good adhesion and stability, no environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

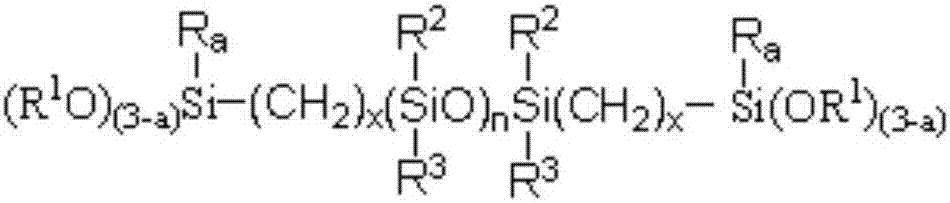

[0047] With 50 parts by mass of the base polymer (I) whose viscosity is 500mPa·s, its molecular formula is as follows:

[0048]

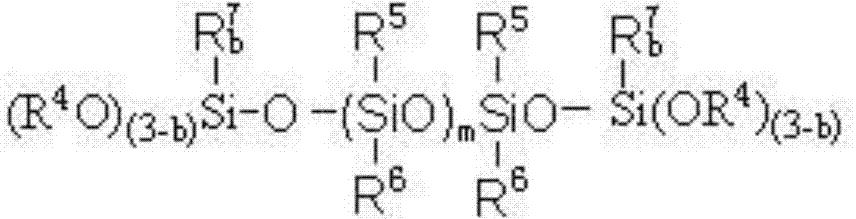

[0049] With 50 parts by mass of the base polymer (II) whose viscosity is 500mPa·s, its molecular formula is as follows:

[0050]

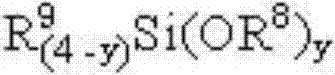

[0051]Put them into a high-speed disperser respectively, evacuate to -0.09MPa~-0.1MPa, and stir for 10min at a speed of 500r / min. Then, add 2 parts by mass of fumed white carbon black R972 after passing through nitrogen to evacuate, disperse at a speed of 500r / min for 5min, vacuumize to -0.09MPa~-0.1MPa, and then disperse at a speed of 2000r / min 15min. Then add 5 parts of methyltrimethoxysilane, 2 parts of γ-aminopropyltrimethoxysilane, and 1 part of tert-butyl titanate after nitrogen evacuation, and quickly evacuate to -0.09MPa~-0.1MPa, at 2000r / min Disperse evenly in a high-speed disperser at a rotating speed, and pack to prepare dealcoholized RTV electronic coating adhesive Ⅰ.

Embodiment 2

[0053] With 60 parts by mass viscosity of the base polymer (I) of 350mPa·s, its molecular formula is as follows:

[0054]

[0055] With 40 mass parts viscosity is the base polymer (II) of 1500mPa s, and its molecular formula is as follows:

[0056]

[0057] Put them into a high-speed disperser respectively, evacuate to -0.09MPa~-0.1MPa, and stir for 10min at a speed of 500r / min. Then, add 3 parts by mass of gas-phase process silica R974 after passing through nitrogen to evacuate, disperse at a speed of 500r / min for 5min, vacuumize to -0.09MPa~-0.1MPa, and then disperse at a speed of 2000r / min 15min. Then add 3 parts of vinyltrimethoxysilane, 1 part of γ-(2,3-epoxypropoxy)propyltrimethoxysilane, and 1 part of tert-butyl titanate after nitrogen evacuation, and quickly evacuate to -0.09MPa ~-0.1MPa, disperse evenly in a high-speed disperser at 2000r / min, pack, and prepare dealcoholized RTV electronic coating adhesive II.

Embodiment 3

[0059] With 70 parts by mass of the base polymer (I) whose viscosity is 350mPa·s, its molecular formula is as follows:

[0060]

[0061] With 30 mass parts viscosity is the base polymer (II) of 1500mPa s, and its molecular formula is as follows:

[0062]

[0063] Put them into a high-speed disperser respectively, evacuate to -0.09MPa~-0.1MPa, and stir for 10min at a speed of 500r / min. Then, add 2.5 parts by mass of fumed white carbon black R974 after passing through nitrogen to evacuate, disperse at a speed of 500r / min for 5min, vacuumize to -0.09MPa~-0.1MPa, and then disperse at a speed of 2000r / min 15min. Then add 3 parts of vinyltrimethoxysilane, 1 part of γ-aminopropyltrimethoxysilane, and 1 part of tert-butyl titanate after nitrogen evacuation, and quickly evacuate to -0.09MPa~-0.1MPa, at 2000r / min Disperse evenly in a high-speed disperser at a rotating speed, and pack to prepare dealcoholized RTV electronic coating adhesive III.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com