High-viscosity polyamide 56 resin, high-strength polyamide 56 industrial yarn and preparation method and application thereof

A technology of high-viscosity polyamide and viscous polyamide, which is applied in the field of polyamide materials, can solve the problems of reducing the breaking strength of fibers, increasing the number of broken filament cakes, and unfavorable high fiber drafting, etc., and achieves melt viscosity. Uniform, increased melt shear rate, better quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

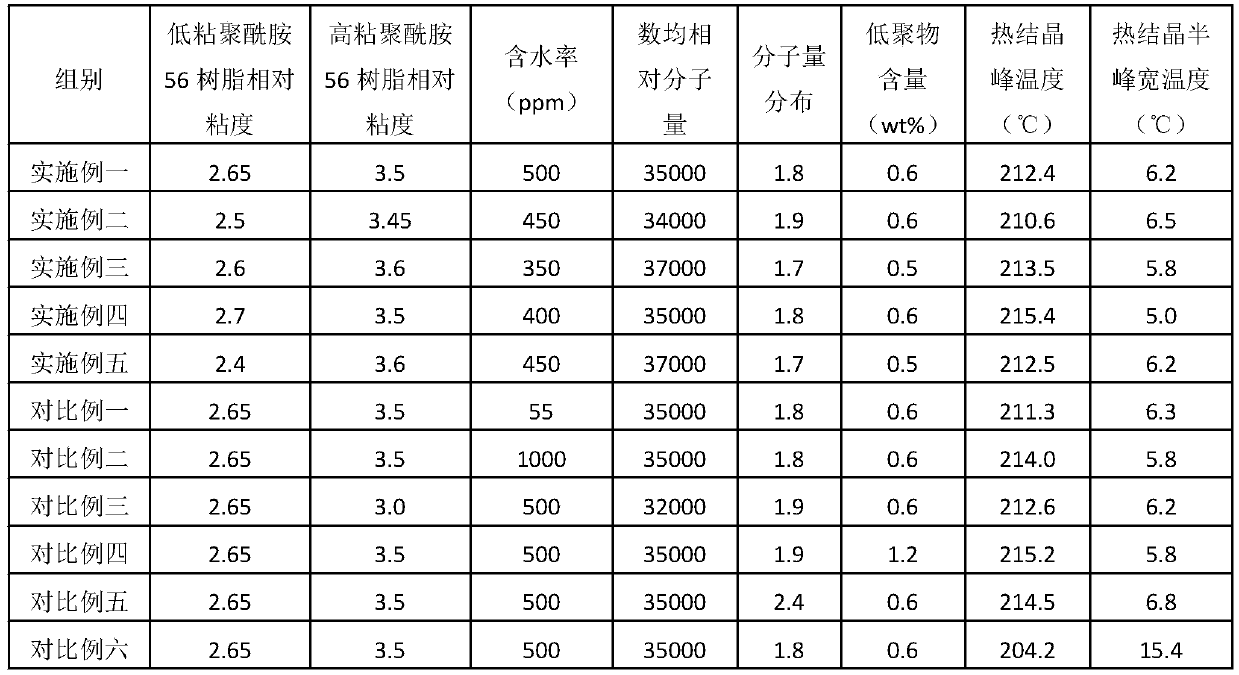

Embodiment 1

[0105] (1) The low-viscosity polyamide 56 resin with a relative viscosity of 2.65 is dried at a high temperature to obtain a tackified polyamide 56 resin; (2) the tackified polyamide 56 resin obtained in step (1) is subjected to resin conditioning Wet treatment to obtain the high-viscosity polyamide 56 resin; the high-temperature drying treatment adopts vacuum protection, and the vacuum degree during the vacuuming is -0.06Mpa; the temperature of the high-temperature drying treatment is 150°C; The time for the high-temperature drying treatment is 20 hours; the equipment for the high-temperature drying treatment is a vacuum drum dryer; the relative viscosity of the tackified polyamide 56 resin is 3.5, and the water content is 55ppm; The moisture content of the high-viscosity polyamide 56 resin is 500ppm; the temperature of the humidity-conditioning treatment of the resin is 100°C, and the humidity-conditioning treatment is carried out by using nitrogen mixed with water vapor, and...

Embodiment 2

[0108] (1) drying the low-viscosity polyamide 56 resin with a relative viscosity of 2.5 to obtain a tackified polyamide 56 resin; (2) performing resin conditioning on the tackified polyamide 56 resin obtained in step (1). Wet treatment to obtain the high-viscosity polyamide 56 resin; the high-temperature drying treatment is to adopt vacuum protection, and the vacuum degree during the vacuuming is -0.08Mpa; the temperature of the high-temperature drying treatment is 160°C; The time for the high-temperature drying treatment is 15 hours; the equipment for the high-temperature drying treatment is a vacuum drum dryer; the relative viscosity of the tackified polyamide 56 resin is 3.45, and the water content is 60ppm; The moisture content of the high-viscosity polyamide 56 resin is 450ppm; the temperature of the resin humidity-conditioning treatment is 105°C, and the humidity-conditioning treatment is carried out by using nitrogen mixed with water vapor, and the nitrogen dew point is ...

Embodiment 3

[0111] (1) The low-viscosity polyamide 56 resin with a relative viscosity of 2.6 is dried at a high temperature to obtain a tackified polyamide 56 resin; (2) the tackified polyamide 56 resin obtained in step (1) is subjected to resin conditioning Wet treatment to obtain the high-viscosity polyamide 56 resin; the high-temperature drying treatment adopts vacuum protection, and the vacuum degree during the vacuuming is -0.07Mpa; the temperature of the high-temperature drying treatment is 180°C; The time for the high-temperature drying treatment is 13 hours; the equipment for the high-temperature drying treatment is a vacuum drum dryer; the relative viscosity of the tackified polyamide 56 resin is 3.6, and the water content is 30ppm; The moisture content of the high-viscosity polyamide 56 resin is 350ppm; the temperature of the resin humidity-conditioning treatment is 110°C, and the humidity-conditioning treatment is carried out by using nitrogen mixed with water vapor, and the nit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com