Fermented coriander jelly and production method thereof

A fermented, coriander technology, applied in the directions of bacteria and food ingredients used in food preparation as taste improvers, food ingredients as odor improvers, etc., can solve the problems of loss of nutrition and bright green, no coriander found, flocculation, etc., To achieve the effect of delicate taste, unique flavor and smooth color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 fermented coriander jelly preparation

[0035] 1. Composition

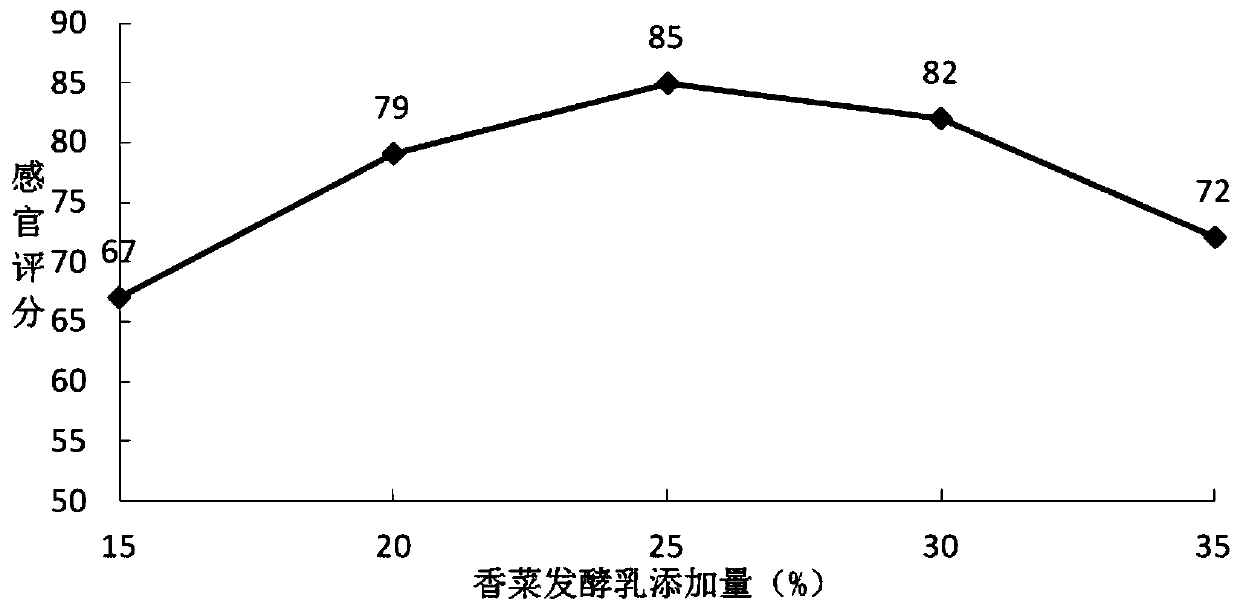

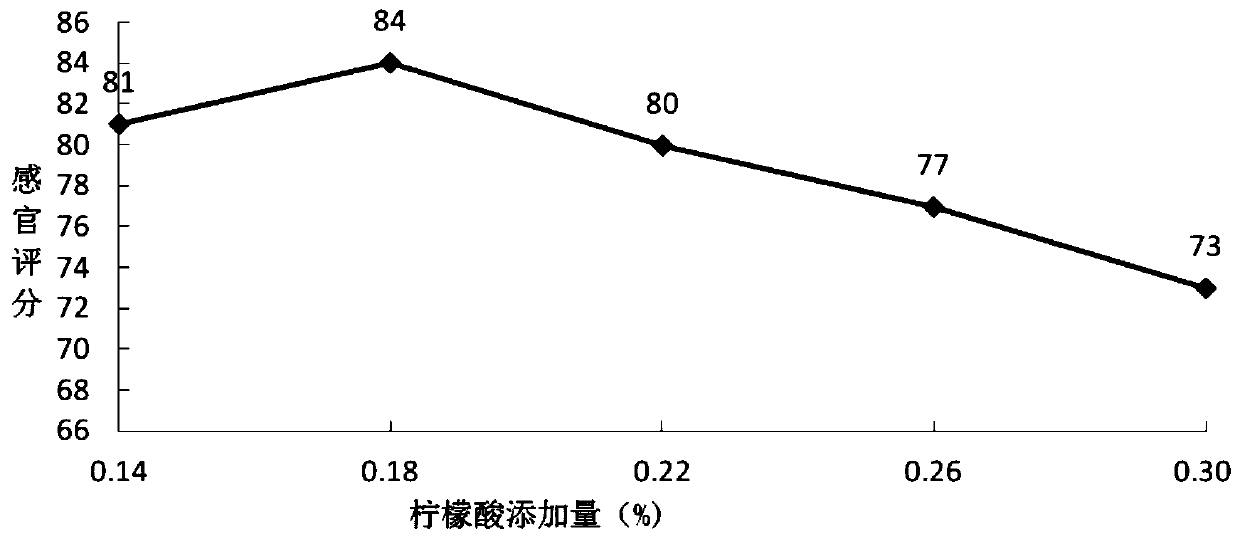

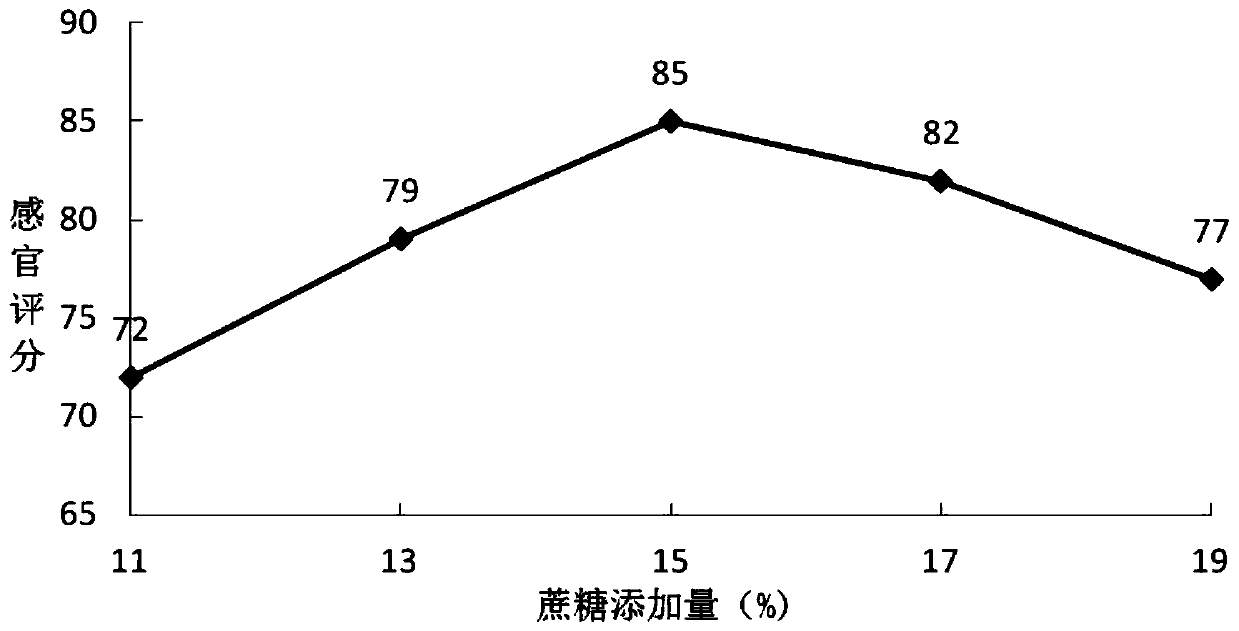

[0036] Coriander fermented milk is 28%, compound gum is 1.3%, sucrose is 15%, and citric acid is 0.18%.

[0037] 2. Preparation method

[0038] (1) Choose fresh coriander with neat branches and leaves, emerald green, no rot and miscellaneous leaves and branches, first rinse with tap water, then soak in distilled water for about 10 minutes, pick up and drain the water. Put the coriander into 1% salt water, blanching at 92°C, rinse with cold water to desalinate, and then put it into the coriander protective agent. Cut it into small pieces with an alcohol-sterilized knife, and then press m (coriander): m (water) = 1:1 to make a pulp, filter (first filter with 4 layers of gauze, and then filter with 8 layers of gauze), the filtrate is For the parsley juice.

[0039] (2) Prepare whole milk powder into 9% reconstituted milk, stir and dissolve at 40°C, filter twice through 8 layers of gauze, steri...

Embodiment 2

[0041] Embodiment 2 fermented coriander jelly preparation

[0042] 1. Composition

[0043] Coriander fermented milk is 15%, compound gum is 1.6%, sucrose is 19%, citric acid is 0.14%.

[0044]2. Preparation method

[0045] (1) With embodiment 1.

