Multistage devolatilization device for nylon 6 melt

A devolatilization device and melt technology, applied in the field of nylon materials, can solve the problems of affecting the production efficiency of PA6, increase in melt viscosity, pipeline blockage, etc., and achieve the effects of high speed, low oligomer content, and reduced content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

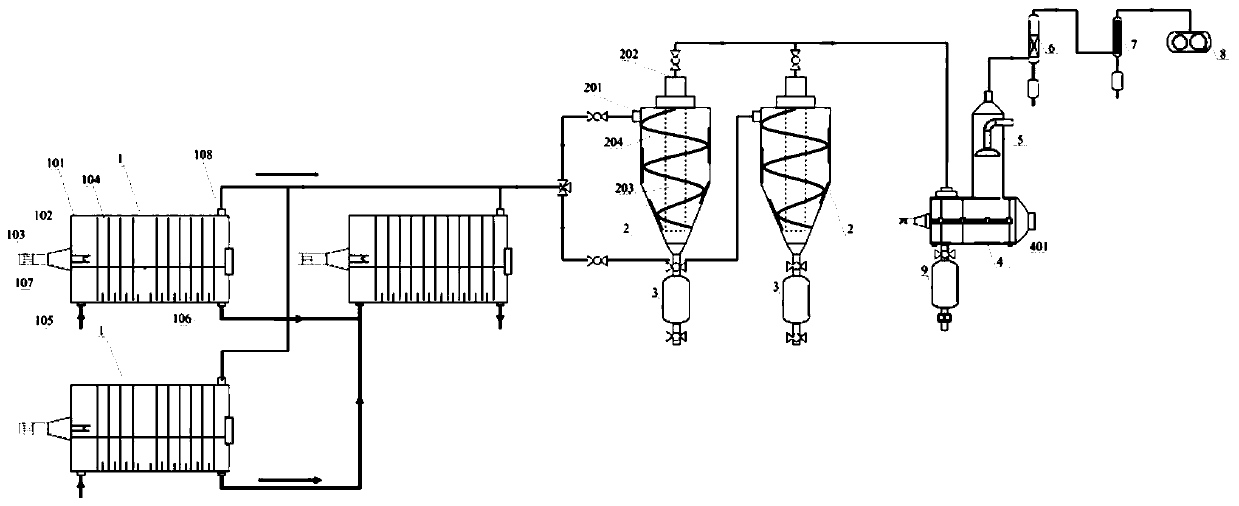

[0053] A nylon 6 melt multi-stage devolatilization device includes a devolatilization system and a component collection system connected in sequence.

