Process for processing canned cubilose through cooperation between microwaves and vacuum pretreatment

A technology of canned bird's nest and microwave vacuum, which is applied in the field of food processing, can solve the problems of changes in texture characteristics of canned food, occurrence of sterilization, poor sterilization effect, etc., and achieve the effect of protecting texture characteristics and nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

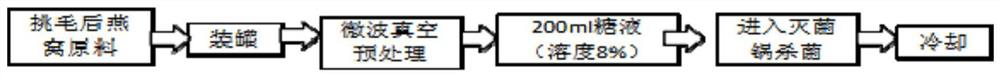

[0021] A kind of microwave cooperating vacuum pretreatment process the technology of canned bird's nest, comprises the steps:

[0022] (1) Pretreatment preparation: put 40g of dry bird’s nest raw materials that are intended to be reduced by microwave vacuum pretreatment into a canned bottle and then put them into the inner frame, and push the inner frame into the microwave vacuum bacteria reduction chamber;

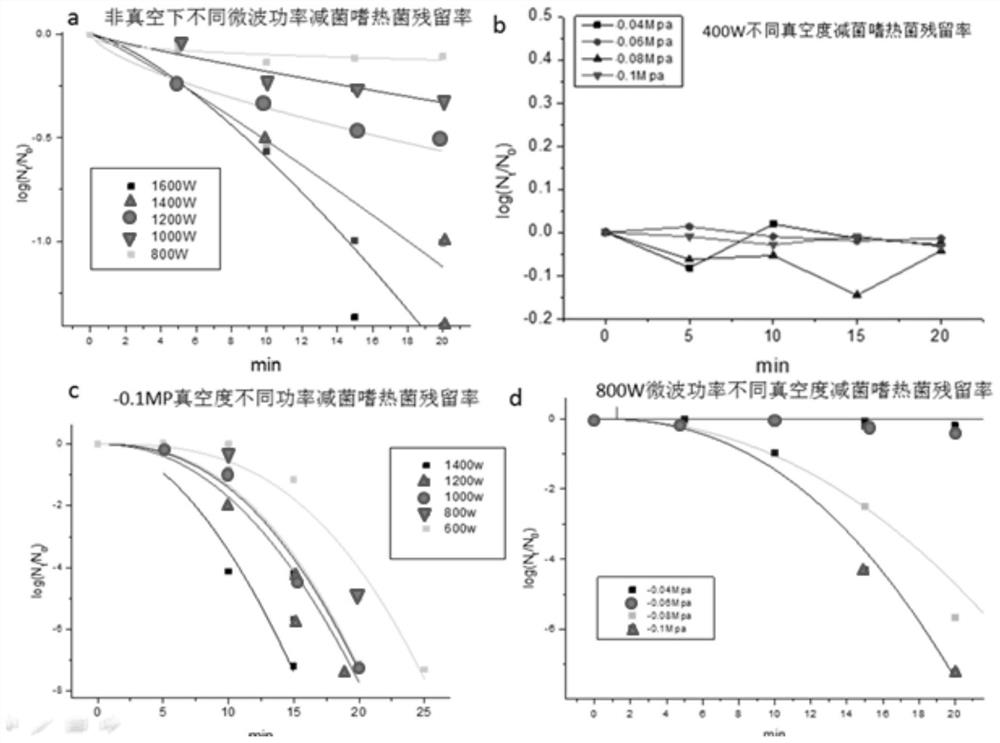

[0023] (2) Vacuuming: Turn on the vacuum pump to extract the air in the cavity, and control the vacuum degree at -0.08~-0.1MPa; the test shows that as the vacuum degree rises, the sterilization effect is significantly improved, but the excessive vacuum will make the water evaporate too quickly, resulting in The bird's nest sample is destroyed, so the preferred vacuum degree is -0.08~-0.1MPa.

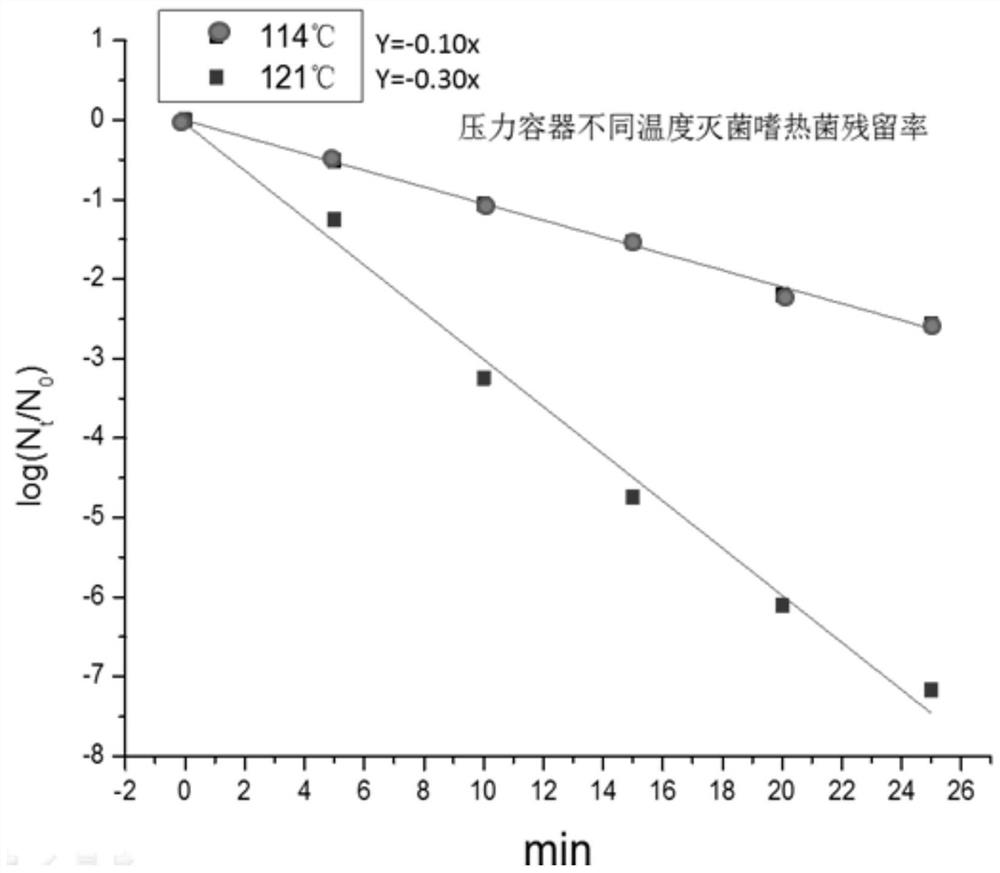

[0024] (3) Microwave vacuum sterilization: set the control panel to set the temperature at 105-115°C, microwave power 800W, and the temperature in the microwave vacuum sterilization...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com