High-rise intelligent three-dimensional production system for prefabricated components

A technology of production system and prefabricated components, applied in the direction of manufacturing tools, ceramic molding workshops, ceramic molding machines, etc., can solve the problems of large impact, low resource utilization, high cost, etc., to reduce steam curing time, occupy less area, improve The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the drawings and embodiments.

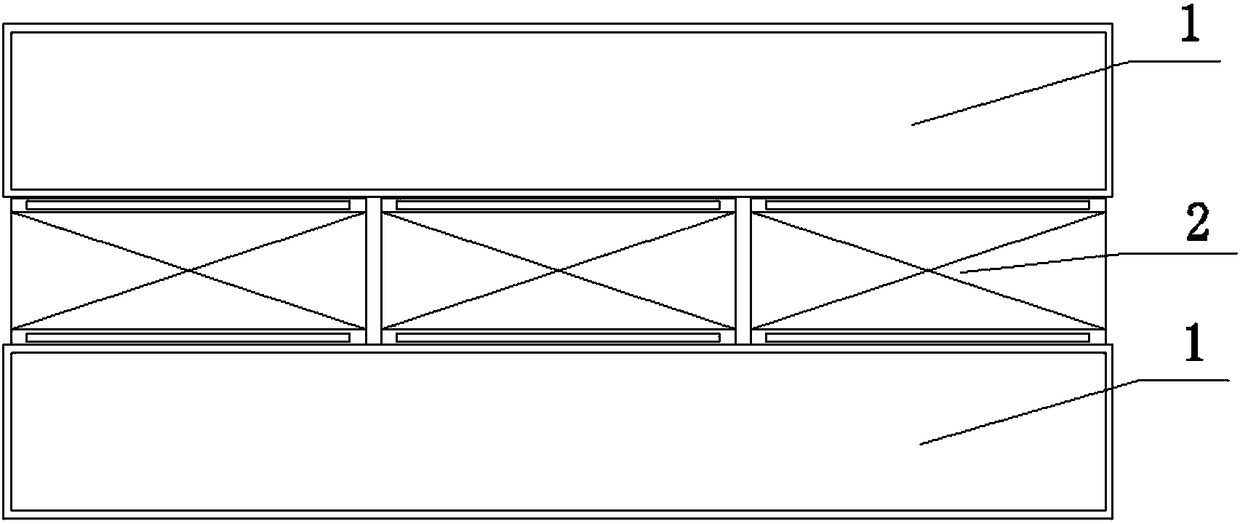

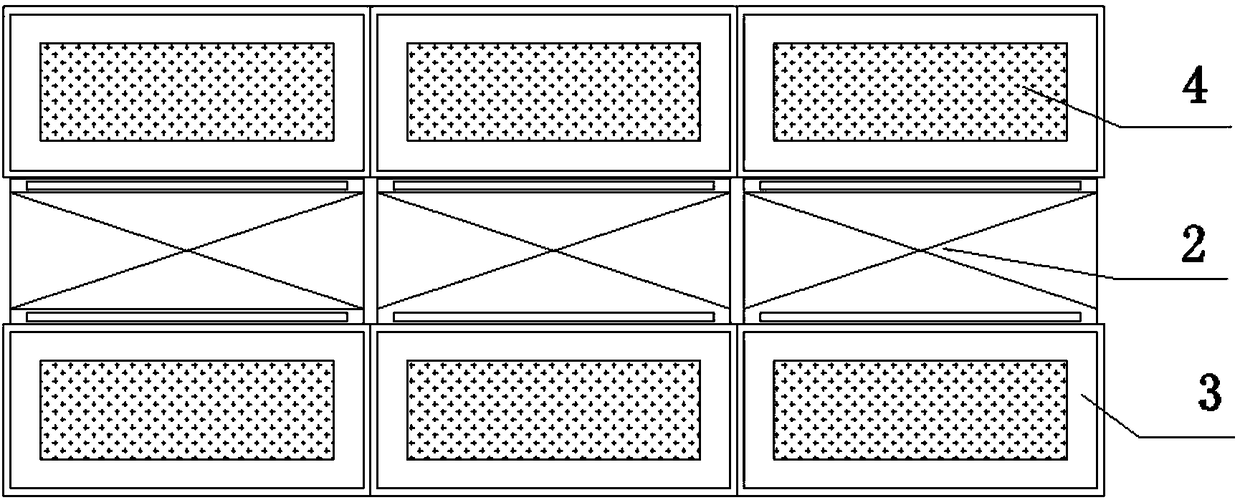

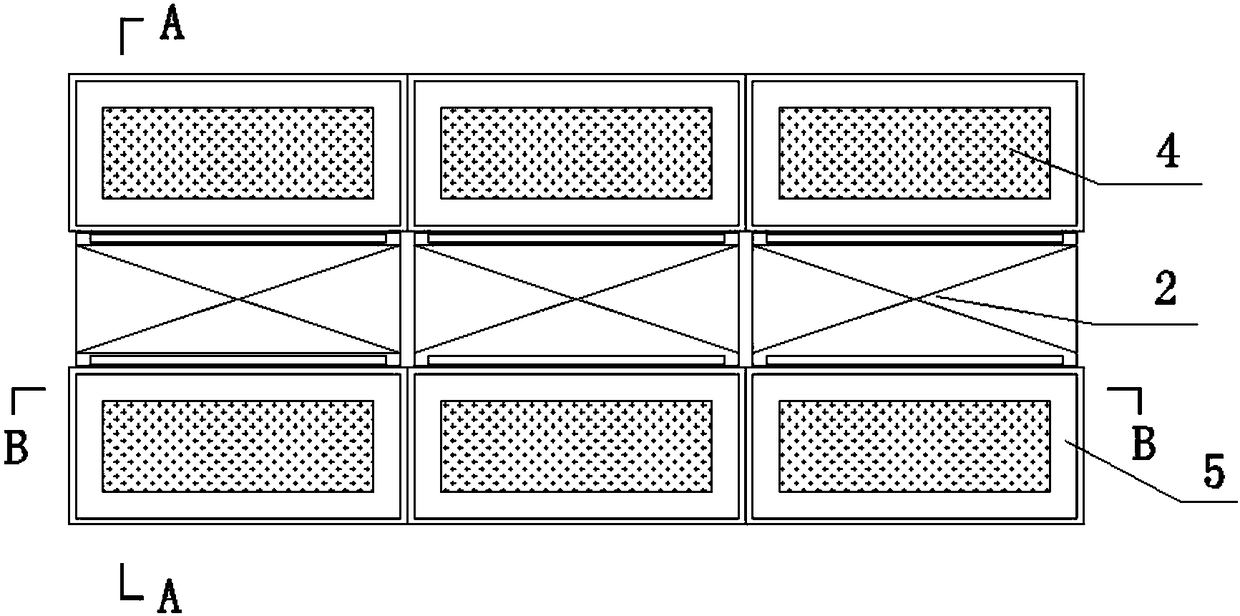

[0033] Such as Figure 1-5 As shown, a high-level intelligent three-dimensional production system for prefabricated components includes a raw material stacking area on the bottom layer 1, a component production area on several middle layers, a component maintenance area 5 on several upper layers, a transportation area and a truck 7. There are component production area 3 and component maintenance area 5 on both sides of the transportation area;

[0034] Both the component production area 3 and the component maintenance area 5 are equipped with mold table legs 6, and the component mold table 4 is placed on the mold table legs 6;

[0035] The transportation area is composed of several vertical transportation elevators 2;

[0036] The vertical transport elevator 2 and the truck 7 work together.

[0037] The present invention is a high-level intelligent three-dimensional product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com