Steam-cured alkali-activated slag concrete and preparation method thereof

A technology of concrete and alkali excitation, applied in the field of building materials, can solve problems such as difficulty in engineering construction, and achieve the effects of reducing energy consumption, improving quality, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

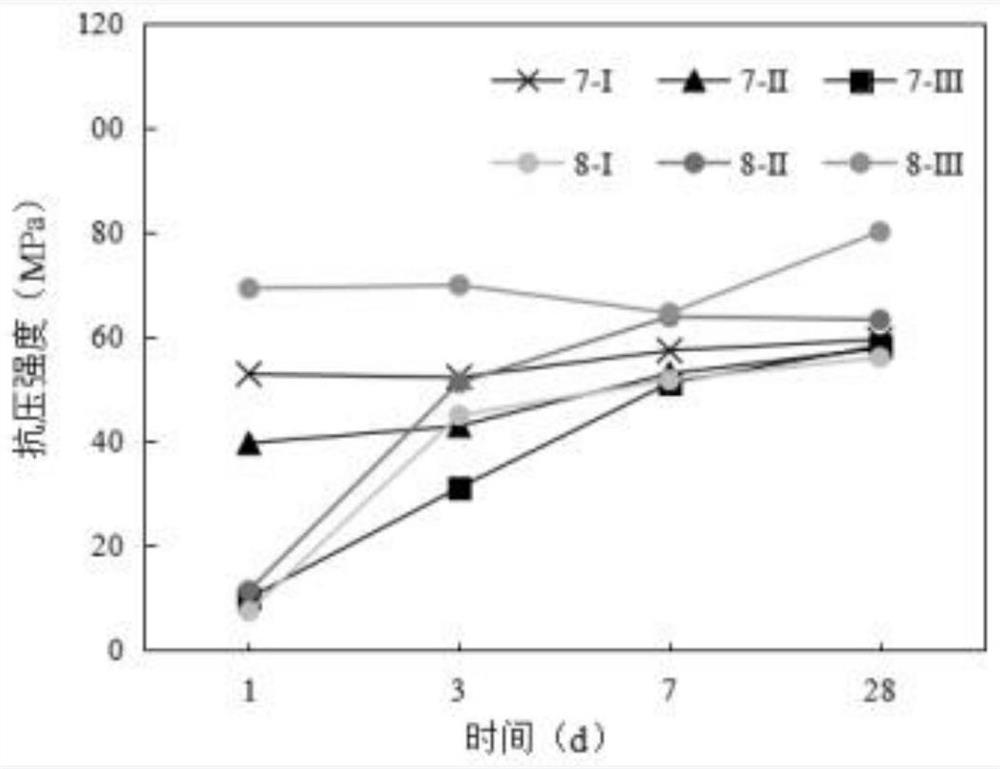

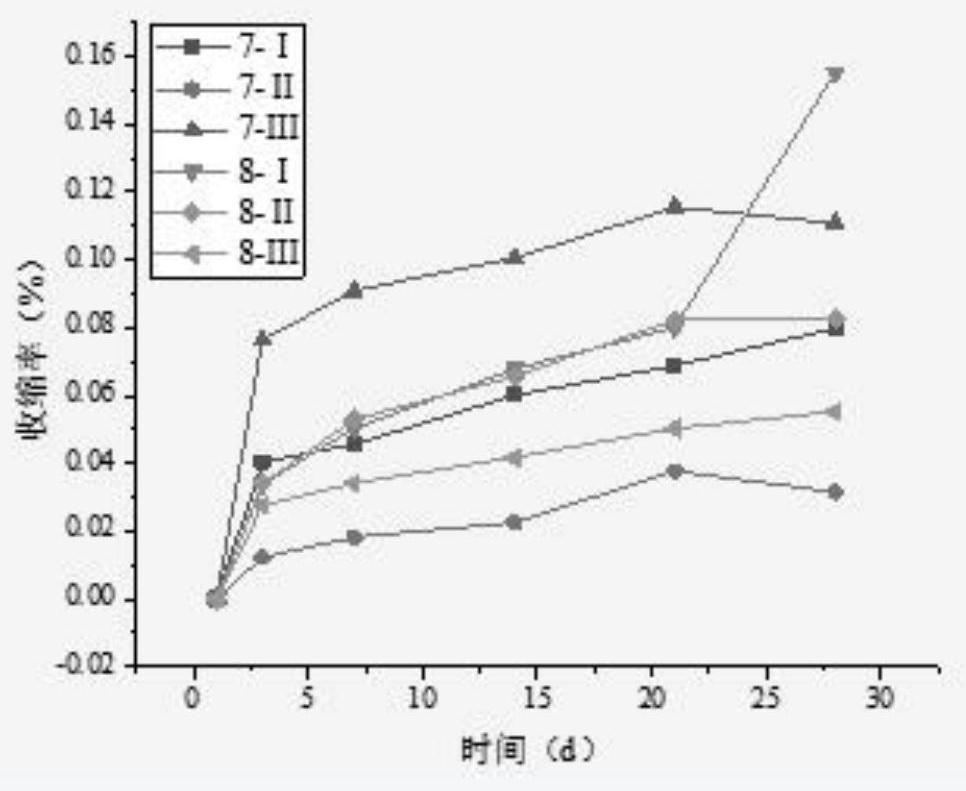

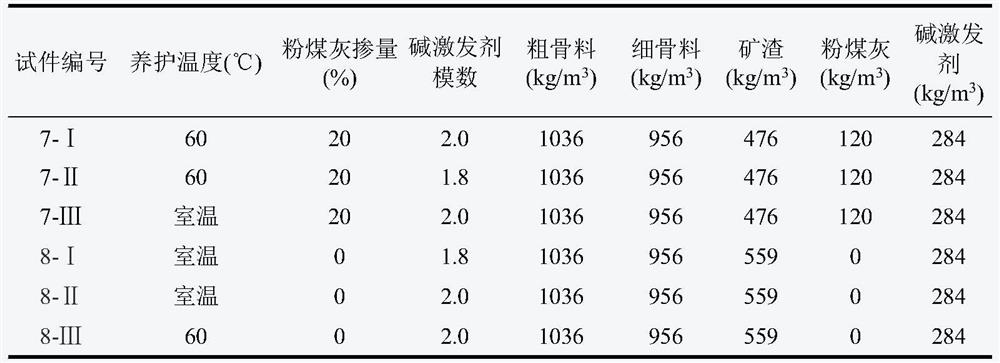

Examples

Embodiment 1

[0019] The raw materials of the steam-cured alkali-activated slag concrete involved in this embodiment include activator, slag, fly ash, coarse aggregate and fine aggregate; the mass percentage of fly ash is 20-30%; the fine aggregate is machine-made sand, The use of machine-made sand to replace river sand, which is a non-renewable resource, is a necessary means to protect natural resources. The water content of machine-made sand has a great impact on the mechanical properties and durability of steam-cured alkali-induced slag concrete. Therefore, the water content of machine-made sand 2% is preferred.

[0020] The technical process of the steam-cured alkali-activated slag concrete preparation method involved in this embodiment is:

[0021] Use a spray can to moisten the coarse aggregate to achieve a saturated surface dry effect. Because the coarse aggregate has a high water absorption rate, it will absorb water during the mixing process. Excessive water absorption will lead to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com