Patents

Literature

91results about How to "Low polymer content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-absorbent agent and method for manufacturing the same

InactiveUS6187872B1Improve securityStable pHOther chemical processesAbsorbent padsPolymer scienceCross linker

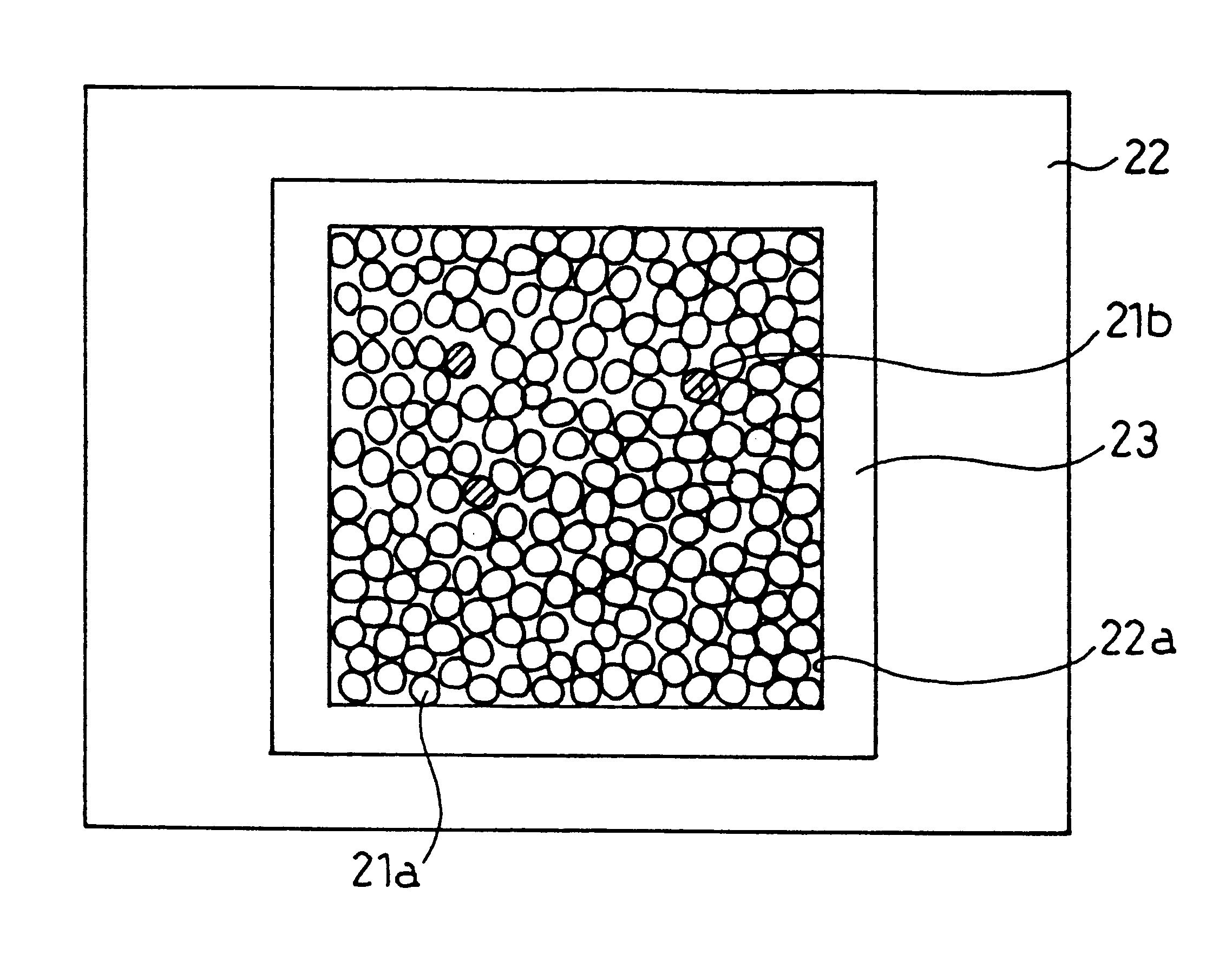

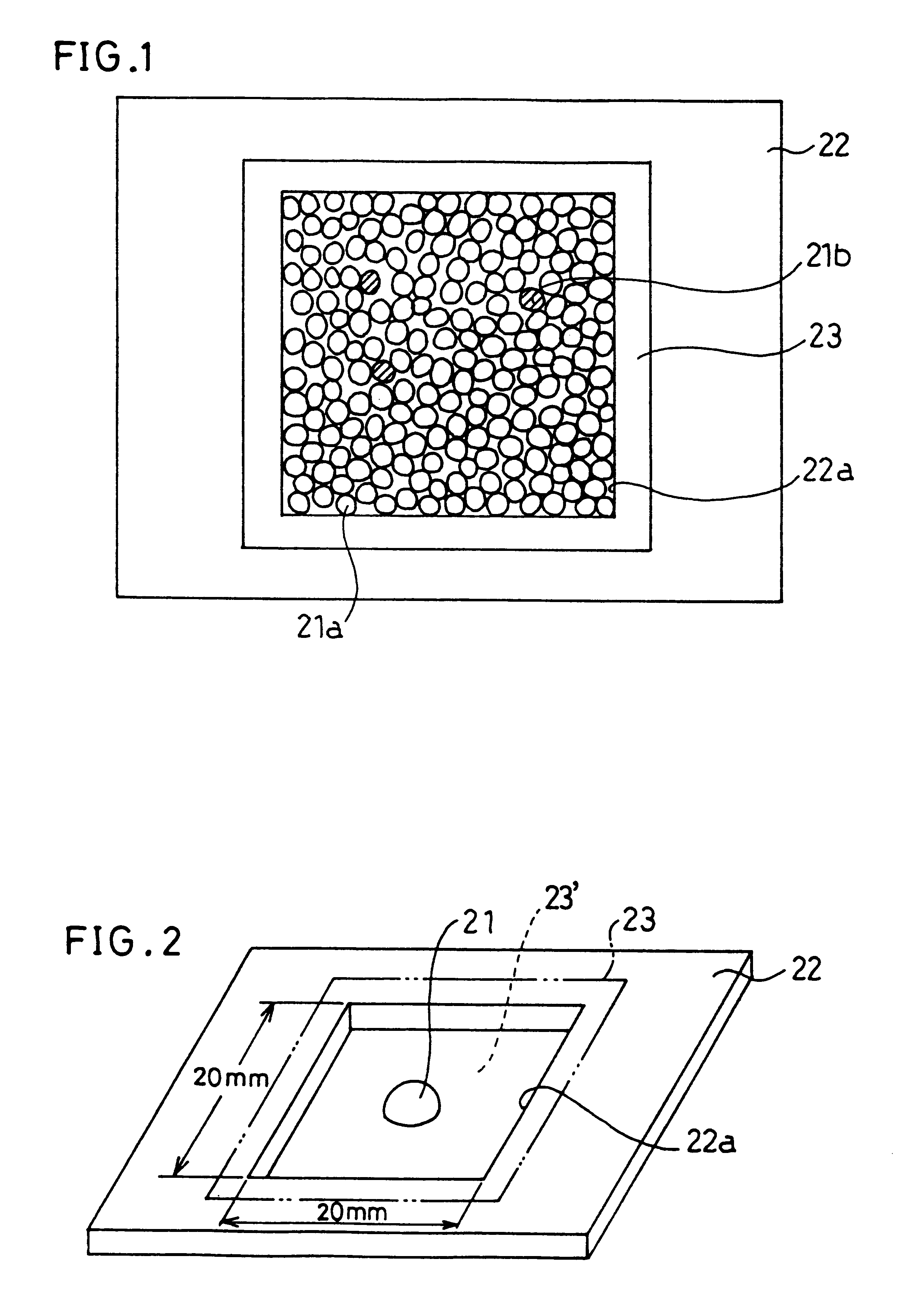

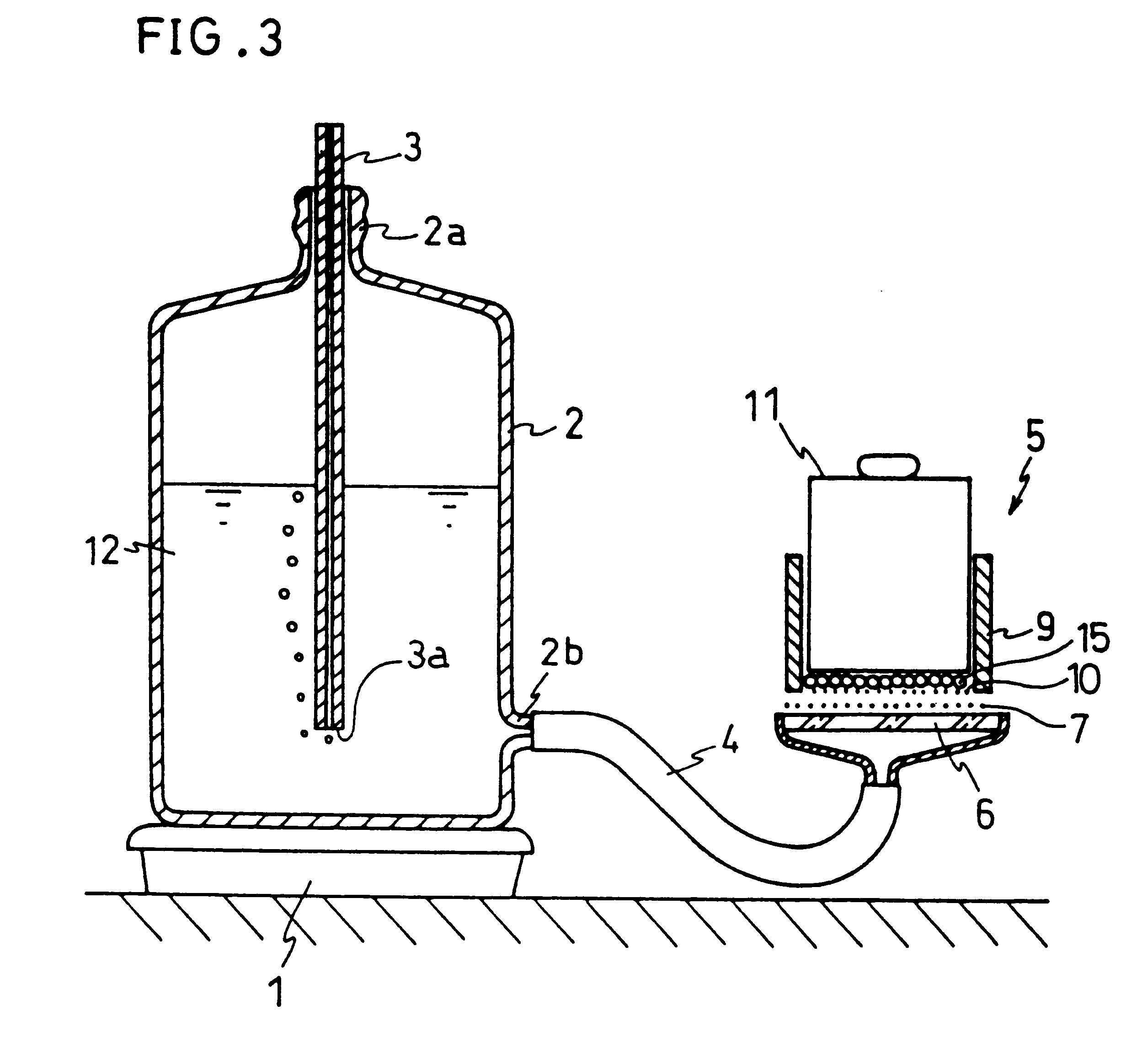

A hydrogel polymer obtained by polymerizing a monomer component including acrylic acid (salt) is post-neutralized so that each of polymer particles derived from a polymer produced by neutralizing the hydrogel polymer has an allowable neutralization ratio. The polymer as obtained by neutralizing the hydrogel polymer is reacted with a crosslinking agent reactive to a functional group of the polymer. The allowable neutralization ratio, for example, is a neutralization ratio which is not lower, by not less than 20 mole percent, or more than, at least 55 mole percent, than an average neutralization ratio of a mass of the polymer particles, and the post-neutralization is carried out so that a number of polymer particles having a non-allowable neutralization ratio outside the allowable neutralization range is not more than 10 in 200 polymer particles, thus obtaining a water-absorbent agent having high absorbency under no applied pressure and high pressure wherein the amount of water soluble component is lower compared with the conventional water-absorbent agent and a change in pH of a swollen gel is small.

Owner:NIPPON SHOKUBAI CO LTD

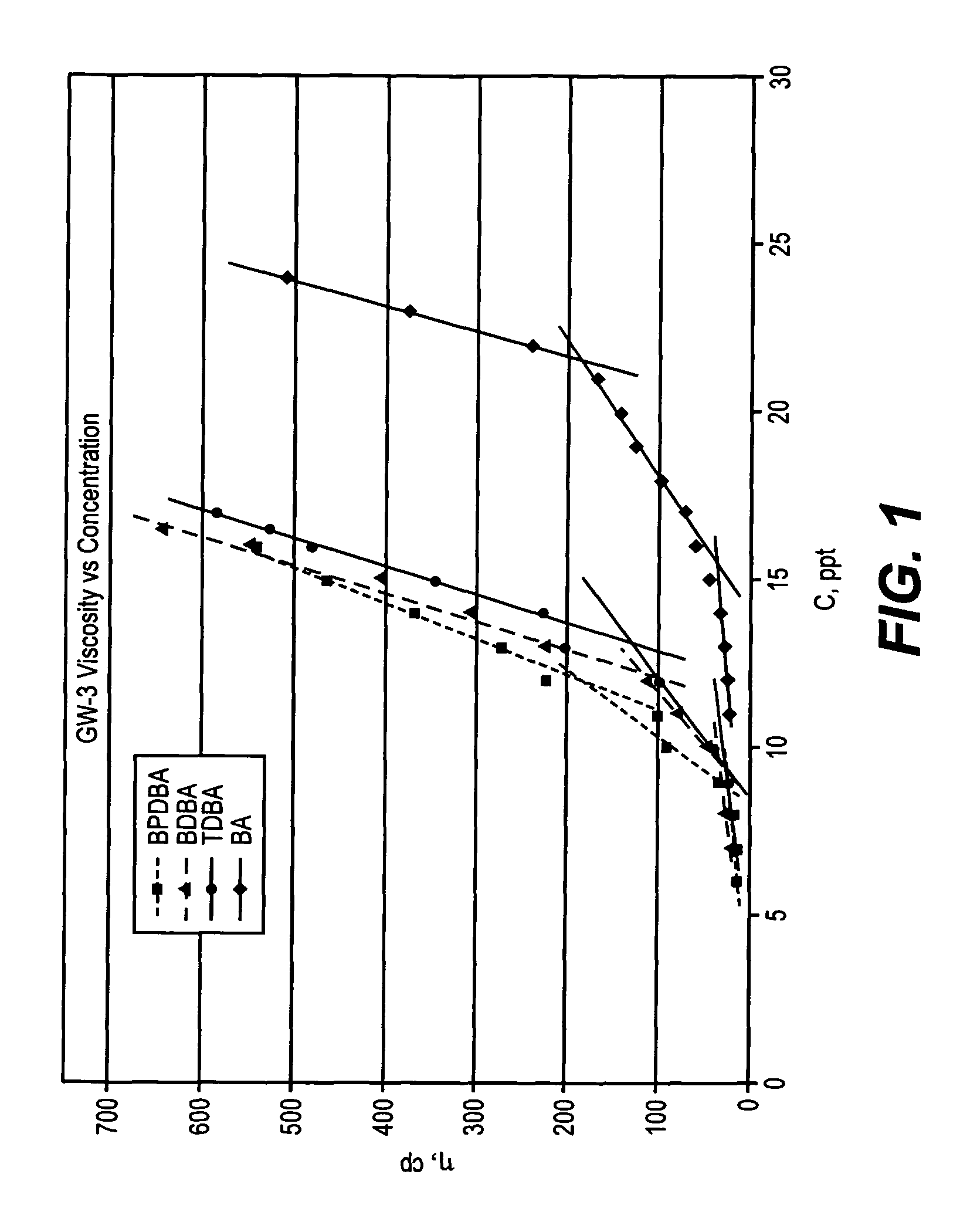

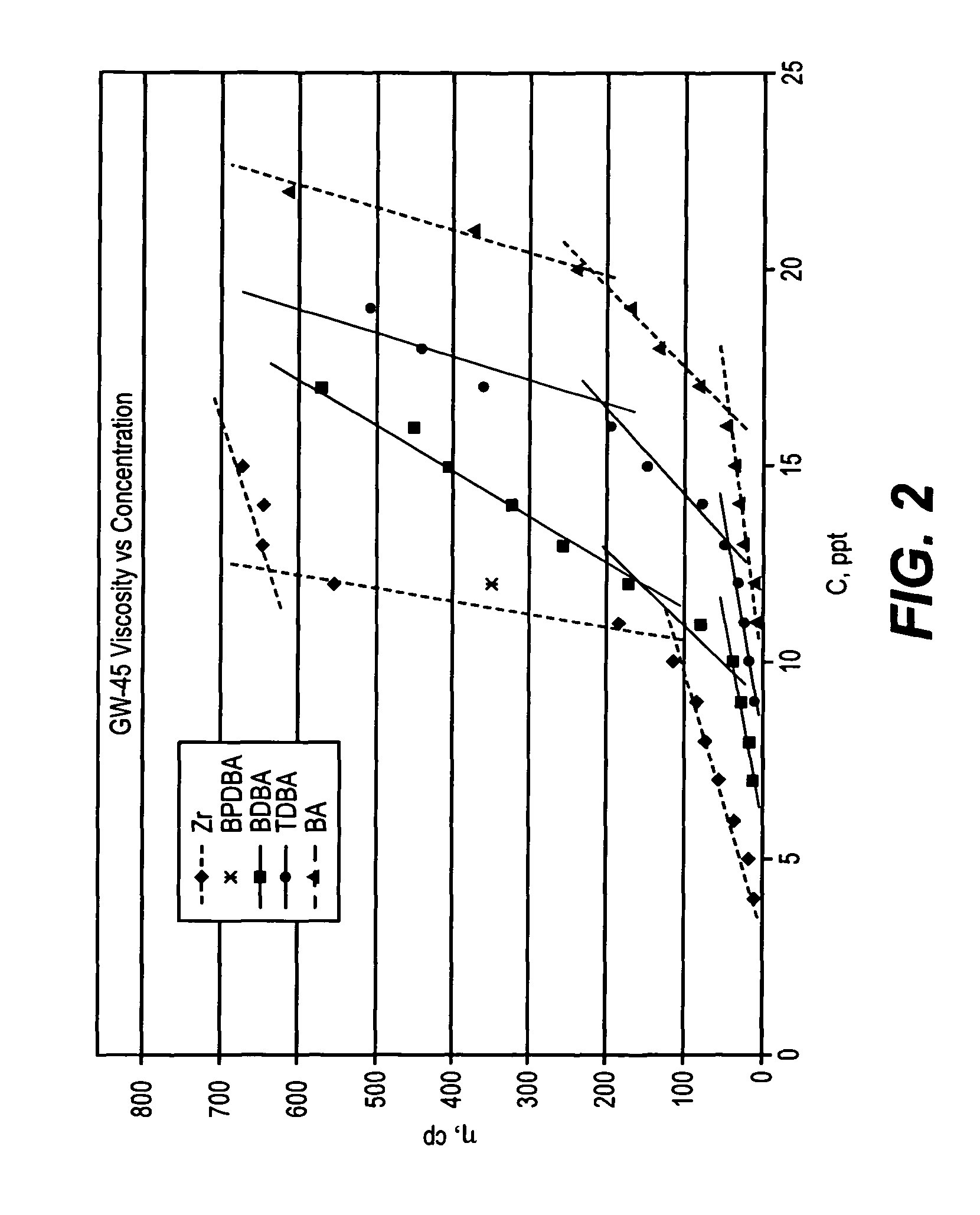

Galactomannan based well treating fluids

ActiveUS20050272612A1Low polymer contentHigh molecular weightFluid removalFlushingPolymer scienceFracturing fluid

A well fracturing fluid is shown which includes an aqueous base fluid, a hydratable polymer, such as a guar gum, and a suitable crosslinking agent for crosslinking the hydratable polymer to form a polymer gel. The hydratable polymer has a higher molecular weight which is achieved by improvements in the processing of the guar split. The higher molecular weight polymer provides improved performance in well fracturing operations.

Owner:BAKER HUGHES INC

Taste masked pharmaceutical composition comprising pH sensitive polymer

InactiveUS20050136115A1Bioavailability is maintainedHigh molecular weightPowder deliveryDispersion deliverySolvent evaporationBioavailability

The present invention discloses a substantially amorphous pharmaceutical composition comprising a drug that can exist in a variety of polymorphic forms and a pH sensitive polymer, which inhibits the crystallization of the drug during formulation and reconstitution. Polymers of higher molecular weight are more effective at lower loading, especially when the drug polymer matrix is prepared by the solvent evaporation or solvent extraction technique. The compositions used as dry syrups maintain bioavailability of the drug and effectively mask the taste of the drug when the composition is reconstituted.