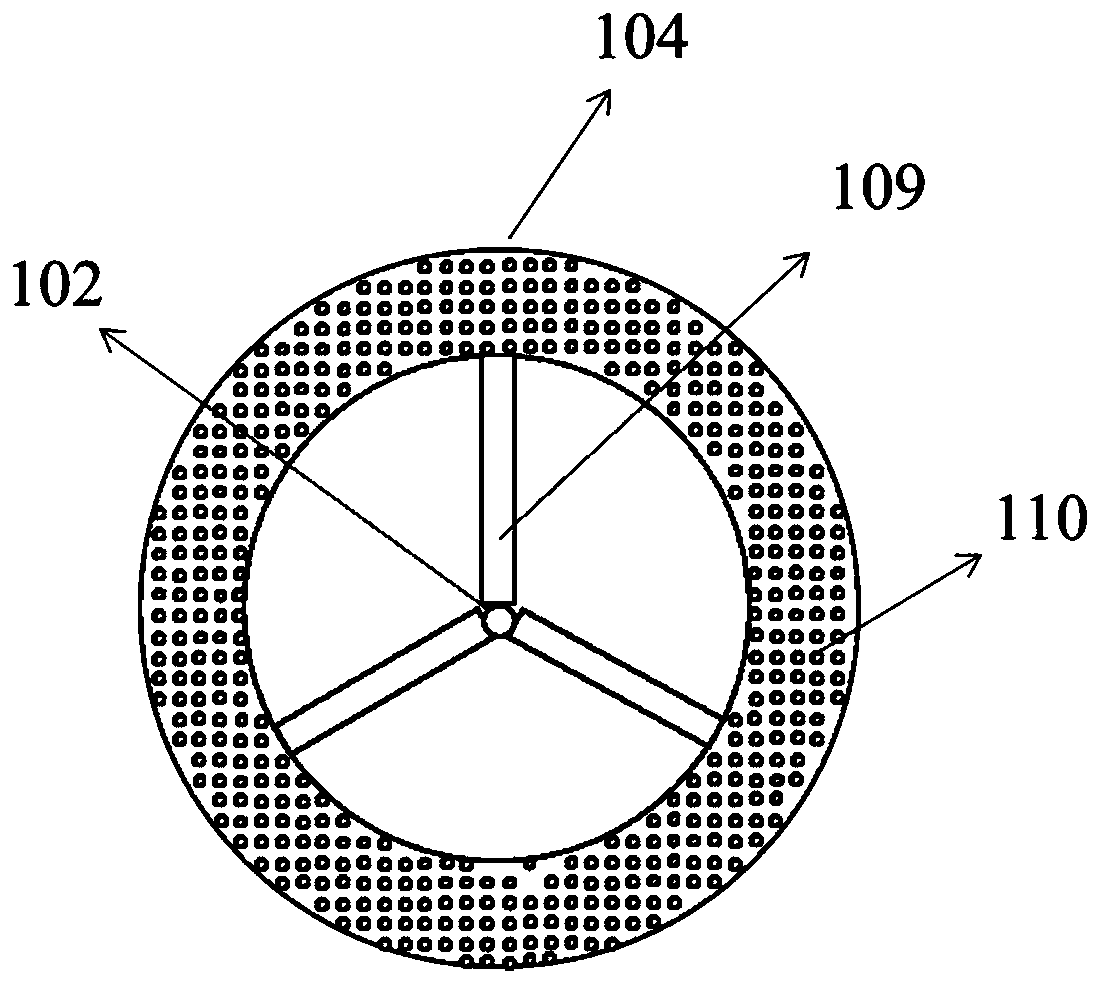

[0054] Among them, such as image 3 As shown, the devolatilization system includes two front and rear devolatilization reactors 1 connected in series; the devolatilization reactor includes a shell 101, a hollow shaft 102, a motor 103, and eleven devolatilizer plates 104; the shell The bottom of the shell is provided with a melt inlet 105 and a melt outlet 106. The middle of the side of the shell is provided with a gas inlet 107, and the top of the shell is provided with a gas outlet 108 (the melt inlet and the melt outlet, the gas inlet and the gas outlet are all located at Opposite side); the hollow shaft is horizontally arranged in the housing and one end of the hollow shaft is connected with the gas inlet, and the motor is used to drive the hollow shaft to rotate; figure 1 As shown, the devolatilizer disk is fixed on the hollow...

Embodiment 2

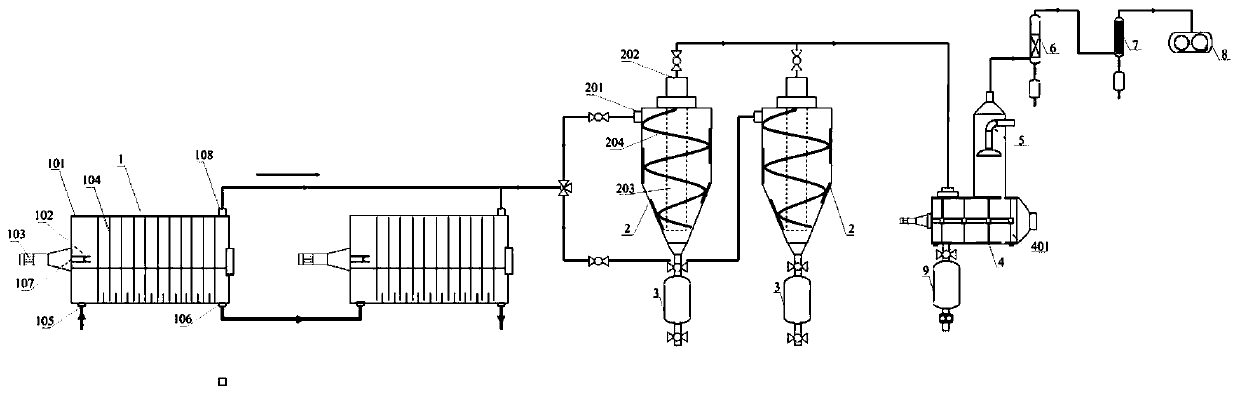

[0065] A nylon 6 melt multi-stage devolatilization device includes a devolatilization system and a component collection system connected in sequence.

[0066] Among them, such as image 3 As shown, the devolatilization system includes two parallel devolatilization reactors 1 and a devolatilization reactor connected in series with the aforementioned two devolatilization reactors in parallel; each of the devolatilization reactors includes a shell 101 , Hollow shaft 102, motor 103 and eleven devolatilizer plates 104; the bottom of the shell is provided with a melt inlet 105, a melt outlet 106, the middle of the side of the shell is provided with a gas inlet 107, the top of the shell is provided There is a gas outlet 108 (the melt inlet and the melt outlet, the gas inlet and the gas outlet are all located on opposite sides); the hollow shaft is horizontally arranged in the shell and one end is connected to the gas inlet, and the motor is used to drive the hollow shaft The shaft rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com