Combined polyether polyol comprising active group-containing polyurethane catalyst and preparation method thereof

A technology of polyurethane catalyst and polyether polyol, which is applied in the field of catalyst and polyurethane, can solve the problems that the storage stability of combined polyether polyol cannot be stored for a long time, and cannot be popularized and used on a large scale.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Add 125 grams of glycerin and 180 grams of sucrose into a 2000 ml stainless steel test kettle with stirring, heating and temperature control devices, and add 2.5 grams of potassium hydroxide. After nitrogen replacement, start stirring and raise the temperature to 100°C, slowly add 700 grams of propylene oxide dropwise, after the epoxide addition is complete, keep the reaction at 115°C for 1 hour, vacuum degas for 1 hour, and then add adipic acid neutralizer 6.6 Gram, stirring for 40 minutes, discharging and bottling to obtain 985 grams of polyether polyol according to Example 1, with a detected hydroxyl value of 447 mgKOH / g.

example 2

[0060] Put pre-melted 285 g of o-toluenediamine into a 2000 ml stainless steel test kettle with stirring, heating and temperature control devices, and add 2.5 g of potassium hydroxide. After nitrogen replacement, start stirring and raise the temperature to 100°C, slowly add 713 grams of propylene oxide dropwise. After the epoxide addition is completed, keep the reaction at 115°C for 1 hour, vacuum degas for 1 hour, and then add adipic acid neutralizer 6.6 Gram, stirring for 40 minutes, discharging and bottling to obtain 978 grams of polyether polyol according to Example 2 with a detected hydroxyl value of 399 mgKOH / g.

Embodiment 3

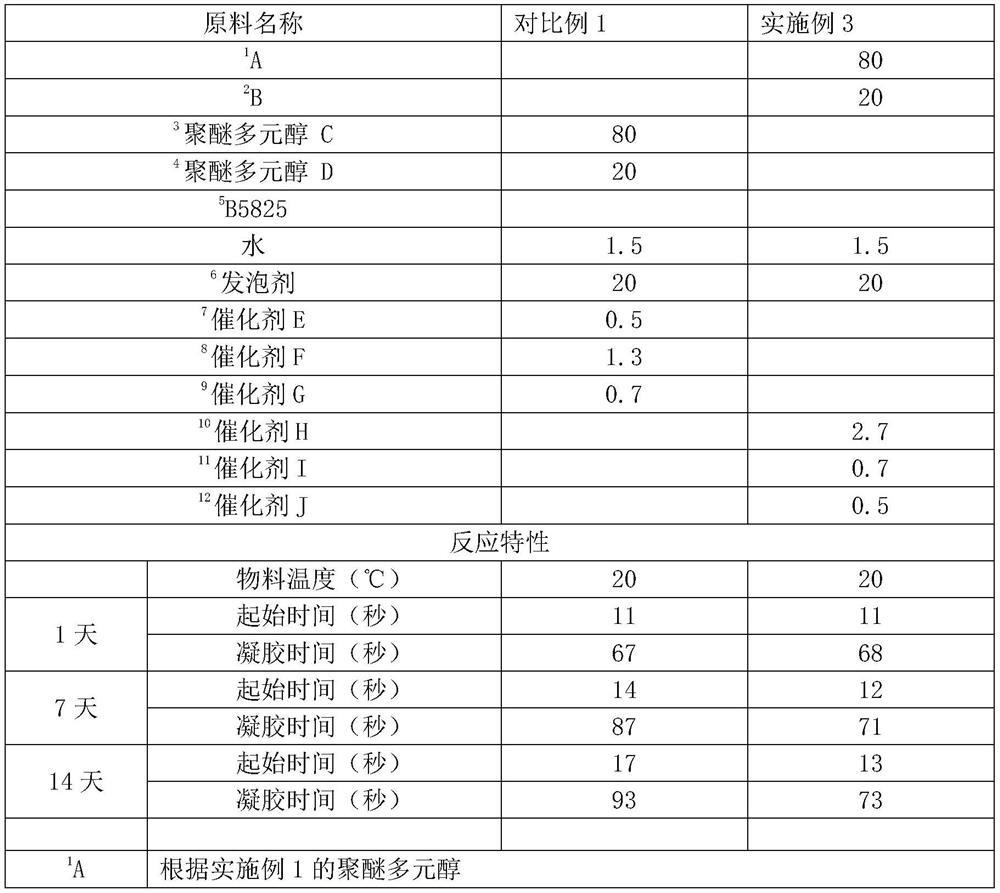

[0063] The above polyether polyol according to Example 1, the polyether polyol according to Example 2 and the polyether polyol processed by traditional refining methods obtained in the market were respectively formulated into a combined polyether for rigid polyurethane foam, and the storage test and Foam detection. The test results are shown in Table 1 below.

[0064] In Table 1, the start time and gel time

[0065] Measure according to the method specified in the standard "HG / T 4574-2014 Method for Measuring the Foaming Reaction Characteristics of Polyurethane Raw Materials".

[0066] Table 1: The combined polyether polyol formula and reaction parameters of Example 3 and Comparative Example 1.

[0067]

[0068]

[0069] It can be seen from Table 1 above that the starting time of the combined polyether polyol according to the present invention after 14 days of storage differs from the starting time of 1 day by 2 seconds, which is almost within the allowable measurement error range. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com