Preparation method of beef tribute balls

A production method and beef technology are applied to the production of beef balls and the field of quick-frozen meat products, which can solve the problems of irregular use of various glue-type accessories, poor organizational structure, insufficient bottom taste, etc., and achieve outstanding product flavor and convenient eating. , Beef mellow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Raw material selection

[0028] Choose 100kg of frozen row acid beef hind legs.

[0029] 2. Unfreeze

[0030] The raw meat is thawed naturally, the temperature in the thawing room is below 15°C, and it is sufficient to thaw until the center temperature of the raw meat is -5°C to 0°C.

[0031] 3. Split

[0032] Segment the thawed meat, pick out the malignant impurities mixed in the raw meat, remove large tendons, diseased parts, lymph, etc.

[0033] 4. Twisting

[0034] The cut beef is twisted once with inner Φ8mm and outer Φ5mm orifice plates.

[0035] 5. Beating

[0036] According to the weight ratio of ground sour beef, sodium tripolyphosphate, edible salt, white sugar, monosodium glutamate, starch, spices, and ice water, the ratio is 1:0.0035:0.018:0.022:0.005:0.05:0.00025:0.24. Raw and auxiliary materials, and then put the prepared raw and auxiliary materials in the crushing machine for beating according to the requirements. First, stir the beef with sodium...

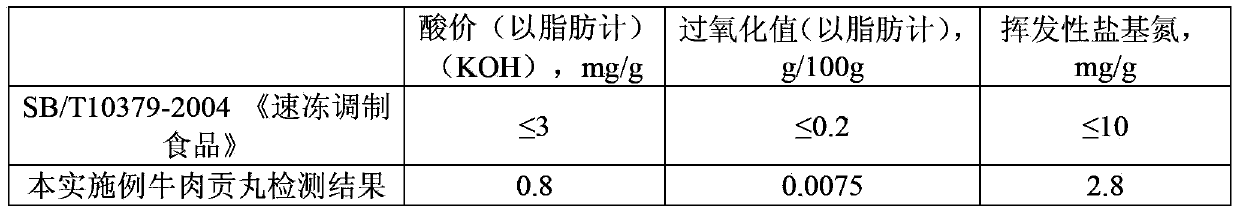

Embodiment 2

[0049] 1. Raw material selection

[0050] Select 100kg of frozen row acid beef hindquarters.

[0051] 2. Unfreeze

[0052] The raw meat is thawed naturally, the temperature in the thawing room is below 15°C, and it is sufficient to thaw until the center temperature of the raw meat is -5°C to 0°C.

[0053] 3. Split

[0054] Segment the thawed meat, pick out the malignant impurities mixed in the raw meat, remove large tendons, diseased parts, lymph, etc.

[0055] 4. Twisting

[0056] The cut beef is twisted once with inner Φ8mm and outer Φ5mm orifice plates.

[0057] 5. Beating

[0058] According to the weight ratio of ground sour beef, sodium tripolyphosphate, edible salt, white sugar, monosodium glutamate, starch, spices, and ice water, the ratio is 1:0.0032:0.022:0.03:0.006:0.055:0.0004:0.20. Raw and auxiliary materials, and then put the prepared raw and auxiliary materials in the crushing machine for beating according to the requirements. First, stir the beef with sodi...

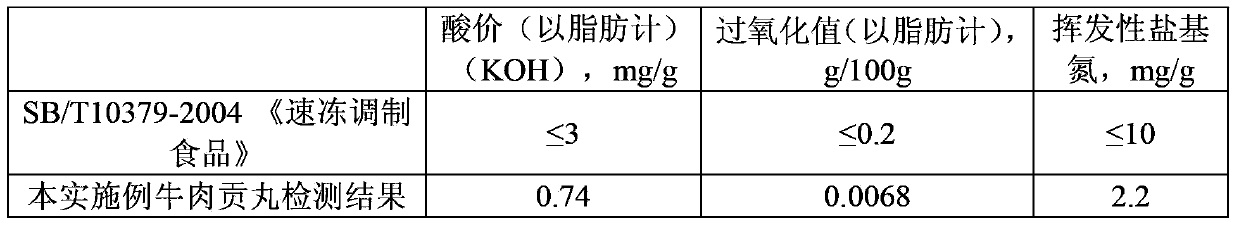

Embodiment 3

[0071] 1. Raw material selection

[0072] Select 100kg of frozen row acid beef hindquarters.

[0073] 2. Unfreeze

[0074] The raw meat is thawed naturally, the temperature in the thawing room is below 15°C, and it is sufficient to thaw until the center temperature of the raw meat is -5°C to 0°C.

[0075] 3. Split

[0076] Segment the thawed meat, pick out the malignant impurities mixed in the raw meat, remove large tendons, diseased parts, lymph, etc.

[0077] 4. Twisting

[0078] The cut beef is twisted once with inner Φ8mm and outer Φ5mm orifice plates.

[0079] 5. Beating

[0080] According to the weight ratio of ground sour beef, sodium tripolyphosphate, edible salt, white sugar, monosodium glutamate, starch, spices, and ice water, the ratio is 1:0.003:0.02:0.02:0.006:0.05:0.0002:0.24. Raw and auxiliary materials, and then put the prepared raw and auxiliary materials in the crushing machine for beating according to the requirements. First, stir the beef with sodium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com