Patents

Literature

53results about How to "Occurrence is very low" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-absorbent agent and method for manufacturing the same

InactiveUS6187872B1Improve securityStable pHOther chemical processesAbsorbent padsPolymer scienceCross linker

A hydrogel polymer obtained by polymerizing a monomer component including acrylic acid (salt) is post-neutralized so that each of polymer particles derived from a polymer produced by neutralizing the hydrogel polymer has an allowable neutralization ratio. The polymer as obtained by neutralizing the hydrogel polymer is reacted with a crosslinking agent reactive to a functional group of the polymer. The allowable neutralization ratio, for example, is a neutralization ratio which is not lower, by not less than 20 mole percent, or more than, at least 55 mole percent, than an average neutralization ratio of a mass of the polymer particles, and the post-neutralization is carried out so that a number of polymer particles having a non-allowable neutralization ratio outside the allowable neutralization range is not more than 10 in 200 polymer particles, thus obtaining a water-absorbent agent having high absorbency under no applied pressure and high pressure wherein the amount of water soluble component is lower compared with the conventional water-absorbent agent and a change in pH of a swollen gel is small.

Owner:NIPPON SHOKUBAI CO LTD

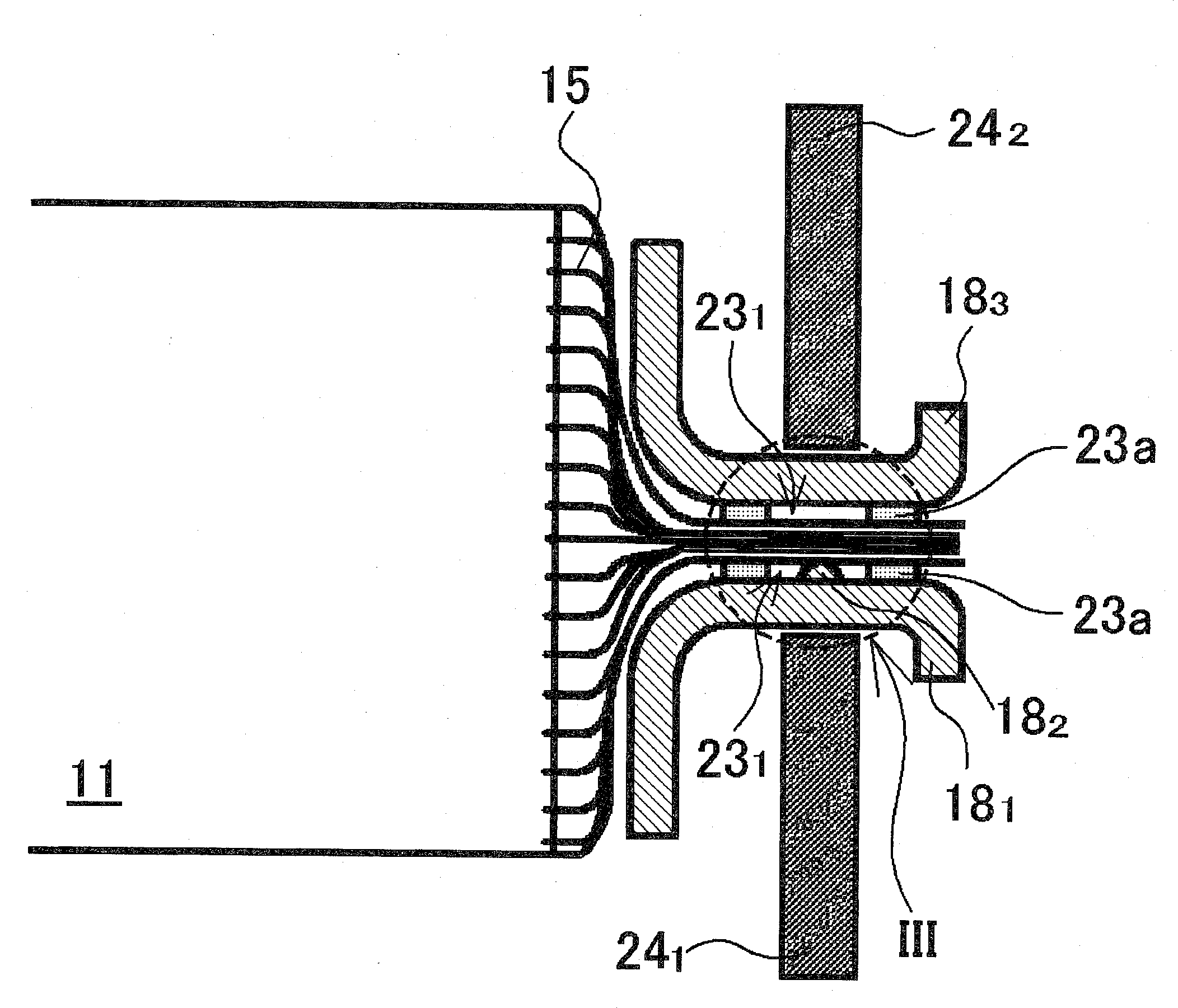

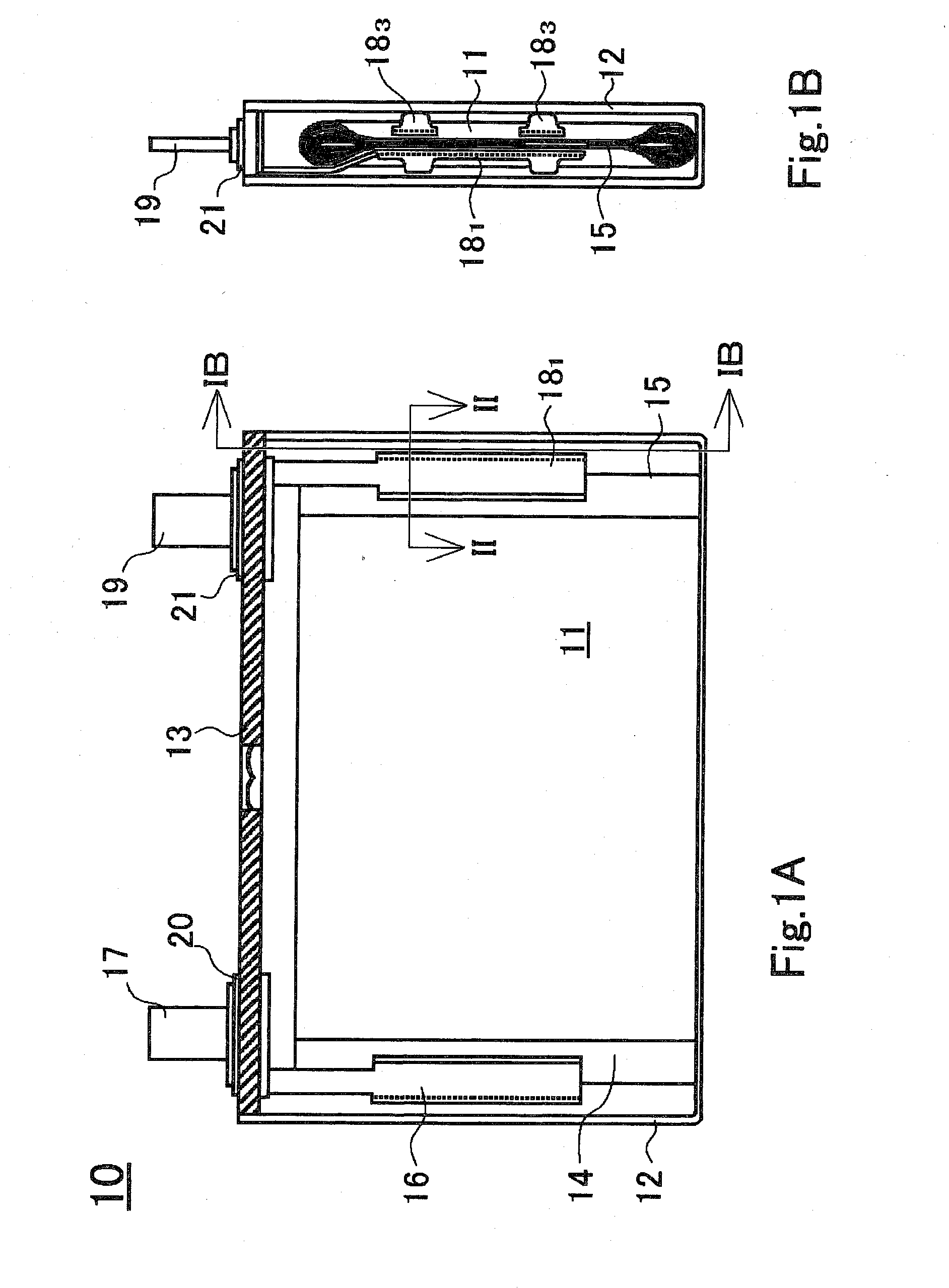

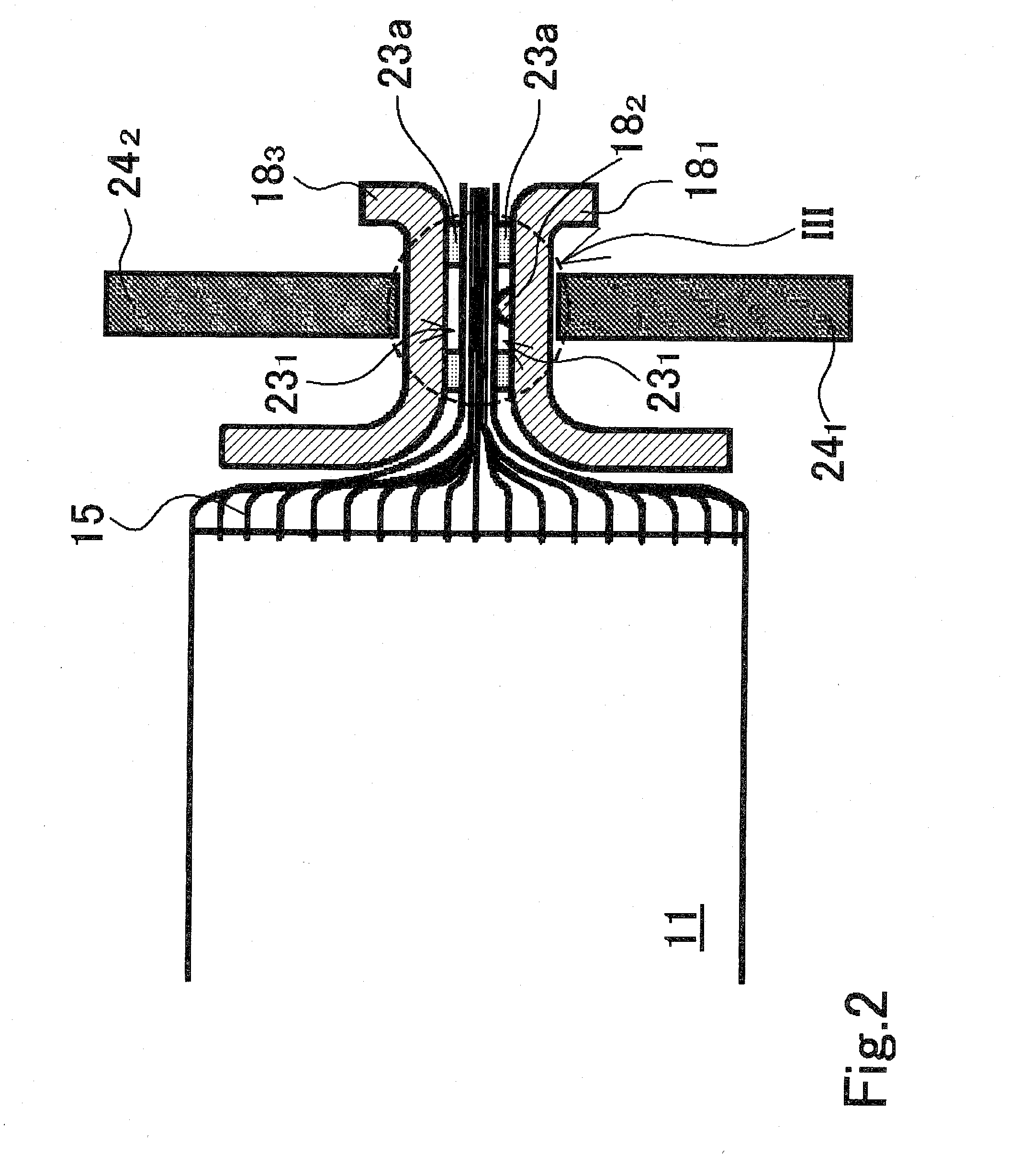

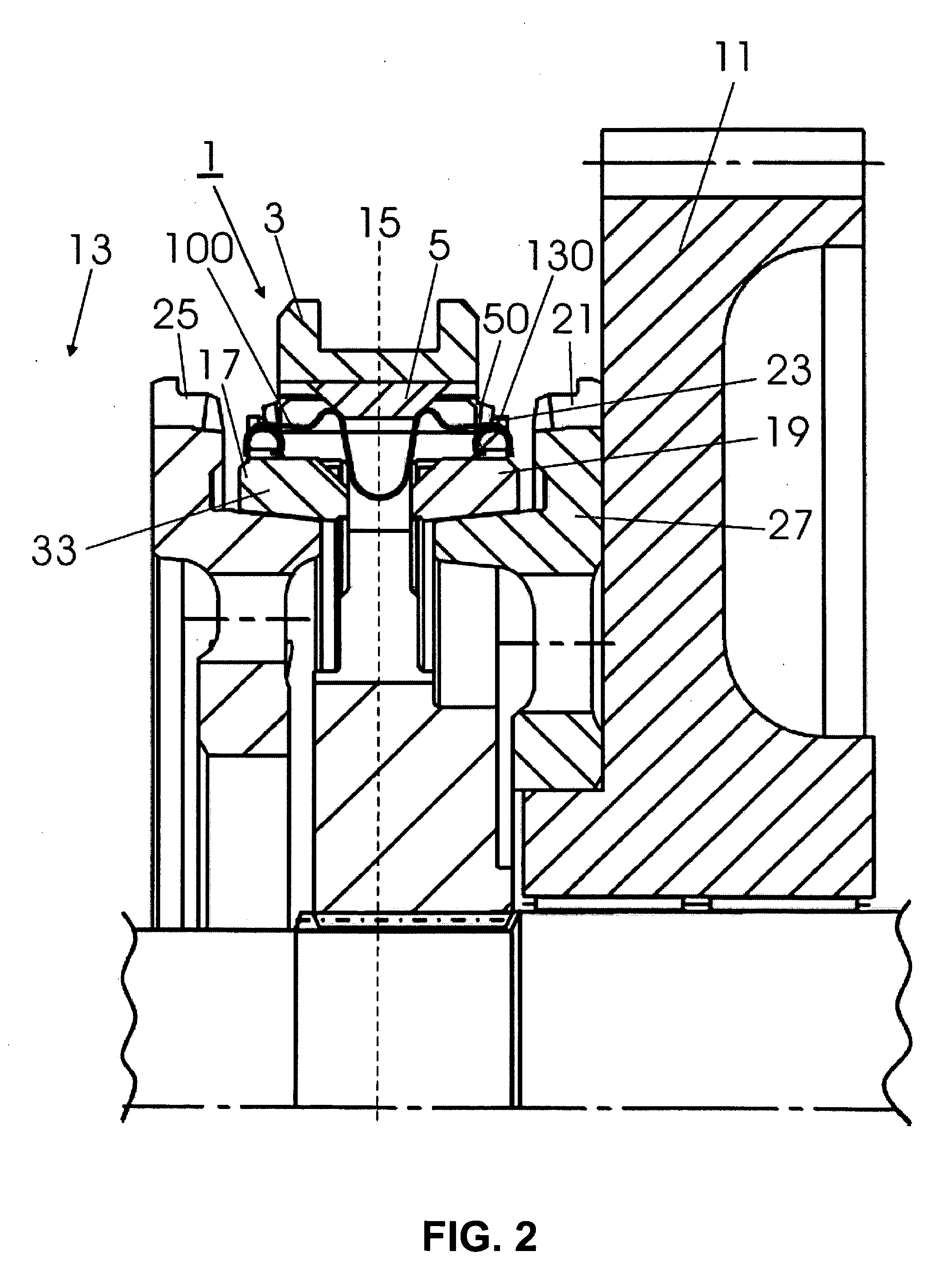

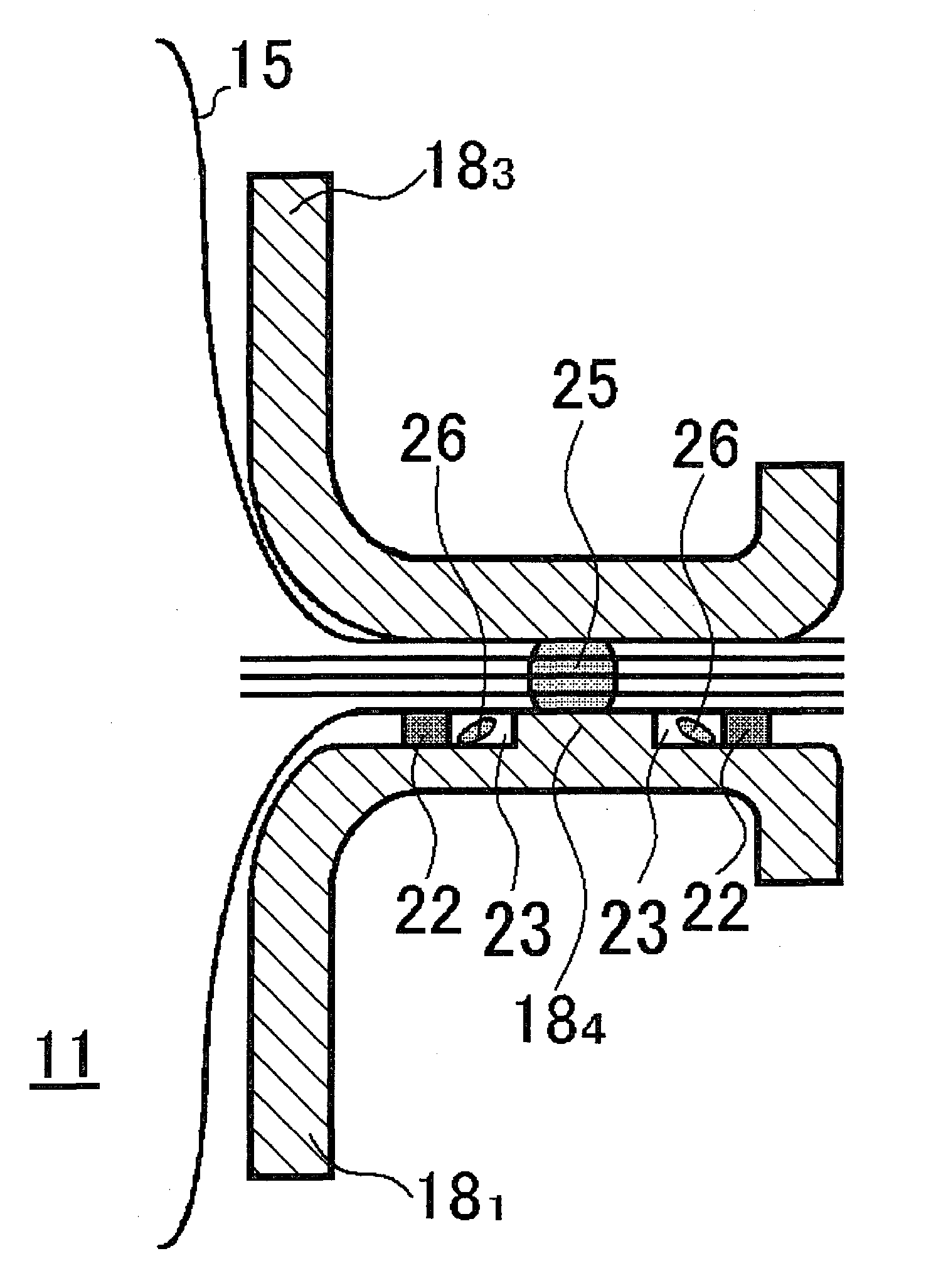

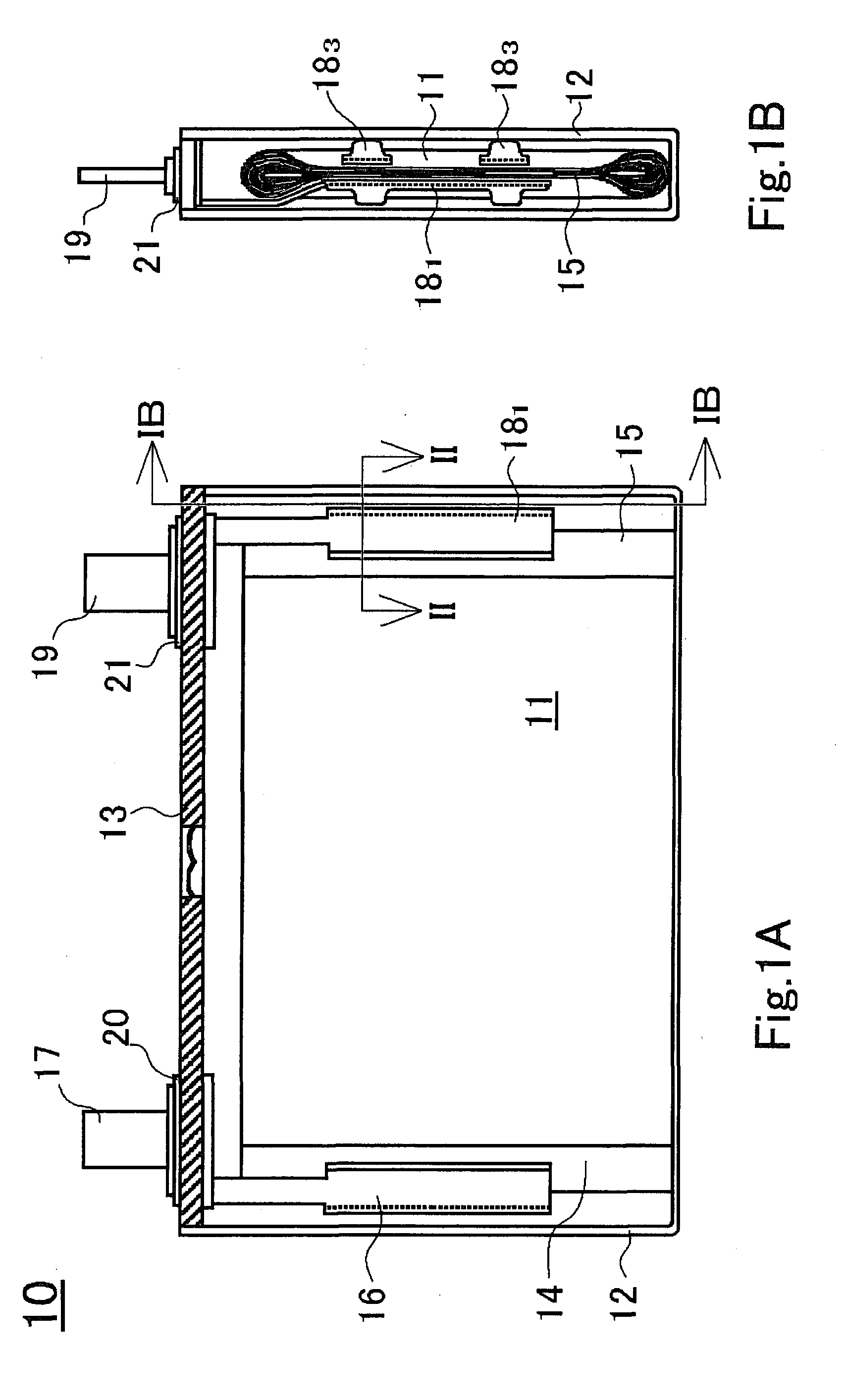

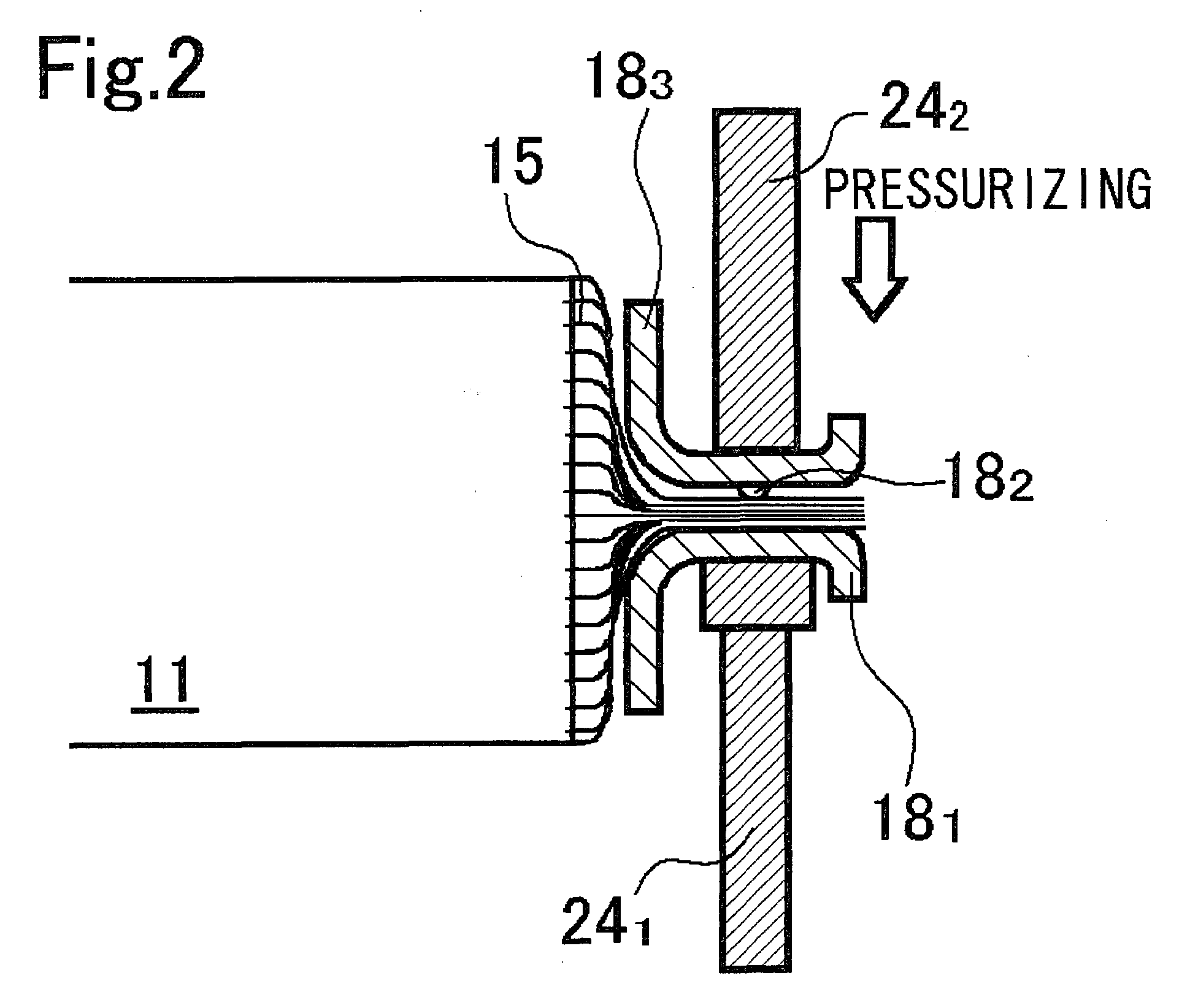

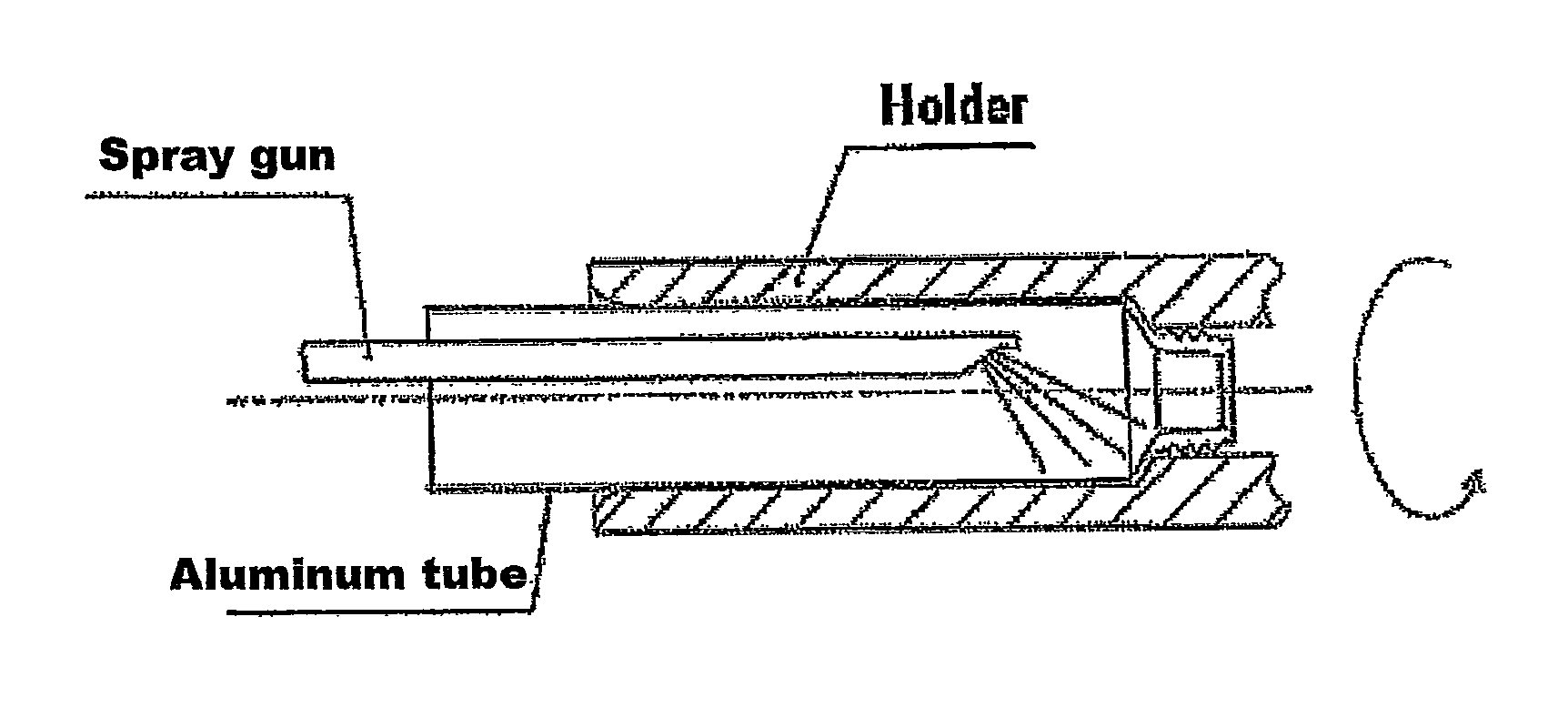

Sealed battery and manufacturing method therefor

ActiveUS20090004561A1High resistance weld reliabilitySatisfy the effectivenessNon-aqueous electrolyte accumulatorsPrimary cellsEngineeringElectrical and Electronics engineering

The present invention's manufacturing method for a sealed battery includes: a process whereby a sealed battery application electrode assembly 11 is formed that has multiple positive electrode substrate exposed portions 14 at one end and multiple negative electrode substrate exposed portions 15 at the other end; a process whereby the negative electrode collector 181 and negative electrode collector receiving part 183 are brought against both surfaces of the part to be welded on at least the negative electrode substrate exposed portions 15, with tape 23a constituted of thermodeposited resin and having an opening 231 in the center being interposed; and a process whereby resistance welding is effected by passing current between the negative electrode collector 181 and negative electrode collector receiving part 183 positioned at the two sides.