Owner:COUNCIL OF SCI & IND RES

Biological Polysiloxanes

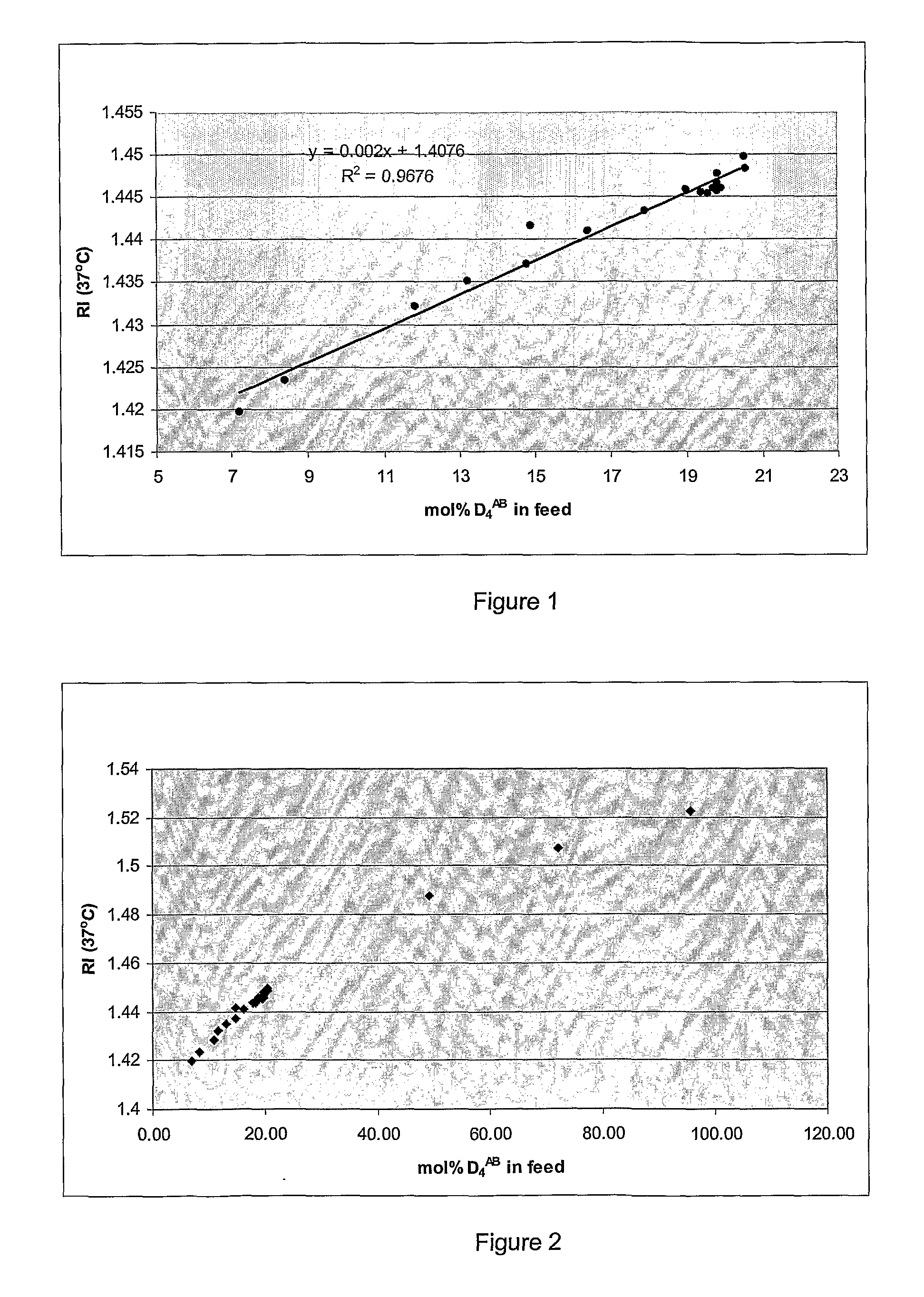

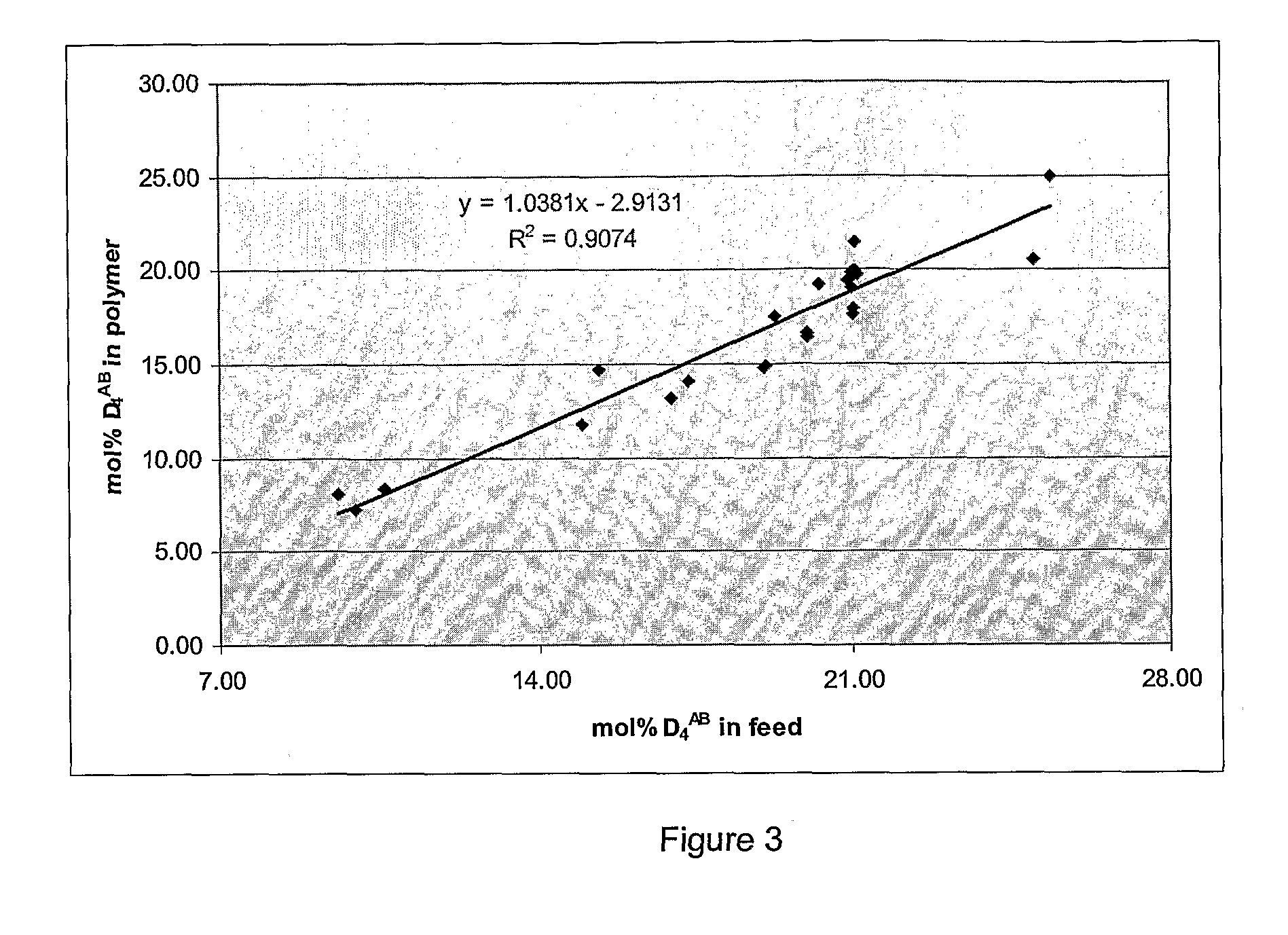

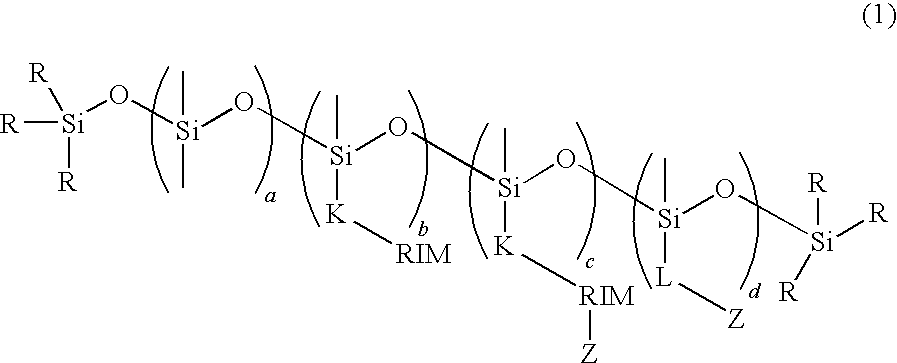

InactiveUS20090276042A1Low polymer contentLimited degreeSilicon organic compoundsOptical articlesChemistrySiloxane

The present invention relates to a macromonomer having a polydimethylsiloxane backbone that has a mol % dimethyl siloxanes, b mol % siloxanes substituted with -K-RIM, c mol % siloxanes substituted with -K-RIM-Z and d mol % siloxanes substituted with -L-Z, and in which the terminal siloxane groups are tri-substituted with R, wherein RIM is a refractive index modifying group; Z is a free radically polymerisable group; K is a spacer group; L is optional and is a spacer group; each R is independently selected from an RIM, a lower alkyl group, hydrogen or Z; and a is a molar percentage of the macromonomer which is in the range of from 0 to 95 mol %; b is a molar percentage of the macromonomer which is in the range of from 5 to 99 mol %; c is a molar percentage of the macromonomer which is in the range of from 0 to 2 mol %; and d is a molar percentage of the macromonomer which is in the range of from 0 to 2 mol %; with the proviso that c and d are not both 0 mol %.

Owner:THE VISION CRC LTD

pH sensitive polymer for inhibiting transformation in drugs

InactiveUS7282218B2Bioavailability is maintainedHigh molecular weightPowder deliveryDispersion deliverySolvent evaporationPH-sensitive polymers

The present invention discloses a substantially amorphous pharmaceutical composition comprising a drug that can exist in a variety of polymorphic forms and a pH sensitive polymer, which inhibits the crystallization of the drug during formulation and reconstitution. Polymers of higher molecular weight are more effective at lower loading, especially when the drug polymer matrix is prepared by the solvent evaporation or solvent extraction technique. The compositions used as dry syrups maintain bioavailability of the drug and effectively mask the taste of the drug when the composition is reconstituted.

Owner:COUNCIL OF SCI & IND RES

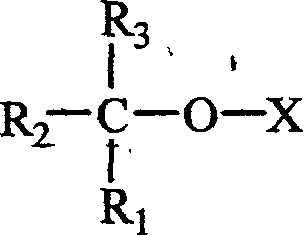

Method of treating polymer

To eliminate a halogen group of a halogen group-terminated vinyl polymer, the present invention provides a method to treat said polymer with an oxy anion compound to thereby eliminate a terminal halogen group easily. Thus, it is possible to improve the storage stability of the polymer or a curable composition comprising said polymer and to prevent various materials coming into contact with the reaction apparatus or the polymer from being corroded. In particular, it is possible to improve the storage stability of a crosslinkable silyl group-containing polymer.

Owner:KANEKA CORP

Preparation method of mezlocillin sodium and mezlocillin sodium for injection

The invention provides a preparation method of mezlocillin sodium and mezlocillin sodium for injection. The preparation method comprises the following steps of: (a) adding mezlocillin acid into water for injection, and cooling material liquor at 12-15 DEG C; (b) dropwise adding a NaHCO3 solution, adjusting the pH value at 5.8-6.5, and stirring until the material liquor is clean and the pH value is stable; (c) raising the temperature of the material liquor to be 20 DGE C+ / -2 DEG C, and stirring for 30-60 minutes; (d) adding active carbon for injections, stirring for 15-30 minutes, and decarburizing by a plate frame filter; (e) degerming and filtering the decarburized filtrate by a 0.45mu m filter and a 0.22mu m filter; and (f) freeze-drying to obtain the mezlocillin sodium finished product. By improving the conventional freeze-drying technology and combining with the improved preparation method of the mezlocillin acid, the method prepares the mezlocillin sodium product with low polymer content, so that the product quality is obviously improved, and the possibility of allergy caused by the product is greatly reduced.

Owner:SUZHOU ERYE PHARMA CO LTD

Preparation method of acrylate polymer/nanometer silicon dioxide composite particles for polycarbonate toughening

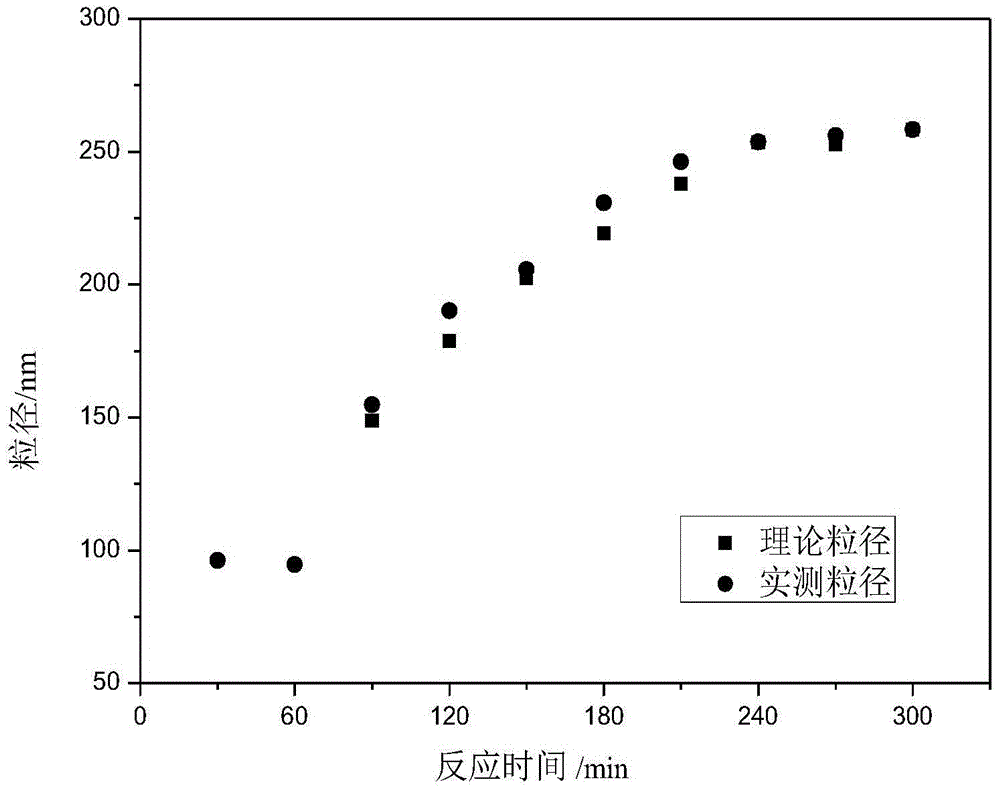

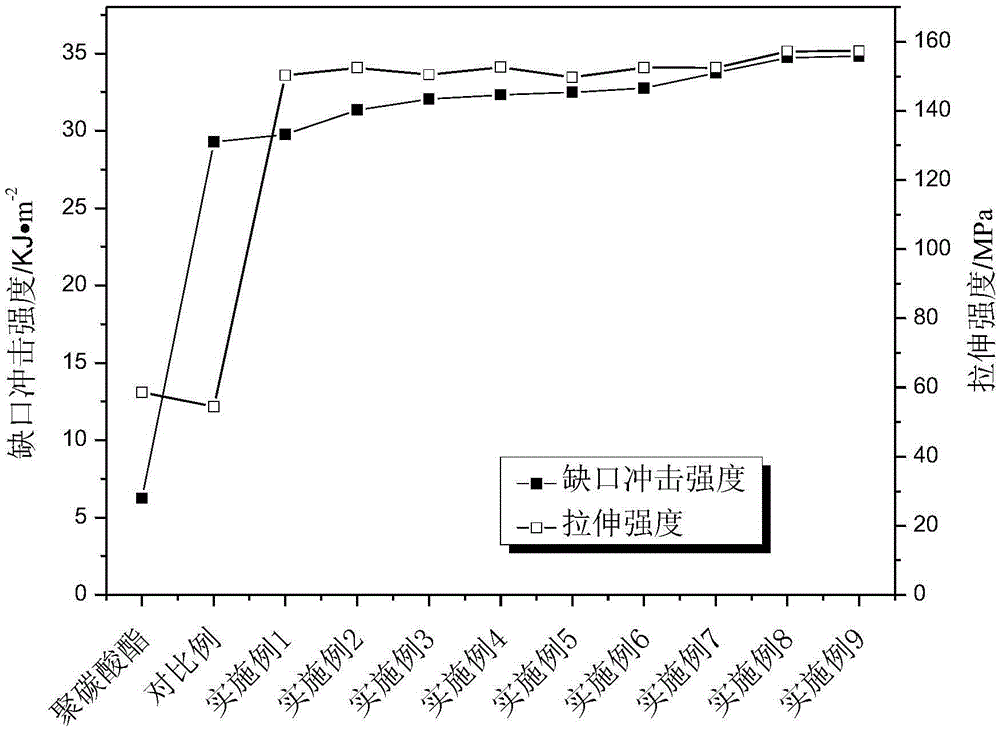

The invention provides a preparation method of acrylate polymer / nanometer silicon dioxide composite particles for polycarbonate toughening. According to the method, acrylate polymer emulsion is prepared by selecting emulsifier dosage and nanometer silicon dioxide dosage, utilizing a seeded emulsion polymerization technology, performing preparation of a seed stage elastomer, increase of elastomer particle size and in-situ coating of a plastic outer layer and adjusting an initiator adding mode, then nanometer silicon dioxide pre-emulsion and the acrylate polymer emulsion are mixed evenly, and the acrylate polymer / nanometer silicon dioxide composite particles are obtained through emulsion breaking. A little amount of the composite particles is added into polycarbonate, the toughness of a polycarbonate substrate material can be remarkably improved by adding the acrylate polymer / nanometer silicon dioxide composite particles 1.96%, low-temperature notch impact strength of the composite material is improved by 287% compared with purer polycarbonate, the breaking elongation rate is improved by 298%, and meanwhile the tensile strength is improved by 157%.

Owner:HEBEI UNIV OF TECH

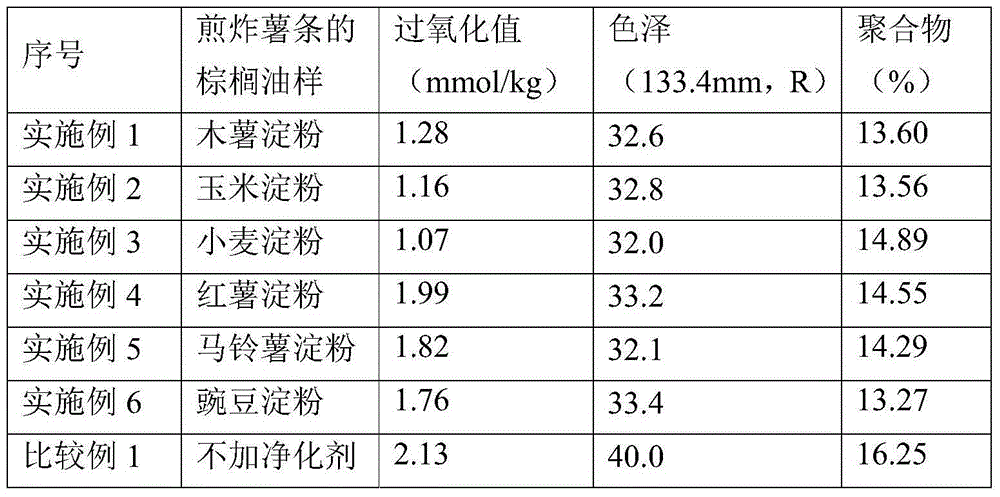

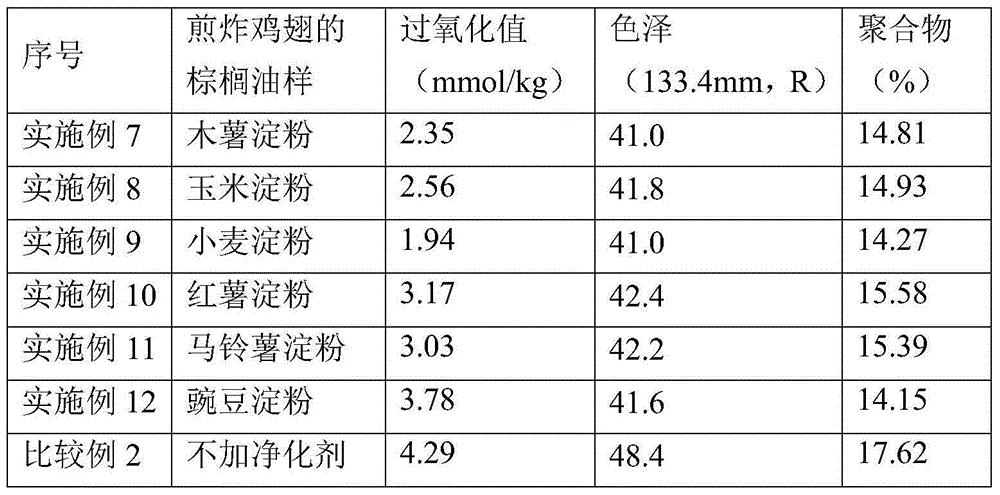

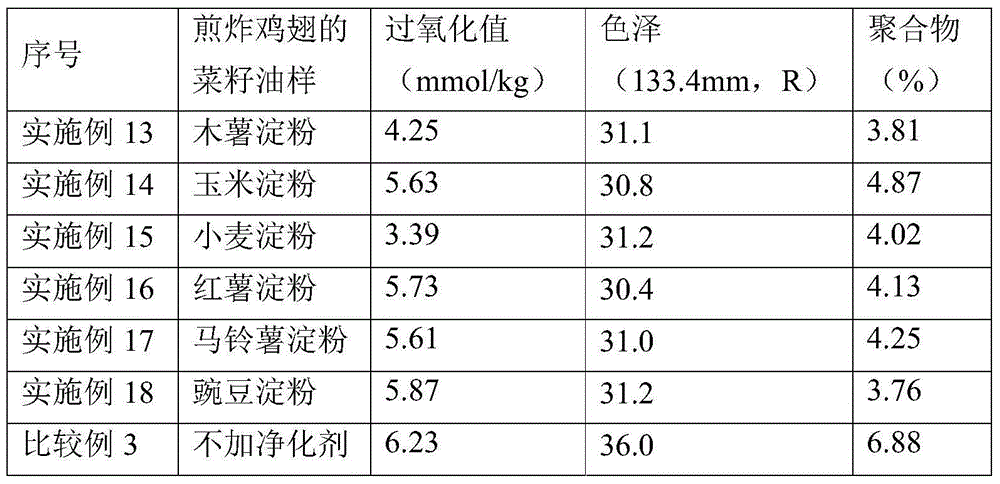

Natural frying oil purifying agent, method of treating frying oil by food starchy materials and usage in purifying frying oil by food starchy materials

ActiveCN104543622ALow costLow peroxide valueFood preparationEdible oils/fats production/working-upPotato starchWheat starch

The present invention discloses a frying oil purifying agent. The frying oil purifying agent are preferably selected two or more food starchy materials from tapioca starch, sweet potato starch, potato starch, wheat starch, corn starch and / or pea starch. The present invention also discloses a method treating frying oil by food starchy materials, as well as usage in purifying frying oil by food starchy materials.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

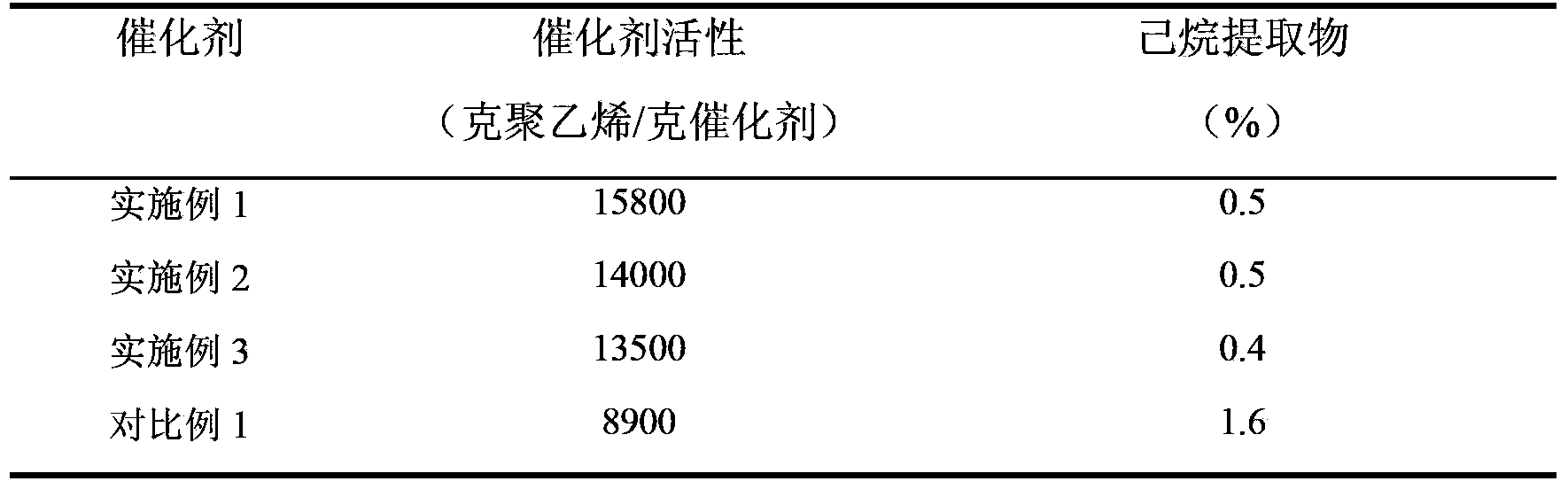

Catalyst component for ethene polymerization and catalyst

The invention relates to a catalyst component for ethene polymerization and a catalyst, and use of the catalyst. The catalyst component comprises a superfine inorganic oxide carrier, the carrier is loaded with a reaction product of a magnesium halide, a halogenated alcohol, at least a titanium halide and at least an electron donor compound, and the catalyst component is obtained by the reaction including the following steps: (1) mother liquor preparation, to be more specific, reacting the magnesium halide, the titanium halide and the halogenated alcohol with the general formula of XnROH in the electron donor compound to prepare mother liquor; (2) carrier mixing, to be more specific, mixing the mother liquor prepared by the step (1) with the superfine inorganic oxide carrier to obtain slurry; and (3) spray forming, to be more specific, performing spray drying on the slurry obtained by the step (2) to obtain the solid catalyst component. The prepared catalyst has high activity when the catalyst is used for ethylene homopolymerization or copolymerization of ethene and other alpha olefins, and the obtained polymers are low in hexane extract, and low in oligomer content.

