High-viscosity polyamide 56 resin, high-strength polyamide 56 industrial yarn and preparation method and application thereof

A high-viscosity polyamide and polyamide technology, applied in the field of polyamide materials, can solve the problems of high winding speed, poor dimensional stability, low fiber crystallization and orientation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

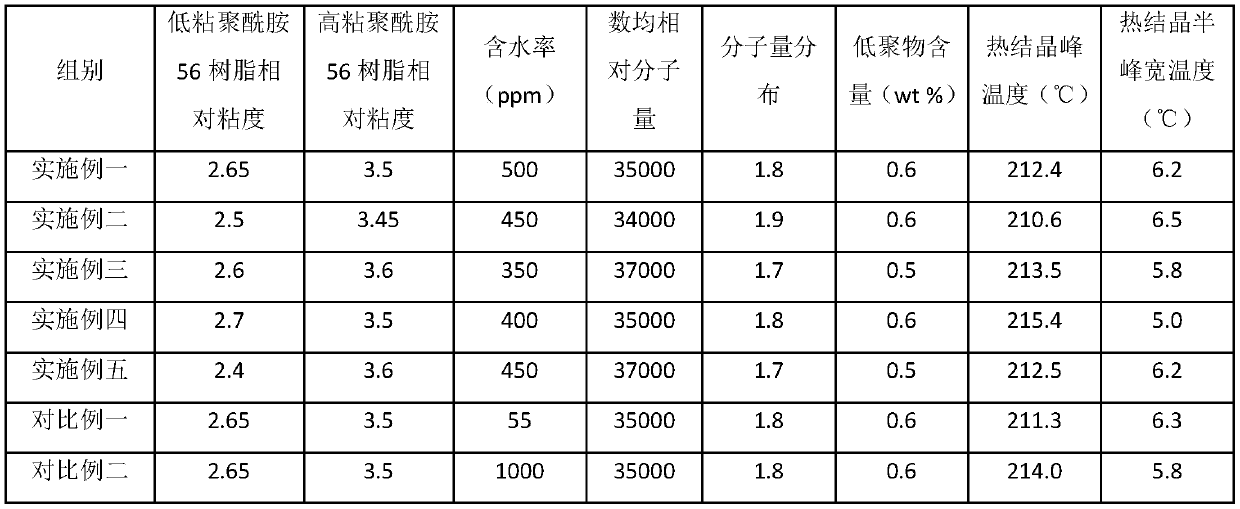

[0122] Embodiment one (preparation of high viscosity polyamide 56 resin):

[0123] (1) The low-viscosity polyamide 56 resin with a relative viscosity of 2.65 is dried at a high temperature to obtain a tackified polyamide 56 resin;

[0124] (2) performing resin humidity conditioning treatment on the tackified polyamide 56 resin obtained in step (1), to obtain the high-viscosity polyamide 56 resin;

[0125] The high-temperature drying treatment adopts vacuum protection, and the vacuum degree during the vacuum pumping is -0.06Mpa; the temperature of the high-temperature drying treatment is 150°C; the time of the high-temperature drying treatment is 20h; the high-temperature drying treatment The equipment for processing is a vacuum drum dryer; the relative viscosity of the tackified polyamide 56 resin is 3.5, and the moisture content is 55ppm; the moisture content of the high-viscosity polyamide 56 resin after the resin humidity control treatment is 500ppm; The temperature of the...

Embodiment 2

[0127] Embodiment two (preparation of high viscosity polyamide 56 resin):

[0128] (1) The low-viscosity polyamide 56 resin with a relative viscosity of 2.5 is dried at a high temperature to obtain a tackified polyamide 56 resin;

[0129] (2) performing resin humidity conditioning treatment on the tackified polyamide 56 resin obtained in step (1), to obtain the high-viscosity polyamide 56 resin;

[0130] The high-temperature drying treatment adopts vacuum protection, and the vacuum degree during the vacuum pumping is -0.08Mpa; the temperature of the high-temperature drying treatment is 160°C; the time of the high-temperature drying treatment is 15h; the high-temperature drying treatment The equipment for processing is a vacuum drum dryer; the relative viscosity of the tackified polyamide 56 resin is 3.45, and the moisture content is 60ppm; the moisture content of the high-viscosity polyamide 56 resin after the resin humidity control treatment is 450ppm; The temperature of the...

Embodiment 3

[0132] Embodiment three (preparation of high viscosity polyamide 56 resin):

[0133] (1) The low-viscosity polyamide 56 resin with a relative viscosity of 2.6 is dried at a high temperature to obtain a tackified polyamide 56 resin;

[0134] (2) performing resin humidity conditioning treatment on the tackified polyamide 56 resin obtained in step (1), to obtain the high-viscosity polyamide 56 resin;

[0135] The high-temperature drying treatment adopts vacuum protection, and the vacuum degree during the vacuuming is -0.07Mpa; the temperature of the high-temperature drying treatment is 180°C; the time of the high-temperature drying treatment is 13h; the high-temperature drying treatment The equipment for processing is a vacuum drum dryer; the relative viscosity of the tackified polyamide 56 resin is 3.6, and the moisture content is 30ppm; the moisture content of the high-viscosity polyamide 56 resin after the resin humidity control treatment is 350ppm; The temperature of the res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com