Owner:SANYO ELECTRIC CO LTD

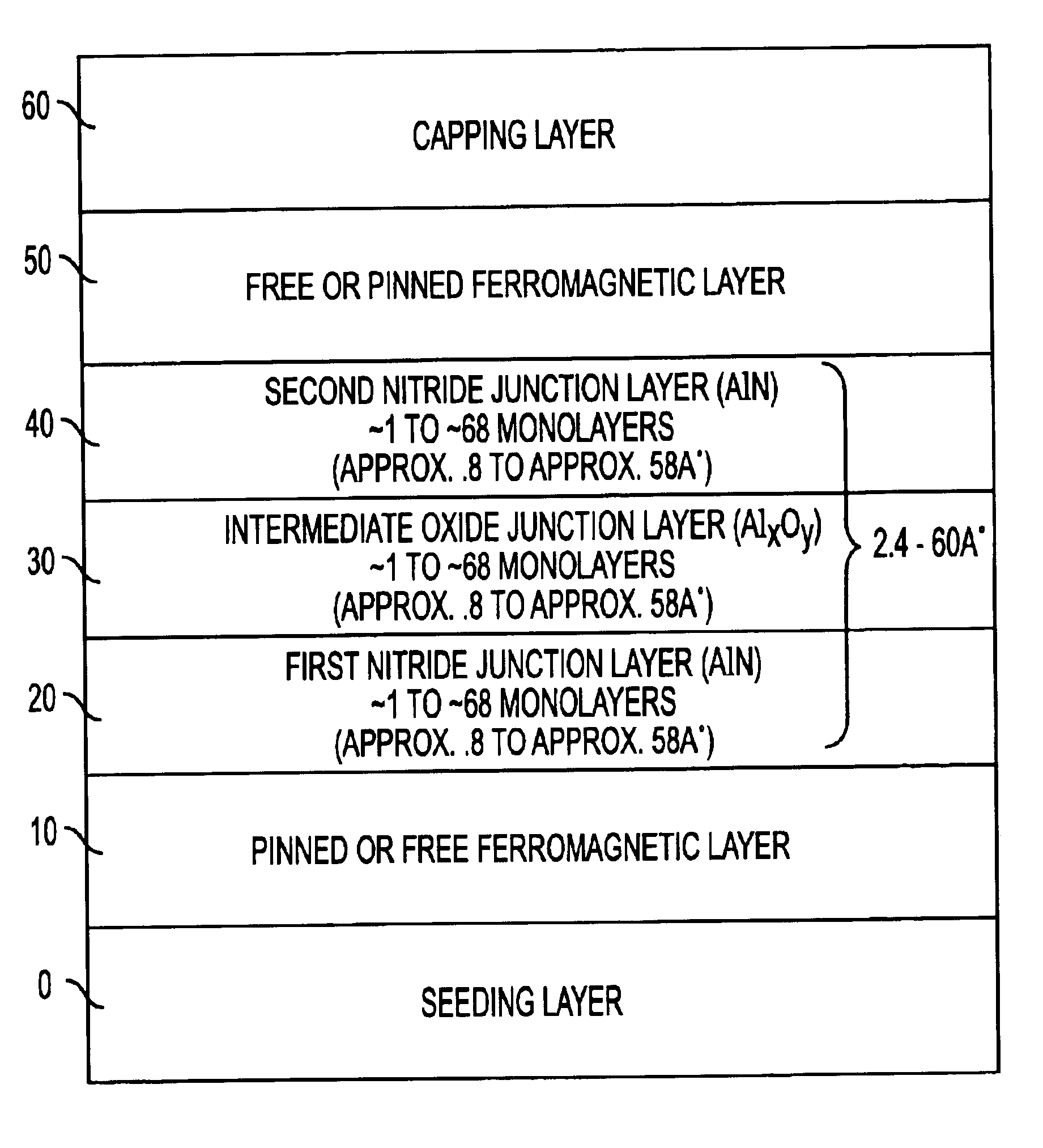

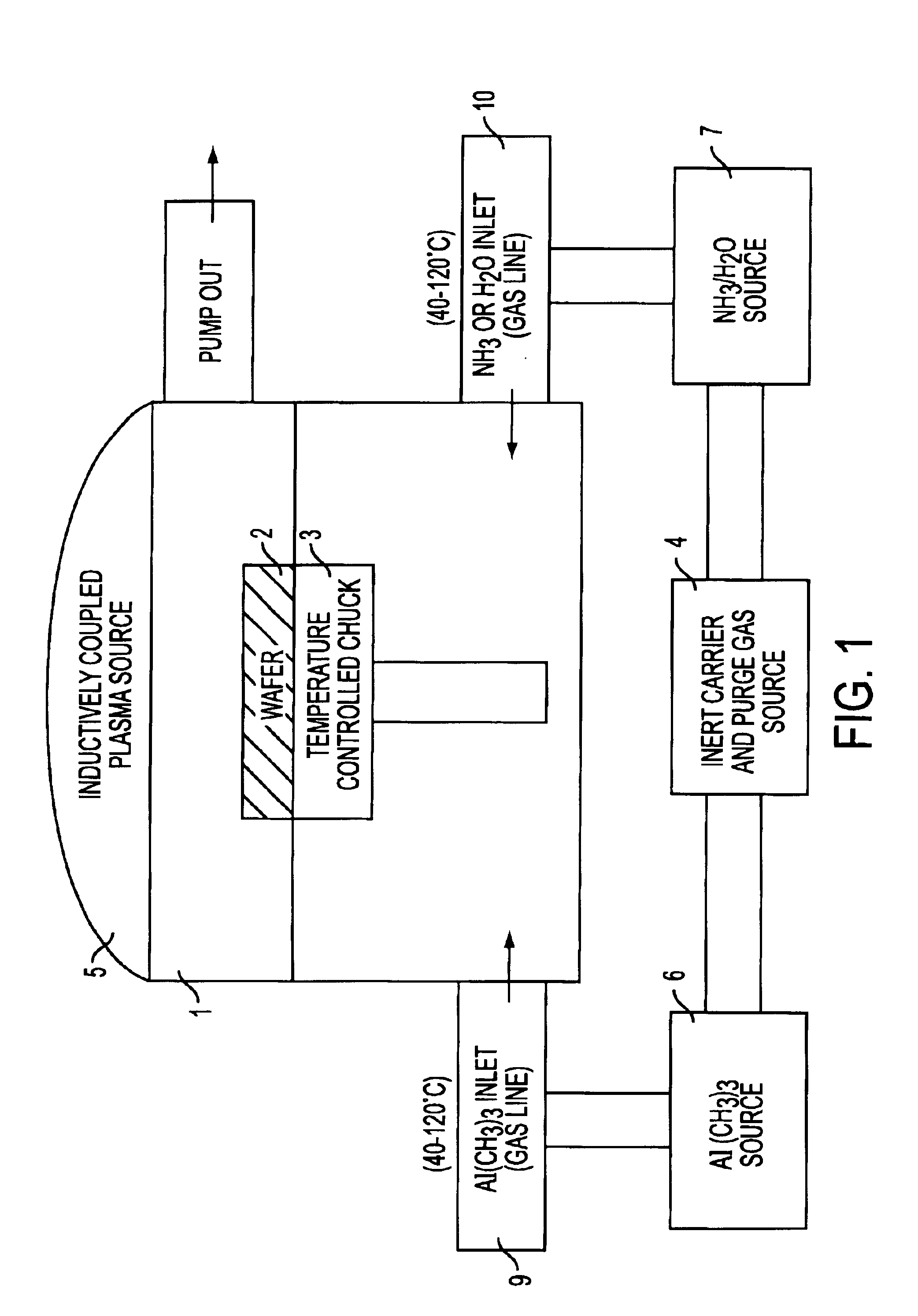

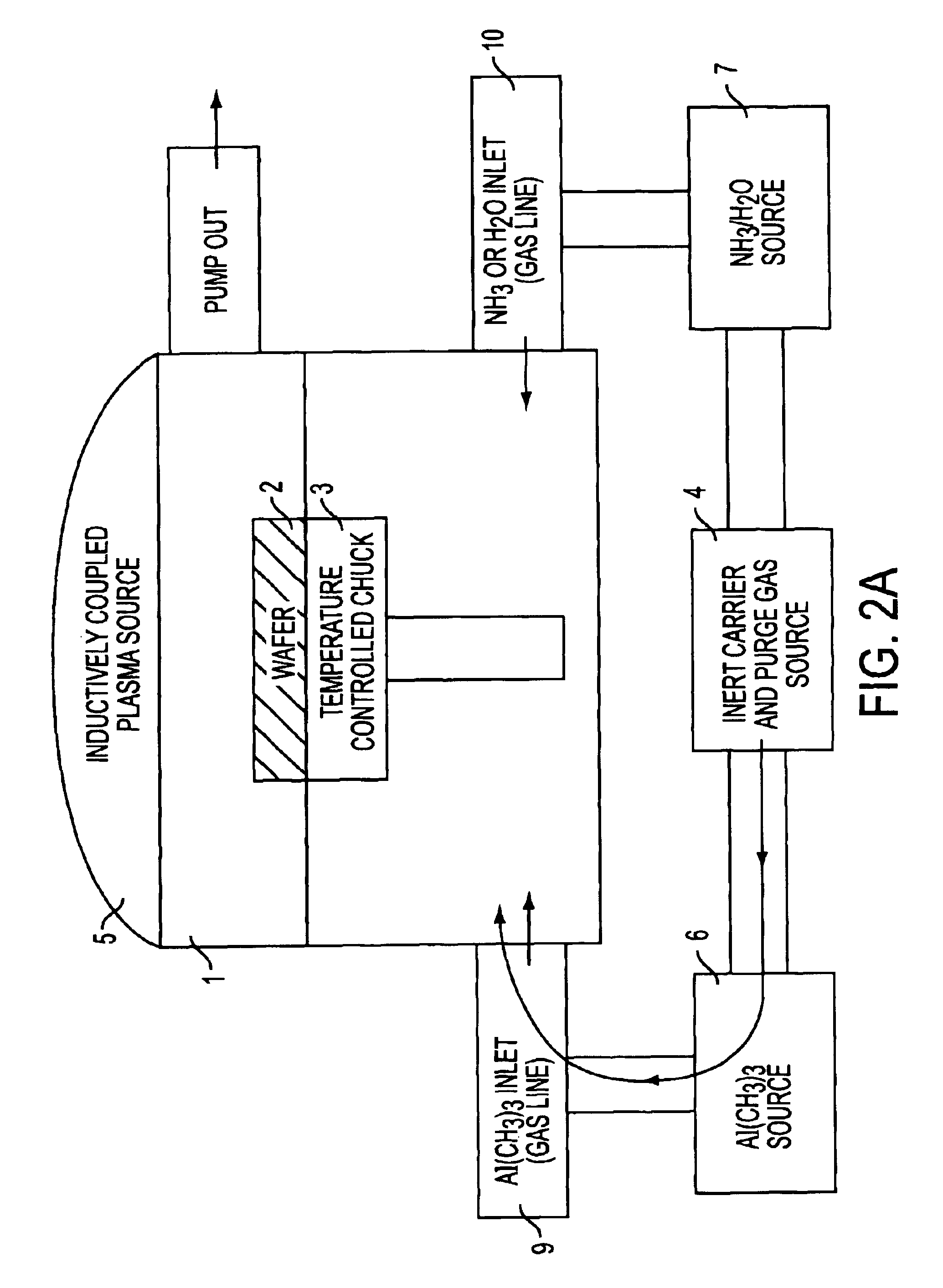

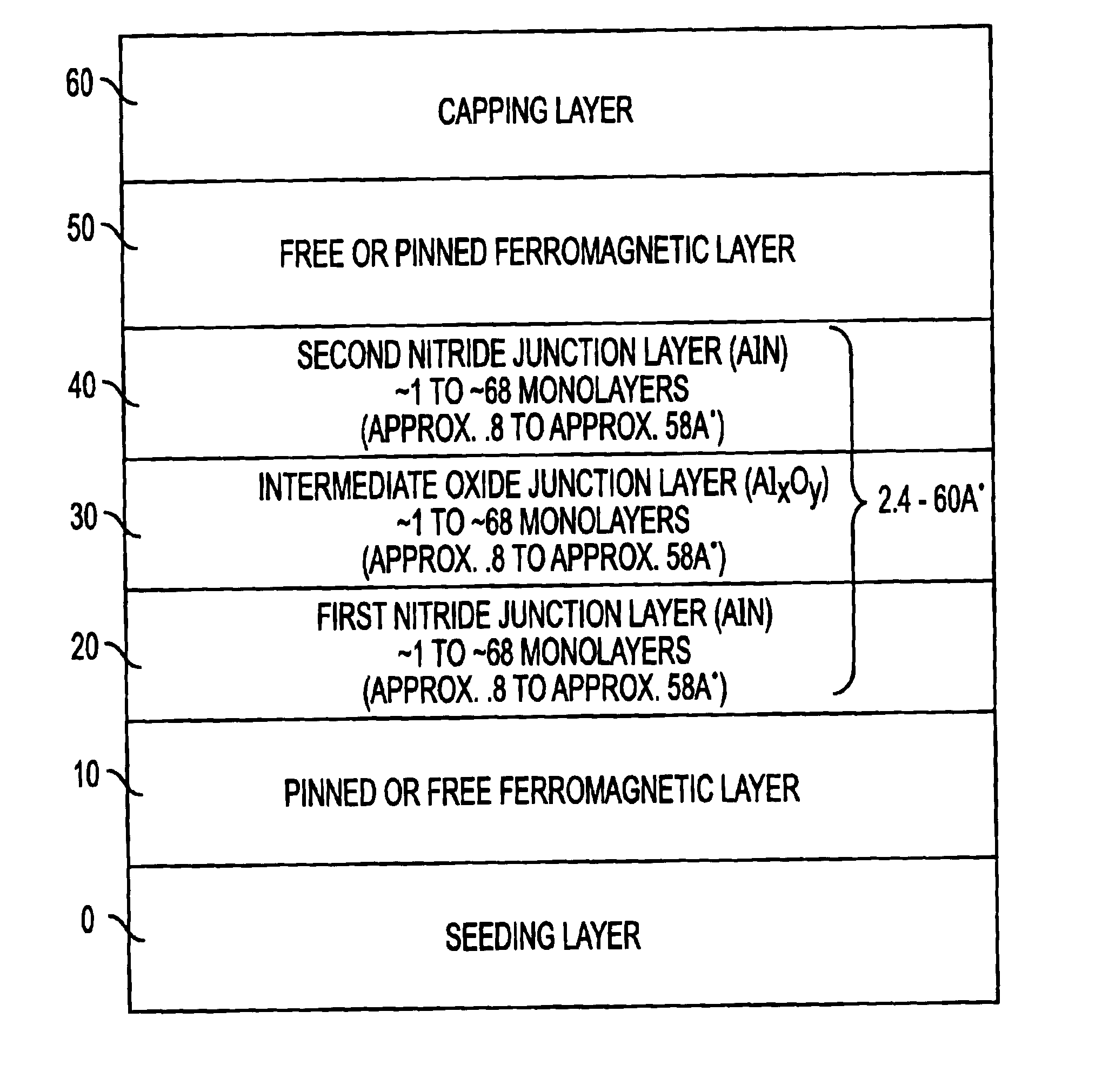

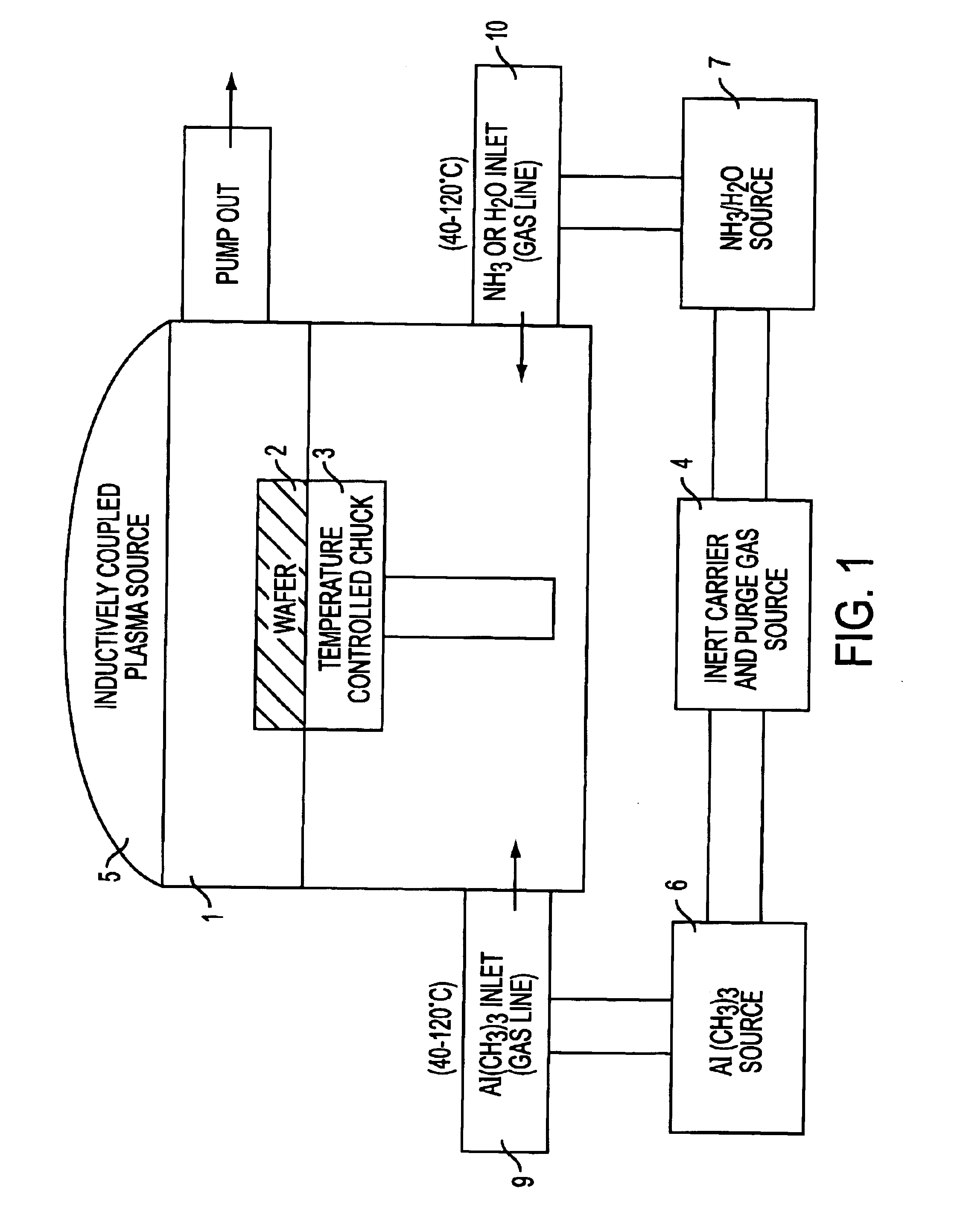

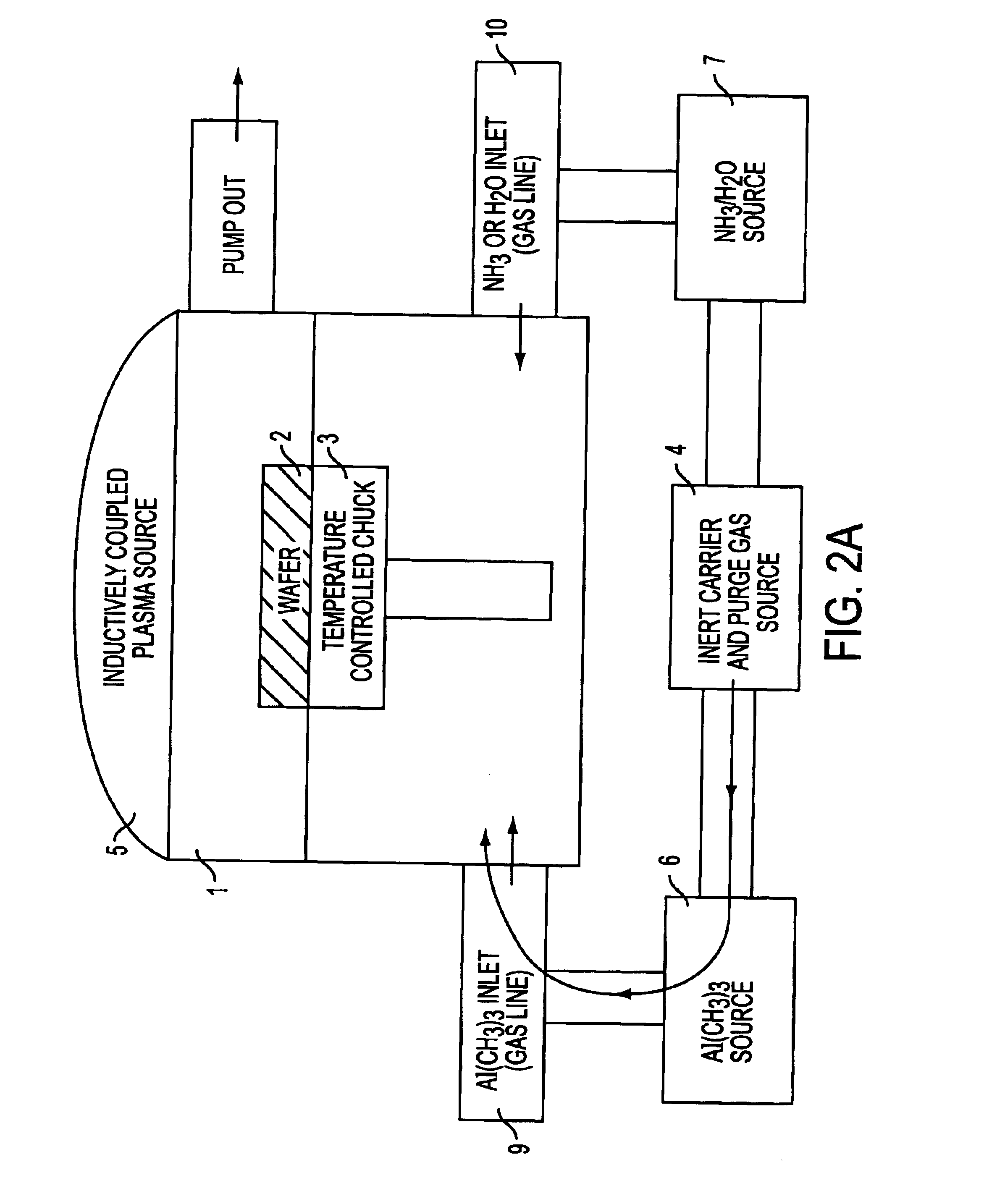

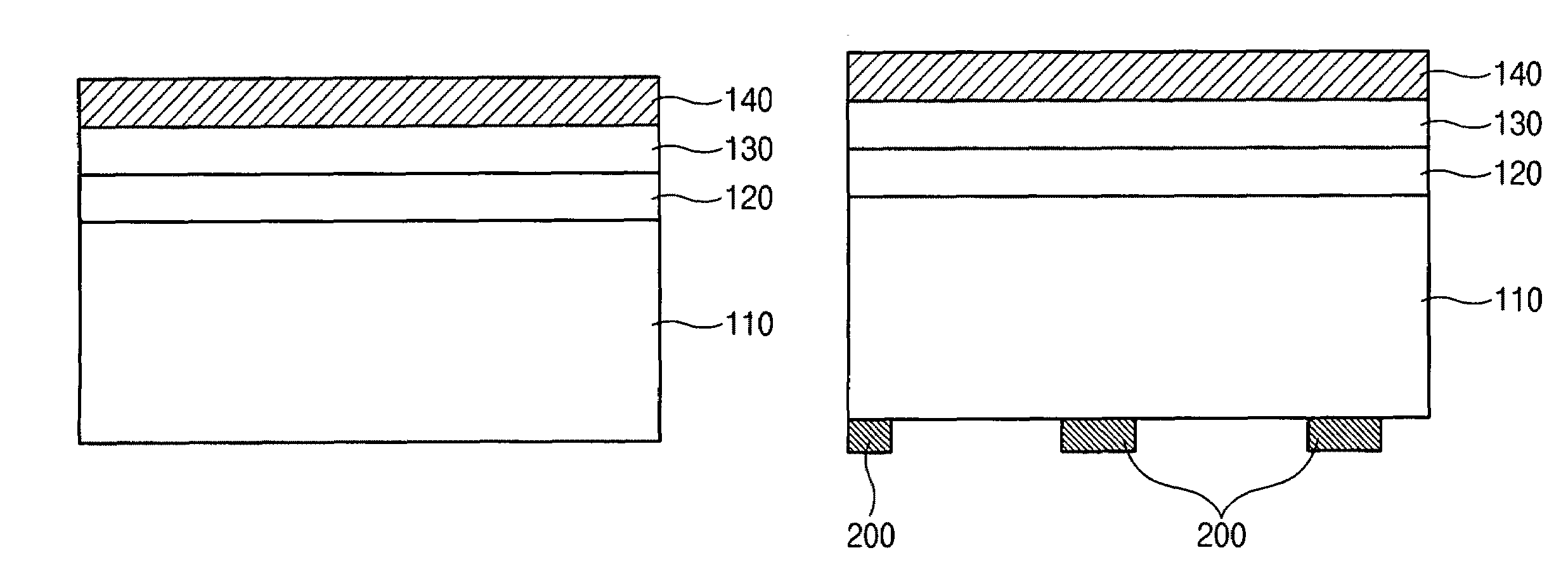

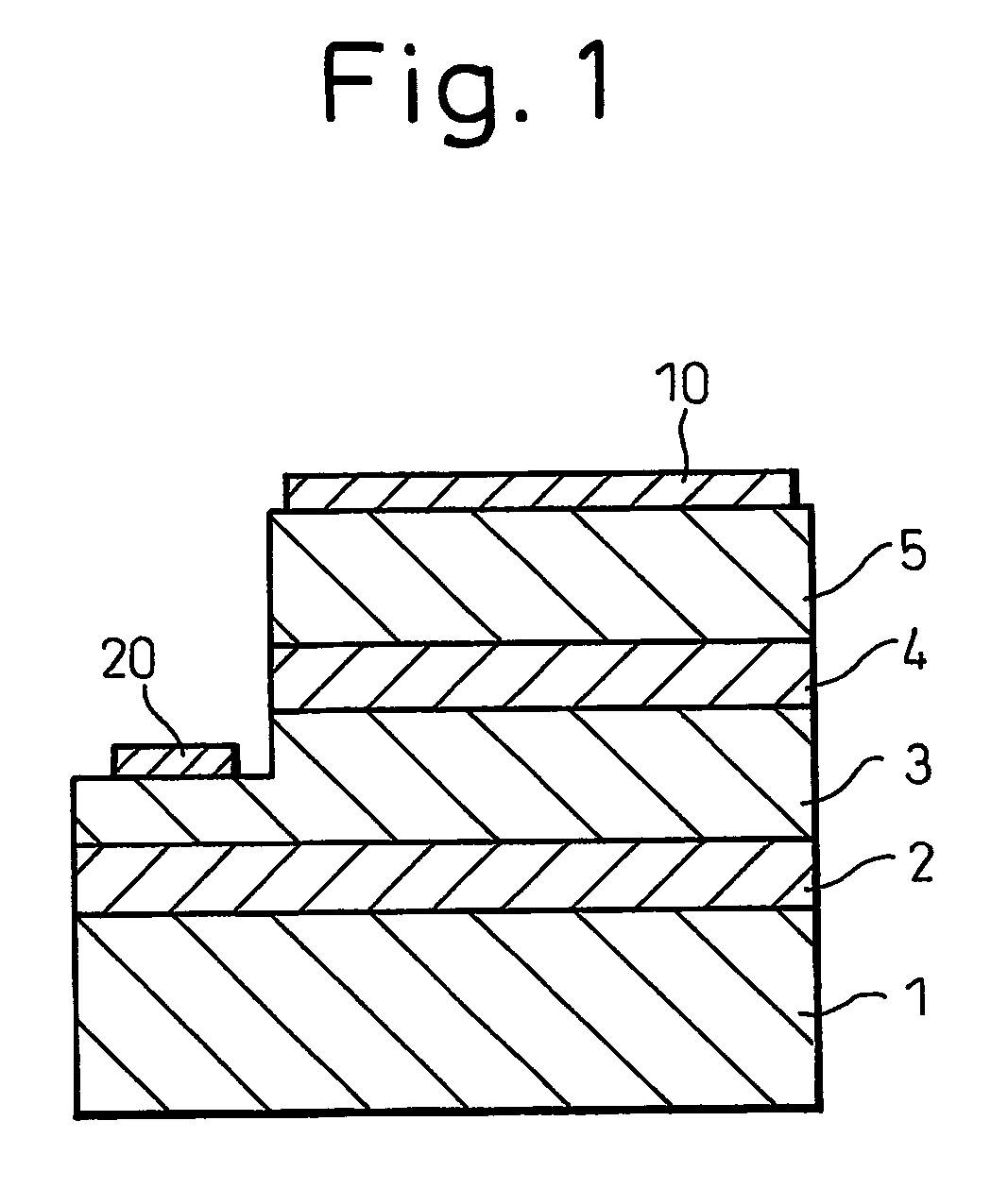

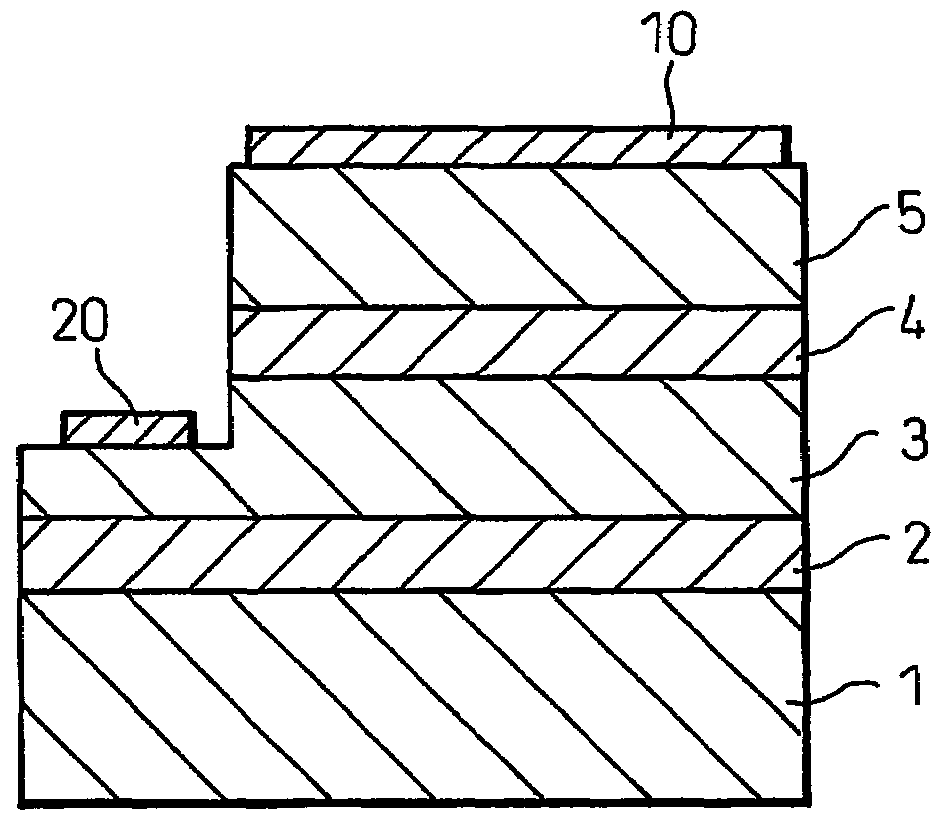

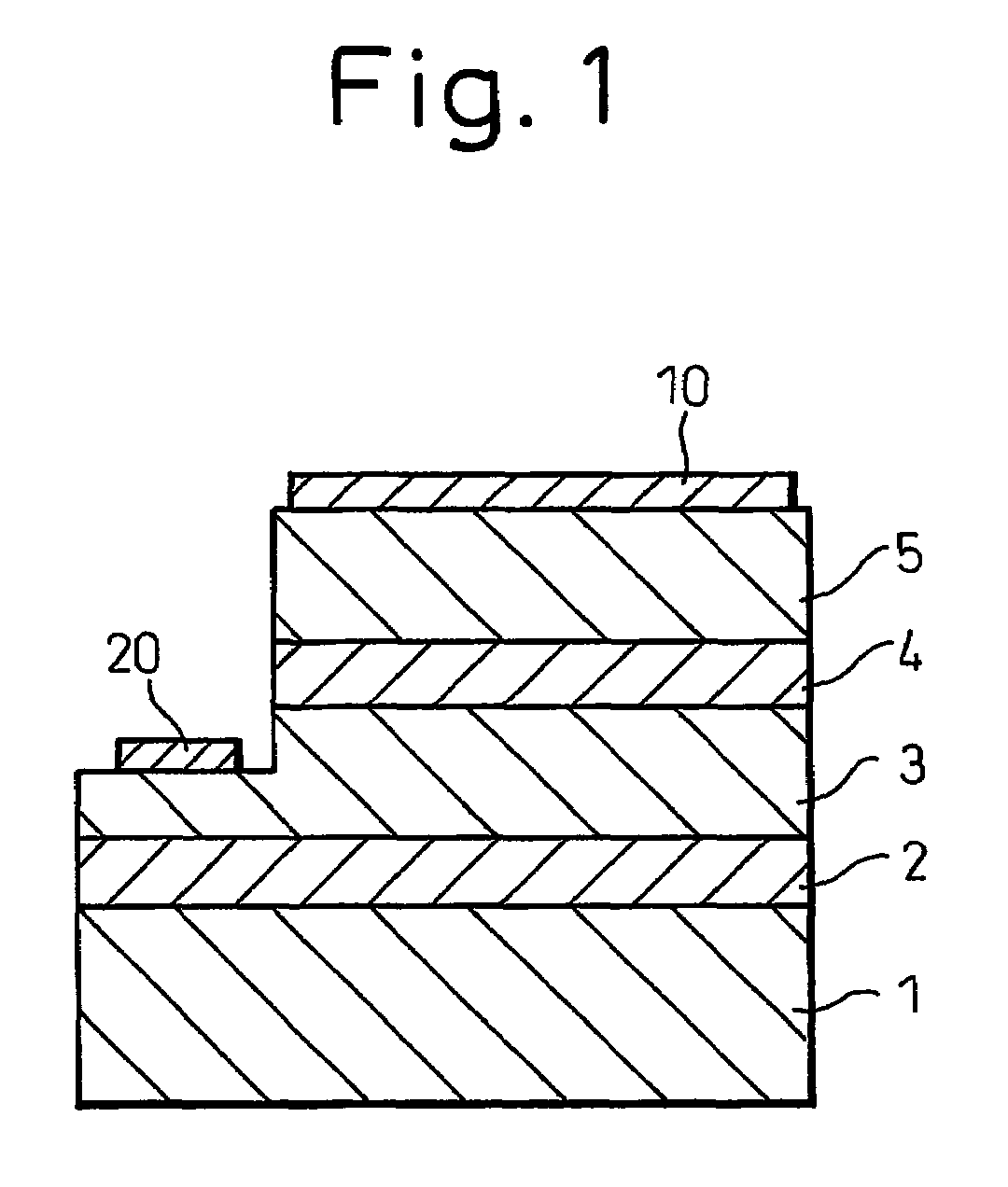

Method of fabricating a multilayer dielectric tunnel barrier structure

InactiveUS6849464B2Reduce resistanceGood shape retentionNanomagnetismChemical vapor deposition applicationMagnetic memoryNitride

A multilayer dielectric tunnel barrier structure and a method for its formation which may be used in non-volatile magnetic memory elements comprises an ALD deposited first nitride junction layer formed from one or more nitride monolayers i.e., AlN, an ALD deposited intermediate oxide junction layer formed from one or more oxide monolayers i.e., AlxOy, disposed on the first nitride junction layer, and an ALD deposited second nitride junction layer formed from one or more nitride monolayers i.e., AlN, disposed on top of the intermediate oxide junction layer. The multilayer tunnel barrier structure is formed by using atomic layer deposition techniques to provide improved tunneling characteristics while also providing anatomically smooth barrier interfaces.

Owner:MICRON TECH INC

Multilayer dielectric tunnel barrier used in magnetic tunnel junction devices, and its method of fabrication

InactiveUS6900455B2Reduce resistanceGood shape retentionNanomagnetismChemical vapor deposition applicationDielectricMagnetic memory

Owner:MICRON TECH INC

Lead-Free Solder Paste and Its Use

