Natural frying oil purifying agent, method of treating frying oil by food starchy materials and usage in purifying frying oil by food starchy materials

A technology of edible starch and frying oil, applied in the production/processing of edible oil/fat, edible oil/fat, application, etc. Affect the original process of frying customer promotion and other issues, to achieve the effects of reducing frying costs, prolonging life, and delaying oil oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

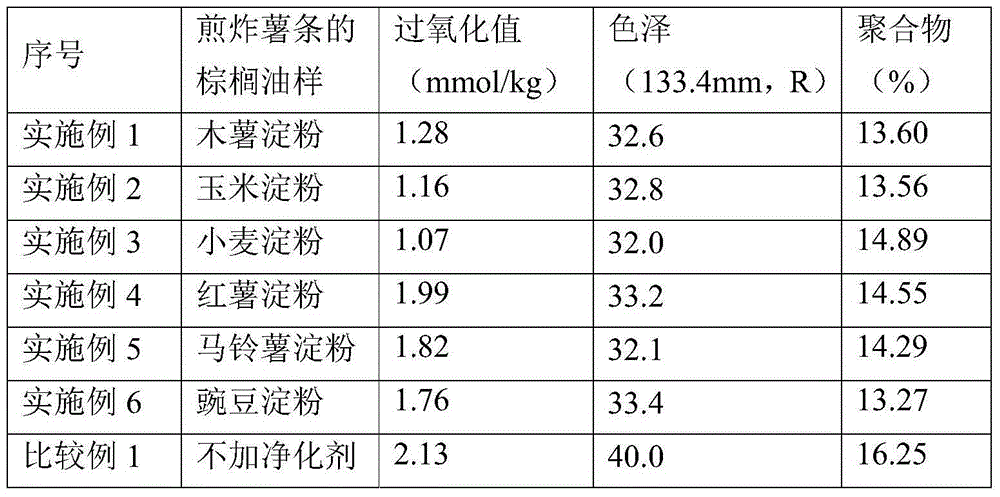

Embodiment 1~6

[0047] The palm oil for frying French fries was prepared as follows: Weigh 2000g of palm oil (Shanghai Kerry Grain and Oil Industry Co., Ltd.) and heat it to 180°C in a frying pan. Weigh 4000g of French fries (Shanghai Dachanghang Food Co., Ltd.) Fry in batches, each batch of frying ends in 3 minutes, remove the French fries and obtain 1000g of palm oil that has fried the French fries.

[0048] Take cassava starch, corn starch, wheat starch, sweet potato starch, potato starch and pea starch respectively, and pass through a 40-mesh sieve to obtain a single-component frying oil purifier. The above-mentioned palm oil that had been fried with French fries was kept at 120° C., and then 50 g of each single-component frying oil purifier was added thereto, that is, the added amount was 5.0 wt % of the weight of the frying oil. Then the obtained mixture was uniformly stirred for 10 min, filtered, and the filtrate was collected to obtain purified frying oil. The peroxide value, color a...

