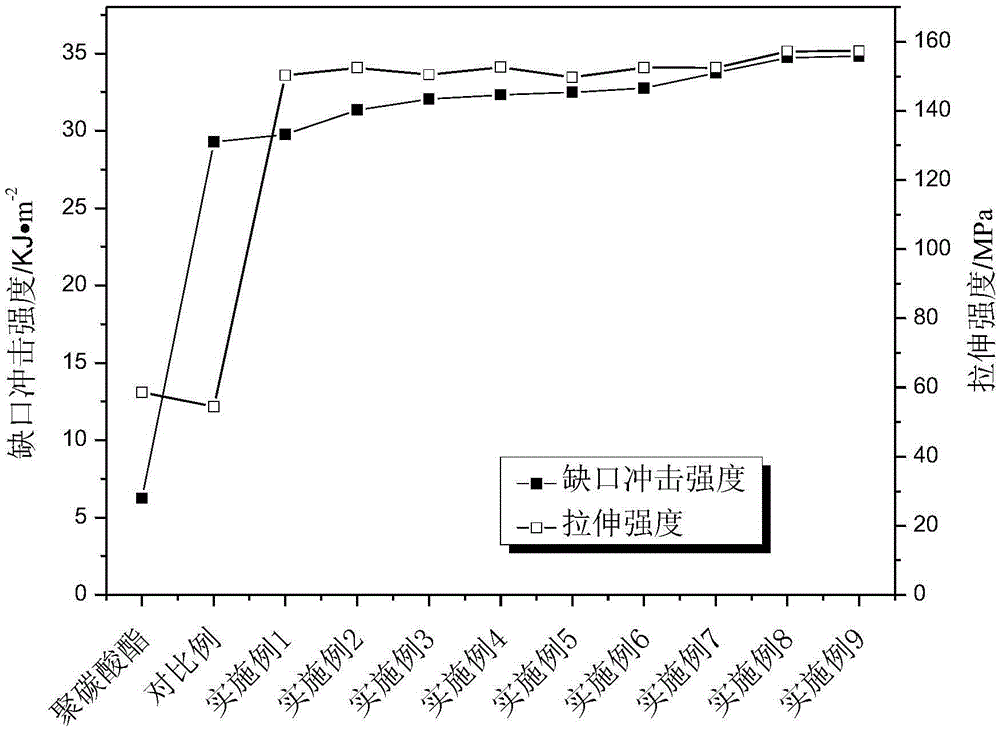

Preparation method of acrylate polymer/nanometer silicon dioxide composite particles for polycarbonate toughening

A nano-silica and acrylate technology, which is applied in the field of preparation of acrylate polymer/nano-silica composite particles for polycarbonate toughening, can solve the problem of poor processing performance and decreased tensile strength of blends, etc. problems, to achieve the effect of good low temperature resistance, improved conversion rate and simplified post-treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] a. Pre-emulsification of seed monomer

[0044] First, add 0.71g of anionic emulsifier sodium dihexyl adipate sulfonate and 150g of deionized water into a 500ml four-neck flask, and mix and stir for 30 minutes; then add 15g of 2-ethyloctyl acrylate to the reactor The monomer and 0.04g of cross-linking agent 1,4-butanediol diacrylate were placed on an electromagnetic stirrer and stirred for 20 minutes to obtain a seed monomer pre-emulsion for later use;

[0045] b. Pre-emulsification of monomers in the growth phase of the nuclear layer

[0046] Add 1.81g anionic emulsifier dihexyl adipate sodium sulfonate, 145g acrylate-2-ethyloctyl monomer and 0.73g crosslinking agent 1,4-butanediol diacrylate into a 400ml beaker, then Place it on an electromagnetic stirrer and mix and stir for 20 minutes to obtain the second layer of monomer pre-emulsion, which is set aside;

[0047] c. Pre-emulsification of the outer monomer

[0048] Add 0.8g of anionic emulsifier dihexyl adipate so...

Embodiment 2~9

[0078] The other steps are the same as in Example 1, but the changes in the quality of the seed stage emulsifier 1 in step a, step d and the quality of emulsifier 2 used in embodiments 2 to 9 are as shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com