ActiveUS20100035072A1Readily cause leaching or electrolytic corrosionEasily brokenPrinted circuit manufactureWelding/cutting media/materialsDicarboxylic acidCarboxylic acid

A solder paste comprising a solder alloy powder and a flux. The volumetric expansion at the time of melting of the solder alloy is at most 0.5%. The flux contains a bisphenol A epoxy resin and a curing agent selected from a carboxylic anhydride and a dicarboxylic acid. The solder paste can be used in applications suitable for high-temperature solders. The solder alloy has an alloy composition comprising, in mass percent, 70-98% of Bi, a total of 0-0.5% of at least one substance selected from Ag, Cu, Sb, In, Zn, Ni, Cr, Fe, Mo, P, Ge, and Ga, and a remainder of Sn.

Owner:SENJU METAL IND CO LTD +1

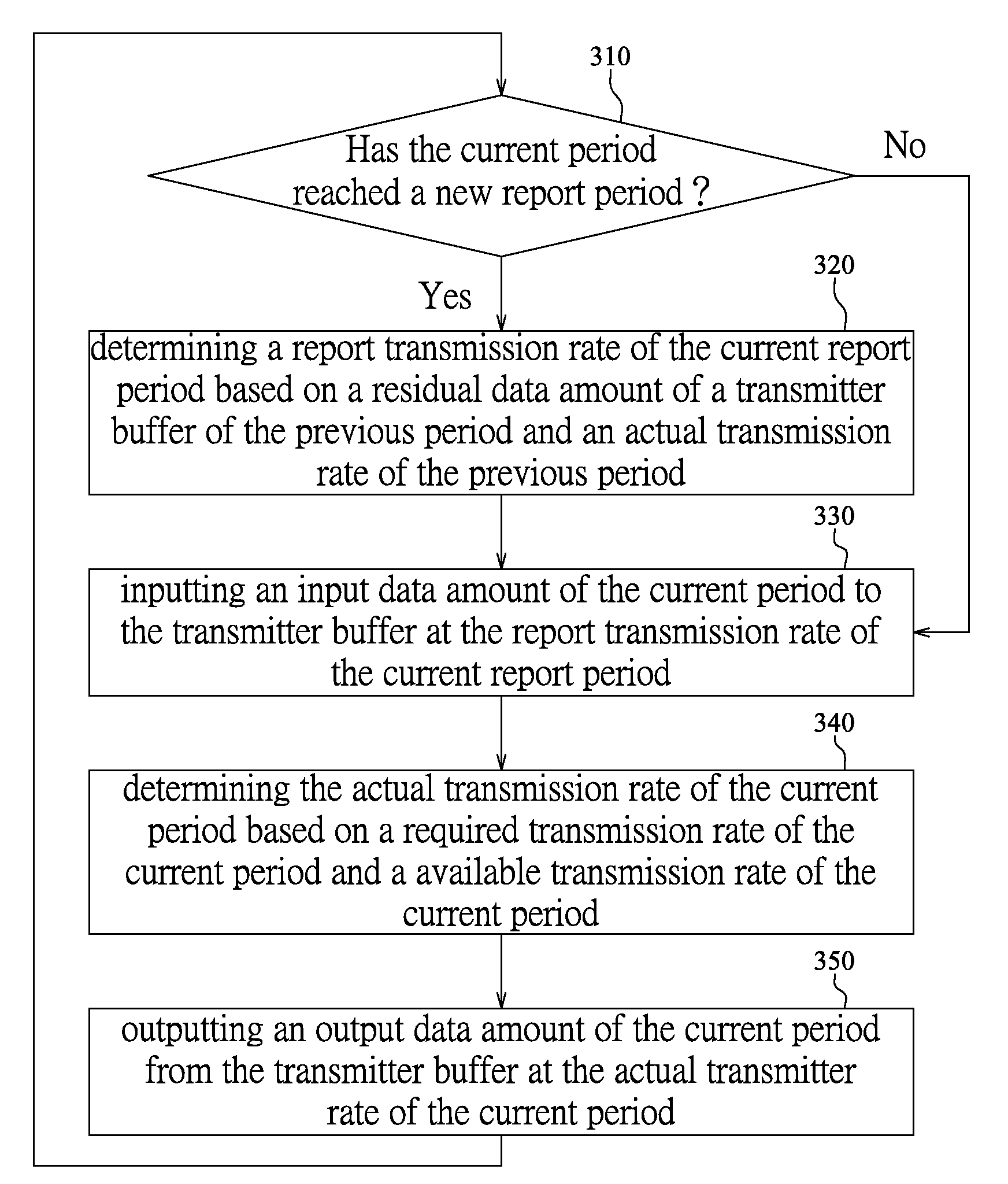

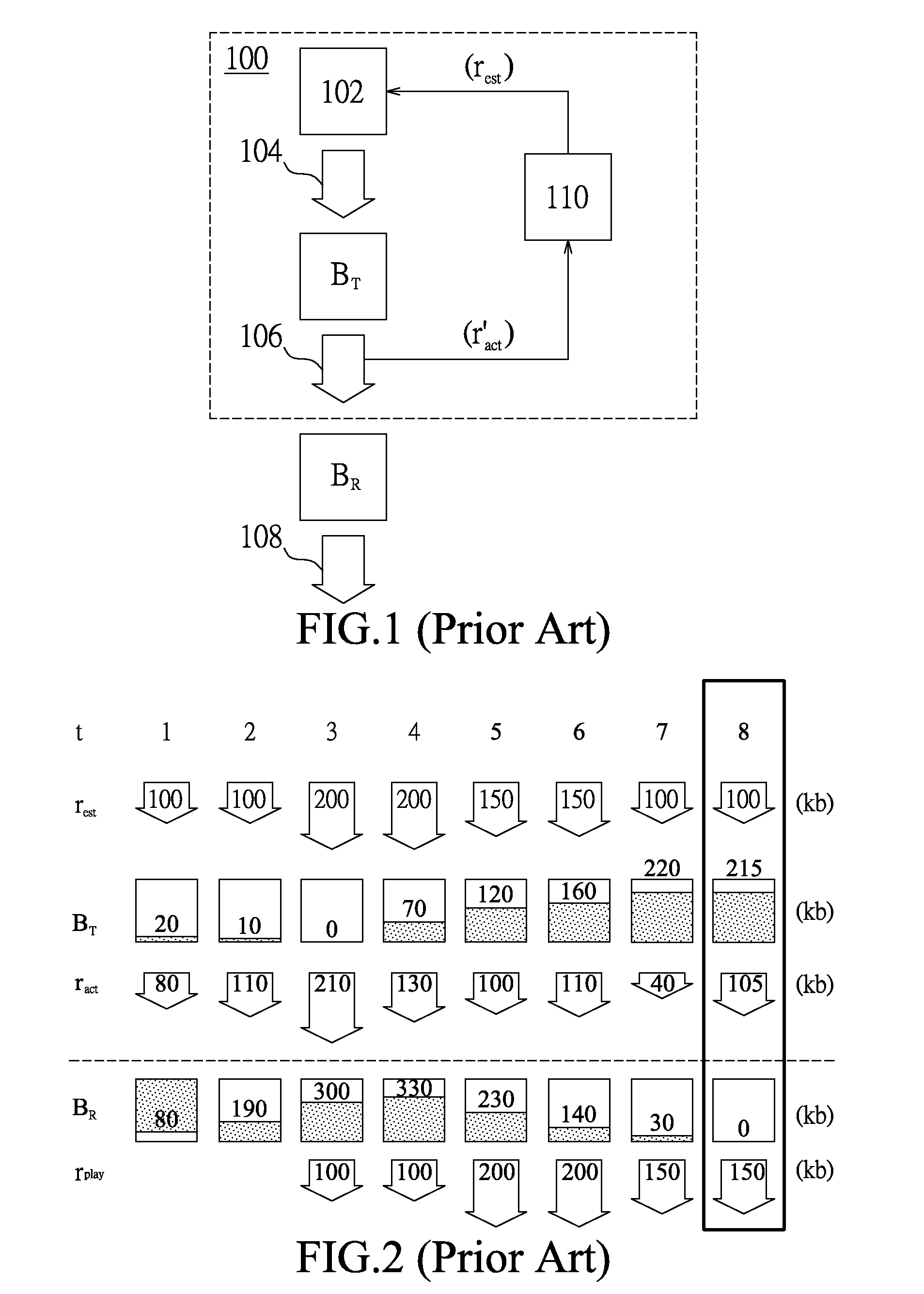

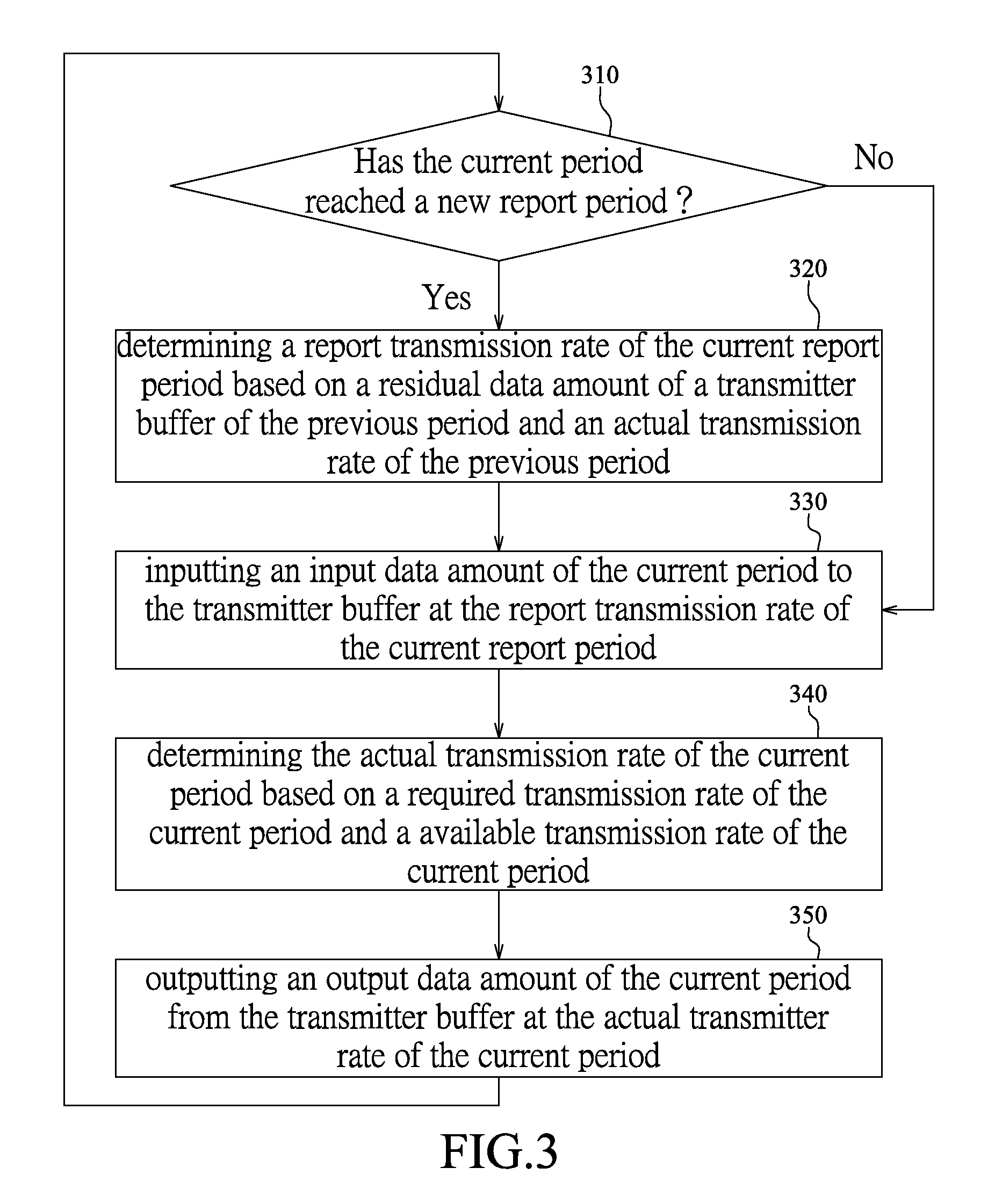

Control method of transmitting streaming audio/video data and architecture thereof

InactiveUS20100235530A1Occurrence is very lowPulse modulation television signal transmissionMultiple digital computer combinationsAudio frequencyTransmitter

A control method and architecture for controlling transmission of streaming audio / video data are disclosed. The method uses a report transmission rate on a transmitter to reduce the playback latency on a receiver. The report transmission rate is determined according to an actual transmission rate and the residual data amount of the previous period of a transmitter buffer. The actual transmission rate is the minimum of an available transmission rate and a required transmission rate, which depends on the residual data amount and the report transmission rate. Therefore, the report transmission rate is adjusted according to the accumulation of residual data of transmitter buffer, which improves the playback latency.