[0046] (2) Prepare whole milk powder into 9% reconstituted milk, stir and dissolve at 45°C, filter twice through 8 layers of gauze, sterilize at 80°C for 10 minutes, and rapidly cool to 42°C. Under aseptic conditions, inoculate Lactobacillus bulgaricus and Streptococcus thermophilus into sterilized milk, add coriander juice, and mix well. In a constant temperature incubator at 40°C, ferment and cultivate for 5 hours. After the fermentation is completed, put it into a refrigerator (4°C) and refrigerate for 8 hours.

[0047] (3) Add an appropriate amount of water to the composite glue, raise the temperature slowly, heat to boiling, and keep the temperature constant for 5 minutes. Dissolve citric acid with a small amount of water f...

Embodiment 3

[0048] Embodiment 3 fermented coriander jelly preparation

[0049] 1. Composition

[0050] Coriander fermented milk is 40%, compound gum is 0.8%, sucrose is 11%, and citric acid is 0.3%.

[0051] 2. Preparation method

[0052] (1) With embodiment 1.

[0053] (2) Prepare whole milk powder into 9% reconstituted milk, stir and dissolve at 38°C, filter twice through 8 layers of gauze, sterilize at 80°C for 10 minutes, and rapidly cool to 38°C. Under aseptic conditions, inoculate Lactobacillus bulgaricus and Streptococcus thermophilus into sterilized milk, add coriander juice, and mix well. In a constant temperature incubator at 44°C, ferment and cultivate for 3 hours. After the fermentation is completed, put it into a refrigerator (4°C) and refrigerate for 15 hours.

[0054] (3) Add an appropriate amount of water to the composite glue, raise the temperature slowly, heat to boiling, and keep the temperature constant for 15 minutes. Dissolve citric acid with a small amount of w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com