Production method of acrylic polymer resin and products produced thereby

A technology of acrylic acid and manufacturing method, which is applied in the field of preparation of low acrylic acid monomer residue and superabsorbent resin, and can solve problems such as high solution viscosity, aggravated product color, and difficult production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

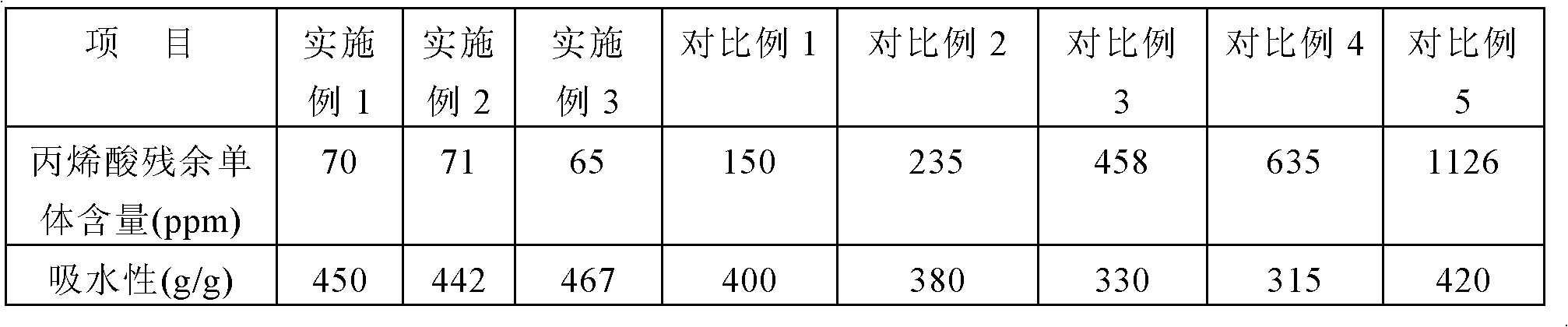

Embodiment 1

[0090] Gel preparation

[0091] at 1m 3 Add 283 kilograms of sodium hydroxide aqueous solution (32wt%) and 351 kilograms of deionized water in the reaction kettle, start the stirring of the reaction kettle, slowly add 225 kilograms of acrylic acid dropwise, keep the temperature of the reaction kettle at 25 ° C, after the addition of acrylic acid is finished, add 0.5 kg of cross-linking agent polyethylene glycol diacrylate and 0.45 kg of cross-linking agent ethoxyglycerin triacrylate, then add 0.6 kg of ammonium persulfate as a polymerization initiator, continue to stir, the reactor is filled with nitrogen, continue Keeping the temperature of the reactor at 25°C, the above-mentioned materials are continuously fed into a continuous conveyor belt with a length of 6000mm and a width of 500mm at a flow rate of 34.5kg / hr, and two microwave generators (W-8512 model, purchased from Guangdong, China) at the entrance of the polymerization conveyor belt Foshan Fujibao Microwave Produc...

Embodiment 2

[0118] Gel preparation

[0119] at 1m 3 Add 283 kilograms of sodium hydroxide aqueous solution (32wt%) and 351 kilograms of deionized water in the reaction kettle, start the stirring of the reaction kettle, slowly add 225 kilograms of acrylic acid dropwise, keep the temperature of the reaction kettle at 25 ° C, after the addition of acrylic acid is finished, add 0.5 kg of cross-linking agent polyethylene glycol diacrylate and 0.45 kg of cross-linking agent ethoxyglycerin triacrylate, then add 0.6 kg of polymerization initiator ammonium persulfate, continue to stir, nitrogen is carried out to the reactor, and continue to maintain the reaction The temperature of the kettle is 25°C, and the above-mentioned materials are continuously fed into a continuous conveyor belt with a length of 6000mm and a width of 500mm at a flow rate of 34.5kg / hr, and two microwave generators (W-8512 model, purchased from Fuji, Foshan, Guangdong, China) at the entrance of the polymerization conveyor b...

Embodiment 3

[0132] Gel preparation

[0133] at 1m 3Add 283 kilograms of sodium hydroxide aqueous solution (32wt%) and 276 kilograms of deionized water in the reaction kettle, start the stirring of the reaction kettle, slowly add 225 kilograms of acrylic acid dropwise, keep the temperature of the reaction kettle at 25 ° C, after the addition of acrylic acid is finished, add 0.5 kg of cross-linking agent polyethylene glycol diacrylate and 0.45 kg of cross-linking agent ethoxyglycerin triacrylate, then add 0.6 kg of polymerization initiator ammonium persulfate, continue to stir, nitrogen is carried out to the reactor, and continue to maintain the reaction The temperature of the kettle is 25°C, and the above-mentioned materials are continuously fed into a continuous conveyor belt with a length of 6000mm and a width of 500mm at a flow rate of 34.5kg / hr, and two microwave generators (W-8512 model, purchased from Fuji, Foshan, Guangdong, China) at the entrance of the polymerization conveyor be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com