Owner:NAT CHIAO TUNG UNIV

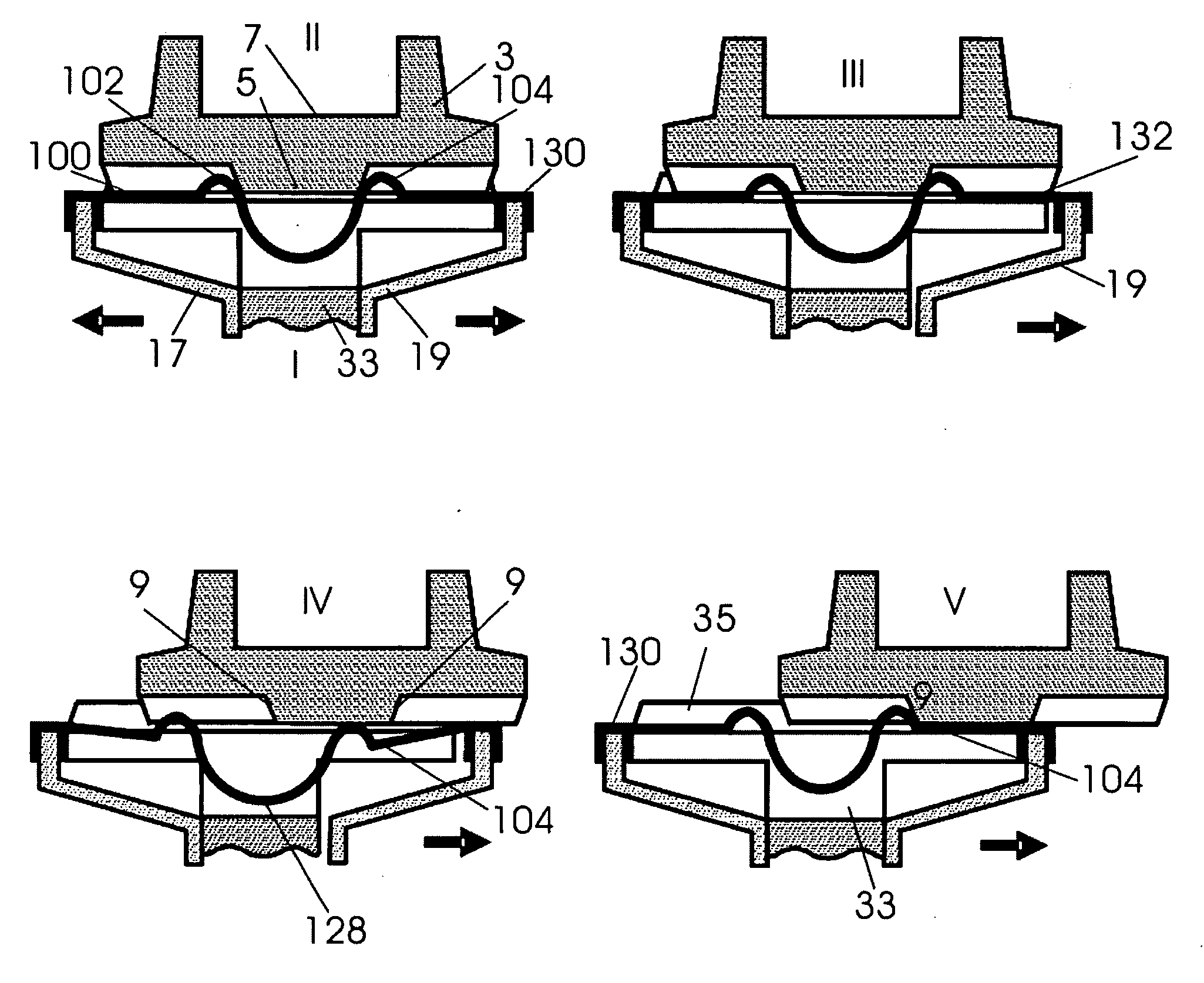

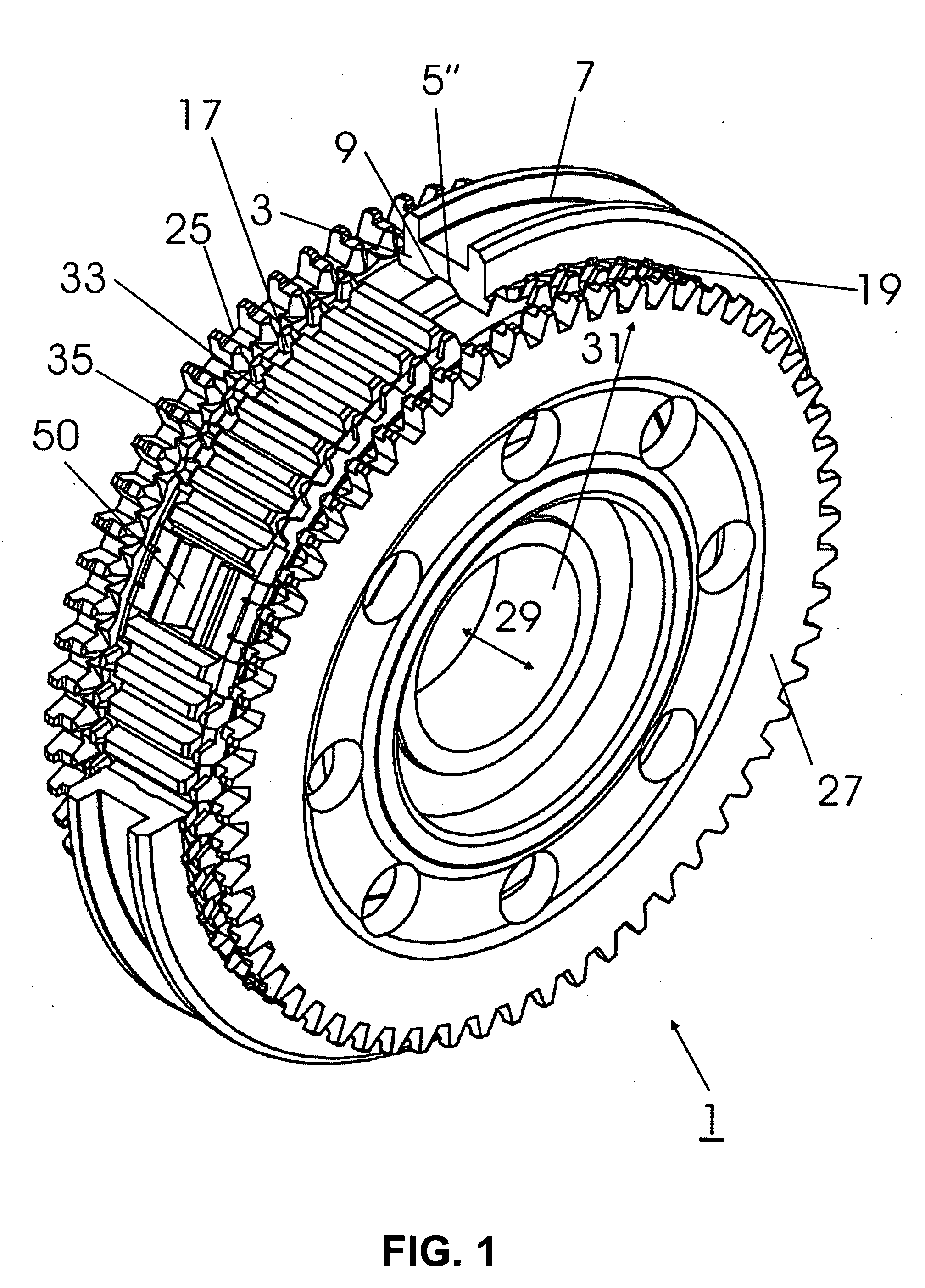

Transmission synchromesh and thrust piece of a transmission synchromesh

InactiveUS20080302624A1Spread the wordImprove reliabilityFriction clutchesInterengaging clutchesDetentEngineering

A transmission synchromesh is provided that includes a pressure element coupled to a synchronizing ring, and one shift sleeve, wherein the pressure element for detent permits an axial position displacement of the shift sleeve relative therewith. A pressure element and a transmission synchromesh method for improved synchronization are also provided.

Owner:HOFER PDC

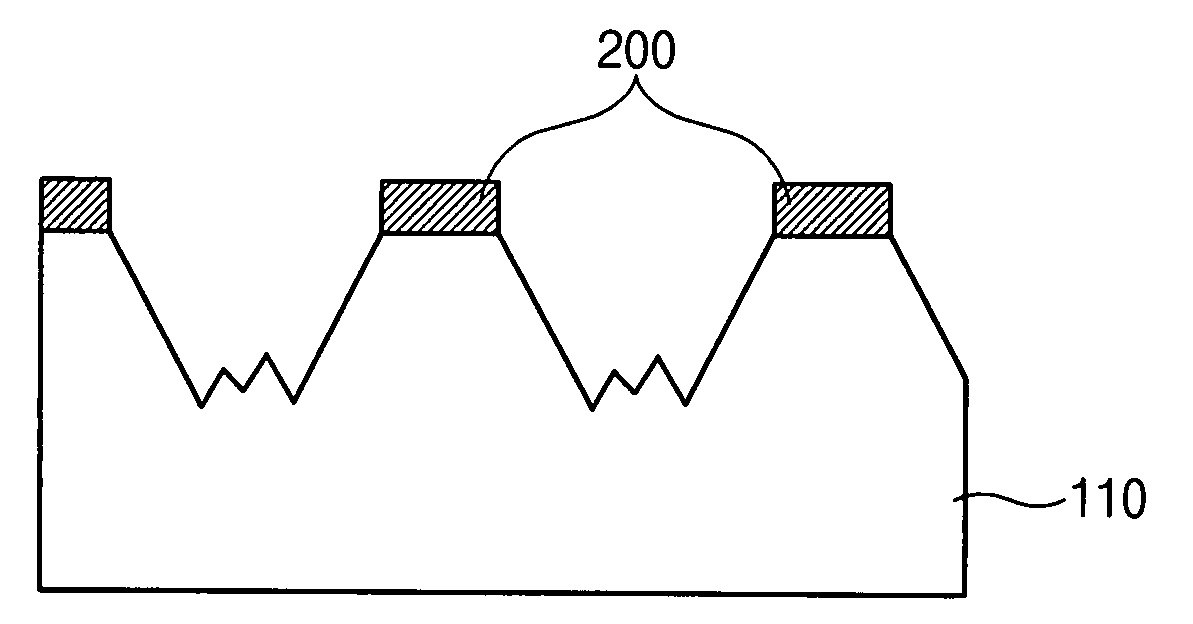

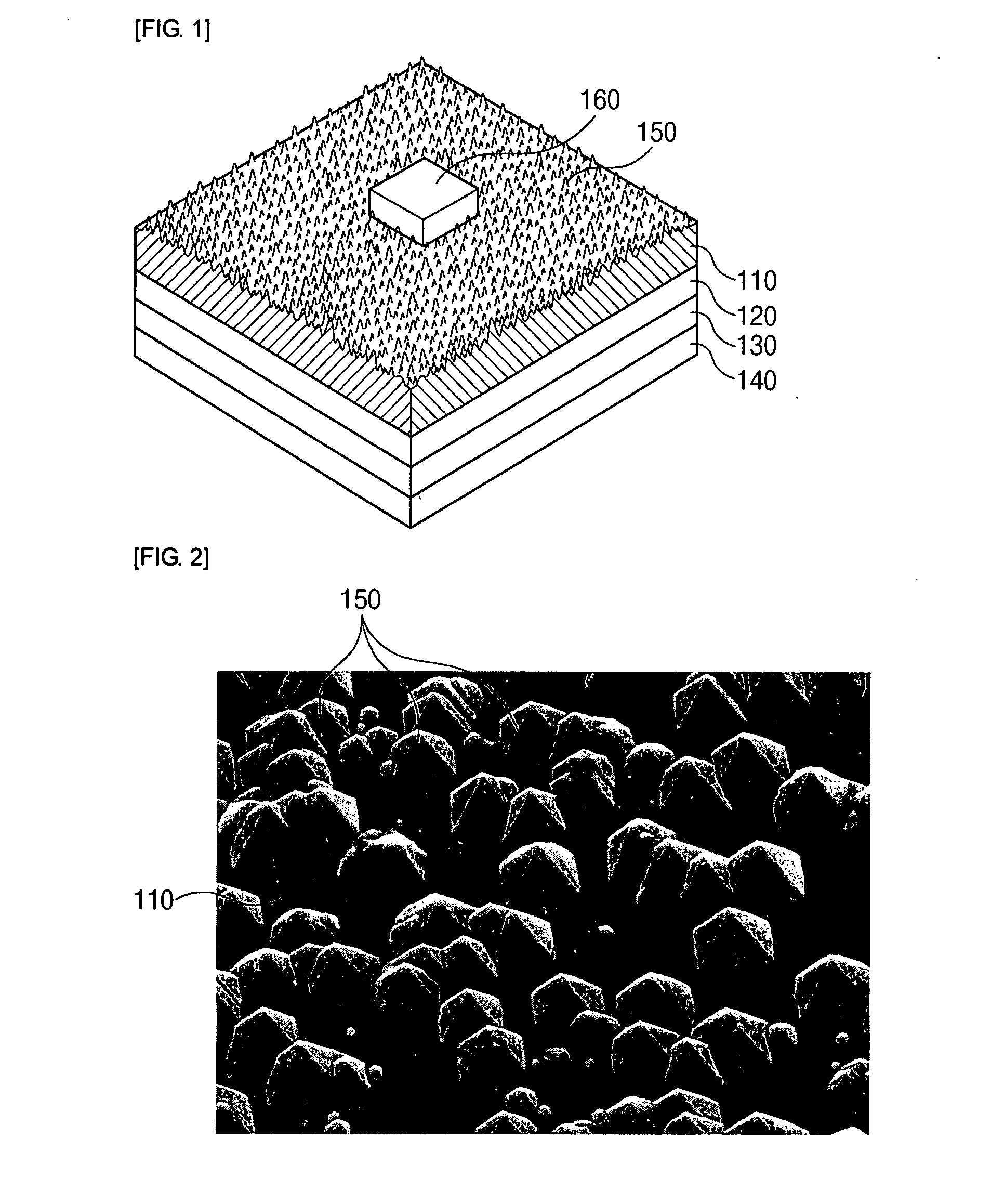

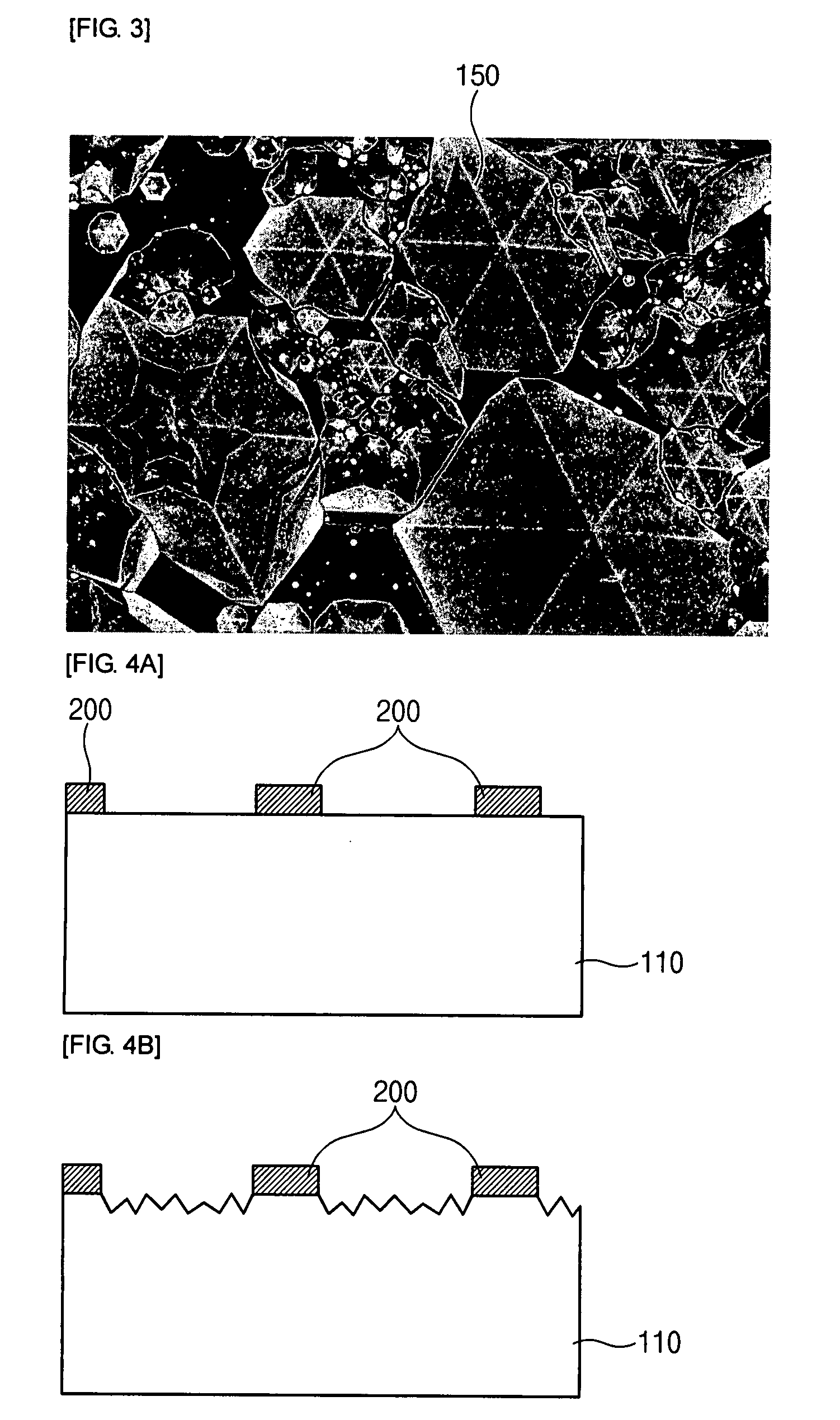

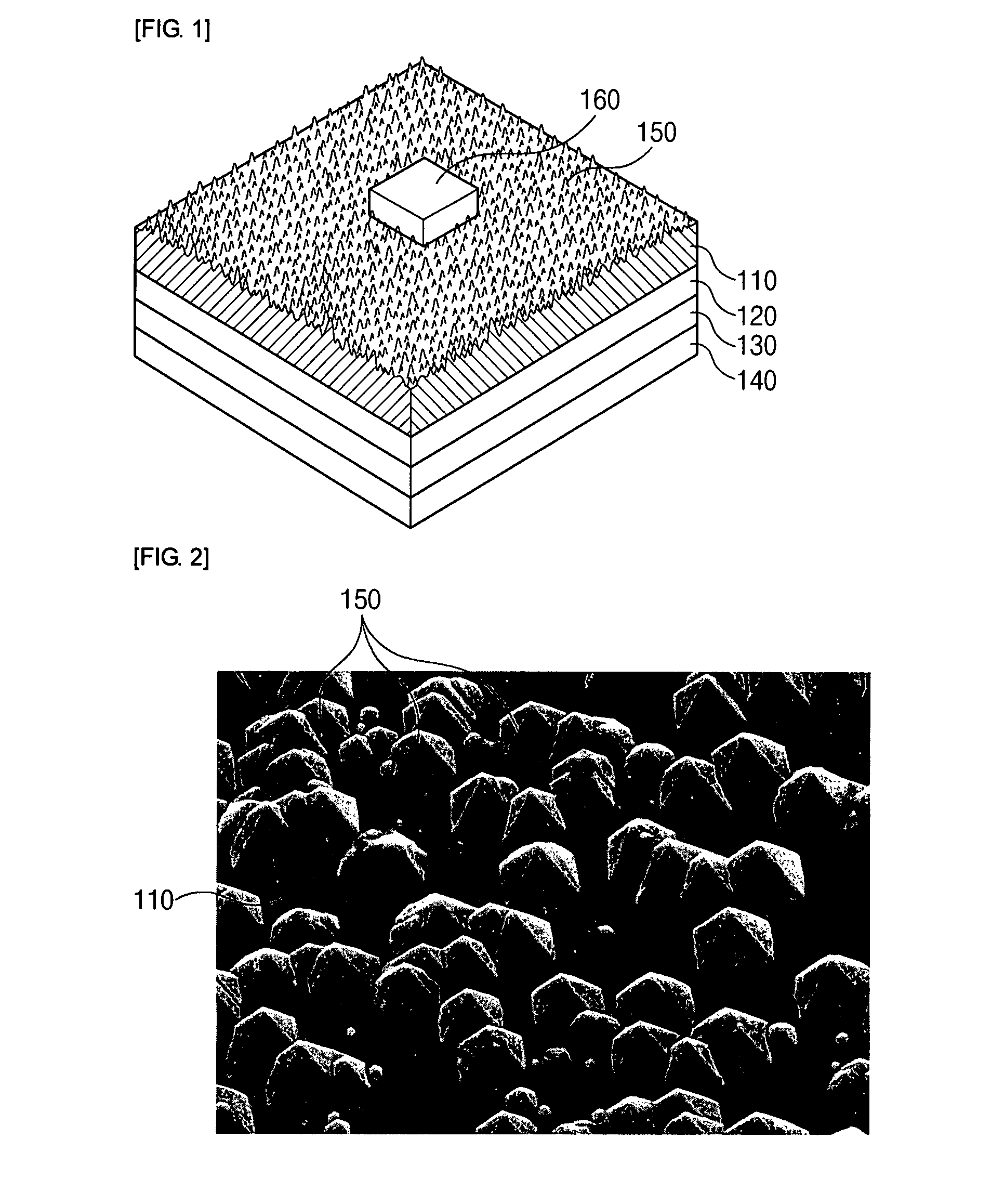

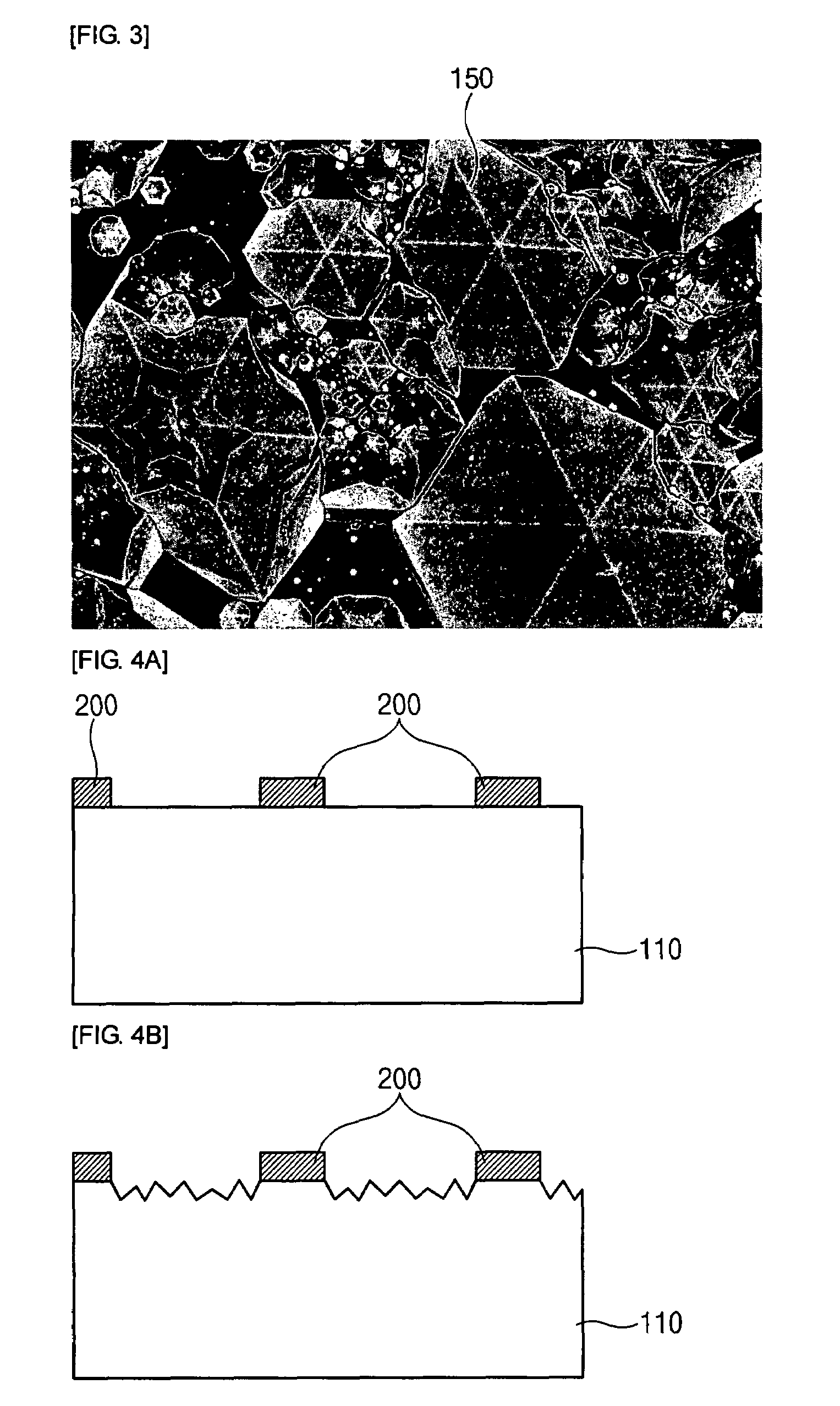

Method of forming surface irregularities and method of manufacturing gallium nitride-based light emitting diode

ActiveUS20080044937A1Low rate of occurrenceReduce incidenceSemiconductor/solid-state device manufacturingSemiconductor devicesGallium nitrideEtching

A method of forming surface irregularities comprises preparing a GaN substrate; forming a mask on a surface of the GaN substrate, the mask defining a surface-irregularity formation region; and wet-etching portions of the surface of the GaN substrate by using the mask as an etching mask. The wet-etching of the GaN substrate is performed until the end of one surface of the GaN substrate to be formed by the wet-etching using the mask meets the end of another surface of the GaN substrate to be formed by the wet-etching using the mask, the another surface being adjacent to the one surface.