Owner:CHINA PETROLEUM & CHEM CORP +1

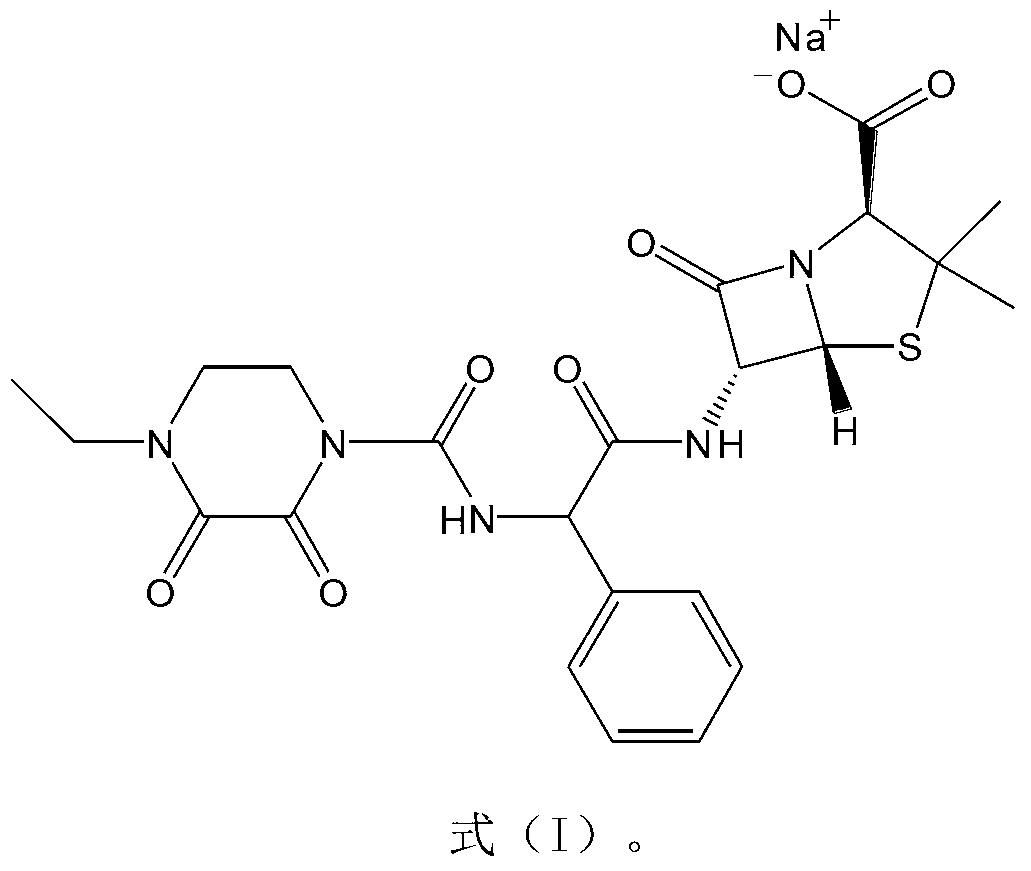

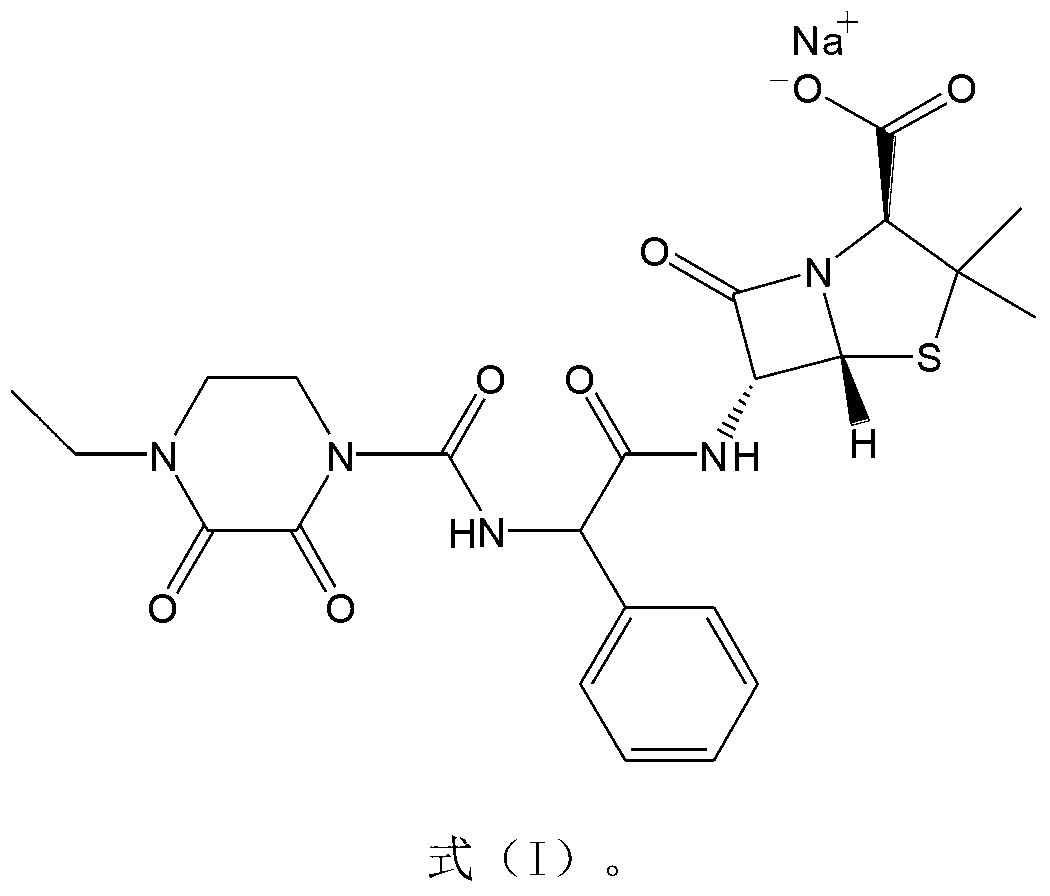

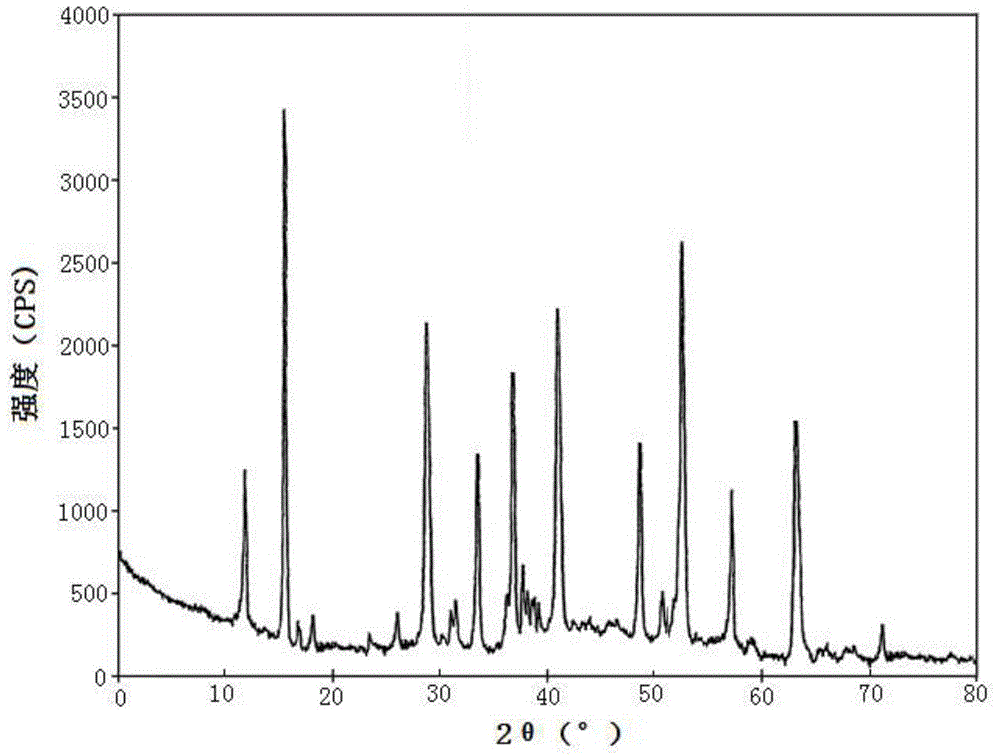

Piperacillin sodium-tazobactam sodium medicine composition and preparation method thereof

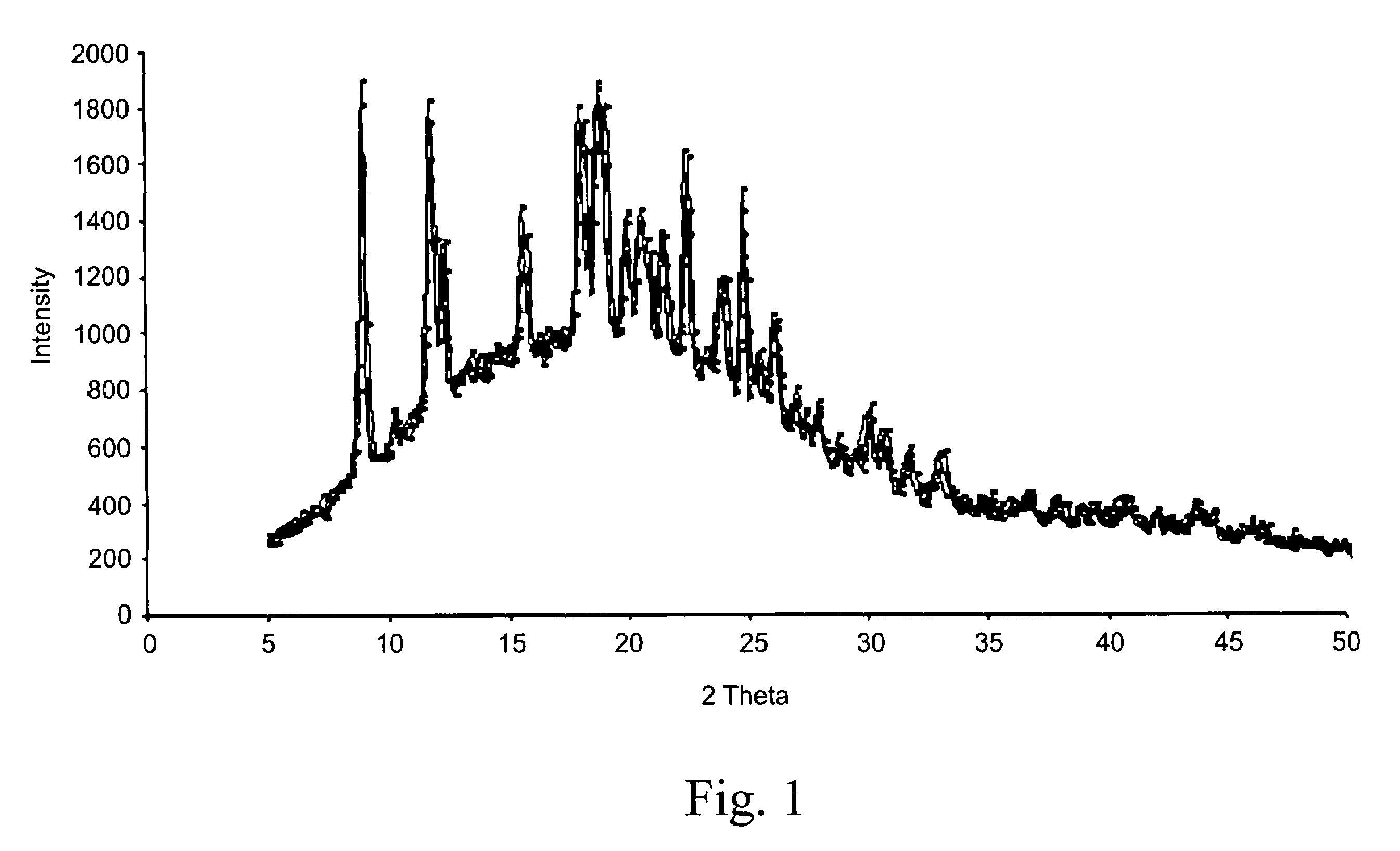

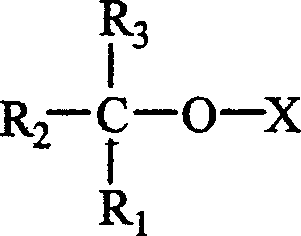

ActiveCN103340866ALow polymer contentImprove stabilityAntibacterial agentsHeterocyclic compound active ingredientsPiperacillin Sodium/ Tazobactam SodiumMass ratio

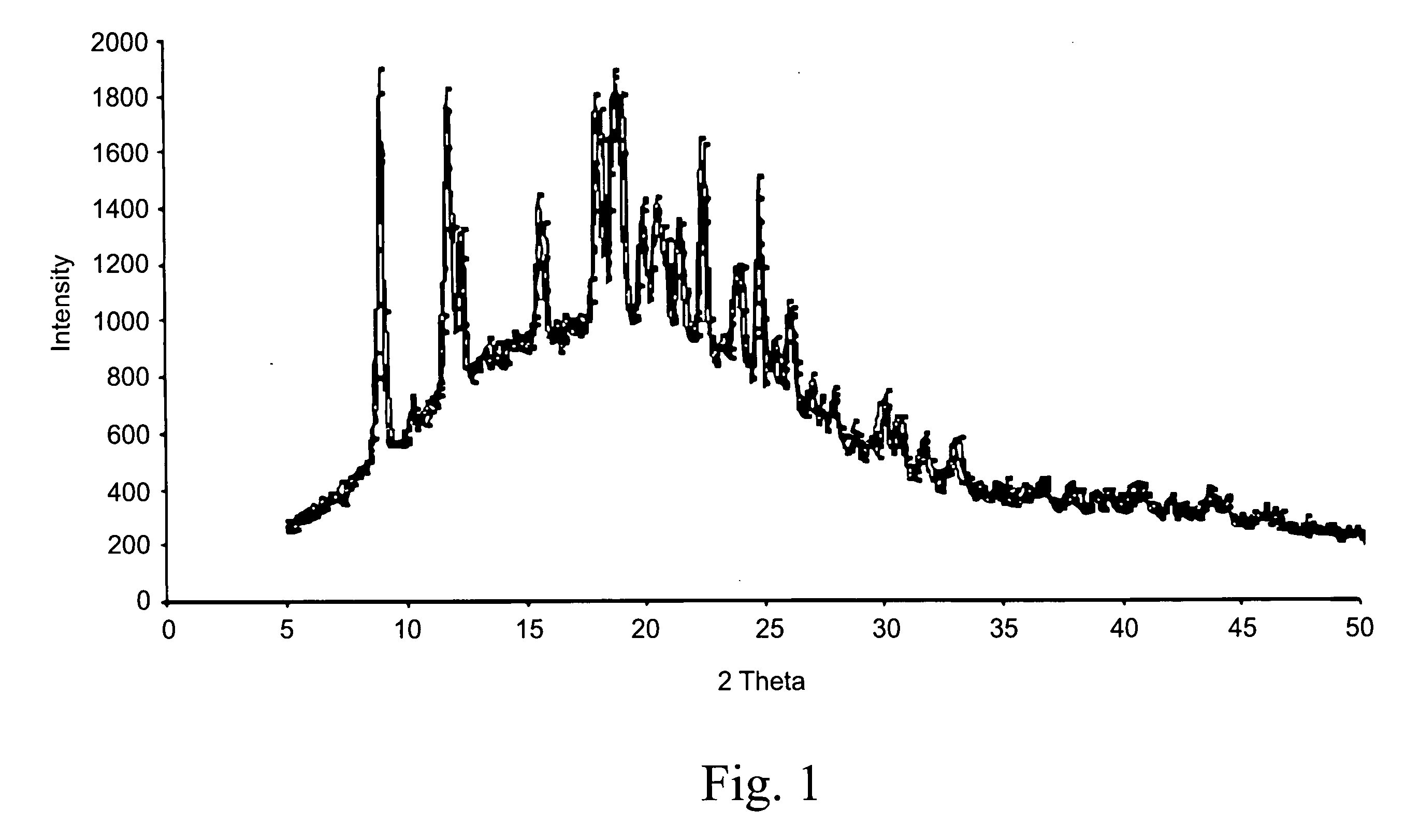

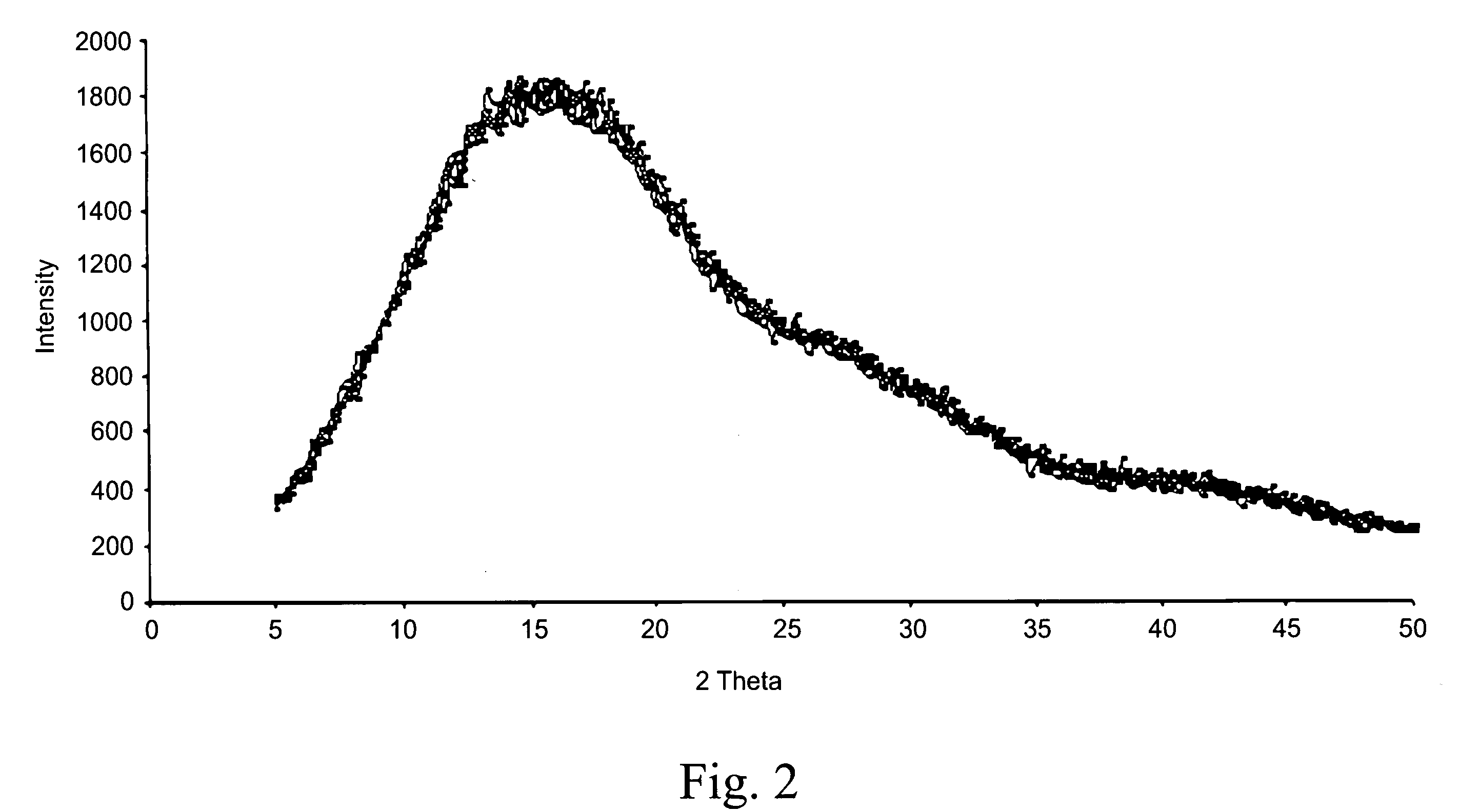

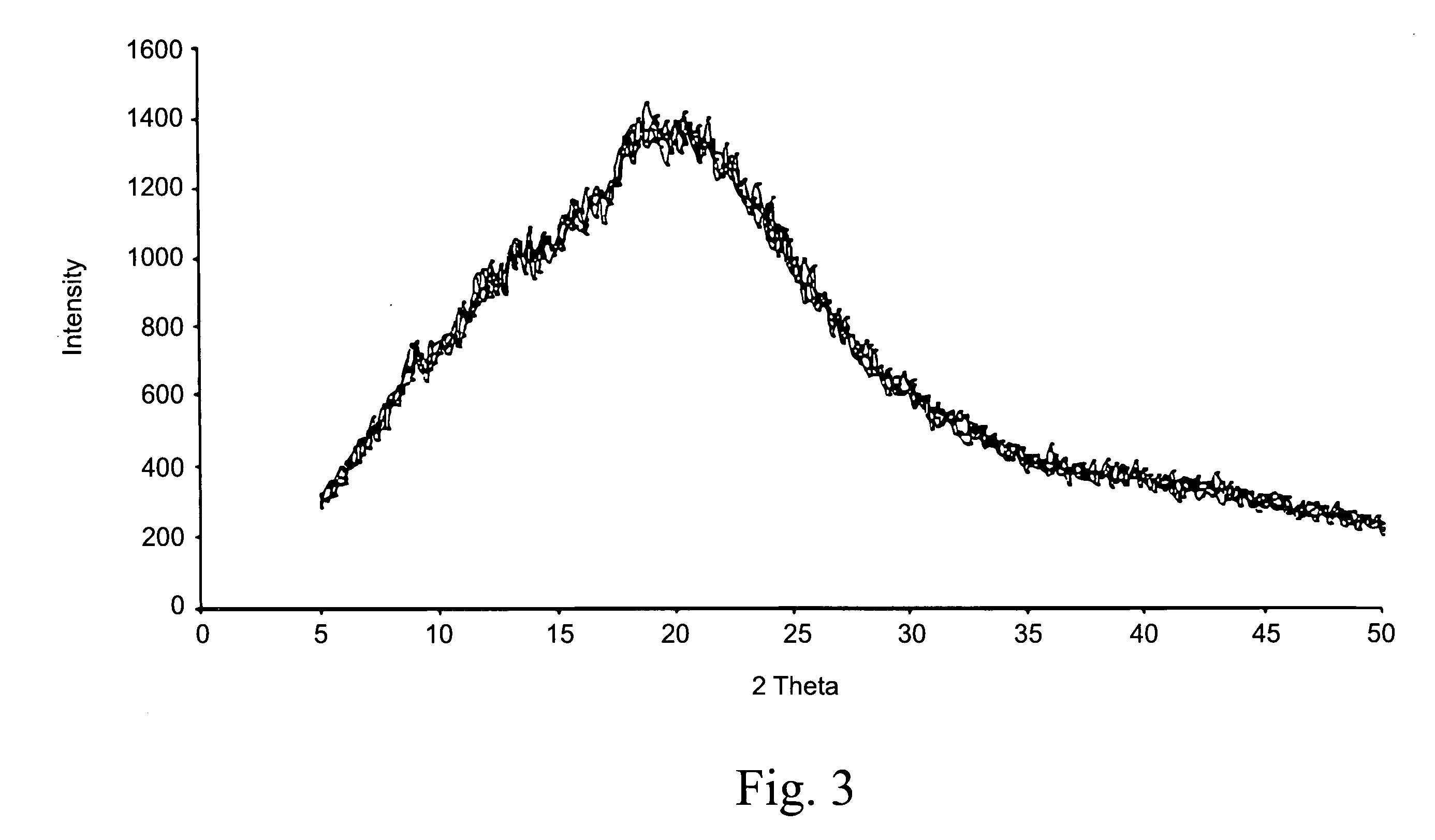

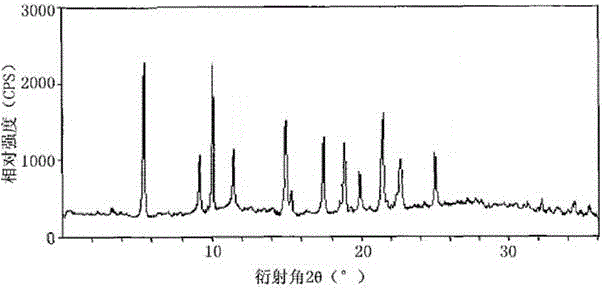

The invention belongs to the technical field of medicine, and in particular relates to a piperacillin sodium-tazobactam sodium medicine composition and a preparation method of the medicine composition. The medicine composition is a sterile powder injection; the mass ratio of the piperacillin sodium to the tazobactam sodium in the medicine composition is 4-20:1; the X-ray powder diffraction pattern of the piperacillin sodium measured by means of powder X-ray diffraction measurement method is shown in Figure 1; the chemical structural formula of the piperacillin sodium is shown in Formula (I); and the content of the piperacillin sodium polymer in the medicine composition provided by the invention is quite low and is not changed obviously in an accelerated test condition and in a long-term test condition. The medicine composition prepared from the piperacillin sodium and the tazobactam sodium provided by the invention also has the advantages of low polymer content and good stability.