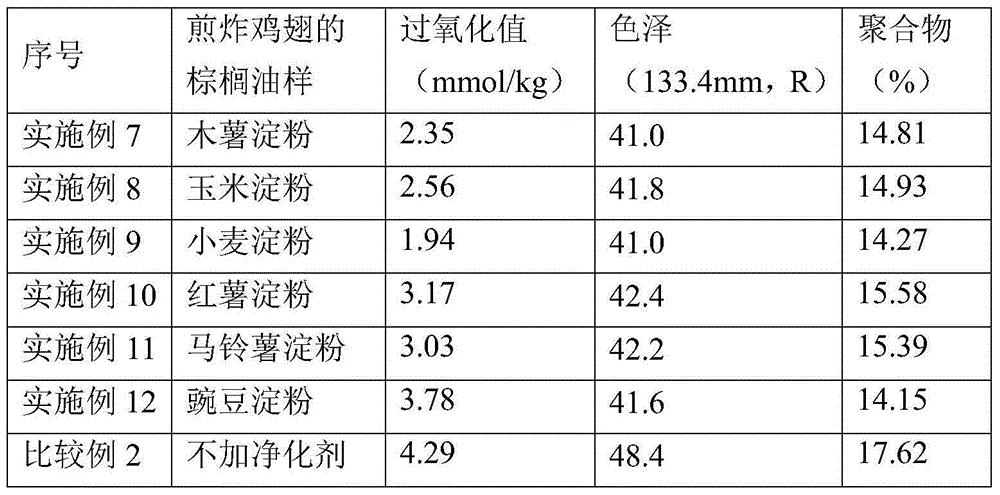

Embodiment 7~12

[0055] The palm oil of fried chicken wings is prepared as follows: Weigh 1500g of palm oil (Shanghai Kerry Grain and Oil Industry Co., Ltd.), heat it to 210°C in a frying pan, and weigh 80 chicken wings with a mass of about 50g (Shanghai Dachanghang Food Co., Ltd.) Fry in 10 batches, and finish frying in 6 minutes each time. After removing the chicken wings, obtain 1000g of palm oil that has fried the chicken wings.

[0056] Take cassava starch, corn starch, wheat starch, sweet potato starch, potato starch and pea starch respectively, and pass through a 40-mesh sieve to obtain a single-component frying oil purifier. The above-mentioned palm oil fried with chicken wings was kept at 60° C., and then 50 g of each single-component frying oil purifier was added thereto, that is, the added amount was 5.0 wt % of the weight of the frying oil. Then the obtained mixture was uniformly stirred for 20 min, filtered, and the filtrate was collected to obtain purified frying oil. The peroxi...

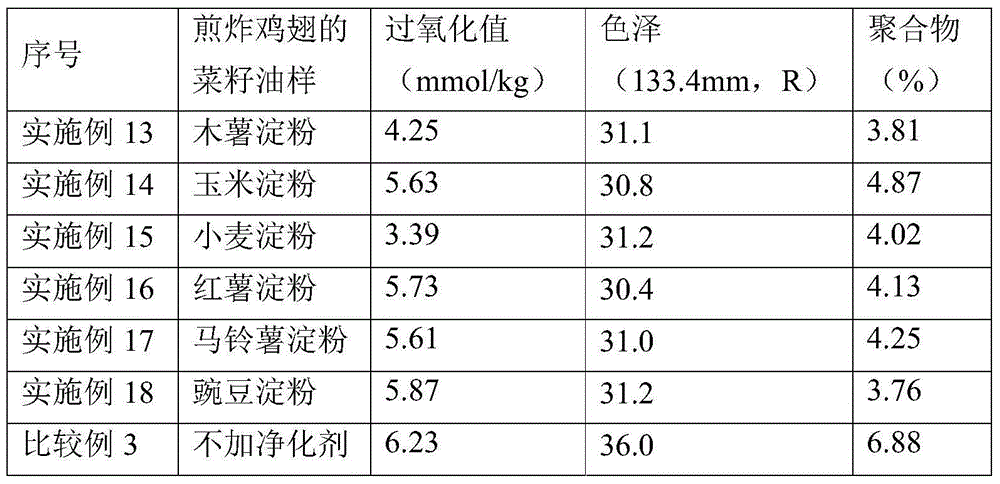

Embodiment 13~18

[0063] The rapeseed oil for frying chicken wings is prepared as follows: Weigh 1500g of rapeseed oil (Shanghai Kerry Grain and Oil Industry Co., Ltd.) and heat it to 210°C in a frying pan. Weigh 80 chicken wings with a mass of about 50g (Shanghai Dachanghang Food company) is divided into 10 batches to fry, and each frying ends in 6 minutes, and the rapeseed oil that 1200g has fried the chicken wings is obtained after removing the chicken wings.

[0064] Tapioca starch, corn starch, wheat starch, sweet potato starch, potato starch and pea starch are taken and passed through a 40-mesh sieve to obtain a single-component frying oil purifier. The above-mentioned rapeseed oil fried with chicken wings was kept at 100° C., and then 60 g of each single-component frying oil purifier was added thereto, that is, the added amount was 5.0 wt % of the weight of the frying oil. Then the obtained mixture was uniformly stirred for 20 min, filtered, and the filtrate was collected to obtain purif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com