Preparation method of high-performance ultrafiltration membrane

An ultrafiltration membrane, a high-performance technology, applied in the field of membrane separation, can solve the problems of reducing the cut-off performance and membrane strength of the ultrafiltration membrane, and cannot significantly affect the permeation flux of the membrane, so as to facilitate the adjustment of the membrane surface pore size and the membrane surface pore size. Uniform distribution and reduced usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

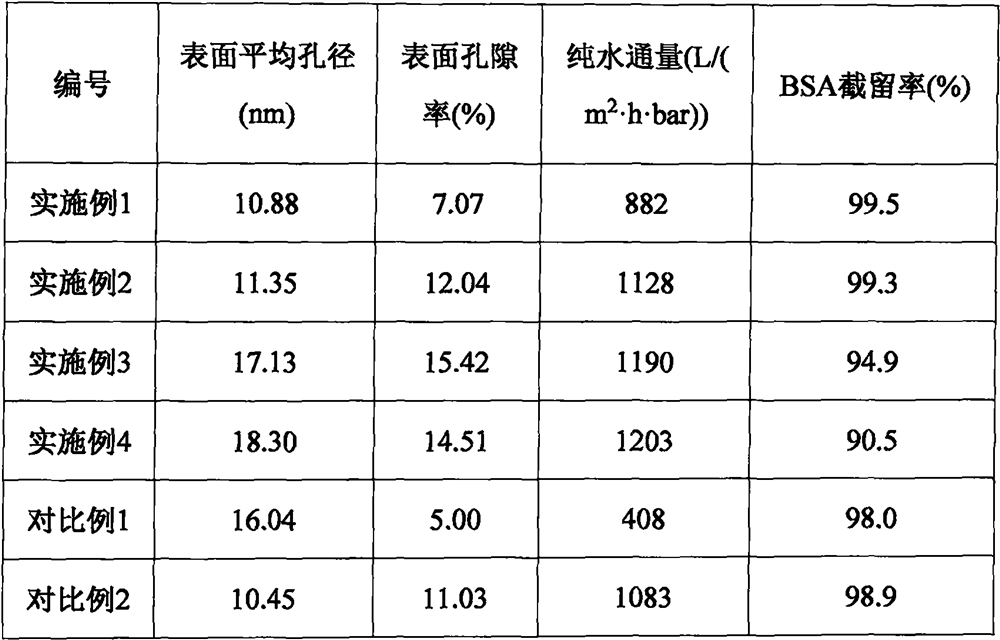

Embodiment 1

[0033] The sulfonated polysulfone (SPSf) of the PES of 4.2g, 0.8g (SPSf) is dissolved in the DMAC solvent of 20g and is formulated into casting solution (film-forming polymer accounts for 20wt% of casting solution gross mass), then to this casting solution Add 2.25g of H in 2 O (accounting for 9wt% of the total mass of the casting solution), 6g of PEG (accounting for 24wt% of the total mass of the casting solution), 0.0125g of CaCO with a particle size of 20nm 3 Particles (accounting for 0.05wt% of the total mass of the casting solution). Mix evenly at 70°C, stir mechanically for 8h and stand at 70°C for 24h and vacuum defoam to obtain a homogeneous casting solution. The scraped 200 μm liquid film was quickly immersed in an aqueous coagulation bath with a pH of 0.5 prepared by hydrochloric acid for phase inversion. After 5 minutes, the base film was taken out and placed in deionized water for storage. The pure water flux and BSA (1000ppm) rejection rate were tested at 0.1MPa...

Embodiment 2

[0035]The sulfonated polysulfone (SPSf) of the PES of 4.2g, 0.8g (SPSf) is dissolved in the DMAC solvent of 20g and is formulated into casting solution (film-forming polymer accounts for 20wt% of casting solution gross mass), then to this casting solution Add 6g of PEG (accounting for 24wt% of the total mass of the casting solution), 0.125g of CaCO with a particle size of 20nm 3 Particles (accounting for 0.5wt% of the total mass of the casting solution). Mix evenly at 25°C, stir mechanically for 8 hours, and stand at 25°C for 24 hours for vacuum defoaming to obtain a homogeneous casting solution. The scraped 100 μm membrane was quickly immersed in a coagulation bath of an aqueous solution with a pH of 2 prepared by hydrochloric acid for phase inversion. After 5 minutes, the basement membrane was taken out and placed in deionized water for storage. The pure water flux and BSA (1000ppm) rejection rate were tested at 0.1MPa, and the pore size and surface porosity were tested aft...

Embodiment 3

[0037] The PVDF of 3.0g is dissolved in the NMP solvent of 22.0g and is mixed with casting solution (film-forming polymer accounts for 12wt% in casting solution), then in this casting solution, add the methyl alcohol of 1.25g (accounting for casting solution total 5wt% of the mass), 6g of PEG (accounting for 24wt% of the total mass of the casting solution), 0.025g of MgCO with a particle size of 120nm 3 Particles (accounting for 0.1wt% of the total mass of the casting solution). Mix evenly at 50°C, mechanically stir for 8h and stand at 50°C for 24h to defoam to obtain a homogeneous casting solution. The film scraped to 300 μm was quickly immersed in an aqueous coagulation bath with a pH of 6 prepared by acetic acid for phase inversion. After 30 minutes, the base film was taken out and stored in deionized water. The pure water flux and BSA (1000ppm) rejection rate were tested at 0.1MPa, and the pore size and surface porosity were tested after the membrane was freeze-dried. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com