Owner:CHINA MEHECO SANYANG PHARMA CO LTD

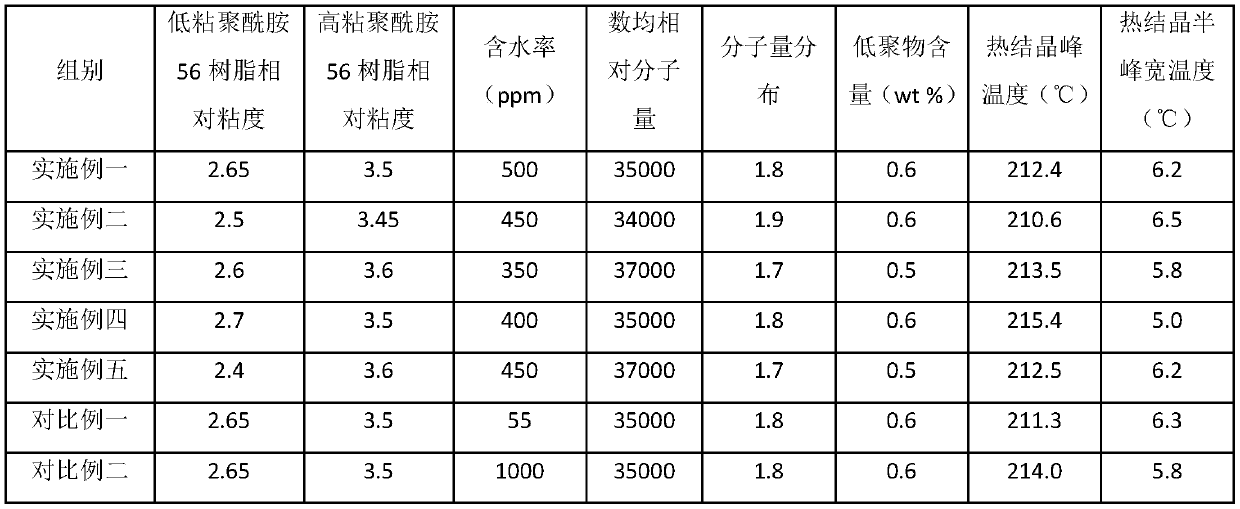

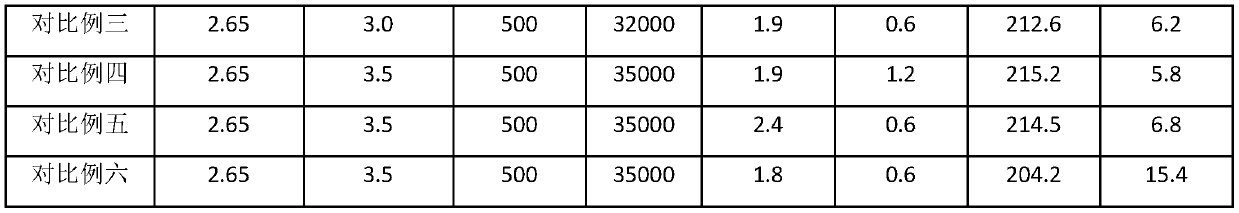

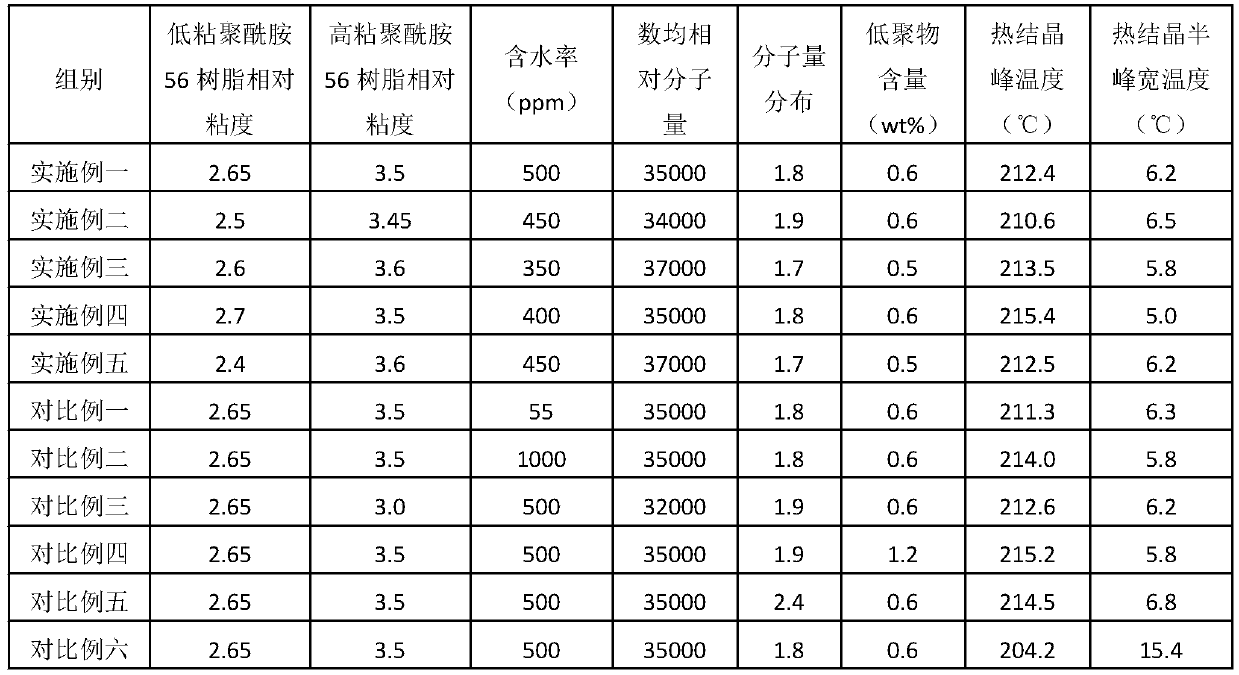

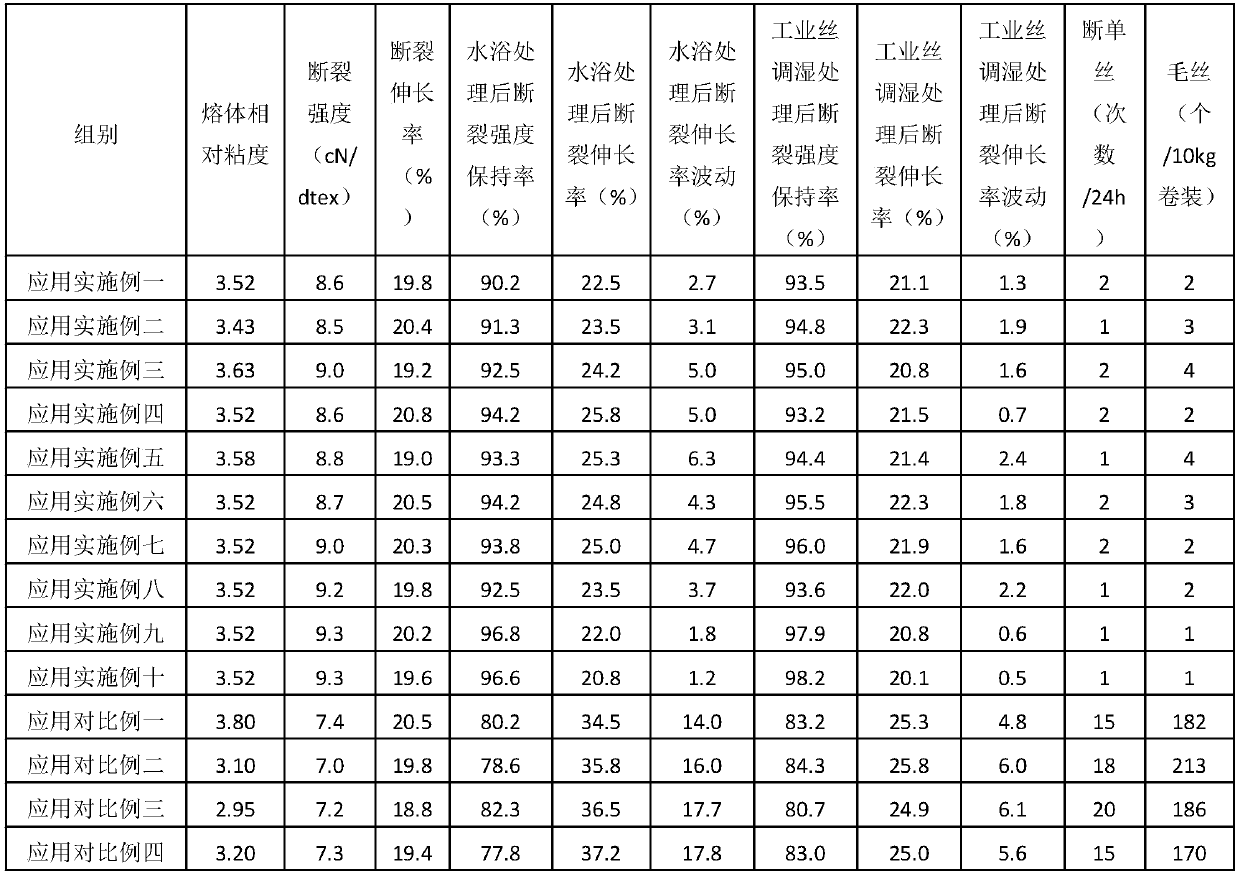

High-viscosity polyamide 56 resin, high-strength polyamide 56 industrial yarn and preparation method and application thereof

ActiveCN111378121AEmission reductionReduce generationTextile/flexible product manufactureMonocomponent polyamides artificial filamentYarnPolymer science

The invention provides a high-viscosity polyamide 56 resin, a high-strength polyamide 56 industrial yarn, and a preparation method and application thereof. The preparation method of the high-strengthpolyamide 56 industrial yarn comprises the following steps of heating and melting high-viscosity polyamide 56 resin by adopting a single-screw or double-screw extruder, drawing in a spinning box to obtain a primary yarn, and then carrying out heat preservation, cooling, oiling, pre-interlacing, multi-stage stretching, tension setting, relaxation setting, main interlacing and winding on the primaryyarn to obtain the high-strength polyamide 56 industrial yarn. The high-strength polyamide 56 industrial yarn provided by the invention has good mechanical properties and heat and humidity resistance, and can be applied to the fields of sewing threads, tire cords, airbag yarns, release cloth, water cloth, canvas, safety belts, ropes, fishing nets, industrial filter cloth, conveyor belts, parachutes, tents and bags.

Owner:CATHAY R&D CENT CO LTD +2

Method of fracturing using guar-based well treating fluid

ActiveUS8895480B2Low polymer contentHigh molecular weightFluid removalFlushingPolymer scienceFracturing fluid

Owner:BAKER HUGHES HLDG LLC

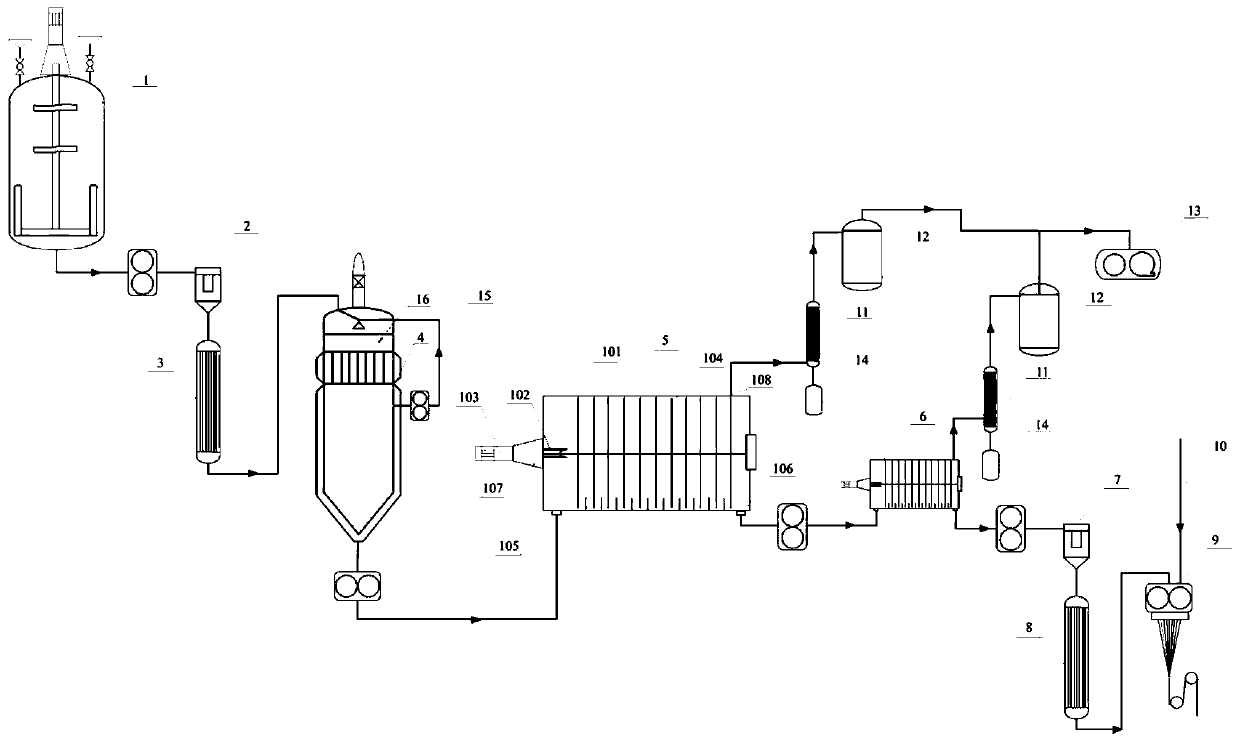

Method for preparing polyester-nylon composite fibers by melt direct spinning

ActiveCN111394831AReduced extractables contentQuality assuranceTextile/flexible product manufactureChemical/physical/physico-chemical stationary reactorsPolyesterFiber

The invention relates to the field of nylon materials, and discloses a method for preparing polyester-nylon composite fibers by melt direct spinning. The method comprises the following steps of 1) burdening, specifically, heating and mixing caprolactam, an end-capping reagent, water and a catalyst to obtain a mixture; 2) ring opening; 3) pre-polycondensation, specifically, carrying out a pre-polycondensation reaction and devolatilization; 4) final polycondensation, specifically, carrying out a final polycondensation reaction and devolatilization; 5) devolatilizing before spinning; and 6) spinning, specifically, directly conveying nylon melt and polyester melt which are devolatilized before spinning to a composite spinning assembly, performing extruding, cooling, oiling, stretching and winding to obtain the polyester-nylon composite fibers. By means of the method, direct spinning after nylon melt polymerization can be achieved, slices do not need to be prepared in advance, and the content of hot water extractables and cyclic dimers in the nylon melt can be effectively controlled; and composite spinning is carried out on the nylon melt and the polyester melt to obtain the polyester-nylon composite fibers in different composite forms.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

