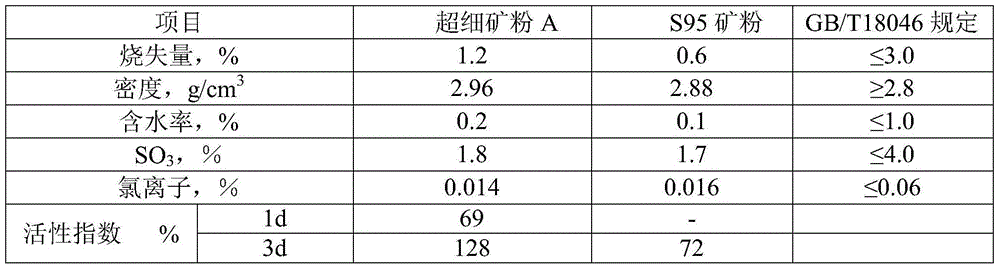

Ultrafine slag powder, and preparation method and application thereof

A technology for ultra-fine slag powder and slag, which is applied in the field of comprehensive utilization of solid waste resources, can solve the problems of severe wear of grinding equipment, affect the activity of slag powder, and increase the preparation cost, so as to simplify the production process, save energy consumption, avoid The effect of increased equipment wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

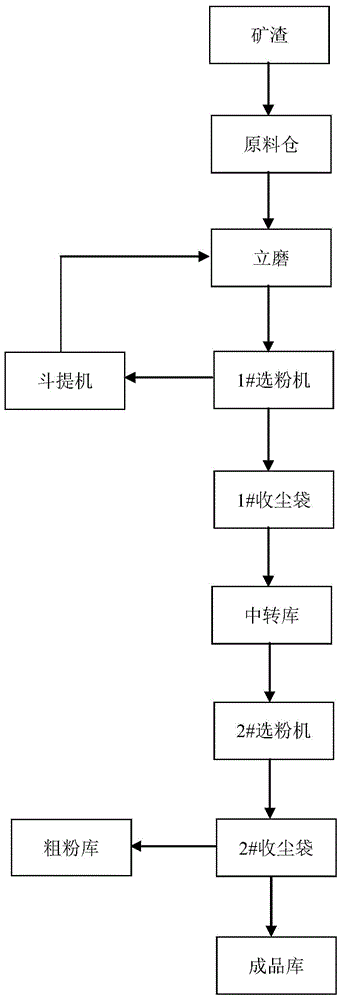

[0034] (1), the granulated blast furnace slag with a moisture content of 5% is transported to the raw material storehouse by a belt conveyor;

[0035] (2), the slag in the raw material warehouse is transported to the vertical mill for pre-grinding through metering and conveying equipment, and hot air is introduced while grinding;

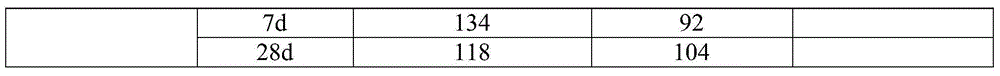

[0036] (3), the pre-grinding pre-abrasives are transported to 1 through pneumatic conveying equipment under the action of negative pressure # The powder classifier is used for classification, and the specific surface area is 450m 2 / kg of mineral powder, through 1 # The dust bag is collected and entered into the transfer warehouse;

[0037] (4), the specific surface area is less than 450m 2 / kg slag coarse powder falls to the bottom of the grinding table of the vertical mill and enters the external circulation, and the slag coarse powder is lifted to the top of the vertical mill by the bucket elevator and then enters the vertical mill for grindin...

Embodiment 2

[0046] (1), the granulated blast furnace slag with a moisture content of 12% is transported to the raw material warehouse by a belt conveyor;

[0047] (2), the slag in the raw material warehouse is transported to the vertical mill for pre-grinding through metering and conveying equipment, and hot air is introduced while grinding;

[0048] (3), the pre-grinding pre-abrasives are transported to 1 through pneumatic conveying equipment under the action of negative pressure # The powder separator is used for classification, and the selected specific surface area is 430m 2 / kg of mineral powder, through 1 # The dust bag is collected and entered into the transfer warehouse;

[0049] (4), the specific surface area is less than 430m 2 / kg slag coarse powder falls to the bottom of the grinding table of the vertical mill and enters the external circulation, and the slag coarse powder is lifted to the top of the vertical mill by the bucket elevator and then enters the vertical mill for...

Embodiment 3

[0057] (1), the granulated blast furnace slag with a moisture content of 9% is transported to the raw material warehouse by a belt conveyor;

[0058] (2), the slag in the raw material warehouse is transported to the vertical mill for pre-grinding through metering and conveying equipment, and hot air is introduced while grinding;

[0059] (3), the pre-grinding pre-abrasives are transported to 1 through pneumatic conveying equipment under the action of negative pressure # The powder classifier is used for classification, and the specific surface area is 400m 2 / kg of mineral powder, through 1 # The dust bag is collected and entered into the transfer warehouse;

[0060] (4), the specific surface area is less than 400m 2 / kg slag coarse powder falls to the bottom of the grinding table of the vertical mill and enters the external circulation, and the slag coarse powder is lifted to the top of the vertical mill by the bucket elevator and then enters the vertical mill for grinding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com