Preparation method for pulverized coal-ash-based porous artificial stone

A technology of porous artificial stone and fly ash, applied in ceramic products, sustainable waste treatment, solid waste management, etc., can solve the problems of long steam curing time, high lime content, low strength, etc., to improve productivity and shorten The effect of steaming time and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A preparation method of fly ash-based porous artificial stone, comprising the following steps:

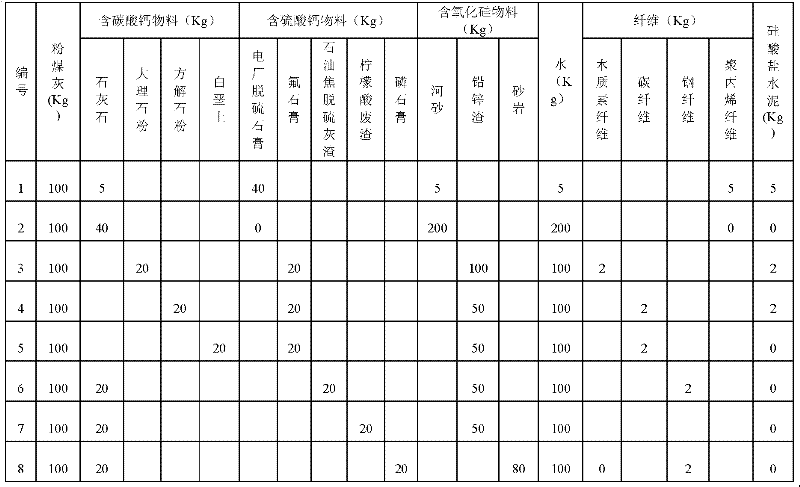

[0020] The first step is to add calcium carbonate-containing material, calcium sulfate-containing material, silicon oxide-containing material, water, fiber and Portland cement to the fly ash, and stir to obtain the fly ash cement slurry; Table 1 Eight example formulation compositions numbered 1-8 are listed.

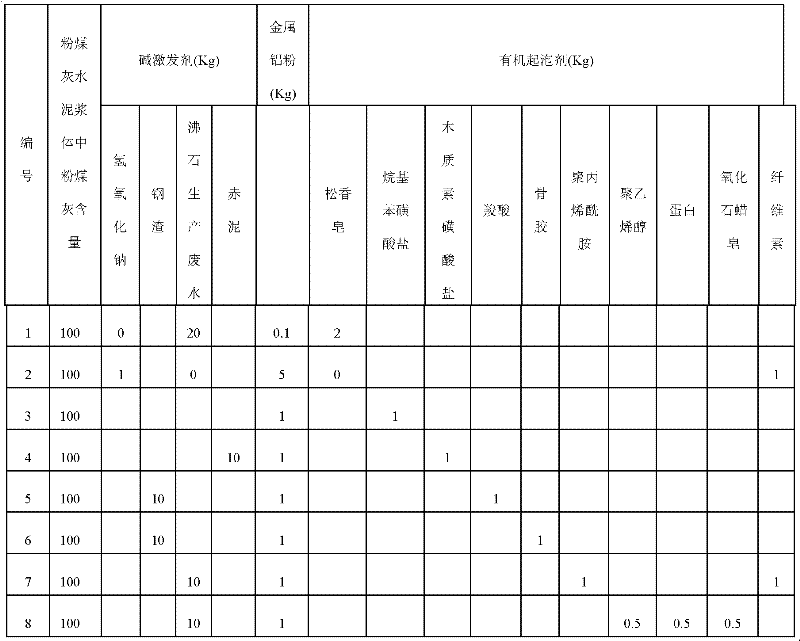

[0021] Second step, in the fly ash cement slurry of the first step, add alkali activator, metal aluminum powder, organic foaming agent, mix to obtain gas-containing fly ash cement slurry; Table 2 has listed different embodiments The amount of alkali activator, metal aluminum powder, and organic foaming agent added.

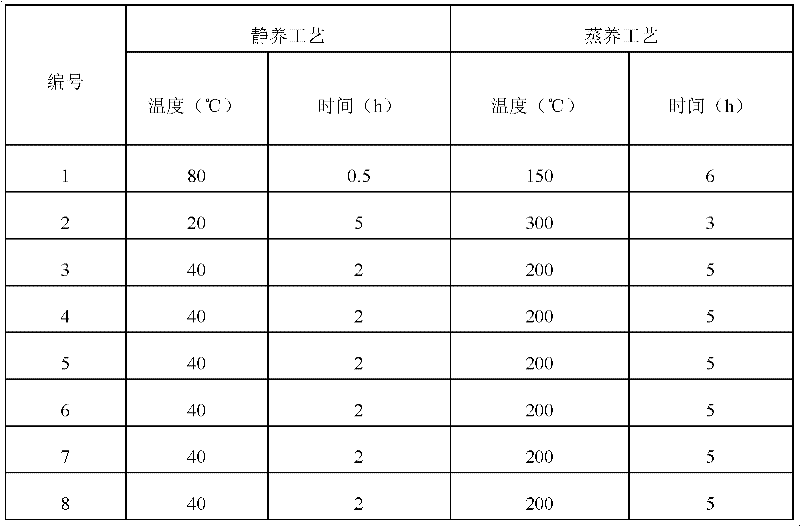

[0022] In the third step, the gas-containing fly ash cement slurry in the second step is poured into the mold, and the cement block or the cement slab is obtained by cutting through static curing; and then the fly ash-based porous artificial stone is obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com