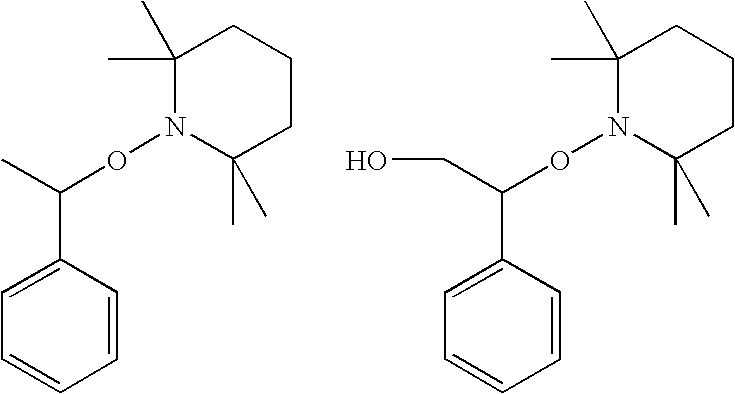

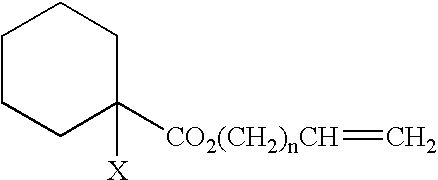

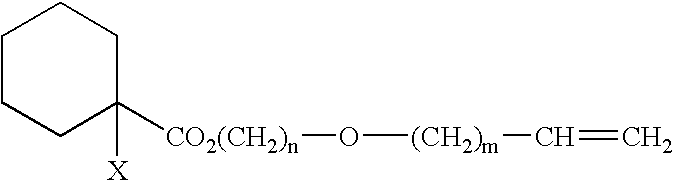

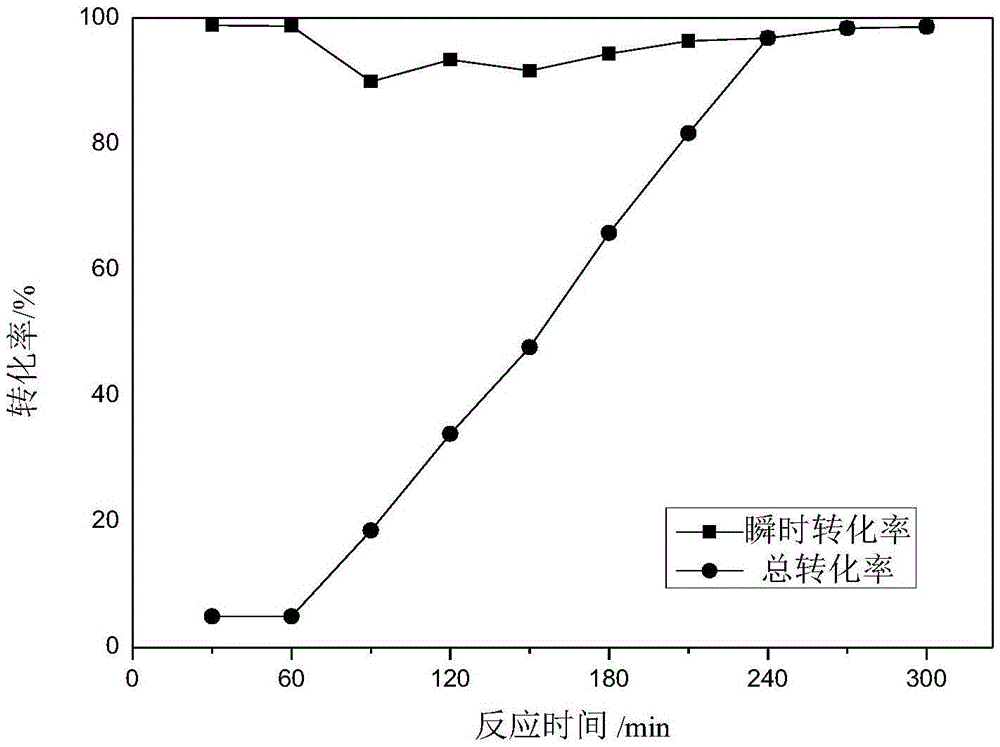

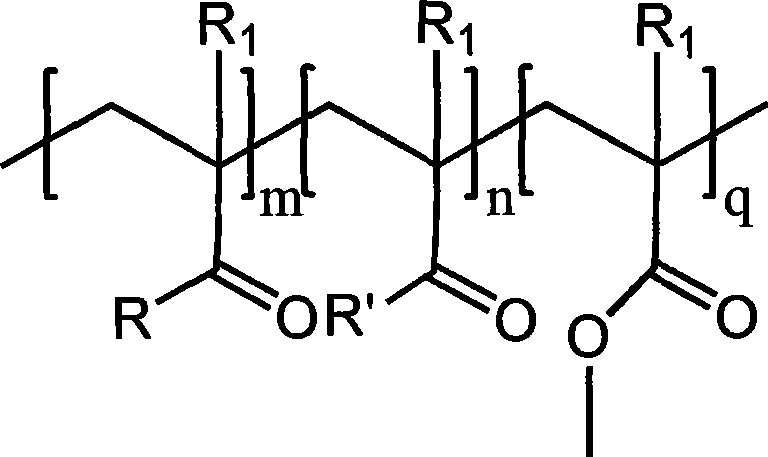

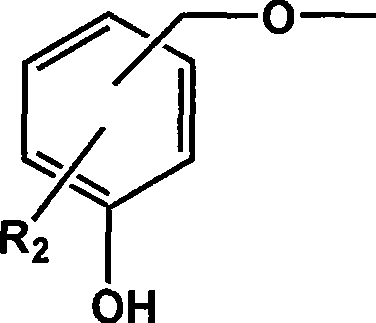

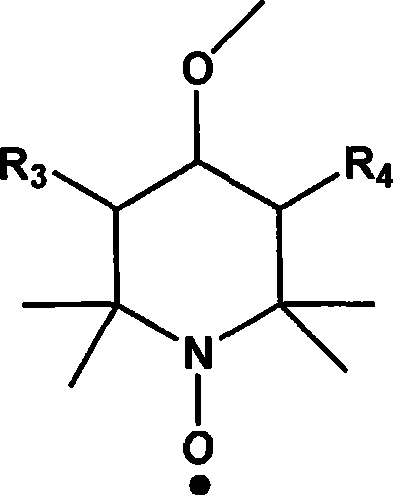

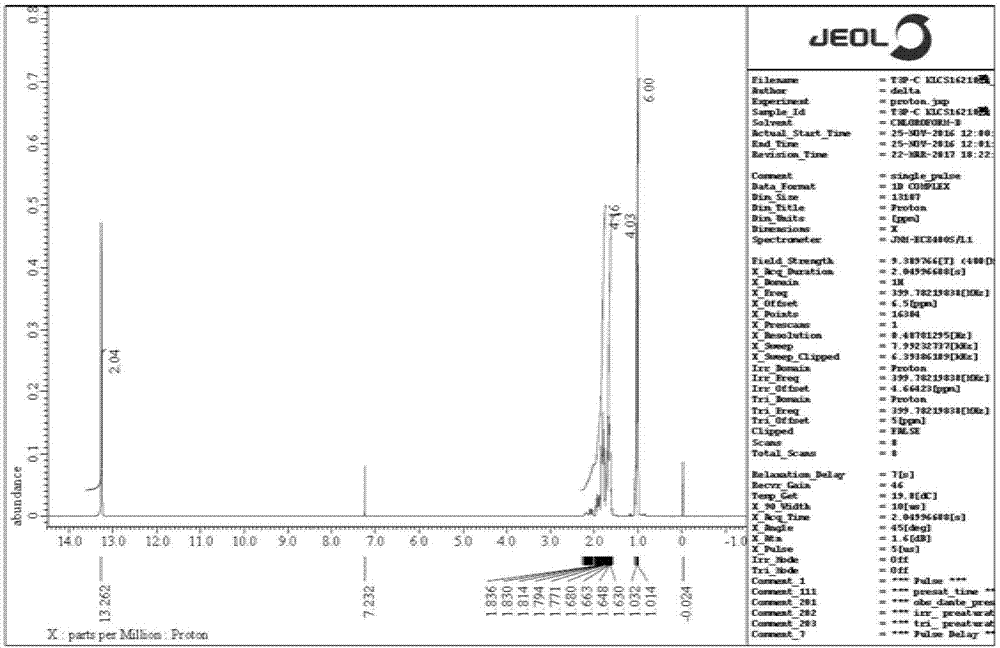

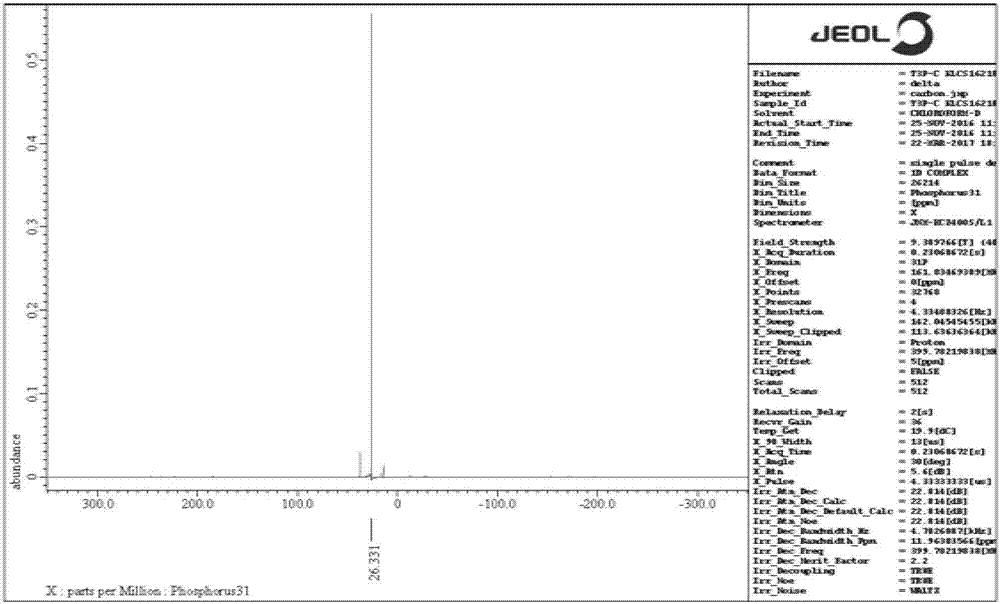

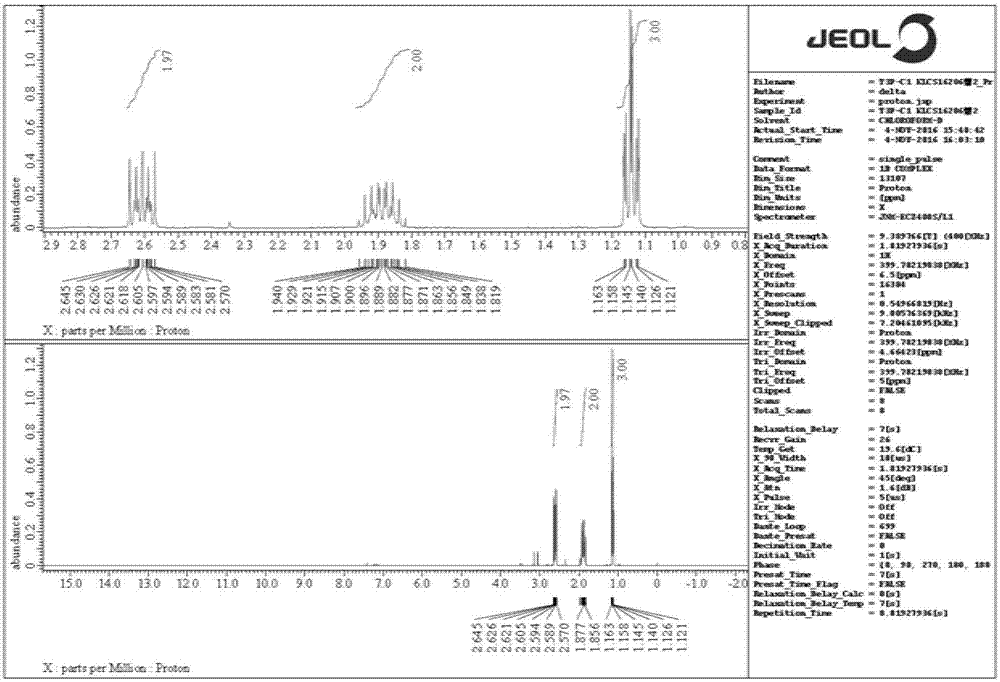

Macromole polymerization inhibitor containing phenolic group and azoxynaphthalene and preparation thereof

The invention discloses a macromolecular polymerization inhibitor containing phenolic groups and nitroxide groups, and a preparation method thereof. The polymethyl acrylate with polymerization degree of p, the phenolic compound and the nitroxide free radical type compound are dissolved in the solvent according to the mol ratio of 1:x:y, the catalyst with mass being 0.5-3.0wt percent of the total mass of the reaction mixture is added in to react at the temperature of 20-80 DEG C and under the 0.05-0.09MPa until the concentration of the phenolic compound and the nitroxide free radical type compound is not changed, the reaction mixture subsides in water, and the polyacrylate main chain is obtained after the sediment is dried and is connected with the macromolecular polymerization inhibitor containing the phenolic groups and the nitroxide free radical groups through ester linkage; and the method has the advantages that the raw material is easily obtained, the operation is simple and the method is convenient for the industrial production. The prepared product can effectively prevent the acrylate from being polymerized in the production process, reduce the content of the low polymer in the product, reduce the consumption of the total polymerization inhibitor and improve the product quality and has the broad industrial application prospect.

Owner:JIANGSU LITIAN TECH

Preparation method of cyclic propyl phosphonic anhydride

ActiveCN107011384AHigh reaction yieldLow costGroup 5/15 element organic compoundsAcetic anhydrideOrganic synthesis

The invention belongs to the technical field of organic synthesis and particularly relates to a preparation method of cyclic propyl phosphonic anhydride. The method comprises the steps of preparing propyl pyrophosphate from propenylphosphonic acid and acetic anhydride as reactants; preparing propyl phosphonyl chloride from propenylphosphonic acid and thionyl chloride as reactants; carrying out further reaction on the propyl pyrophosphate and the propyl phosphonyl chloride to prepare the cyclic propyl phosphonic anhydride. According to the prepared cyclic propyl phosphonic anhydride, the reaction yield is high and the total yield can reach 68-72%, the cyclic propyl phosphonic anhydride is low in cost and high in purity, the titration purity is greater than 99.5%, the content of free acid is smaller than 100ppm, the polymer content is low, and use of a lithium battery additive can be met. The preparation method is simple, safe, environment-friendly, high in efficiency, cheap and available in raw materials, wide in market prospect and suitable for massive production.

Owner:VALIANT CO LTD

Fracturing method using polyboronic compound

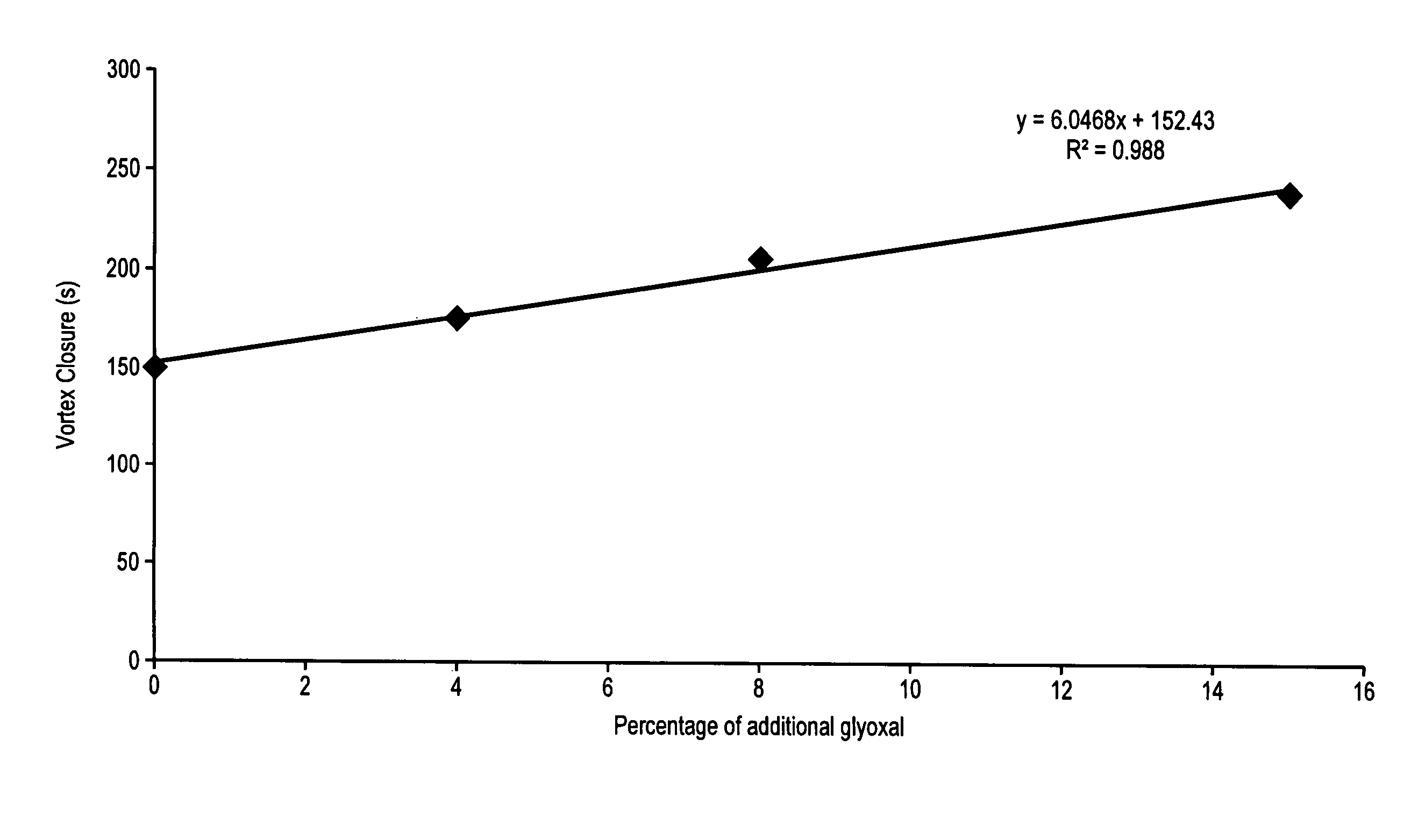

InactiveUS9534167B2Low polymer contentImprove efficiencyFluid removalGroup 3/13 element organic compoundsCompound (substance)Glyoxal

Polyboronic compounds useful as delayed crosslinking agents may be produced by using a polyamine as base scaffold and incorporating boron via reaction with intermediate borates which may be formed in the condensation reaction between boric acid and a diol. A di-aldehyde, such as glyoxal, may be introduced following caustic treatment of the reaction mixture of polyaminoboronate to form the polyboronic compound.

Owner:BJ SERVICES LLC +1

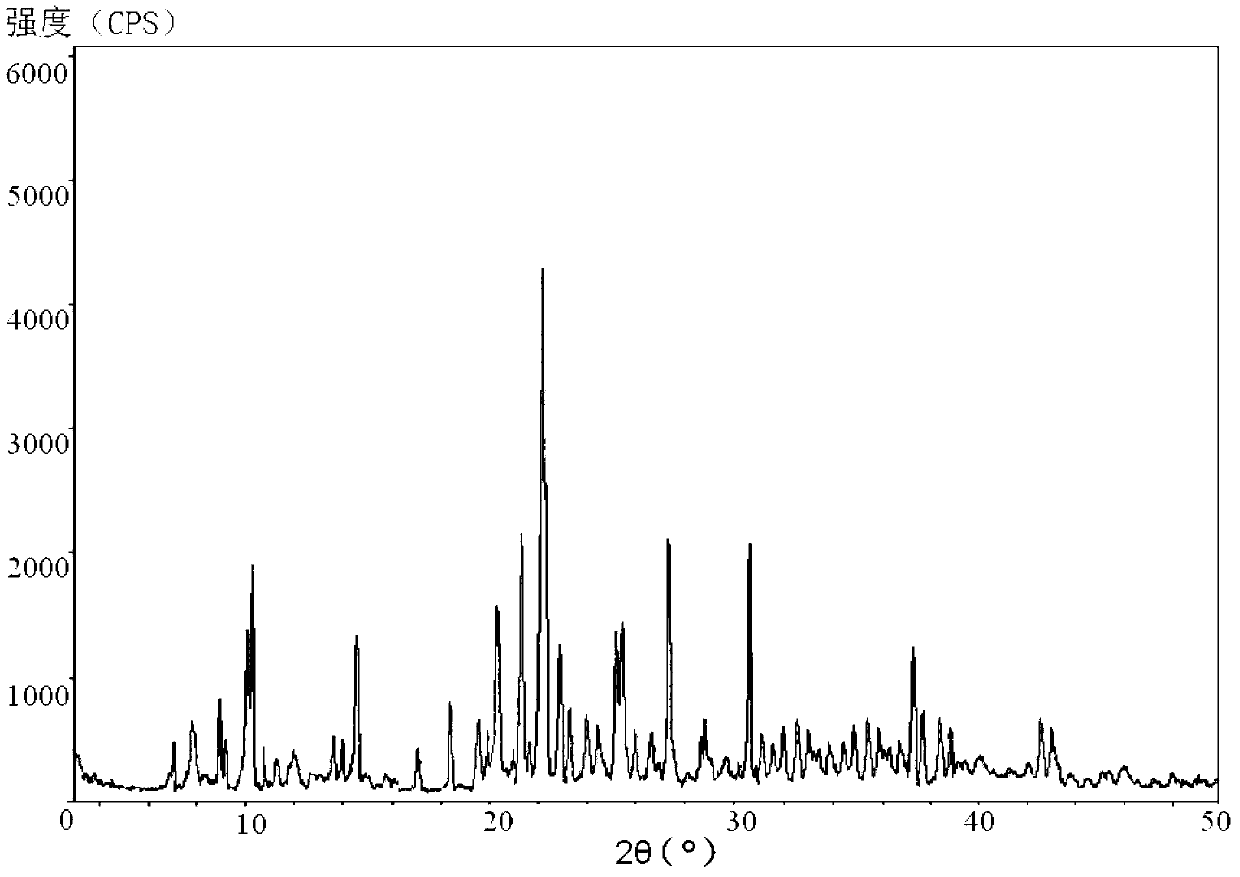

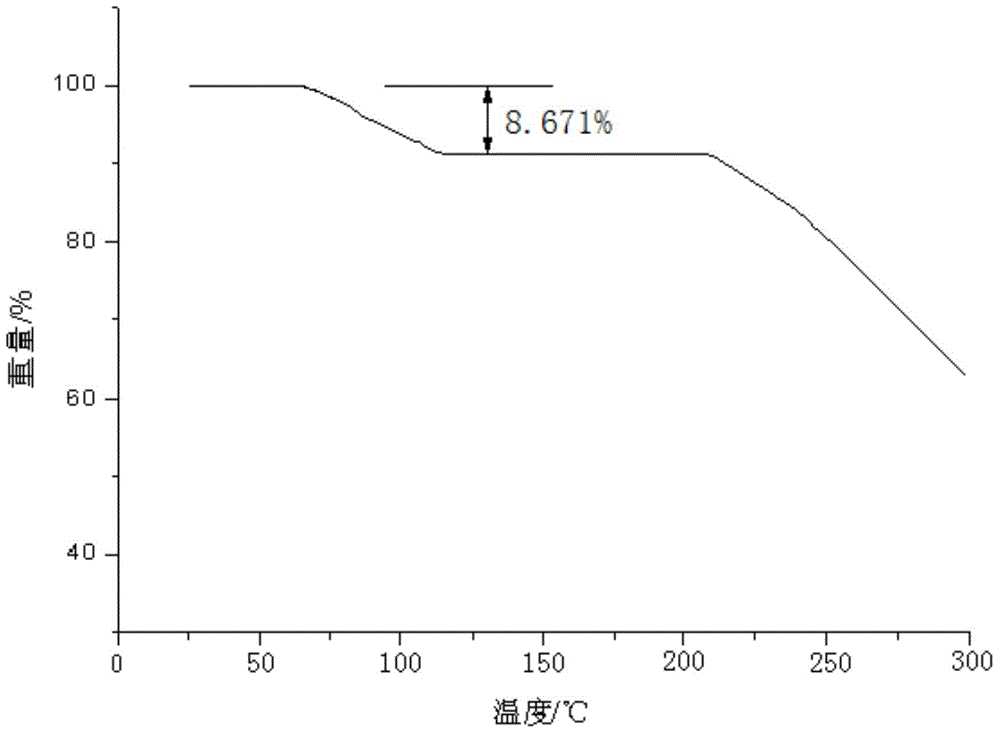

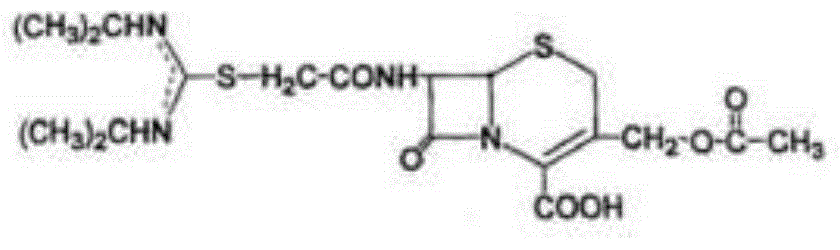

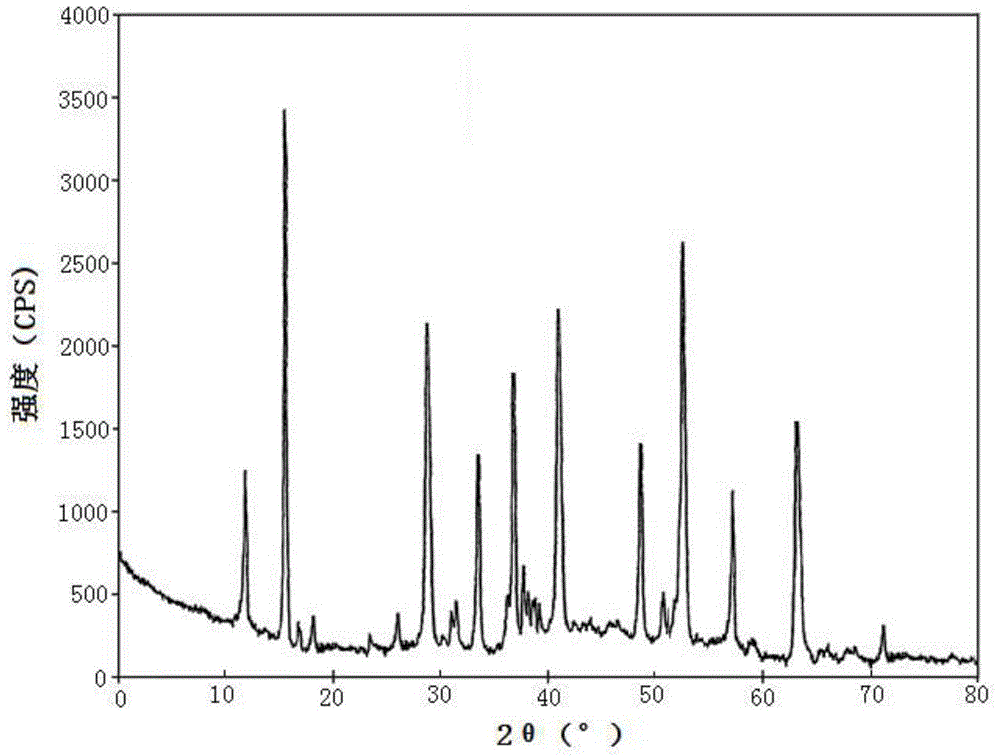

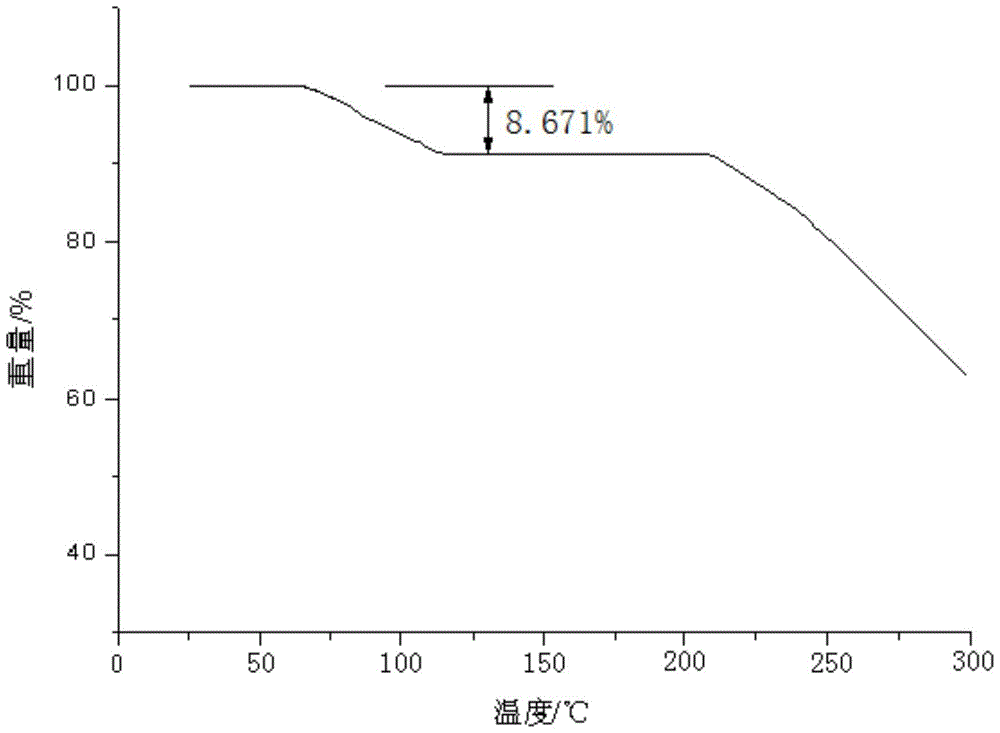

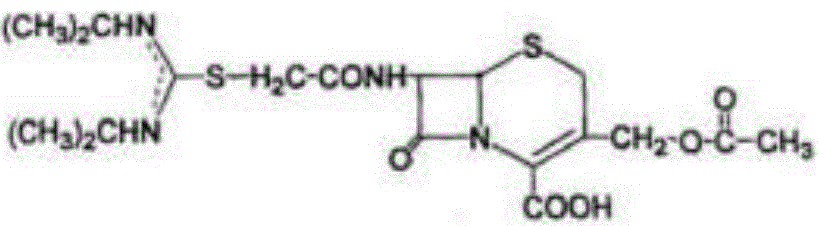

Cefathiamidine compound

ActiveCN104910186AReduce contentLow polymer contentAntibacterial agentsPowder deliveryAntibiosisStaphylococcus aureus

The invention belongs to the technical field of medicines, and concretely relates to a cefathiamidine compound. The cefathiamidine compound is a cefathiamidine hydrate, the structure of the cefathiamidine compound is represented by formula (I), and the X-ray powder diffraction pattern of the cefathiamidine compound is represented by figure 1. The cefathiamidine compound is a novel crystal form compound of the cefathiamidine hydrate, and is different from cefathiamidine compounds reported in the prior art. A result of tests shows that the new crystal form compound of the cefathiamidne hydrate has lower content of high-molecular polymers than cefathiamidine in the prior art, and the content of the high-molecular polymers does not obviously increase with the prolongation of the storage time; and the compound has substantial antibiosis activity on Staphylococcus aureus, coagulase negative staphylococci and Enterococcus faecalis.

