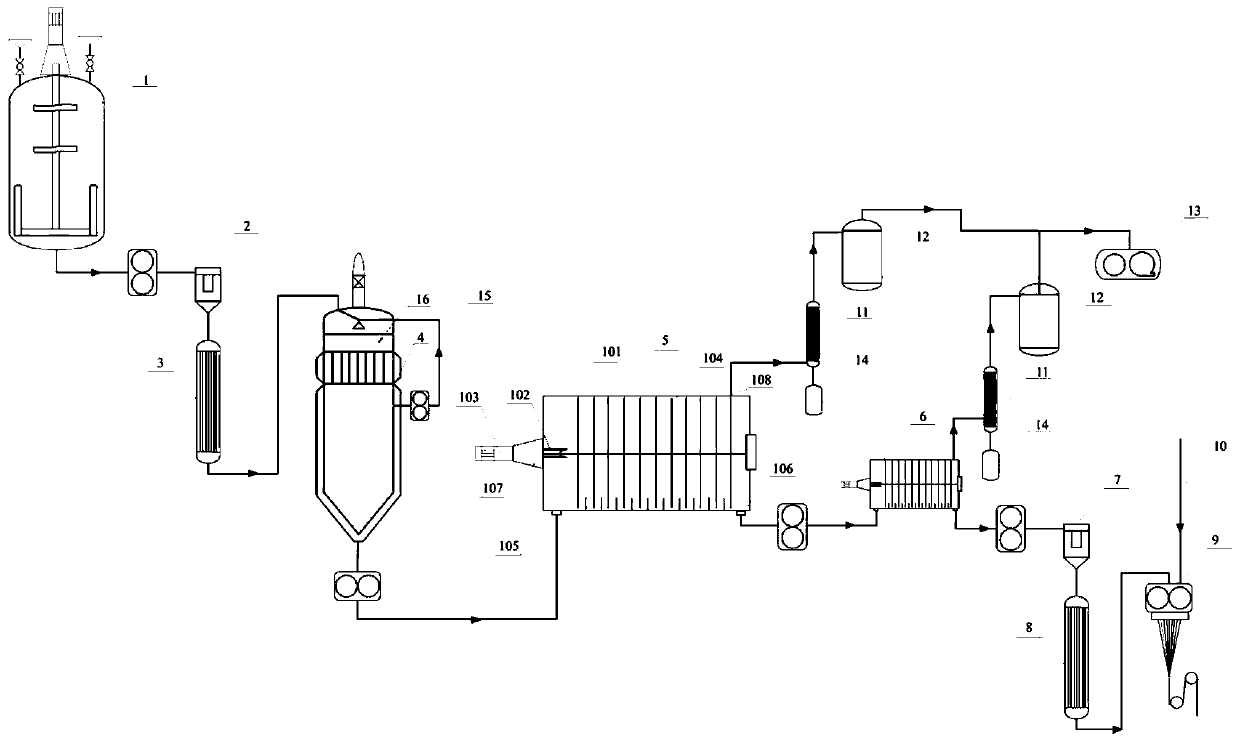

Method for preparing polyester-nylon composite fibers by melt direct spinning

A polyester-nylon composite fiber, melt direct spinning technology, applied in the field of nylon materials, can solve the problems of low polymer molecular weight, slow reaction speed, oligomer control, etc., to reduce oligomer content, reduce content, and ensure quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