Owner:SAMSUNG ELECTRONICS CO LTD

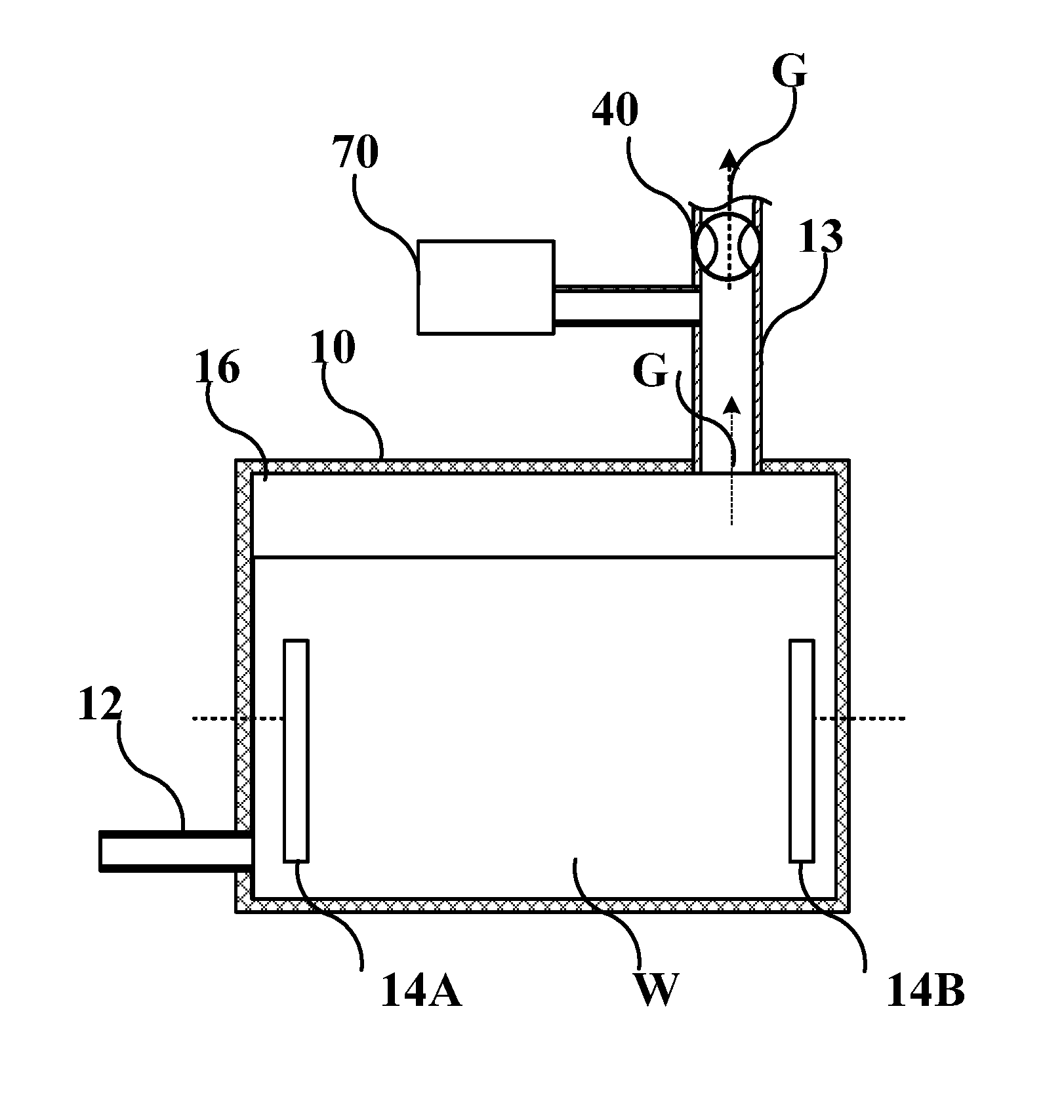

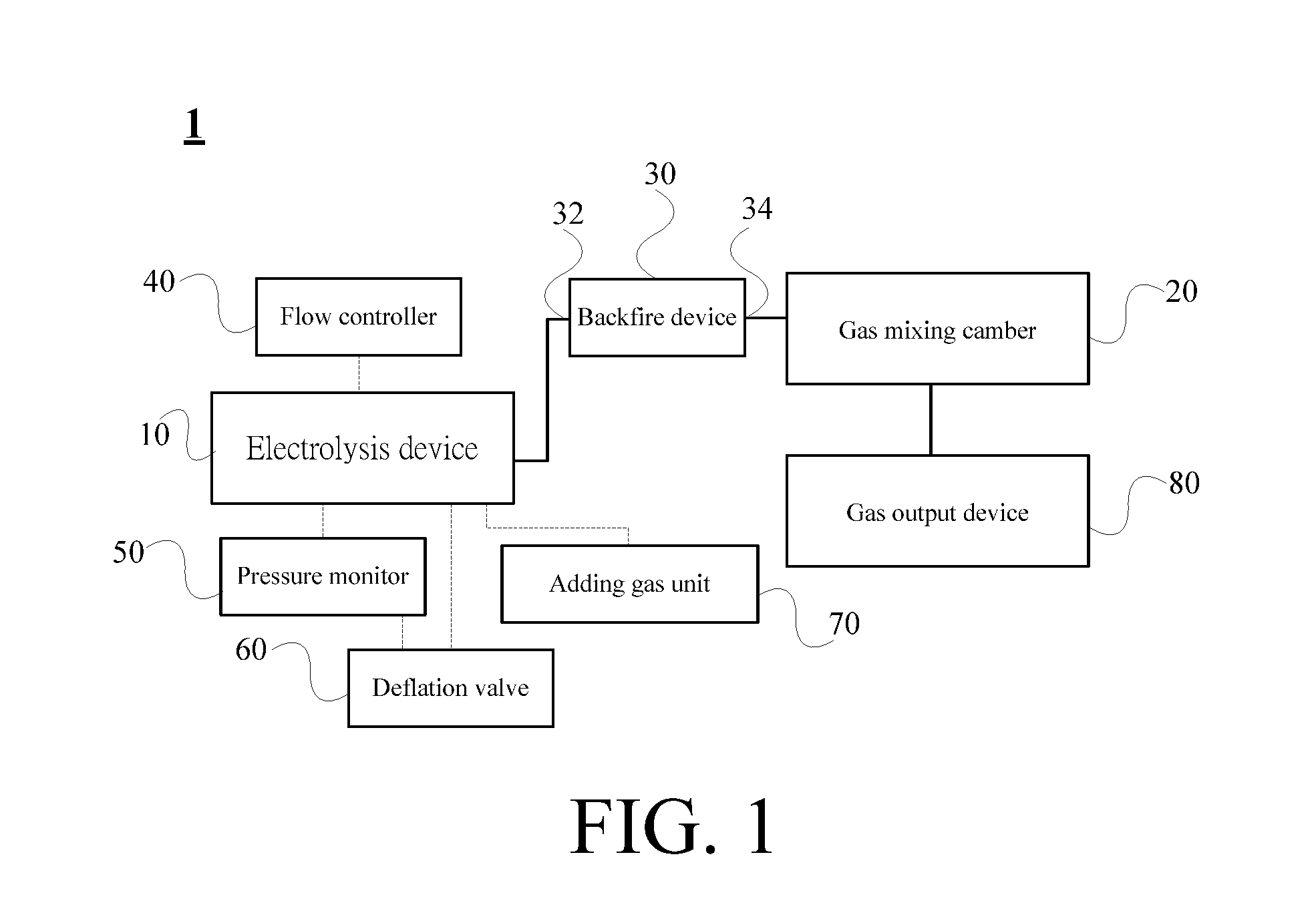

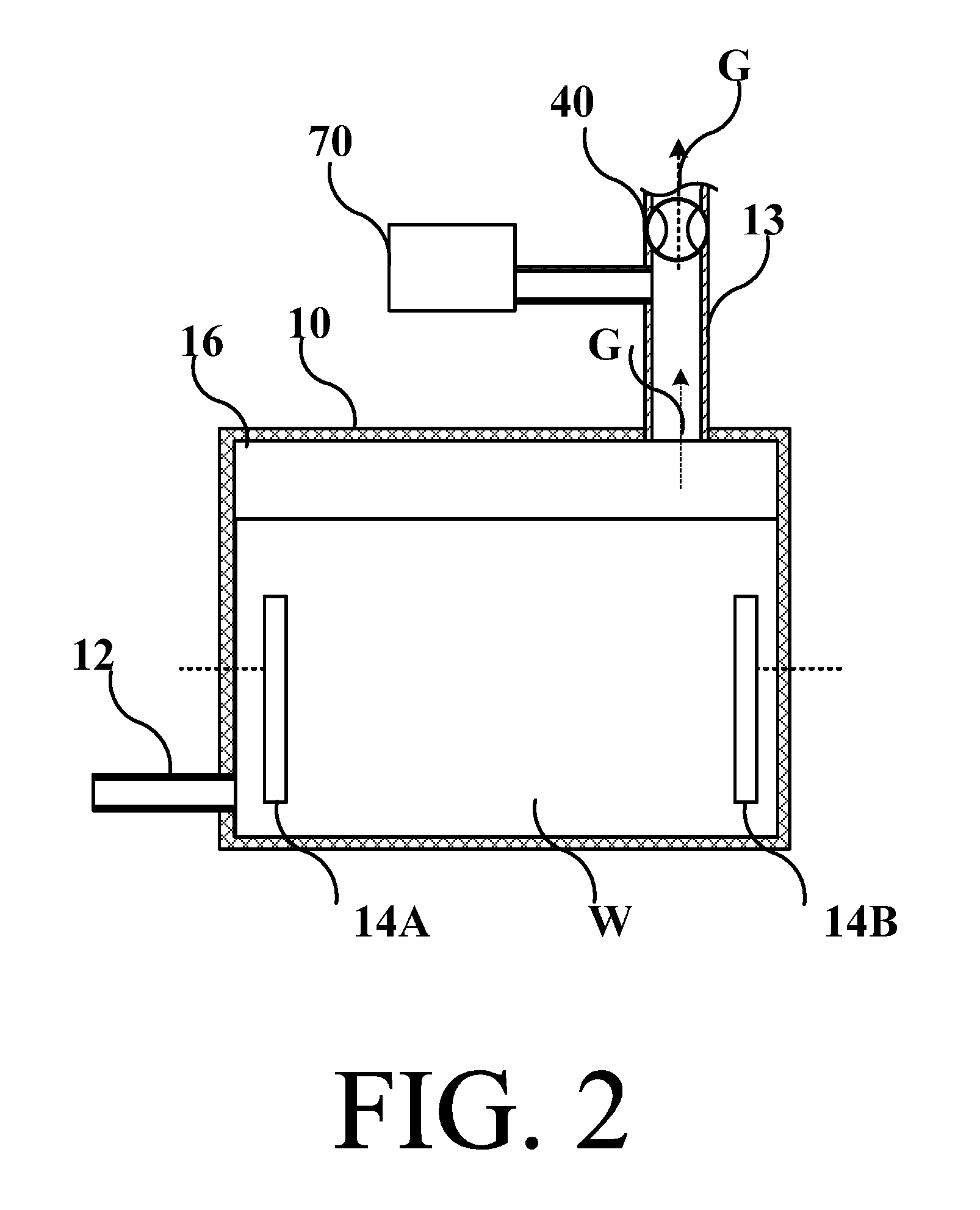

Gas generator

A gas generator for health is provided. The gas generator for health includes an electrolysis device, a gas mixing chamber and a gas output device. The electrolysis device is for electrolyzing water to produce a combination gas including hydrogen and oxygen. The gas mixing chamber includes a shell and a cover. The shell has an anti-explosion hole. The cover is separatably disposed on the anti-explosion hole, and the diameter of the anti-explosion hole is larger than 0.5 cm. The gas mixing chamber is connected to the electrolysis device for receiving the combination gas. A vaporized gas is generated by the gas mixing chamber and mixed with the combination gas to produce a healthy gas. The gas output device is connected to the gas mixing chamber for outputting the healthy gas to a user to breath.

Owner:LIN HSIN YUNG

Method of forming surface irregularities and method of manufacturing gallium nitride-based light emitting diode

ActiveUS7601621B2Reduce incidenceOccurrence is very lowSemiconductor/solid-state device manufacturingSemiconductor devicesEtchingGallium nitride

Owner:SAMSUNG ELECTRONICS CO LTD

Lead-free solder paste and its use

ActiveUS8227536B2Readily cause leaching or electrolytic corrosionEasily brokenPrinted circuit manufactureWelding/cutting media/materialsCarboxylic acidDicarboxylic acid

A solder paste comprising a solder alloy powder and a flux. The volumetric expansion at the time of melting of the solder alloy is at most 0.5%. The flux contains a bisphenol A epoxy resin and a curing agent selected from a carboxylic anhydride and a dicarboxylic acid. The solder paste can be used in applications suitable for high-temperature solders. The solder alloy has an alloy composition comprising, in mass percent, 70-98% of Bi, a total of 0-0.5% of at least one substance selected from Ag, Cu, Sb, In, Zn, Ni, Cr, Fe, Mo, P, Ge, and Ga, and a remainder of Sn.