Owner:SHANDONG LUOXIN PARMACEUTICAL GROUP STOCK CO LTD +1

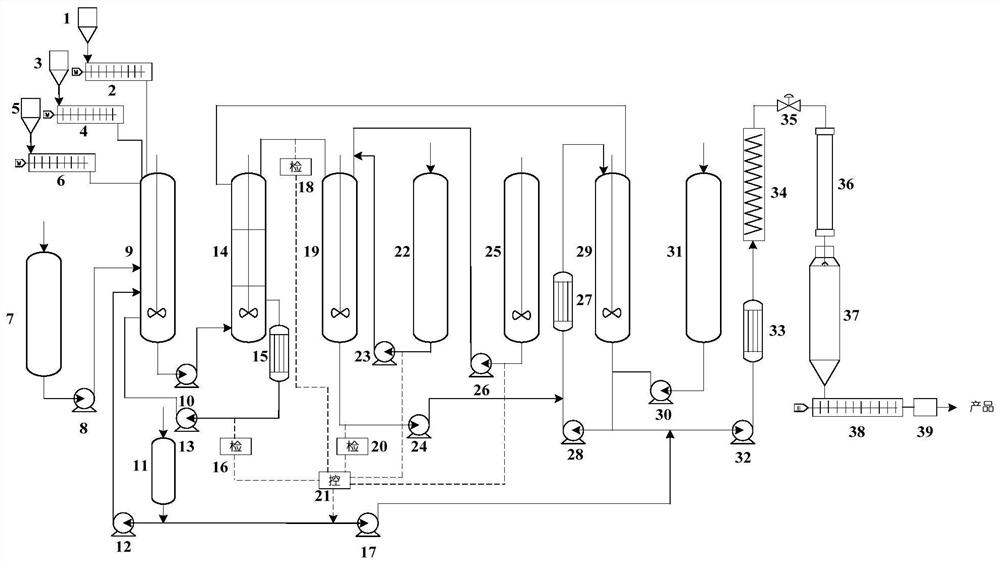

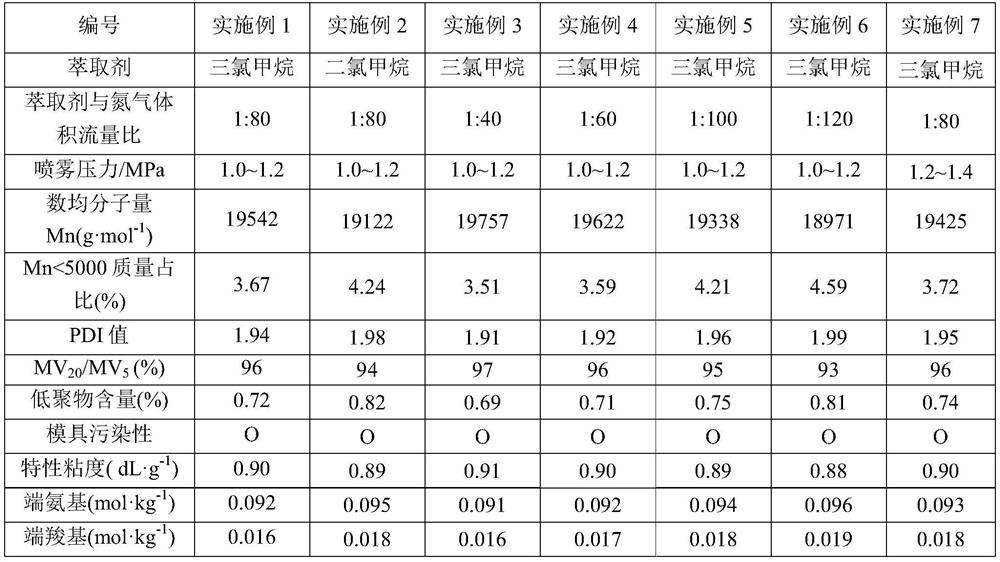

Continuous preparation method of semi-aromatic polyamide with low oligomer content and product thereof

The invention discloses a continuous preparation method of semi-aromatic polyamide with low oligomer content, which comprises the following steps: (a) by using water as a solvent and diamine and binary as initial feeding materials, adding a catalyst, pulping, heating to dissolve, neutralizing and salifying; (b) dehydrating and concentrating the salt solution obtained after neutralizing and salifying, detecting the content of diamine in the steam condensate, adjusting the molar ratio of amine to acid to be greater than 1.0, and then carrying out a prepolymerization reaction; and (c) sequentially carrying out flash evaporation spraying and circulating air drying containing extraction agent steam on the pre-polymerization reaction liquid, melting and tackifying by an extruder, and carrying out underwater pelletizing to obtain semi-aromatic polyamide particles with low oligomer content. The extractant vapor is selected from dichloromethane and / or trichloromethane vapor. The preparation method disclosed by the invention is simple in process and short in production period; and the content of oligomers in the semi-aromatic polyamide product is remarkably reduced and is lower than 0.85%, the molecular weight distribution is narrow, no pollution is caused to a mold during molding processing, and the semi-aromatic polyamide product can be widely applied to the fields of electronics, electrics, automobiles and the like.

Owner:ZHEJIANG NHU SPECIAL MATERIALS

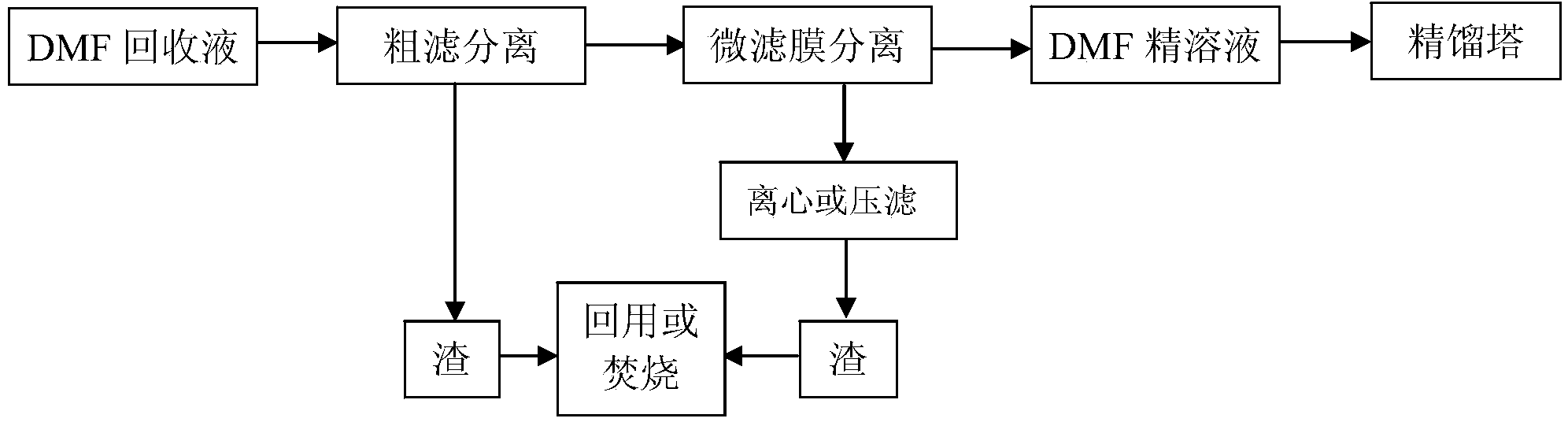

Pretreatment method for rectifying and recovering dimethyl formamide (DMF) waste liquid of polyurethane (PU) synthetic leather

InactiveCN103623605AReduce turbidityOligomer contentFractional distillationLeather industryPretreatment method

The invention discloses a pretreatment method for rectifying and recovering dimethyl formamide (DMF) waste liquid of polyurethane (PU) synthetic leather. The pretreatment method comprises the following steps: (1) pumping the DMF waste liquid from a waste water storage tank of a PU synthetic leather production line into a coarse filter consisting of a stainless steel filter screen by using an infusion pump and performing first-stage separation to obtain coarse filtration DMF waste liquid; and (2) allowing the coarse filtration DMF waste liquid obtained by first-stage separation to enter a microfiltration hollow fiber membrane separation device and performing second-stage separation to obtain a DMF fine solution for rectification and recovery. By the pretreatment method for rectifying and recovering the DMF waste liquid of the PU synthetic leather provided by the invention, the problems of high pollution and high energy consumption of rectification and recovery of the DMF waste liquid in the PU synthetic leather industry are solved; the aims of energy saving and emission reduction in the production process of the PU synthetic leather are fulfilled, and economic benefit, social benefit and environmental benefit are organically unified.

Owner:ZHEJIANG UNIV OF TECH

A kind of cefathiamidine compound

ActiveCN104910186BReduce contentLow polymer contentAntibacterial agentsOrganic active ingredientsX-rayStaphylococcus aureus

The invention belongs to the technical field of medicines, and concretely relates to a cefathiamidine compound. The cefathiamidine compound is a cefathiamidine hydrate, the structure of the cefathiamidine compound is represented by formula (I), and the X-ray powder diffraction pattern of the cefathiamidine compound is represented by figure 1. The cefathiamidine compound is a novel crystal form compound of the cefathiamidine hydrate, and is different from cefathiamidine compounds reported in the prior art. A result of tests shows that the new crystal form compound of the cefathiamidne hydrate has lower content of high-molecular polymers than cefathiamidine in the prior art, and the content of the high-molecular polymers does not obviously increase with the prolongation of the storage time; and the compound has substantial antibiosis activity on Staphylococcus aureus, coagulase negative staphylococci and Enterococcus faecalis.

Owner:SHANDONG LUOXIN PHARMA GRP CO LTD +1

Printing and dying process for improving easy dyeing property of polyester fabric

InactiveCN109295750AEnhanced stainabilityHigh color fastnessDyeing processColour fastnessDisperse dye

The invention discloses a printing and dying process for improving easy dyeing property of a polyester fabric. The dyeing prescription of the polyester fabric is composed of a disperse dye, glacial acetic acid and a dye leveller. The process comprises the following steps: checking whether the fabric appearance has smudginess or defects or not, after the inspection, placing the fabric for 12 to 24hours to eliminate the tension generated when the fabric is printed, when the fabric is placed for the required time, placing the polyester fabric in a washing machine, keeping the water temperature at 60 to 90 DEG C, and repeatedly cleaning the material for three times. The printing and dying process is characterized in that the disperse dye having small molecules, weak polarity, poor solubilityin water and good compatibility is used for dyeing polyester, the polyester fabric is more easily printed and dyed, and the easy dyeing property of the polyester fabric is improved, and the temperature and time of the reduction cleaning are strictly controlled, the color fastness of the polyester fabric after printing and dyeing is improved, and the problem that the polyester fabric is easily fading is avoided.

Owner:ZHEJIANG YINGFENG TECH CO LTD

Devolatilization method of nylon 6 melt

ActiveCN111333834AAchieve direct melt spinningReduce manufacturing costNylon materialPolymer science

The invention relates to the field of nylon materials, and discloses a devolatilization method of a nylon 6 melt. The method comprises the following steps: 1) introducing nylon 6 melt and water-containing hot nitrogen into a front-end devolatilization reaction kettle, carrying out devolatilization, conveying the devolatilized nylon 6 melt into a rear-end devolatilization reaction kettle, and carrying out secondary devolatilization; 2) feeding a gaseous mixture into a high-boiling-point component removal tower, condensing the high-boiling-point components in the gaseous mixture, and then discharging; and 3) feeding the remaining gaseous mixture into a low-boiling-point component removal tower, carrying out spraying, fractionation and condensation on the gaseous mixture in a rising process,discharging the low-boiling-point components, and discharging the remaining gas after vacuum treatment. According to the invention, efficient devolatilization can be carried out on nylon 6 melt, and the condensation polymerization reaction of the nylon 6 can be inhibited in the devolatilization process, so that the influence on the spinning forming process due to the violence of the molecular weight of the nylon 6 under the vacuum condition is avoided, time is provided for nylon 6 amide exchange, the molecular weight distribution is narrowed, and the melt quality is improved.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

High-viscosity polyamide 56 resin, high-strength polyamide 56 industrial yarn and preparation method and application thereof

ActiveCN111423578AImprove qualityIncreased melt shear rateArtificial filament heat treatmentTextile/flexible product manufactureYarnPolymer science

The invention provides a high-viscosity polyamide 56 resin, a high-strength polyamide 56 industrial yarn, and preparation methods and applications of the high-viscosity polyamide 56 resin and the high-strength polyamide 56 industrial yarn. The preparation method of the high-strength polyamide 56 industrial yarn comprises the following steps: heating and melting high-viscosity polyamide 56 resin byadopting a single-screw or double-screw extruder, drawing in a spinning box to obtain a primary yarn, and then carrying out heat preservation, cooling, oiling, pre-interlacing, multi-stage stretching, tension setting, relaxation setting, main interlacing and winding on the primary yarn to obtain the high-strength polyamide 56 industrial yarn. The high-strength polyamide 56 industrial yarn provided by the invention has good mechanical properties and heat and humidity resistance, and can be applied to the fields of sewing threads, tire cords, airbag yarns, release cloth, water cloth, canvas, safety belts, ropes, fishing nets, industrial filter cloth, conveyor belts, parachutes, tents and bags.

Owner:CATHAY R&D CENT CO LTD +2

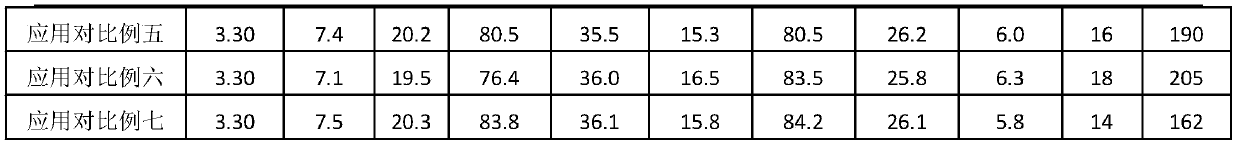

Preparation method of high-performance ultrafiltration membrane

PendingCN113244778AHigh porosityImprove throughputSemi-permeable membranesAir atmospherePolymer science

The invention relates to a preparation method of a high-performance ultrafiltration membrane, which comprises the following steps: (1) adding a certain amount of a membrane-forming polymer into a certain amount of a solvent, fully dissolving the membrane-forming polymer at 25-70 DEG C to obtain a membrane casting solution, and adding a pore-foaming agent into the membrane casting solution and fully dissolving the pore-foaming agent; dispersing nano foaming particles in a solvent, ultrasonically dispersing for 10-30 minutes, adding the nano foaming particles into the membrane casting solution, continuing to stir at 25-70 DEG C to form a uniform solution, and performing vacuum defoaming at 25-70 DEG C for 24 hours; (2) coating the surface of a supporting membrane with the membrane casting solution to form a liquid membrane with a certain thickness, and naturally evaporating the liquid membrane in an air atmosphere for 10-60 seconds; (3) immediately putting the liquid membrane into an acidic aqueous solution coagulating bath, carrying out phase conversion to form a membrane, and completing phase conversion to form the membrane after 1-5 minutes, so as to obtain an ultrafiltration membrane; and (4) putting the obtained ultrafiltration membrane into distilled water or glycerol for preservation.

Owner:TIANJIN POLYTECHNIC UNIV

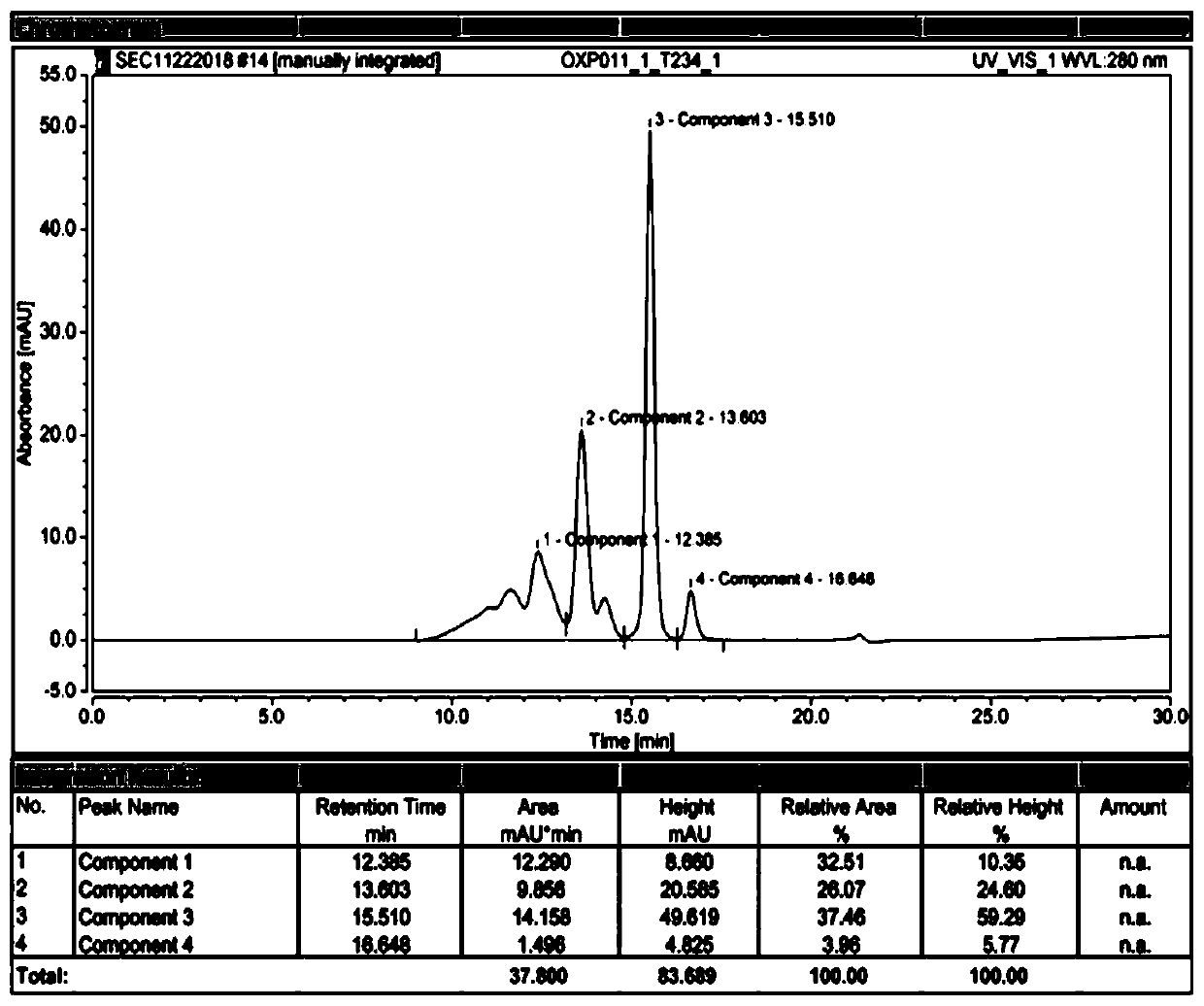

Preparation method of polymerized hemochrome low in content of polymer oligomers

ActiveCN111217904ACompliant with reduced molecular weight requirementsLow polymer contentAntibody mimetics/scaffoldsHaemoglobins/myoglobinsDimerPolymer science

The invention relates to a preparation method of polymerized hemochrome low in content of polymer oligomers, and particularly provides a preparation method of cross-linking hemochrome. The preparationmethod comprises the steps of a, diluting deoxyhemoglobin; b, enabling a cross-linking agent namely glutaraldehyde and the diluted deoxyhemoglobin to be subjected to a cross-linking reaction; c, adding a reducing agent to end the cross-linking reaction, removing the unreacted cross-linking agent and the reducing agent for ending the cross-linking reaction in the manner of an ultrafiltration liquid exchange manner so as to obtain the cross-linking hemochrome, wherein in the step a, the concentration of the diluted deoxyhemoglobin achieves 1-3g / dL, and N- acetyl-L- cysteine is added to the hemochrome, so that the mass ratio of the hemochrome to the N- acetyl-L- cysteine in the solution is (5-10) to 1, and the mass ratio of the hemochrome to the cross-linking agent is 1000 to (29-45 ). The polymerized hemochrome prepared by the method is low in content of dimers and low in content of polymer oligomers.