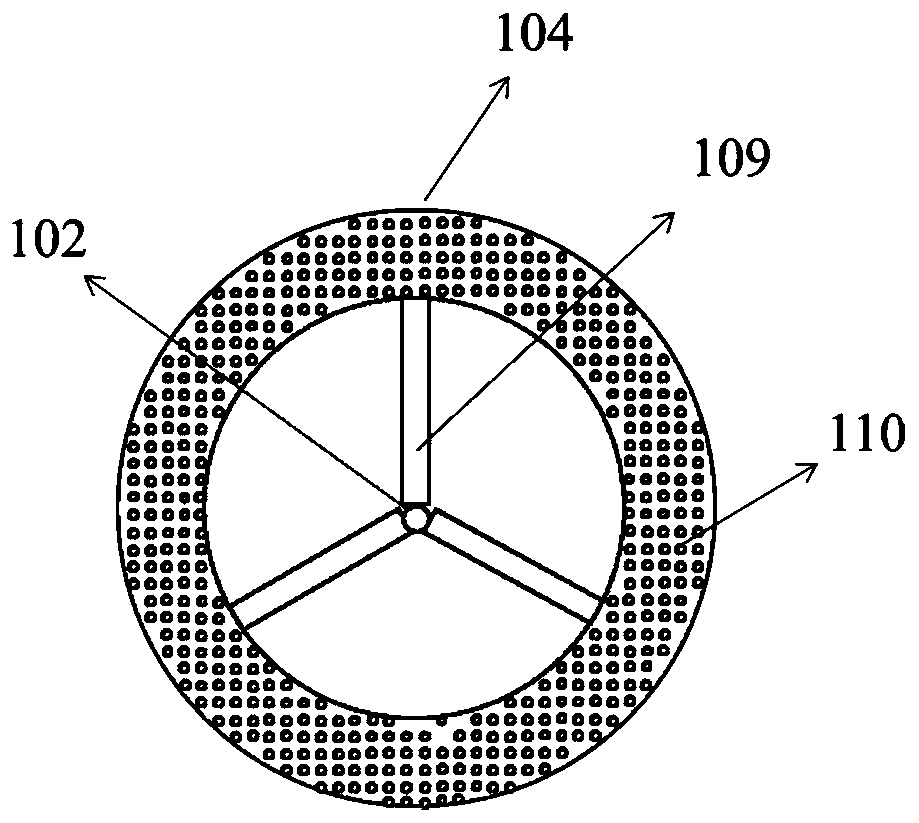

Method used

Image

Examples

Embodiment 1

[0079] The first step: at a temperature of 80°C, caprolactam, terephthalic acid, deionized water and NH 2 (CH 2 ) 6 COOH was mixed in proportion, and stirred for 30 minutes under the condition of mechanical stirring (100r / min); among them, relative to caprolactam, the amount of deionized water added was 2wt%, the amount of terephthalic acid added was 0.2wt%, and the amount of NH 2 (CH 2 ) 6 The amount of COOH added is 0.5wt%;

[0080] The second step: After the mixture obtained in the first step is heated by the melt pump and the pre-heater, it is transported to the ring-opening kettle for ring-opening reaction. The polymerization temperature is controlled at 215 ° C, and the polymerization pressure is controlled at 1.5 MPa; the reaction time is The 0.8h prepolymer is transported to the top of the tower by a melt pump, mixed with fresh caprolactam, and the reflux rate is 1.3wt% of the caprolactam flow rate. When the following conditions are met, the reaction is terminated...

Embodiment 2

[0091] Step 1: Mix caprolactam, phthalic acid, deionized water and nylon 66 salt in proportion at a temperature of 130°C, and stir for 30 minutes under mechanical stirring (140r / min); For caprolactam, the addition of deionized water is 5wt%, the addition of phthalic acid is 0.2wt%, and the addition of nylon 66 salt is 0.05wt%;

[0092] The second step: After the mixture obtained in the first step is heated by the melt pump and the pre-heater, it is transported to the ring-opening kettle for ring-opening reaction. The polymerization temperature is controlled at 255 ° C, and the polymerization pressure is controlled at 0.3 MPa; the reaction time is The 1.2h prepolymer is transported to the top of the tower by a melt pump, mixed with fresh caprolactam, and the reflux rate is 0.5wt% of the caprolactam flow rate. When the following conditions are met, the reaction is terminated: the molecular weight of the obtained prepolymer is 8470, the extractable content is ≤9.2wt%, and the cyc...

Embodiment 3

[0103] The first step: at a temperature of 90°C, caprolactam, HOOC (CH 2 ) 4 COOH, deionized water and NH 2 (CH 2 ) 6 COOH was mixed in proportion, and stirred for 30min under the condition of mechanical stirring (80r / min); the amount of deionized water added was 2.7wt% relative to caprolactam, and HOOC(CH 2 ) 4 The amount of COOH added is 0.3wt%, NH 2 (CH 2 ) 6 The amount of COOH added is 0.4wt%;

[0104] The second step: After the mixture obtained in the first step is heated by the melt pump and the pre-heater, it is transported to the ring-opening kettle for ring-opening reaction. The polymerization temperature is controlled at 225 ° C, and the polymerization pressure is controlled at 0.8 MPa; the reaction time is The 0.7h prepolymer is transported to the top of the tower by a melt pump, mixed with fresh caprolactam, and the reflux flow is 0.7wt% of the caprolactam flow. When the following conditions are met, the reaction is terminated: the molecular weight of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com