Owner:SENJU METAL IND CO LTD +1

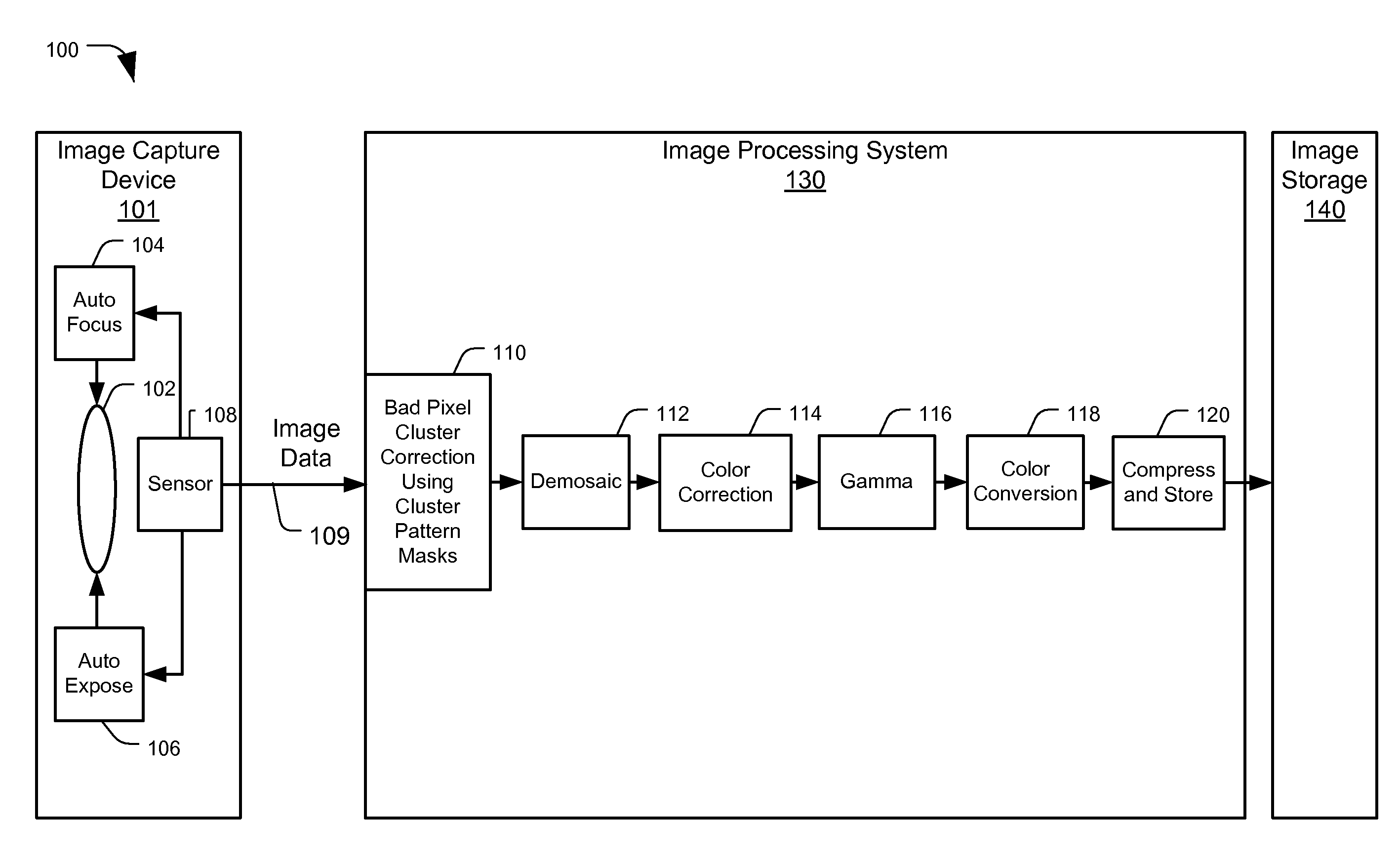

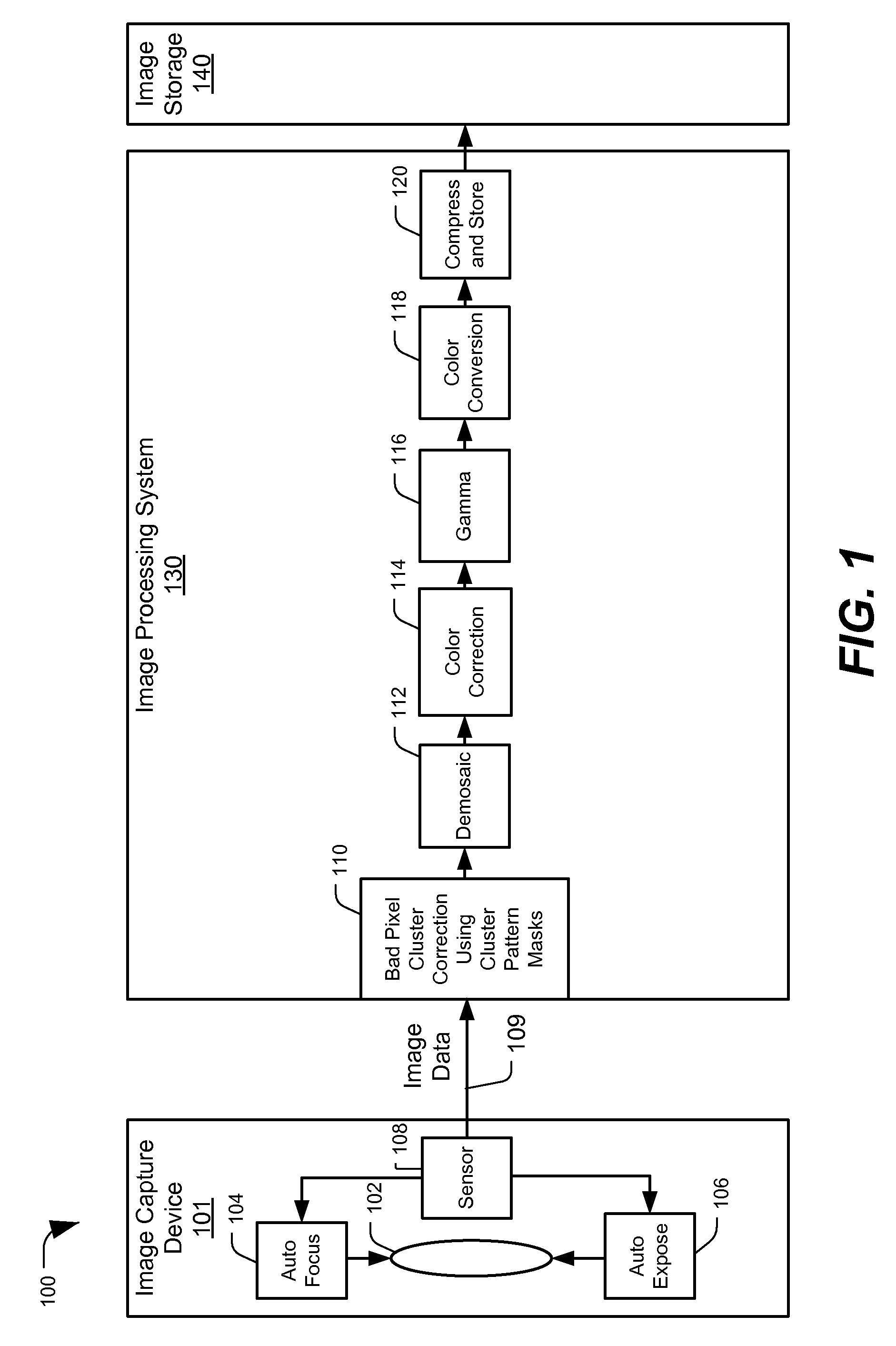

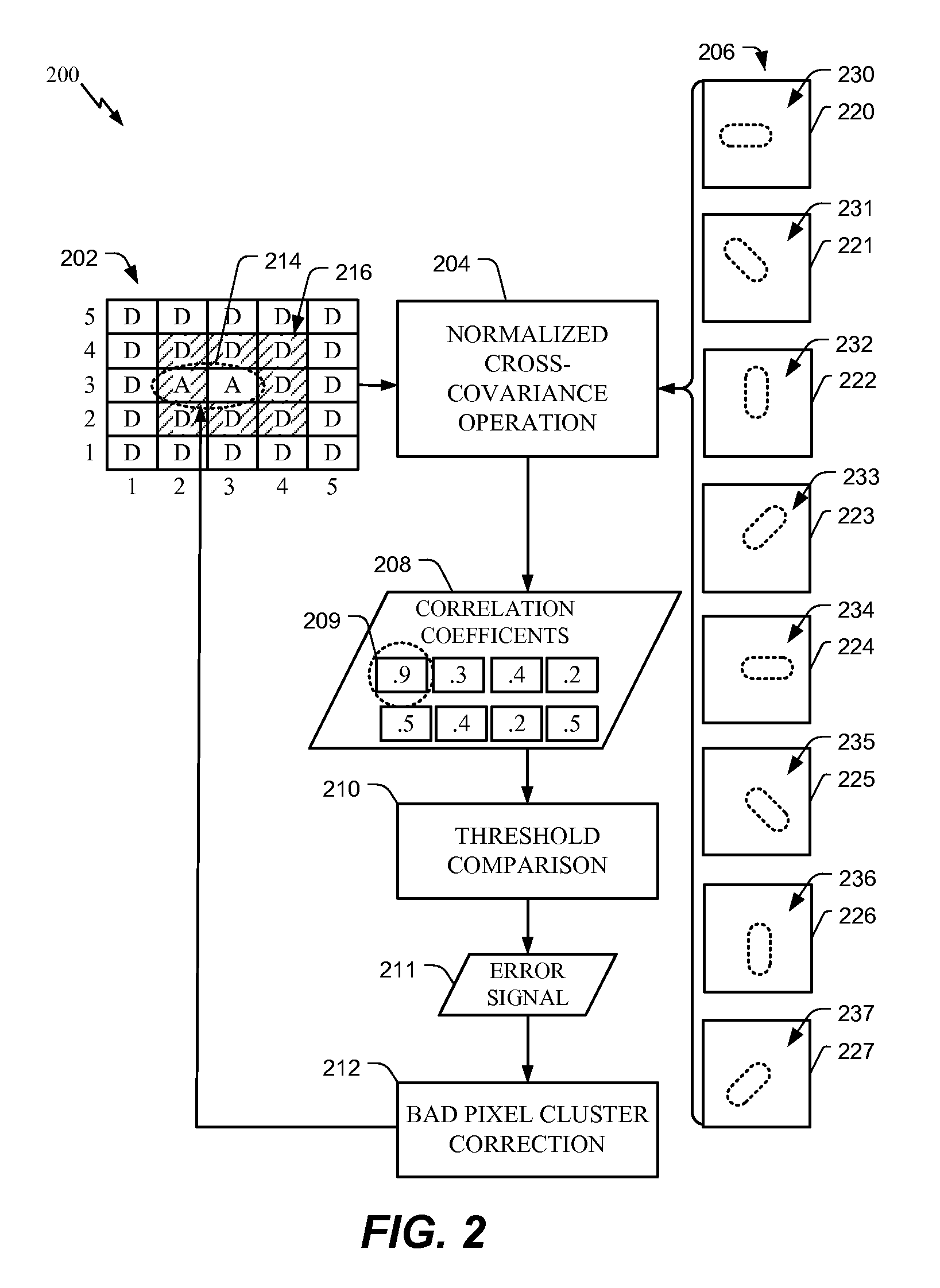

Bad pixel cluster detection

InactiveUS8208044B2Improve accuracyOccurrence is very lowTelevision system detailsColor signal processing circuitsCorrelation coefficientComputer vision

Owner:QUALCOMM INC

Method for manufacturing p-type group iii nitride semiconductor, and group iii nitride semiconductor light-emitting device

ActiveUS20070090369A1Few stepsIncrease production capacityPolycrystalline material growthLaser detailsDopantLight emitting device

An object of the present invention is to provide an efficient method for manufacturing a p-type group III nitride semiconductor that has adequate carrier concentration and a surface with a low occurrence of crystal damage. The inventive method for manufacturing a p-type group III nitride semiconductor comprises: (a) growing a group III nitride semiconductor containing a p-type dopant at 1000° C. or higher in an atmosphere containing H2 gas and / or NH3 gas; and (b) after the growth of the group III nitride semiconductor, substituting the H2 gas and NH3 gas with an inert gas at a temperature higher than 800° C. while reducing the temperature.

Owner:TOYODA GOSEI CO LTD

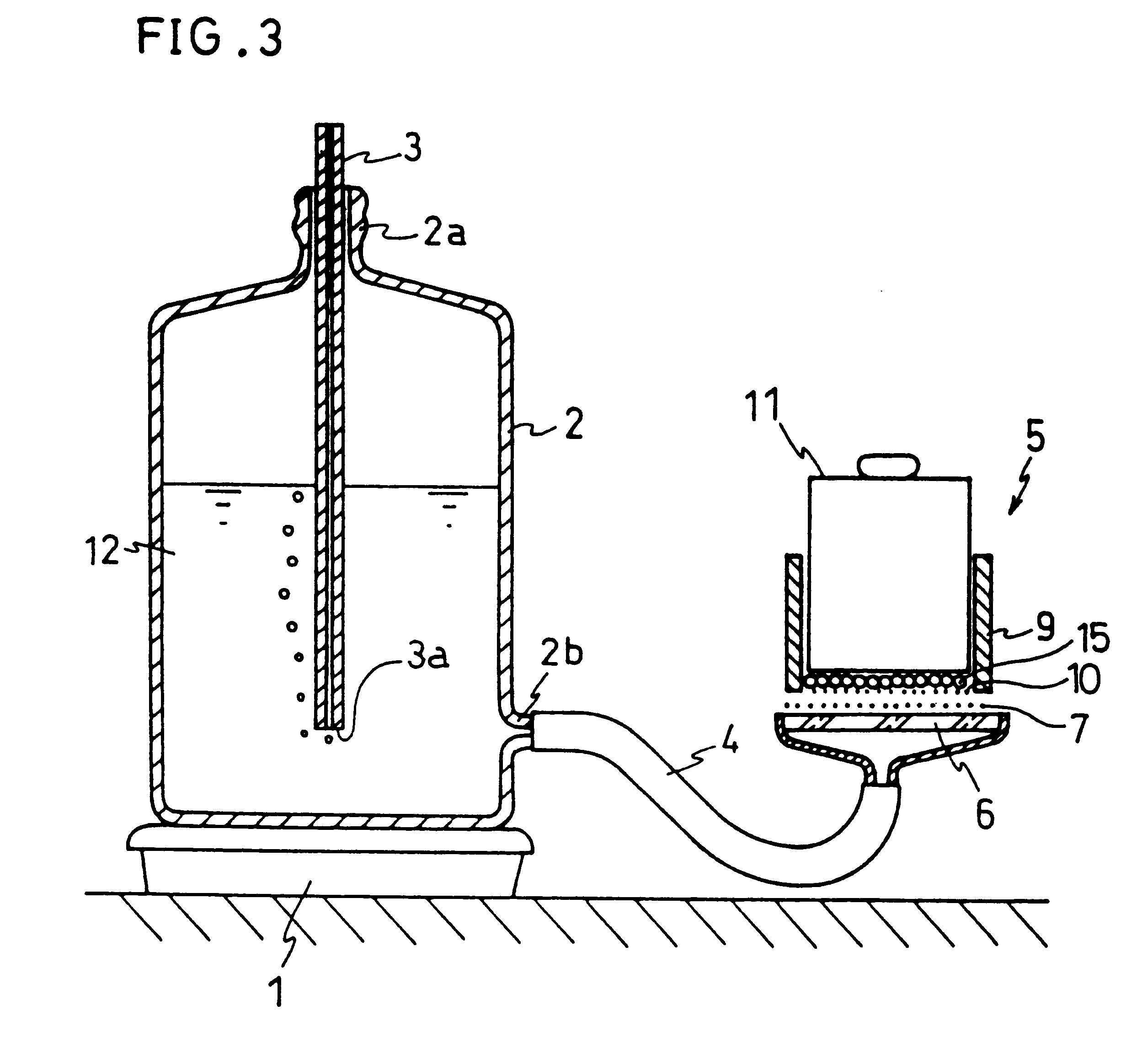

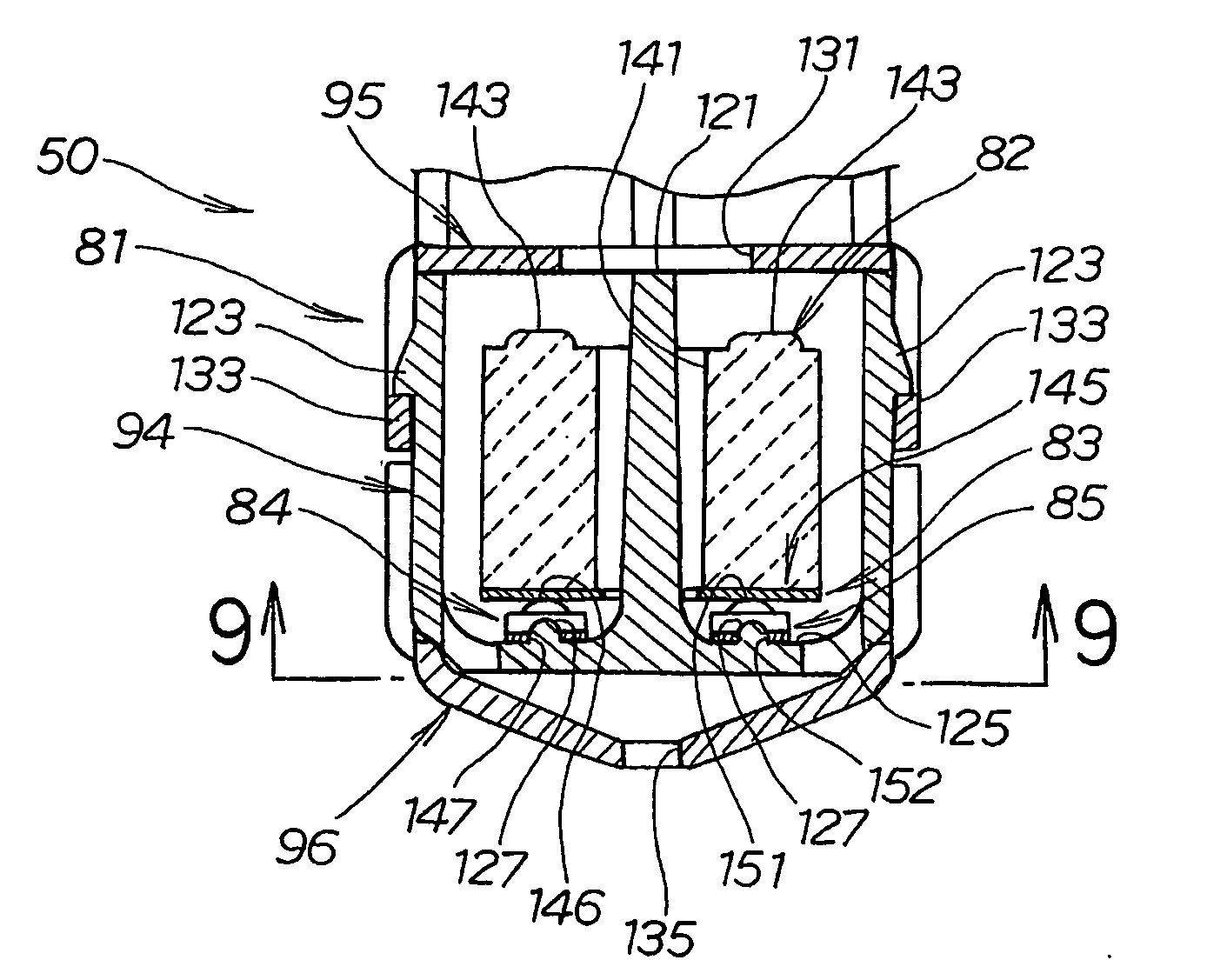

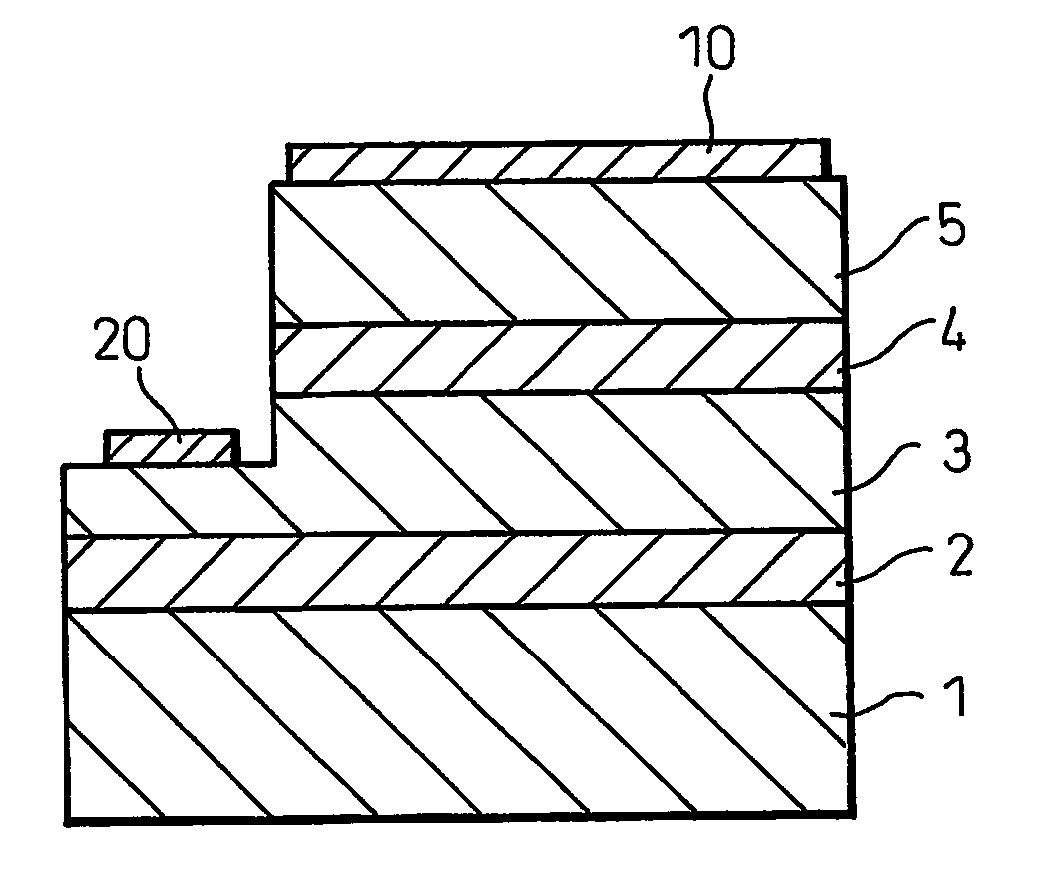

Sealed battery

ActiveUS20090087736A1Occurrence is very lowPrevent movementActive material electrodesWound/folded electrode electrodesEngineeringElectrical and Electronics engineering

A sealed battery including: an electrode assembly 11 having multiple positive electrode substrates exposed at one end and negative electrode substrates exposed at the other end; and collectors 181 and collector receiving parts 183 that are resistance-welded on both sides of the multiple positive or the multiple negative electrode substrates or both, grooves 23 being formed around the resistance-welded portion of at least one of the collector 181 and the collector receiving part 183. Due to the spattered particles 26 generated during the resistance-welding being captured within the grooves 23, few particles burst into the inside of the electrode assembly 11 or into the outside.