Owner:REDPHARM BEIJING BIOPHARMACEUTICAL INST CO LTD +1

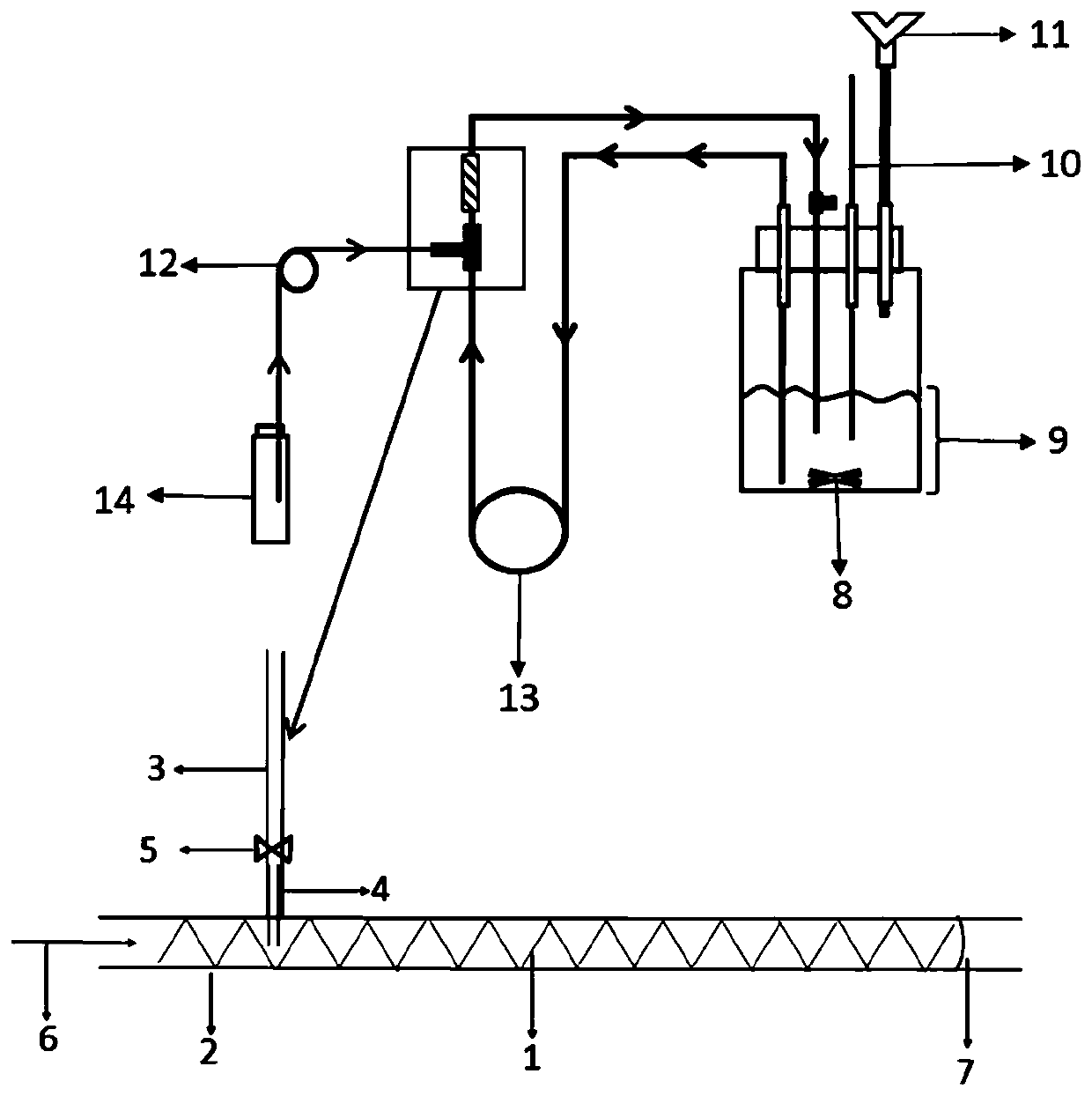

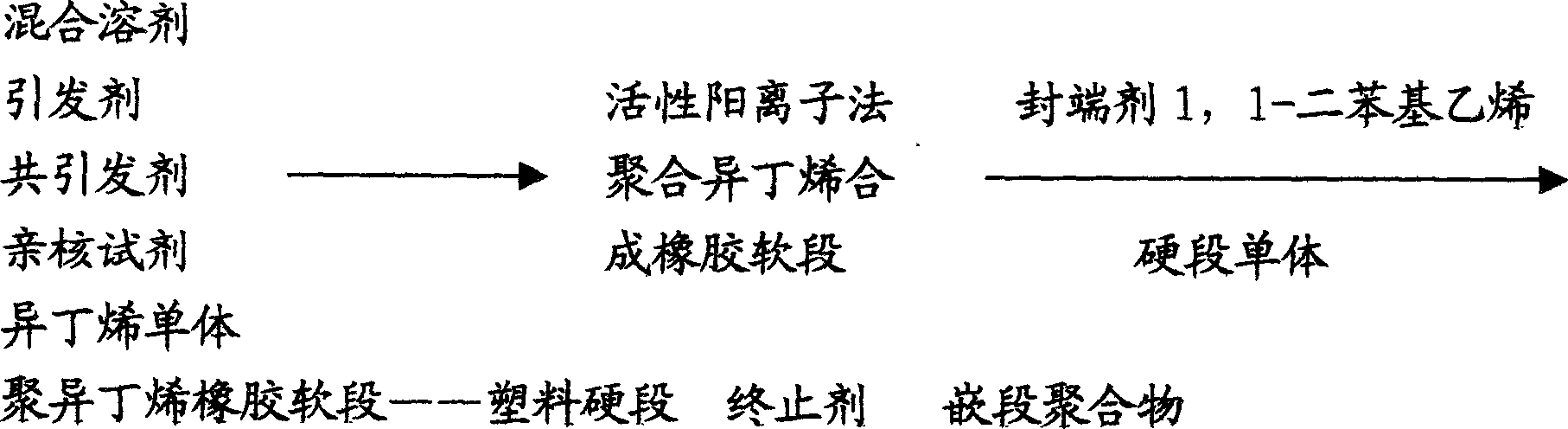

Multi-arm star-type thermoplastic elastomer synthesizing method

This invention refers to a kind of synthetic method of poly-armed star-like polyolefin thermoplastic elastomer, which belongs to high molecular compound of carbon-and-carbon dangling bond reaction. The synthetic method is as follows: under the ordinary pressure, low temperature and the protection of dry nitrogen gas, get the soft section of active cation polyisobutylene synthetic rubber, hard section monomer of plastic and terminator from the component solvent, initiator, coinitiator and soft section monomer, then get the 4-armed star-like block thermoplastic elastomer, whose relative molecular weight is between 180000 and 250000 and whose molecular weight distributes between 2.0 and 3.5. The advantage of the invention lies in the high molecular weight and excellent performance and refers to many thermoplastic elastomers.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

