A kind of preparation method of acrylic water-absorbing resin with low extractables content

A water-absorbent resin and acrylic technology, which is applied in the field of acrylic water-absorbent resin preparation, can solve the problems of increasing the content of extractables, and achieve the effects of reducing the content of extractables, reducing the content of residual monomers, and preventing the content of extractables from increasing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

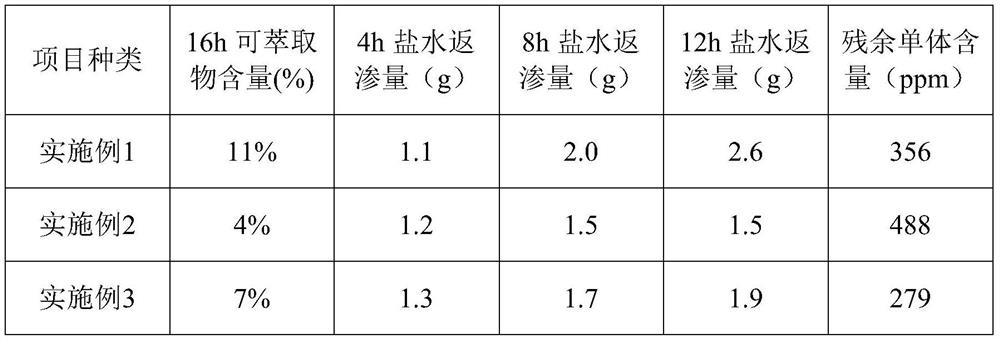

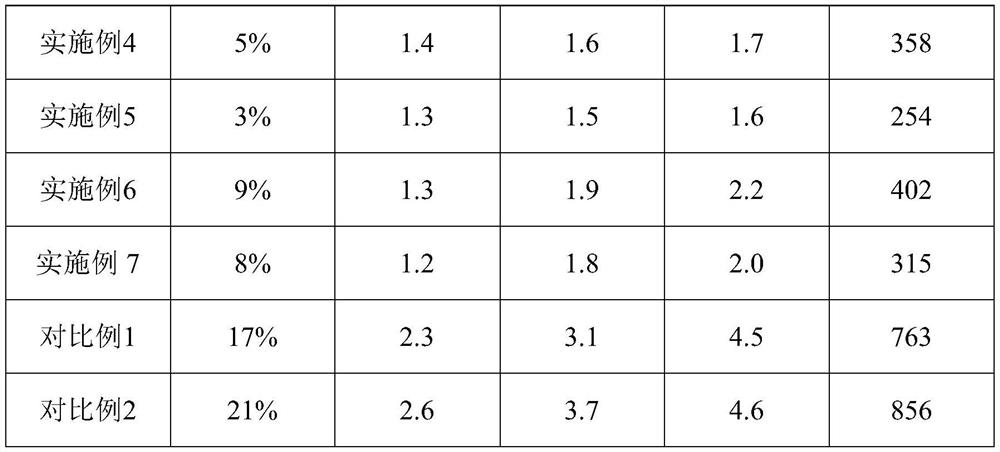

Examples

Embodiment 1

[0051] Add 2000g acrylic acid and 4600g water to the reaction kettle, and add 3.5g concentration to be 32wt% NaOH solution, control the temperature of the neutralization liquid to be 40 ° C, add 10g pentaerythritol triallyl ether to the reaction kettle, and the reaction solution flows into the polymerization. 20g of hydrogen peroxide with a concentration of 10wt%, 10g of vitamin C solution with a concentration of 10wt% and 6g of tert-butyl hydroperoxide were added to the reaction solution at the same time, and then the polymerization tank was transported to the plasma generator. After 800W power discharge After 20s, react for another 60min to obtain about 6600g of polymer hydrogel, which is granulated by a granulator to obtain gel particles with a size of 1-10mm, and 2780g of 32wt% NaOH solution and 3.3g of NaOH solution are added during granulation. Talc powder, dried in an oven at 170°C for 70min, ground and sieved in turn to obtain 150-800μm primary acrylic water-absorbent r...

Embodiment 2

[0053] Add 1800g acrylic acid and 1700g water to the reaction kettle, and add 1250g concentration to be 32wt% NaOH solution, control the neutralization liquid temperature to be 0 ℃, add 7.2g pentaerythritol triallyl ether to the reaction kettle, and the reaction solution flows into the polymerization tank, and at the same time, 14.4g of sodium persulfate solution with a concentration of 10wt%, 18g of sodium metabisulfite solution with a concentration of 5wt% and 18g of 2'2-azo-bis(2-methyl) with a concentration of 10wt% were added to the reaction solution. propylamidine dihydrochloride solution, and then the polymerization tank was transported to the plasma generator, after 30W power discharge for 300s, and then reacted for 30min to obtain about 4800g of polymer hydrogel, which was granulated by a granulator to obtain the size It is a 1-10mm gel particle, and 1100g of 32wt% NaOH solution and 25g of talc are added during granulation, dried in an oven at 180°C for 50min, ground a...

Embodiment 3

[0055] Add 1600g acrylic acid and 2900g water to the reaction kettle, and add 280g concentration to be 32wt% NaOH solution, control the temperature of the neutralization liquid to be 10 ° C, add 4.8g ethoxylated glycerol triacrylate to the reaction kettle, and the reaction liquid flow into the polymerization tank, and at the same time add 8g hydrogen peroxide with a concentration of 10wt%, 4g vitamin C solution with a concentration of 5wt% and 16g of 2'2-azo[2-methyl-N-(2 with a concentration of 10wt% to the reaction solution. -Hydroxyethyl) propionamide] solution, and then the polymerization tank was transported to the plasma generator, after 400W power discharge for 200s, and then reacted for 40min to obtain about 4800g of polymer hydrogel, which was granulated by a granulator to obtain Gel particles with a size of 1-10mm are added with 1900g of 32wt% NaOH solution and 40g of talc during granulation, dried in an oven at 150°C for 160min, ground and sieved in turn to obtain 15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com