A kind of making method of silicone glove and polyorganosiloxane mixed solution

A polyorganosiloxane and a production method technology, applied in the direction of coating and the like, can solve the problems of unreported application of silicone gloves, unsuitable silicone gloves, unreported silicone gloves, etc., to improve refractive index, radiation resistance, hardness, etc. Low, high-intensity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A polyorganosiloxane mixed solution, the mixed solution includes polyorganosiloxane containing vinyl and polyorganosiloxane containing Si-H bond, and the polyorganosiloxane containing vinyl and polyorganosiloxane containing The weight ratio of polyorganosiloxane with Si-H bond is 10:1;

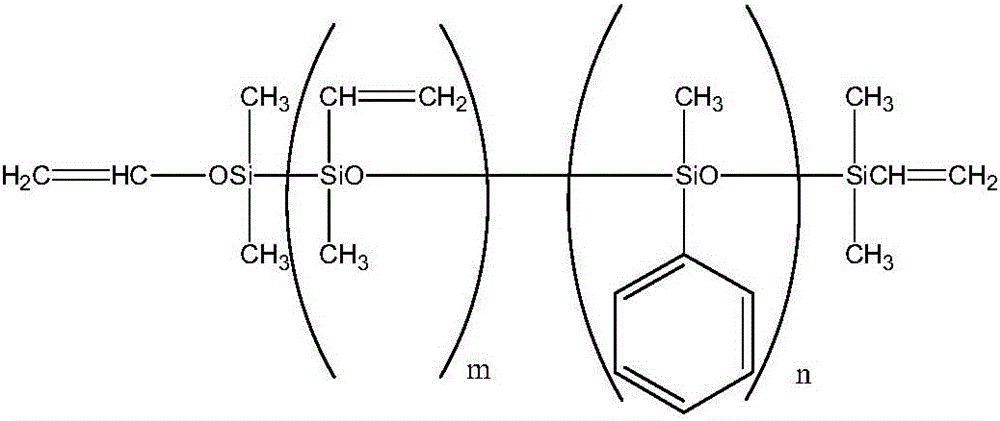

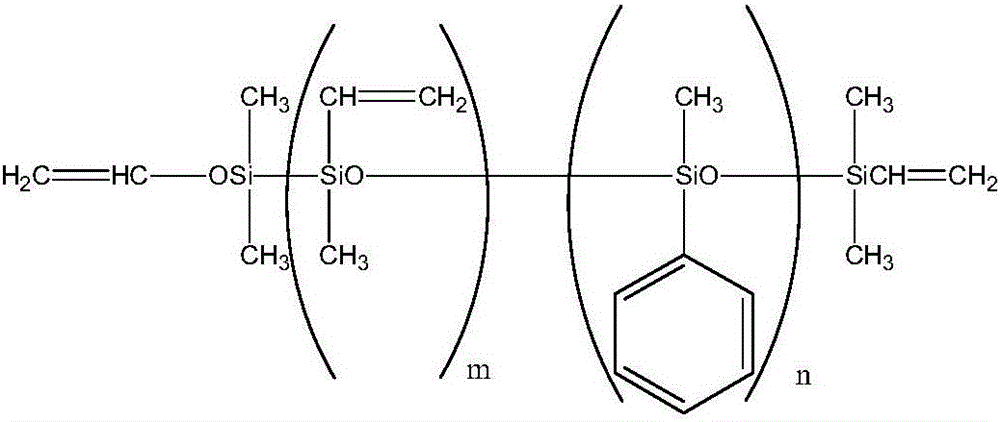

[0033] The structural formula of the polyorganosiloxane containing vinyl is as follows:

[0034]

[0035] In the formula, m and n are independently selected from natural numbers ranging from 500 to 1500;

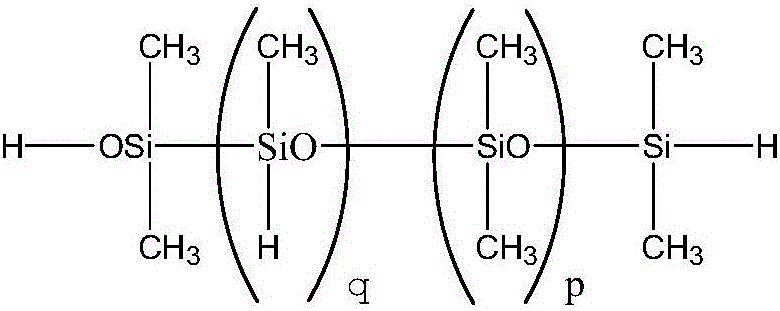

[0036] The structural formula of the polyorganosiloxane containing Si-H bonds is as follows:

[0037]

[0038] In the formula, p and q are independently selected from natural numbers ranging from 20 to 50;

[0039] Based on the weight of polyorganosiloxane containing vinyl, the mixed solution also contains the weight percentages of the following components:

[0040] Platinum catalyst: 1.2%; Methylvinylcyclotetrasiloxane: 3.0%.

[0041] The above is based on the weight of pol...

Embodiment 2

[0045] A polyorganosiloxane mixed solution, the mixed solution includes polyorganosiloxane containing vinyl and polyorganosiloxane containing Si-H bond, and the polyorganosiloxane containing vinyl and polyorganosiloxane containing The weight ratio of polyorganosiloxane of Si-H bond is 12:1;

[0046] The structural formula of the polyorganosiloxane containing vinyl is as follows:

[0047]

[0048] In the formula, m and n are independently selected from natural numbers ranging from 500 to 1500;

[0049] The structural formula of the polyorganosiloxane containing Si-H bonds is as follows:

[0050]

[0051] In the formula, p and q are independently selected from natural numbers ranging from 20 to 50;

[0052] Based on the weight of polyorganosiloxane containing vinyl, the mixed solution also contains the weight percentages of the following components:

[0053] Platinum catalyst: 0.3%; Methylvinylcyclotetrasiloxane: 1.0%.

[0054] Put the glove liner on the ceramic glove ...

Embodiment 3

[0056] A polyorganosiloxane mixed solution, the mixed solution includes polyorganosiloxane containing vinyl and polyorganosiloxane containing Si-H bond, and the polyorganosiloxane containing vinyl and polyorganosiloxane containing The weight ratio of polyorganosiloxane with Si-H bond is 8:1;

[0057] The structural formula of the polyorganosiloxane containing vinyl is as follows:

[0058]

[0059] In the formula, m and n are independently selected from natural numbers ranging from 500 to 1500;

[0060] The structural formula of the polyorganosiloxane containing Si-H bonds is as follows:

[0061]

[0062] In the formula, p and q are independently selected from natural numbers ranging from 20 to 50;

[0063] Based on the weight of polyorganosiloxane containing vinyl, the mixed solution also contains the weight percentages of the following components:

[0064] Platinum catalyst: 1.0%. The platinum catalyst is an alcohol-modified chloroplatinic acid catalyst; methyl vinyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com