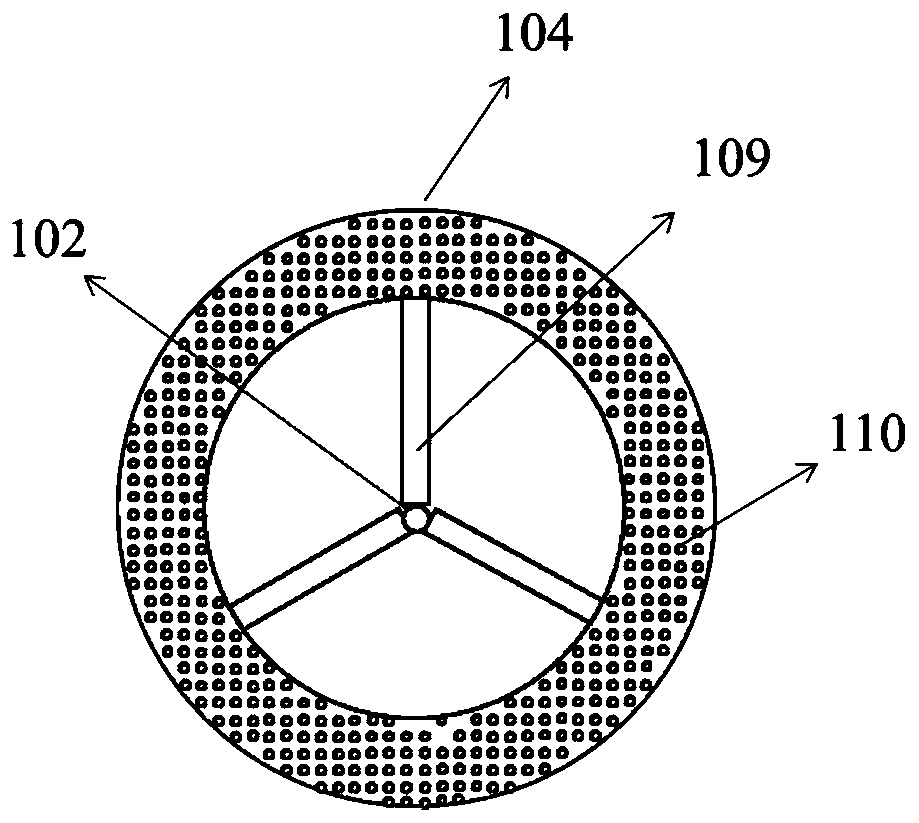

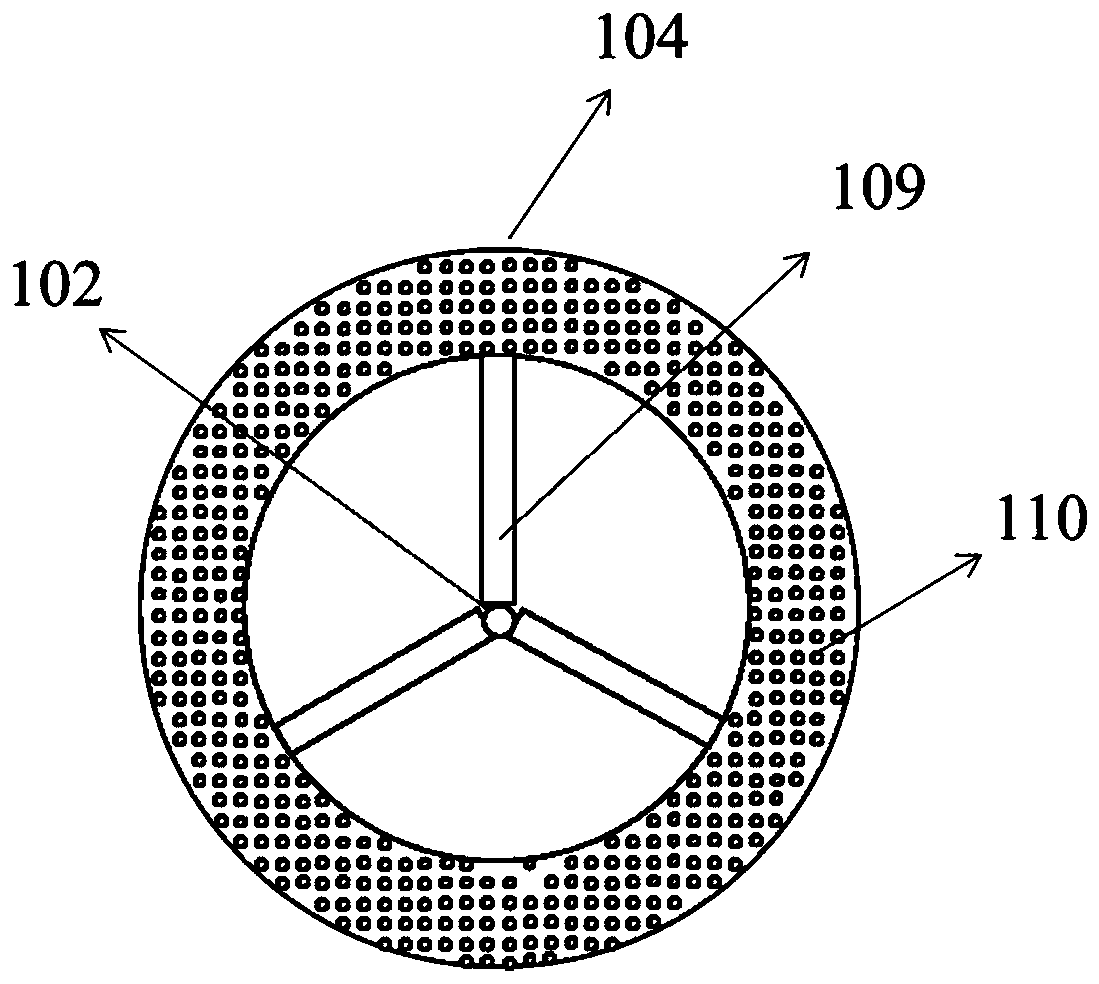

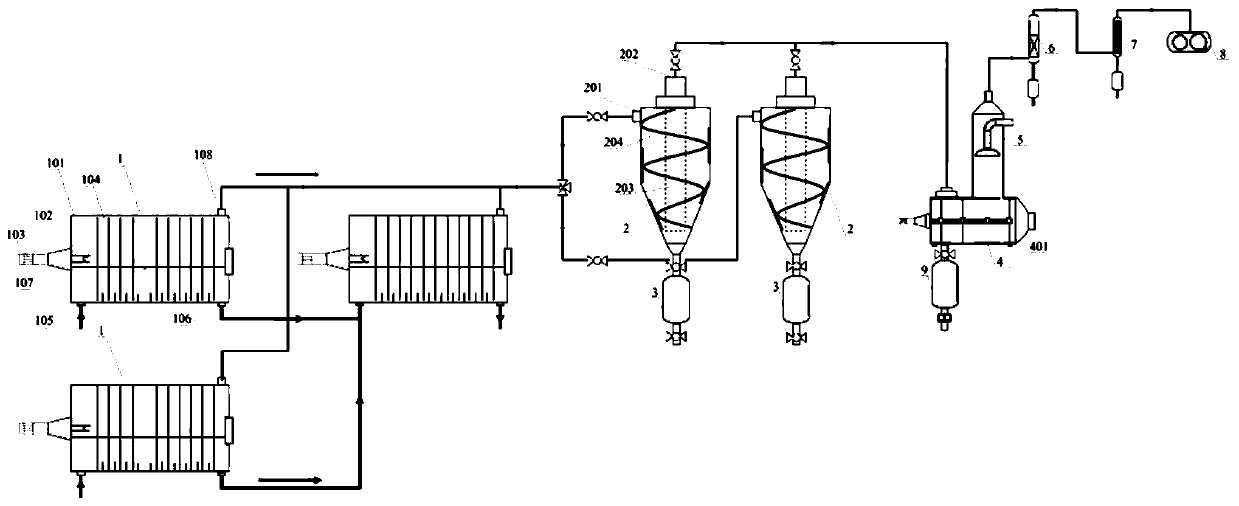

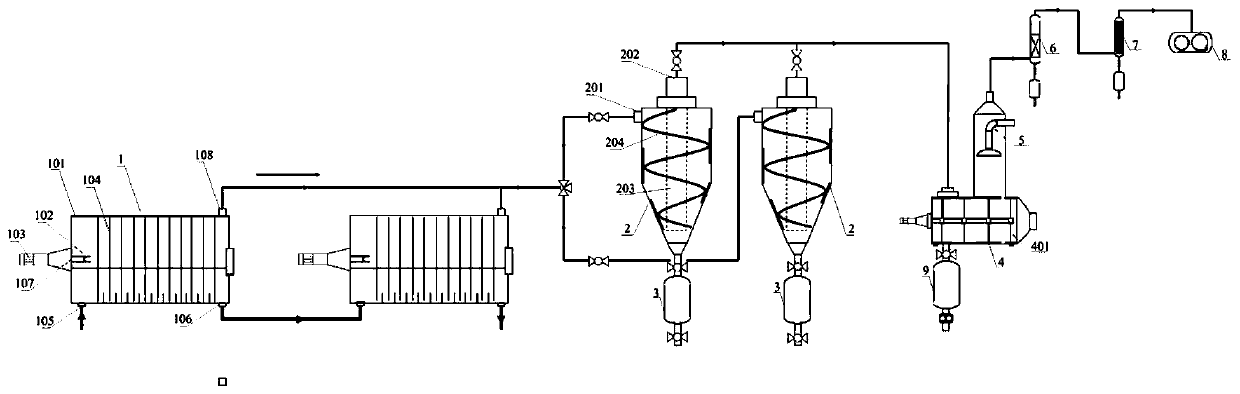

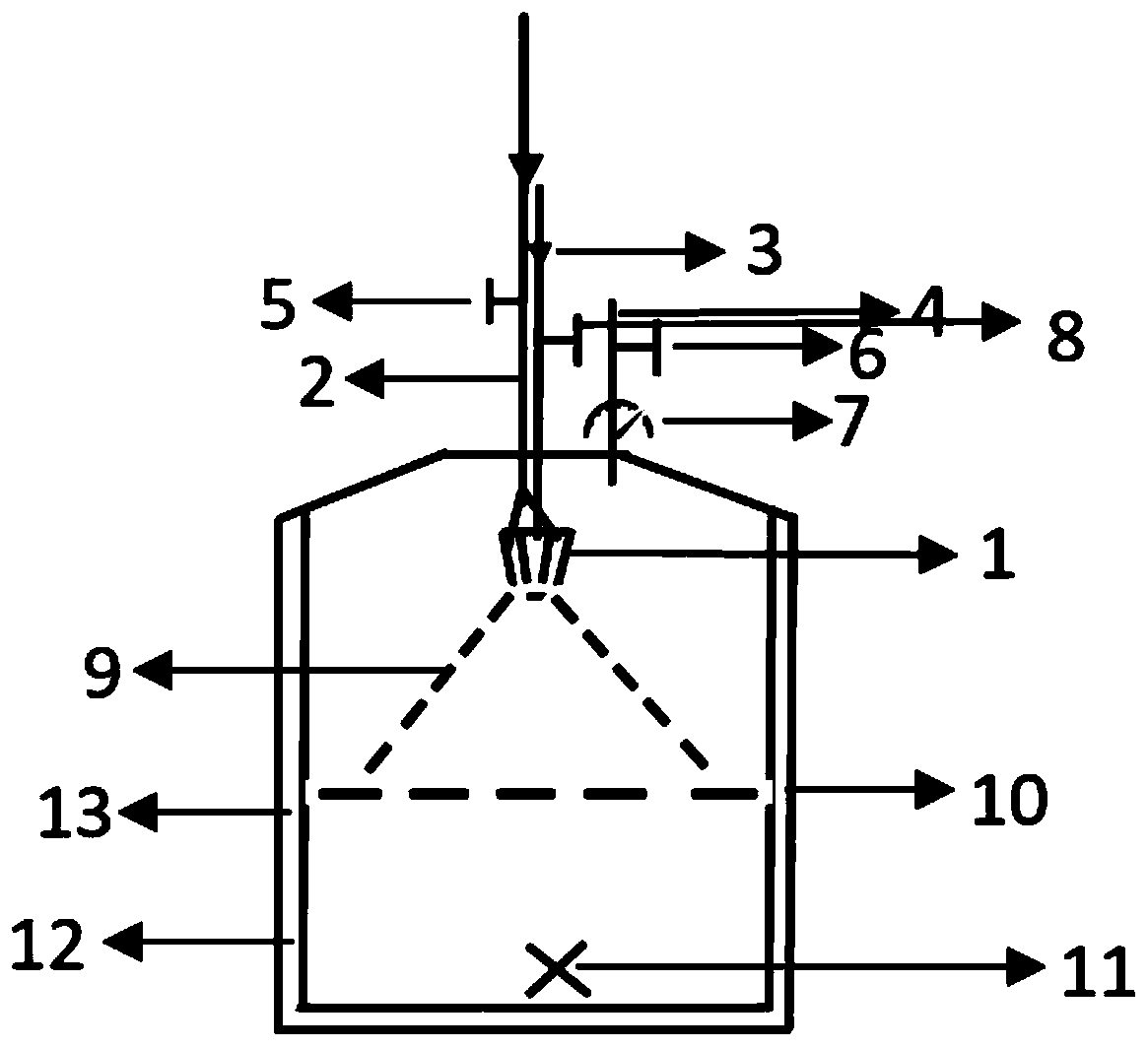

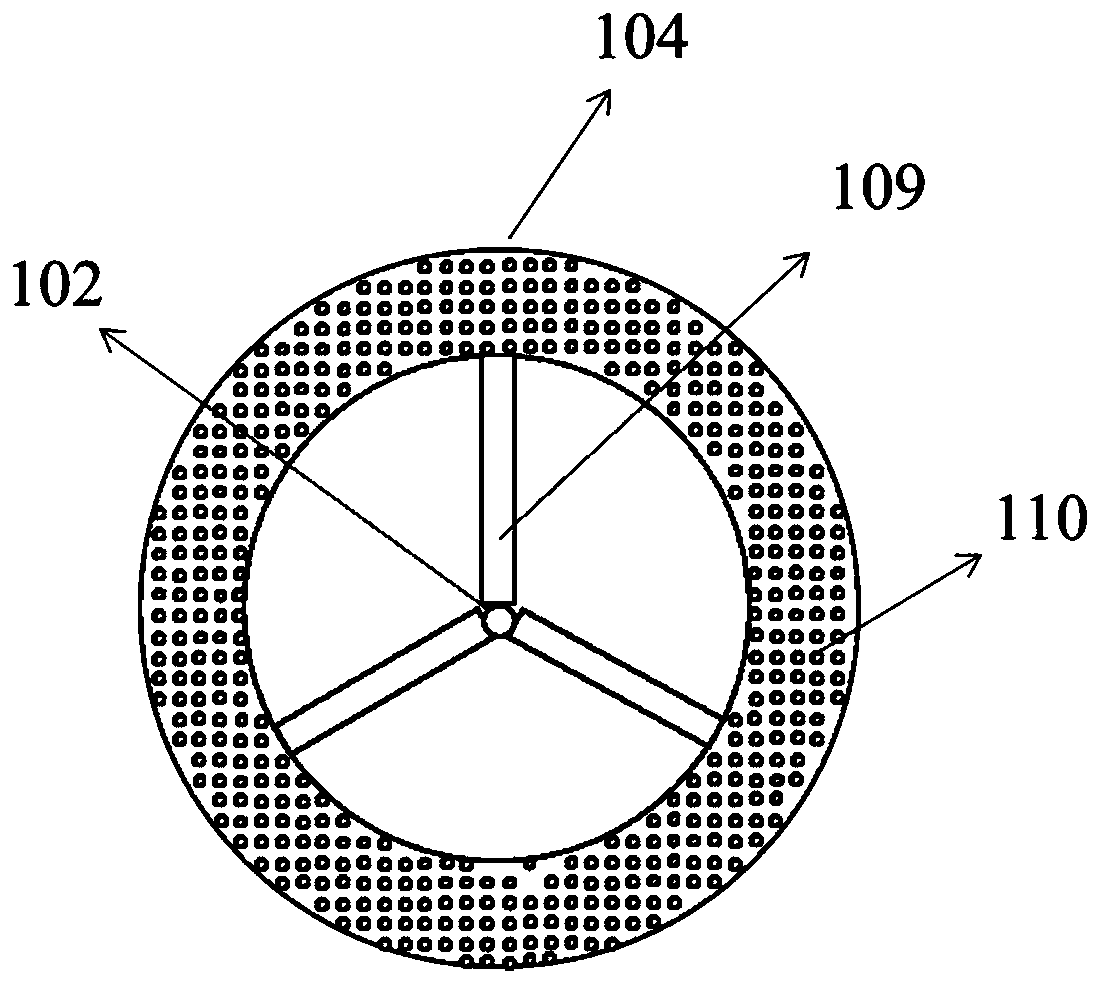

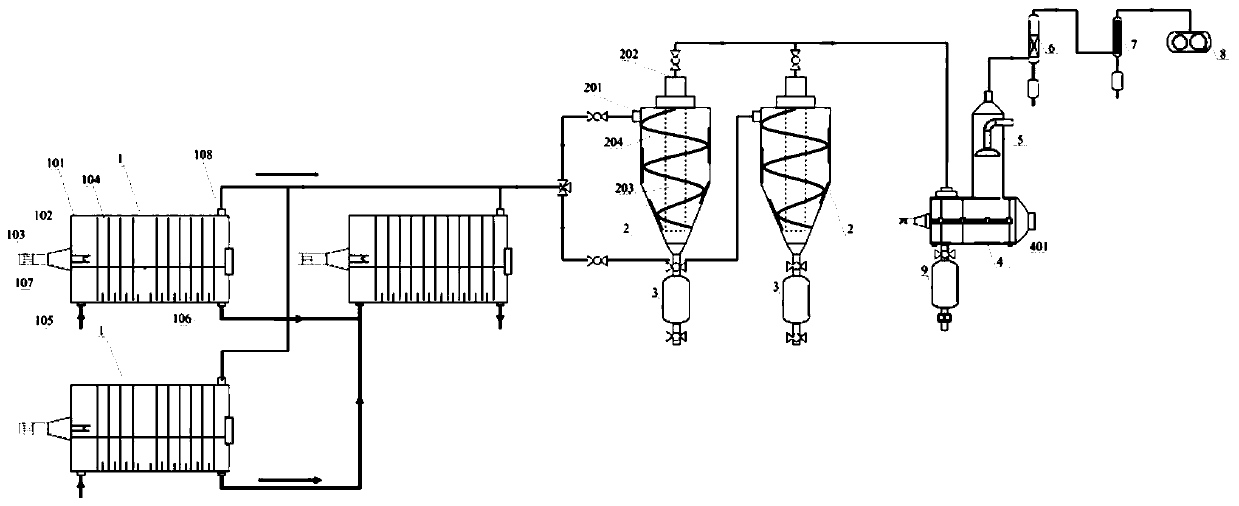

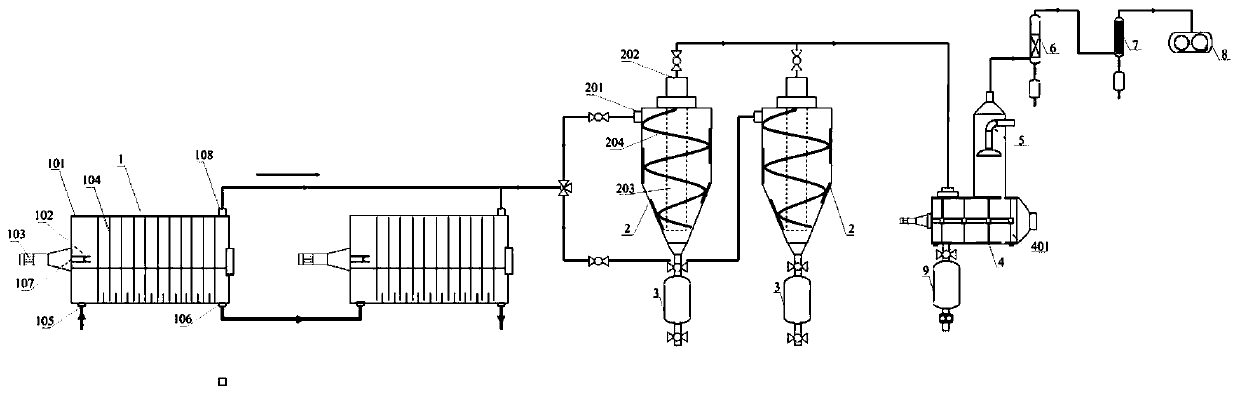

Multistage devolatilization device for nylon 6 melt

ActiveCN111574709AAchieve direct melt spinningReduce manufacturing costVacuum condensationMultiple-effect/fractional condensationNylon materialPolymer science

The invention relates to the field of nylon materials, and discloses a multistage devolatilization device for nylon 6 melt. The multistage devolatilization device comprises a devolatilization system and a component collection system which are connected in sequence, wherein the devolatilization system comprises a plurality of devolatilization reaction kettles which are connected in series and / or inparallel; each devolatilization reaction kettle comprises a shell, a hollow rotating shaft, a motor and a devolatilization disc, the hollow rotating shaft is horizontally arranged in the shell, one end of the hollow rotating shaft communicates with a gas inlet, the devolatilization disc is fixed on the hollow rotating shaft, air holes are distributed in the devolatilization disc, and a gas outletof the devolatilization reaction kettle is connected with the component collection system; and the component collecting system comprises a high-boiling-point component removing unit and a low-boiling-point component removing unit which are connected in sequence. According to the invention, efficient devolatilization can be carried out on the nylon 6 melt, the polycondensation reaction of nylon 6can be inhibited in the devolatilization process, influence on a spinning forming process due to the sudden increase of the molecular weight of the nylon 6 under a vacuum condition is avoided, time isprovided for nylon 6 amide exchange, molecular weight distribution is narrowed, and melt quality is improved.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

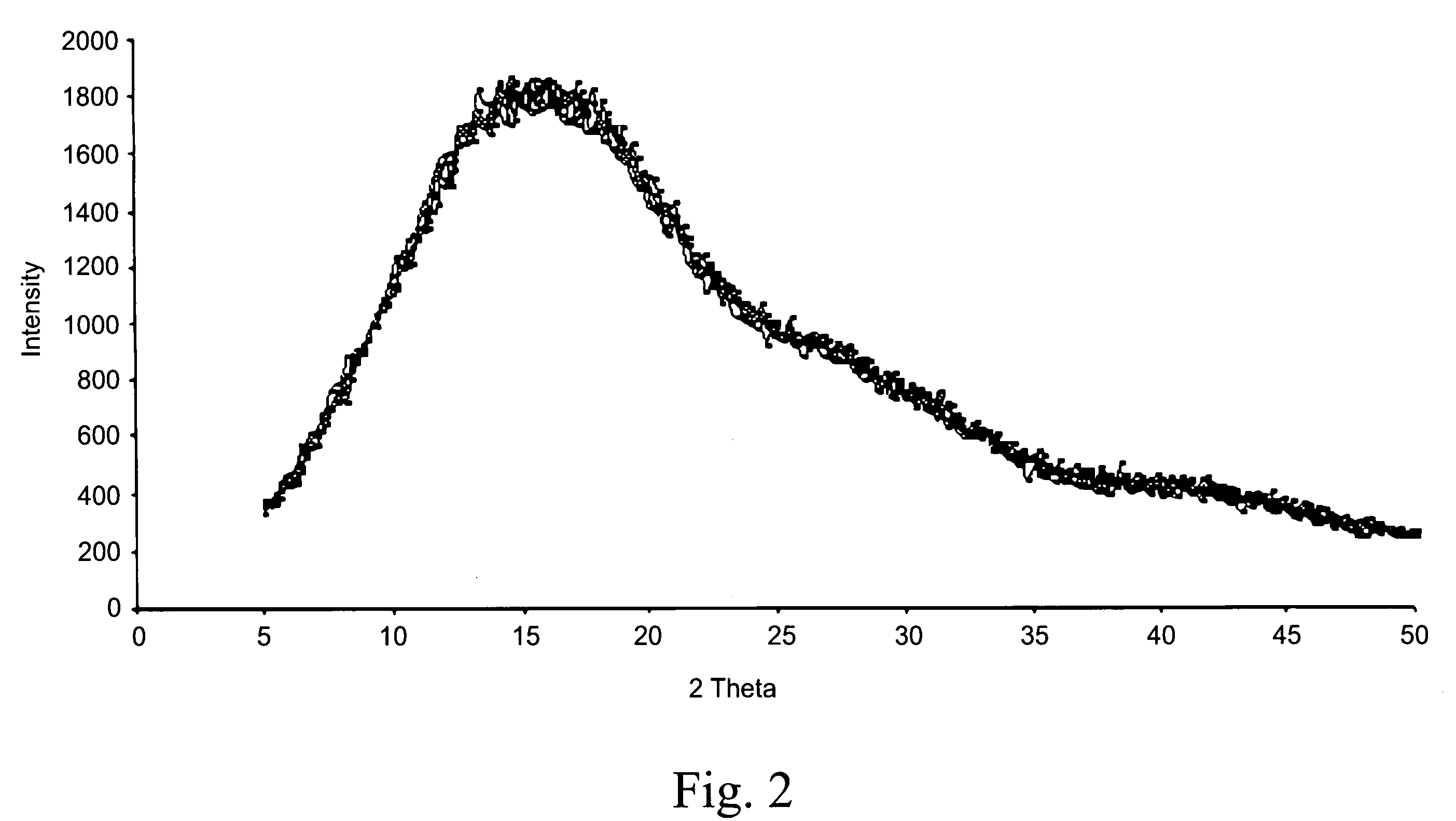

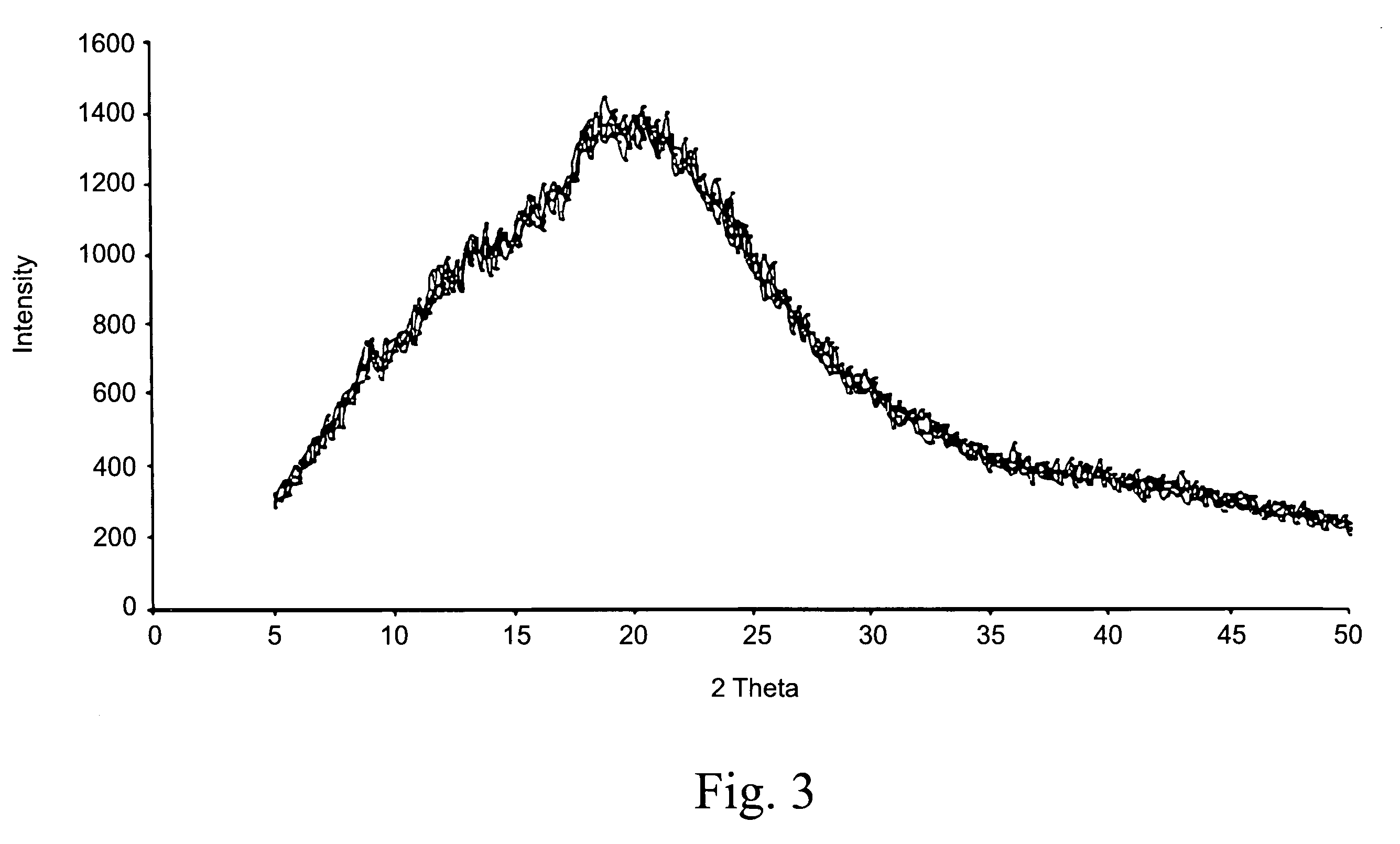

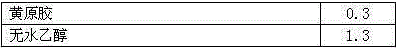

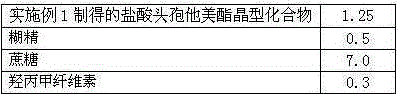

Medicinal cefetamet pivoxil hydrochloride dry suspension for treating sensitive bacterial infection diseases

InactiveCN105193736AReduce contentLow impurity contentAntibacterial agentsOrganic active ingredientsBiotechnologyCellulose

The invention discloses a medicinal cefetamet pivoxil hydrochloride dry suspension for treating sensitive bacterial infection diseases and belongs to the technical field of medicine. The dry suspension is prepared from cefetamet pivoxil hydrochloride, dextrin, sucrose, HPMC, xanthan gum and absolute ethyl alcohol. The cefetamet pivoxil hydrochloride is a novel crystal-form compound. As shown in Figure 1 of X-ray powder diffraction diagram obtained by means of Cu-K alpha ray measurement, the cefetamet pivoxil hydrochloride is different from cefetamet pivoxil hydrochloride reported in the prior art. Tests find that the dry suspension prepared from the novel crystal-form compound of the cefetamet pivoxil hydrochloride is low in high-molecular polymer content and good in stability, and the content of high-molecular polymers gradually decreases along with prolonging of storage time; meanwhile, the composition has more remarkable antibacterial activity with respect to pneumococcocci and hemophilus influenza and also has strong antibacterial activity with respect to enterococcocci and staphylococcocci.

Owner:QINGDAO HUAZHICAO PHARMA CO LTD

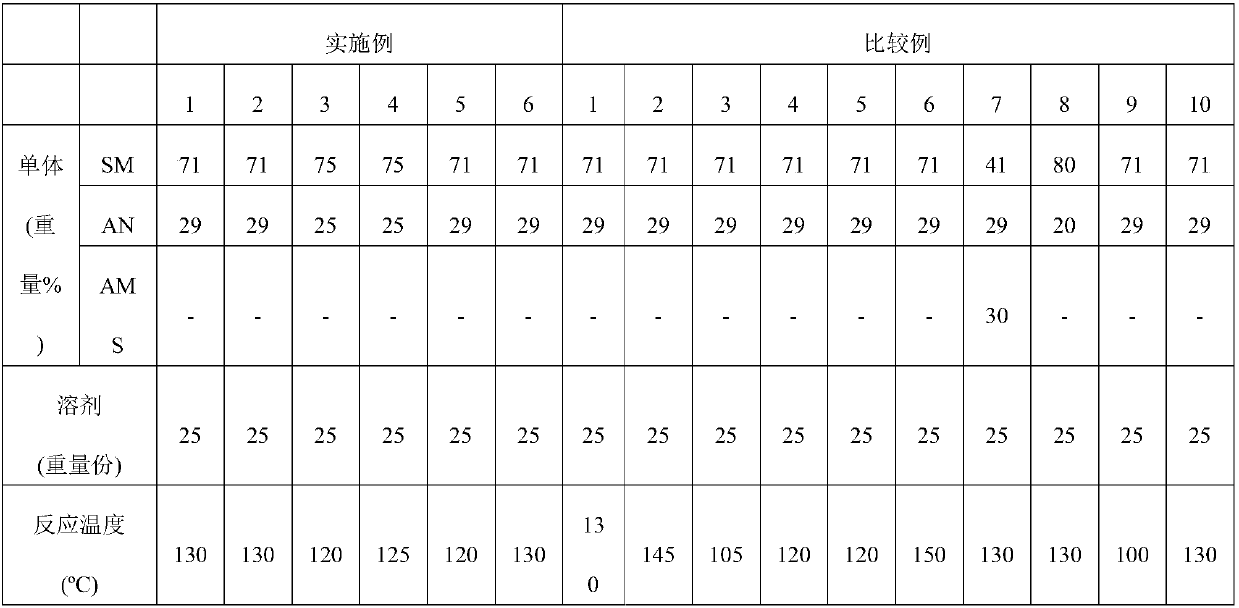

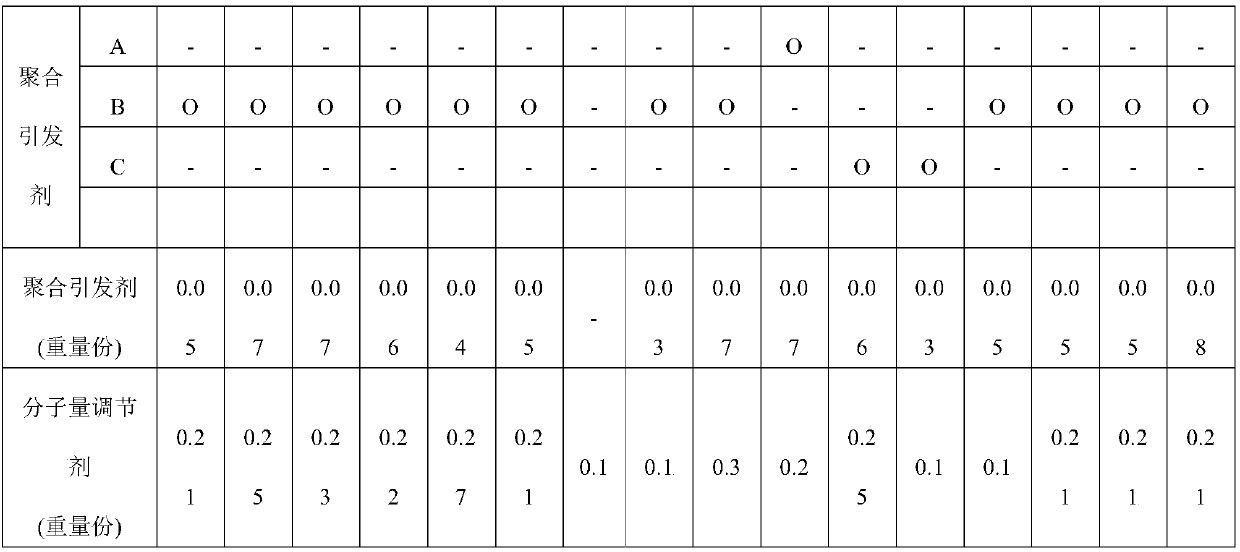

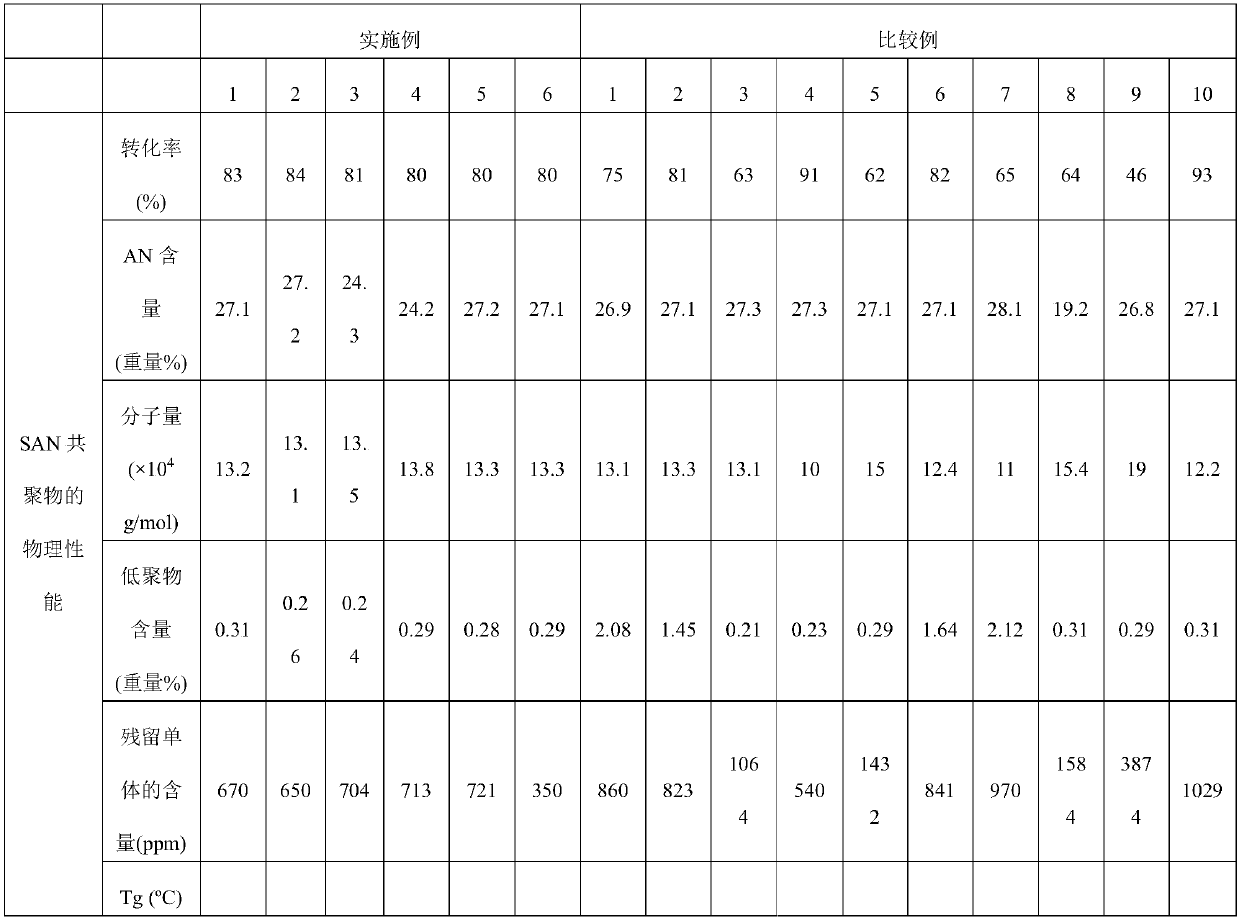

Method for preparing aromatic vinyl-unsaturated nitrile-based copolymer and aromatic vinyl-unsaturated nitrile-based copolymer prepared thereby

The present invention provides a method for preparing an aromatic vinyl-unsaturated nitrile-based copolymer and an aromatic vinyl-unsaturated nitrile-based copolymer prepared using the method, wherein, in the preparation of an aromatic vinyl-unsaturated nitrile-based copolymer, of which the content of unsaturated nitrile-based monomer-derived structural units in a copolymer is 22-30 wt%, the contents of oligomers and unreacted monomers are decreased, and as a result, excellent heat resistance and remarkably improved surface quality can be obtained, and particularly, when a product is used in aclosed high-temperature environment, the residues generated on a surface of the product and the mold deposits generated during injection molding can be reduced.

Owner:LG CHEM LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com