Vinegar processed pseudo-ginseng and processing technology and application thereof

A processing technique, the technology of notoginseng, applied in the direction of medical preparations containing active ingredients, plant raw materials, digestive system, etc., can solve the problems of low content and damage to the medicinal efficacy of notoginseng, so as to increase the content and shorten the steaming time , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

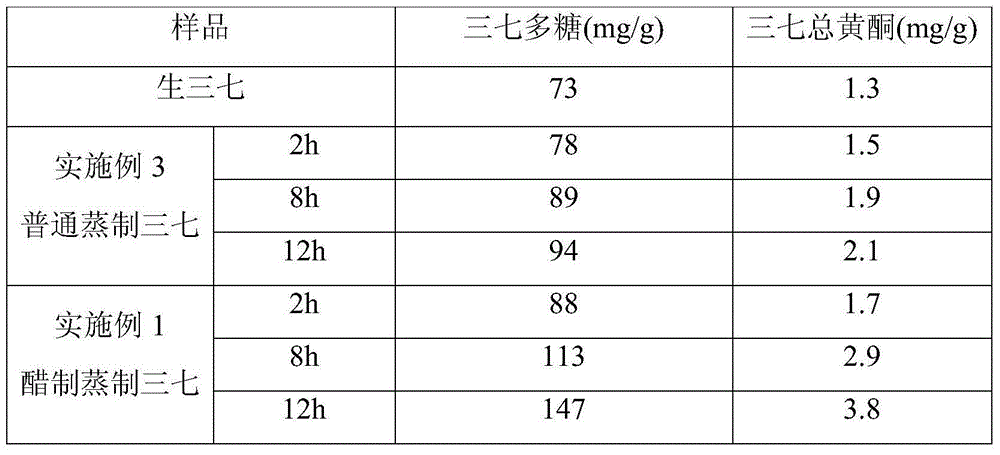

[0031] Embodiment 1 fresh notoginseng vinegar system steaming

[0032] Use fresh Panax notoginseng as raw material, remove the non-medicinal parts such as roots and hairs, wash it, cut it into small pieces, dry it at 50°C, and crush it into coarse powder. Take 100g of coarse powder, 100g of 9-degree rice vinegar, and soak at room temperature for 12 hours. It is advisable to submerge the 9-degree rice vinegar with the Sanqi raw material, then take out the Sanqi soaked in 9-degree rice vinegar, and steam it under normal pressure for 12 hours, and the steaming is over. Then take it out, put it in a hot air circulation oven and dry it at 50°C for 5 hours, when the moisture content in the medicinal material is 7%-13%, take it out and let it cool, seal it and pack it.

Embodiment 2

[0033] Example 2 Dried Panax notoginseng vinegar making and steaming

[0034] Using dried notoginseng as raw material, it is crushed into coarse powder passing through a 20-mesh sieve. Take 100g of coarse powder, take 50g of 9-degree rice vinegar, soak at room temperature for 6 hours, it is advisable to submerge the 9-degree rice vinegar into the raw material of Panax notoginseng, then take out the notoginseng soaked in 9-degree rice vinegar, and steam it under high pressure at 110°C for 2 hours After steaming, when the pressure drops to normal pressure, take it out and put it in a hot air circulation oven to dry at 70°C for 4 hours. When the moisture content in the medicinal material is 7%-13%, take it out and let it cool, and seal it to get ready.

Embodiment 3

[0035] Example 3 Fresh Panax notoginseng Ordinary Steaming

[0036] Using fresh Panax notoginseng as raw material, it is crushed into coarse powder passing through a 20-mesh sieve. Take 100g of coarse powder, steam at normal pressure for 12 hours, take it out after steaming, put it in a hot air circulation oven and dry it at 50°C for 5 hours, when the moisture content in the medicinal material is 7%-13%, take it out and let it cool, and seal the package , that is.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com