Structure-oriented composite initiator system and acrylamide polymer and preparation method and application thereof

A composite initiator, structure-oriented technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of difficulty in obtaining acrylamide polymers, cumbersome process operations, etc., and achieve low residual monomer content, water-soluble Good performance, high molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

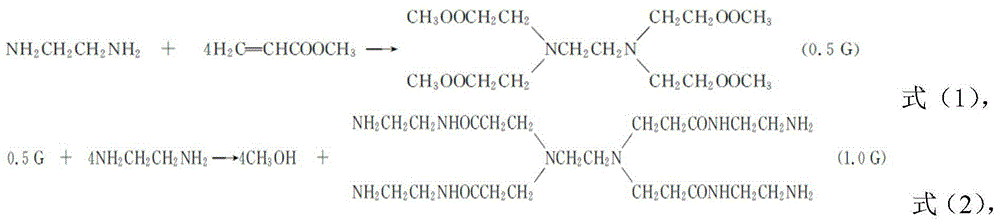

Method used

Image

Examples

preparation example Construction

[0033] The present invention also provides a method for preparing an acrylamide polymer, which includes polymerizing acrylamide and a temperature-resistant and salt-resistant monomer in water in the presence of an initiator and an inorganic basic substance, wherein the initiator Contains the structure-oriented composite initiator system provided by the invention.

[0034] The acrylamide polymer in the present invention refers to a polymer obtained by reacting acrylamide with a temperature-resistant and salt-resistant monomer under copolymerization conditions, including a structural unit formed by acrylamide and a temperature-resistant and salt-resistant monomer. structural unit.

[0035] According to the preparation method of the acrylamide polymer of the present invention, in the presence of an initiator and an inorganic basic substance, the method of polymerizing acrylamide and a temperature-resistant and salt-resistant monomer in water can be a conventional method in the ar...

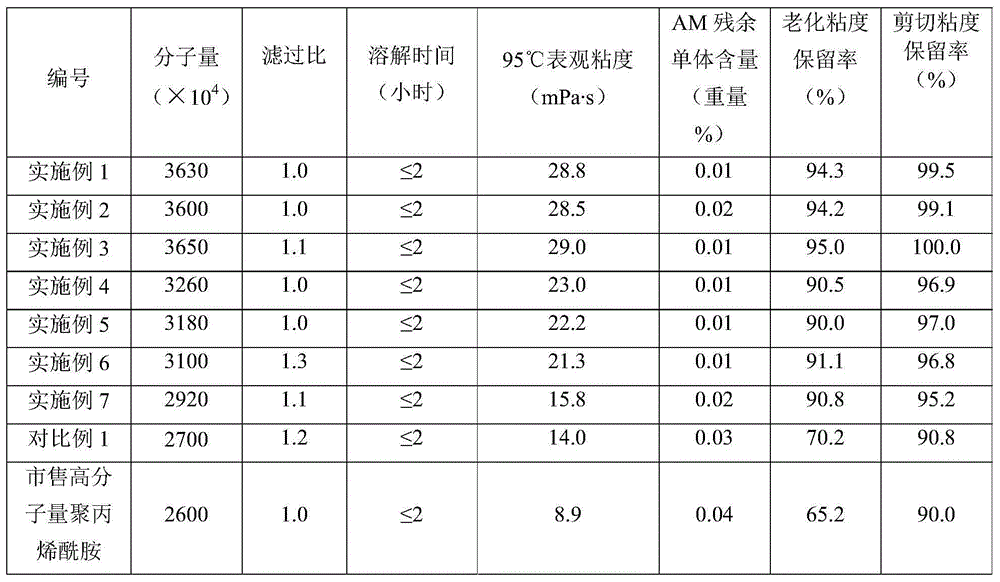

Embodiment 1

[0076] This example is used to illustrate the structure-oriented composite initiator and acrylamide polymer according to the present invention and the preparation method thereof.

[0077] Add 200 kilograms of deionized water to the batching kettle, add 100 kilograms of acrylamide, 0.2 kilograms of 2-acrylamido-2-methylpropanesulfonic acid, and add sodium hydroxide solution with a concentration of 20% by weight under stirring to adjust The pH value of the obtained solution reaches 5, and the temperature of the solution is controlled at 5°C with frozen brine, and the monomer solution is pumped into the polymerization kettle, and the high-purity nitrogen is used for deoxygenation for 0.5 hours. -Amine dendrimers, 5 grams of water-soluble azo initiator 2,2'-azobis(2-amidinopropane) dihydrochloride, add 2.5 grams of sodium bisulfite and 5 grams of ammonium persulfate, continue to pass Nitrogen was used until the thermocouple in the polymerization kettle began to heat up, and the re...

Embodiment 2

[0079] This example is used to illustrate the structure-oriented composite initiator and acrylamide polymer according to the present invention and the preparation method thereof.

[0080]Add 2000 kilograms of deionized water in the batching kettle, under stirring state, add 100 kilograms of acrylamide, 200 kilograms of 2-acrylamido-2-methylpropanesulfonic acid, add the sodium hydroxide solution that concentration is 20% by weight, adjust The pH value of the obtained solution is 9, and the temperature of the solution is controlled by refrigerated brine to 15°C. The monomer solution is pumped into the polymerization kettle, and the high-purity nitrogen gas is used to remove oxygen for 0.5 hours, and 40 grams of ethylenediamine is added as the core (third generation) polyamide -Amine dendrimers, 50 grams of water-soluble azo initiator 2,2'-azobis(2-amidinopropane) dihydrochloride, add 40 grams of sodium bisulfite and 50 grams of ammonium persulfate, continue to pass Nitrogen unti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com