Owner:SANYO ELECTRIC CO LTD

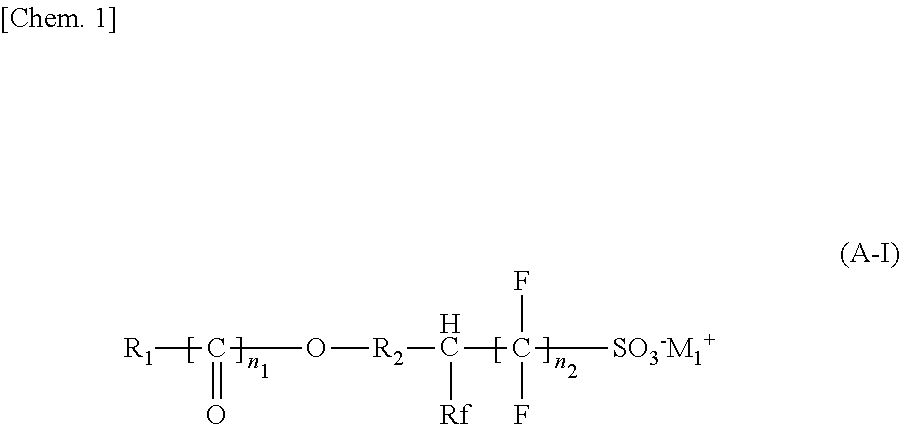

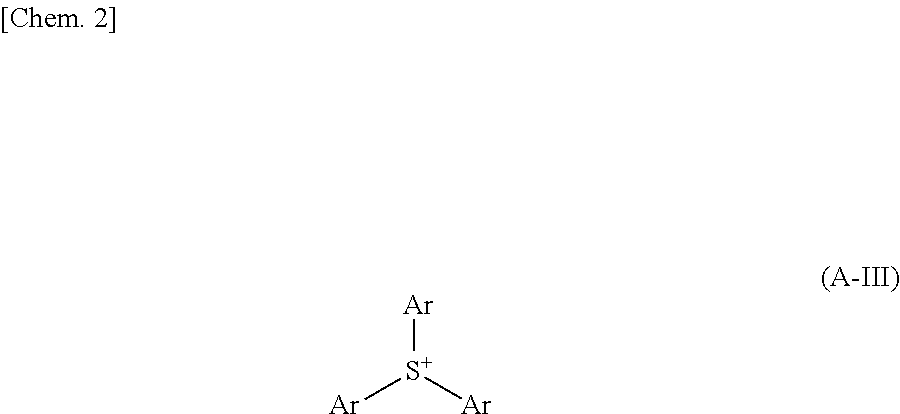

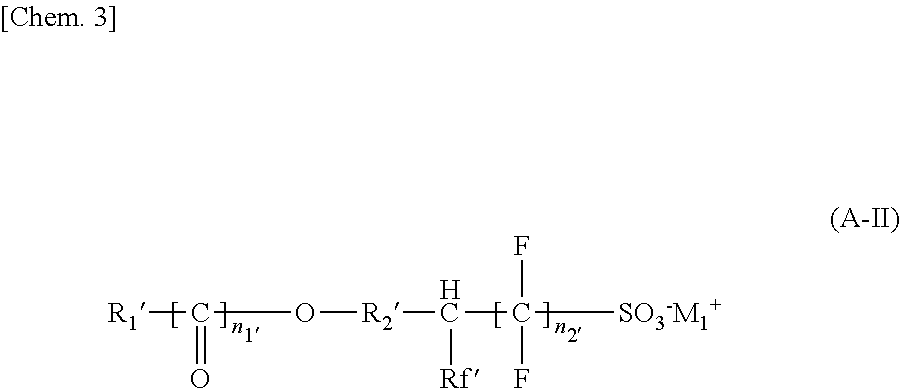

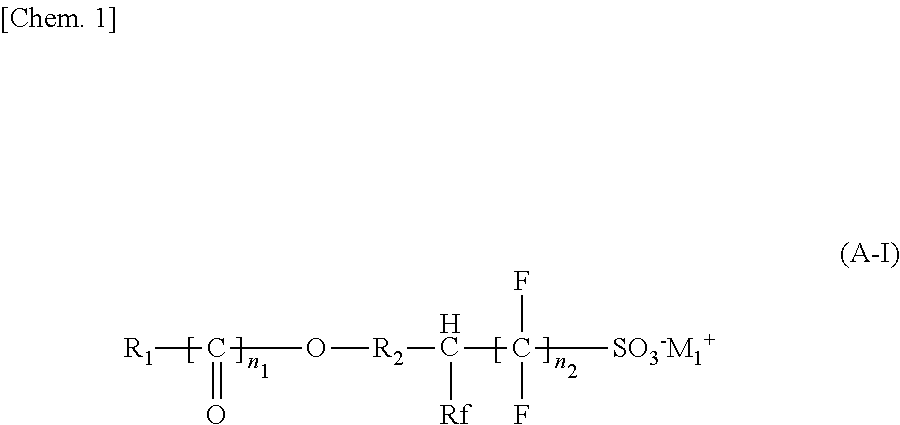

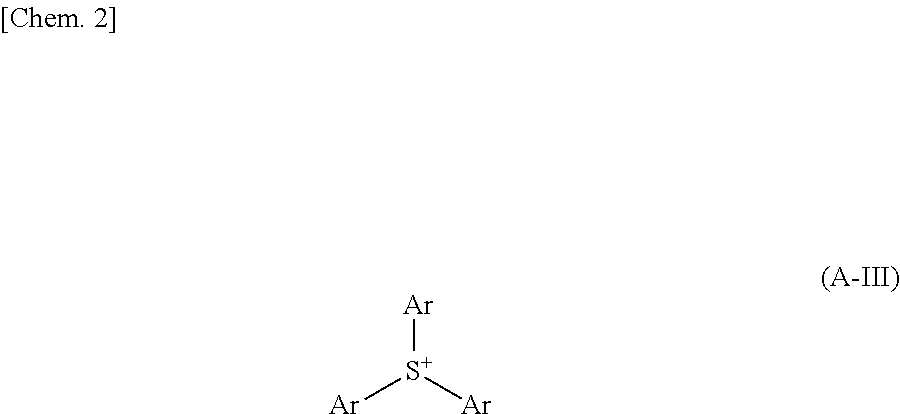

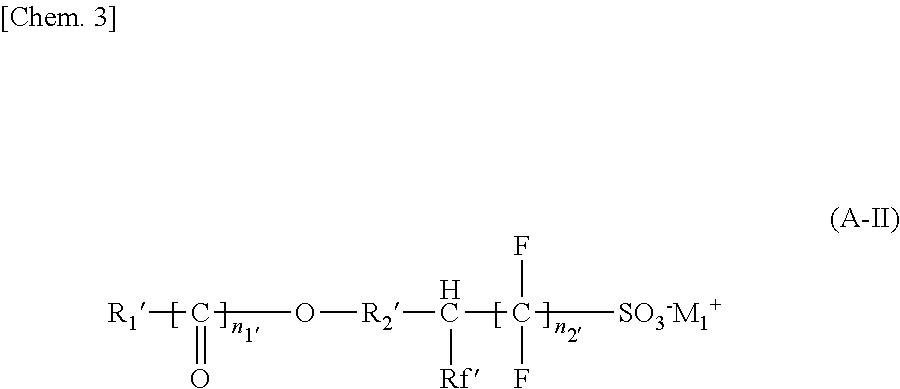

Actinic ray-sensitive or radiation-sensitive resin composition, and, resist film, pattern forming method, electronic device manufacturing method, and electronic device, each using the composition

ActiveUS9291892B2Pattern roughnessOccurrence is very lowPhotomechanical exposure apparatusMicrolithography exposure apparatusActinic RaysChemical compound

Disclosed are an actinic ray-sensitive or radiation-sensitive resin composition including (A) a compound capable of generating an acid by irradiation of actinic rays or radiation, and (B) a resin of which solubility in an alkali developer increases by being decomposed by the action of an acid, and, a resist film, a pattern forming method, an electronic device manufacturing method, and an electronic device, each using the composition, wherein the actinic ray-sensitive or radiation-sensitive resin composition contains at least one type of a specific compound represented by General Formula (A-I) and at least one type of a specific compound represented by General Formula (A-II) as the compound (A).

Owner:FUJIFILM CORP

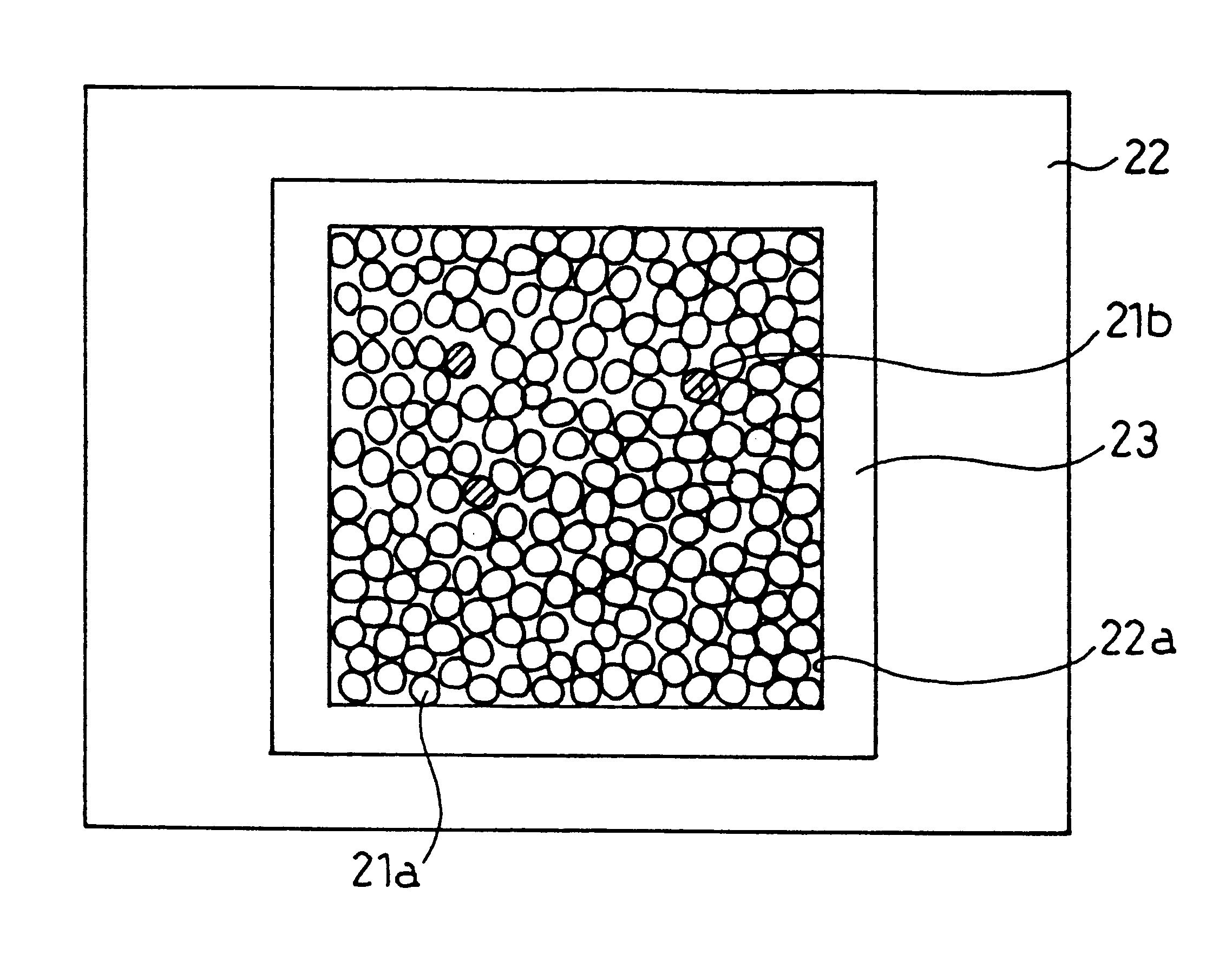

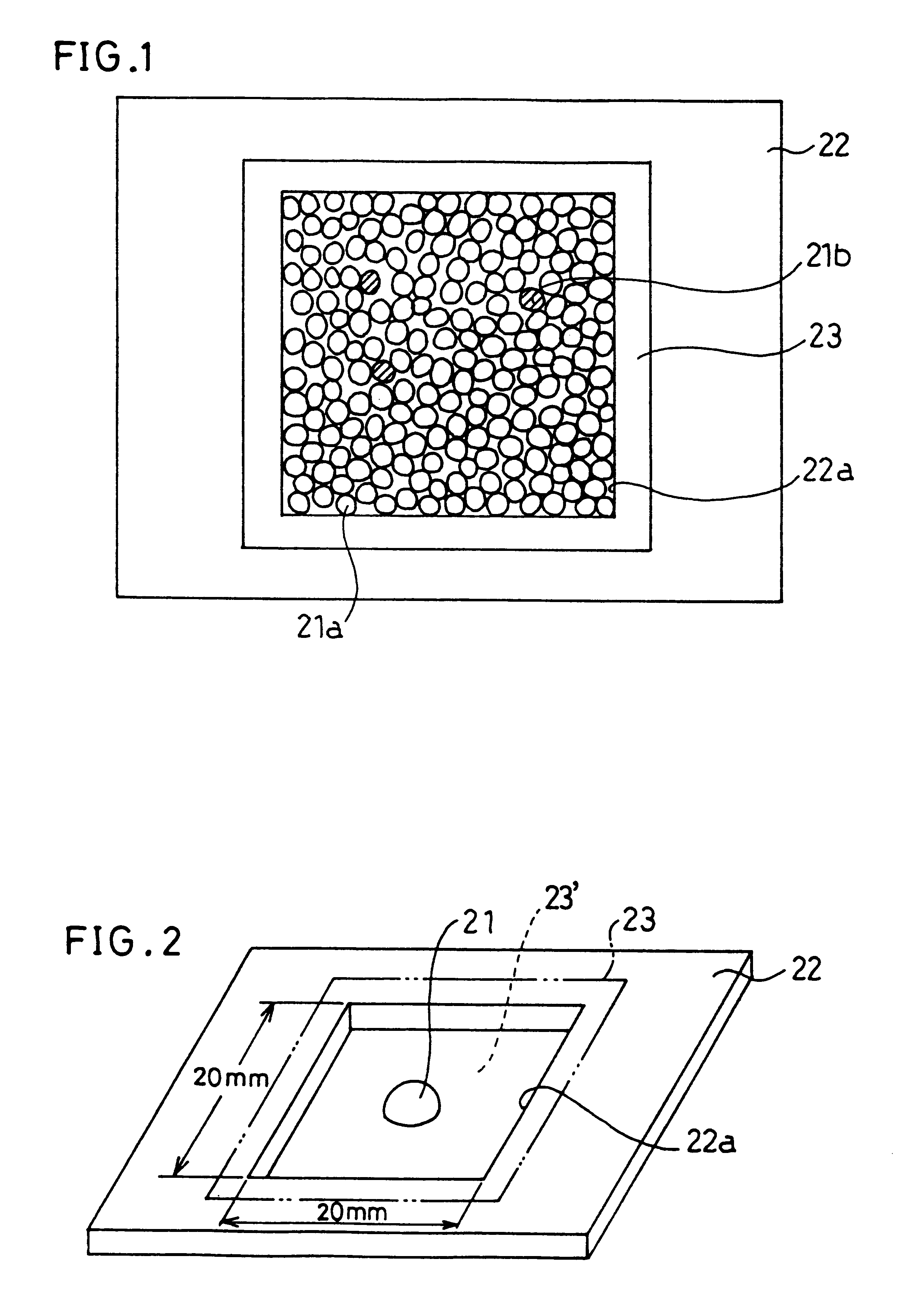

Coating material and container coated with the coating material

ActiveUS8394884B2Good chemical resistanceMaintain good propertiesSynthetic resin layered productsMixingPhysical chemistryAqueous dispersion

A coating material includes a first aqueous dispersion (A) and a second aqueous dispersion (B) wherein a dispersoid of the first aqueous dispersion (A) has an average particle diameter of 1 to 20 μm and a dispersoid of the second aqueous dispersion (B) has an average particle diameter 1 / 100 to ⅕ of that of the dispersoid of the first aqueous dispersion (A), and the mass ratio (the aqueous dispersion (A) / the aqueous dispersion (B)) of the dispersoid of the first aqueous dispersion (A) to the dispersoid of the second aqueous dispersion (B) is 2 / 1 to 100 / 1. Also provided is a container, which is coated with the coating material and has excellent properties.

Owner:TAISEI KAKO CO LTD

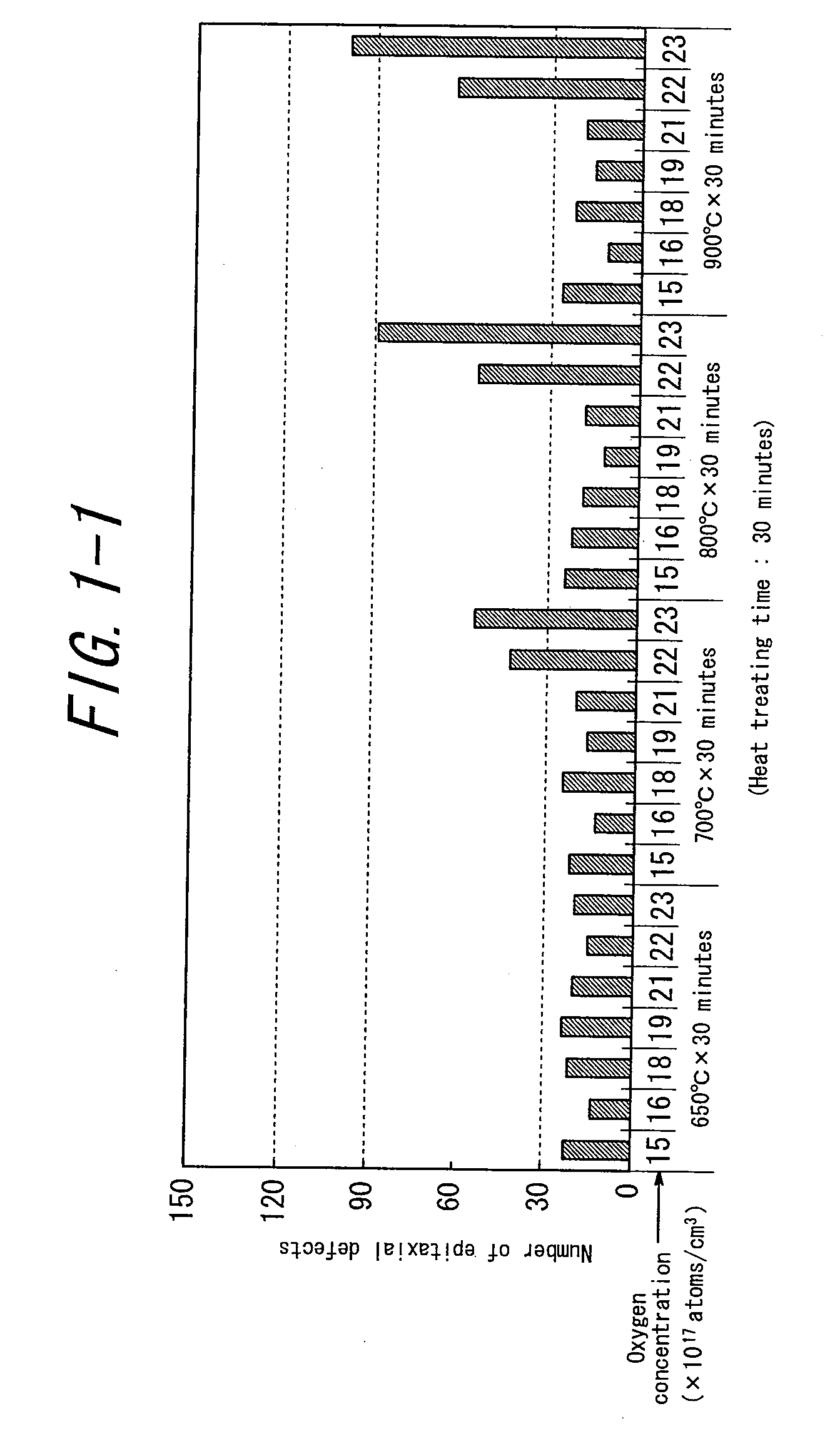

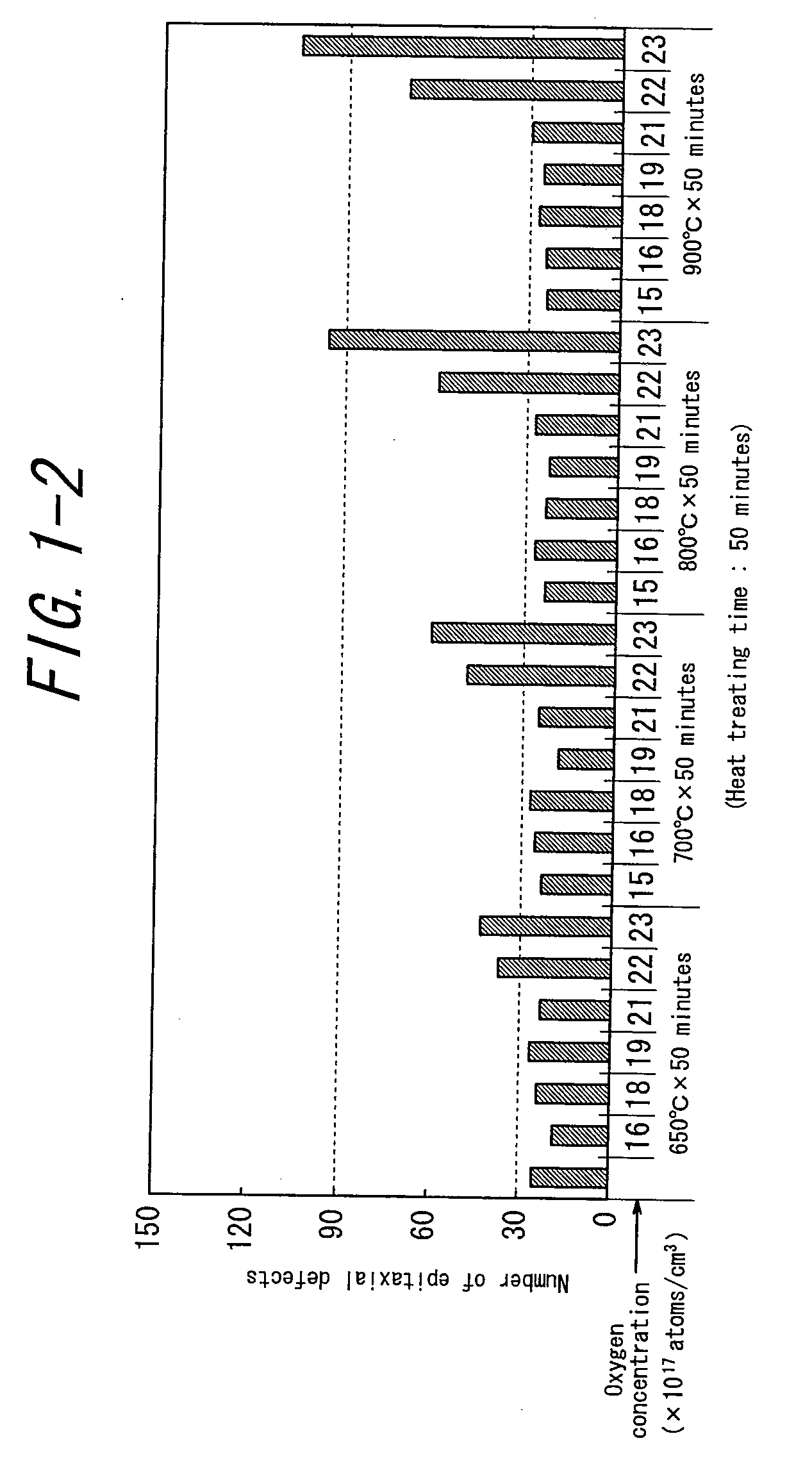

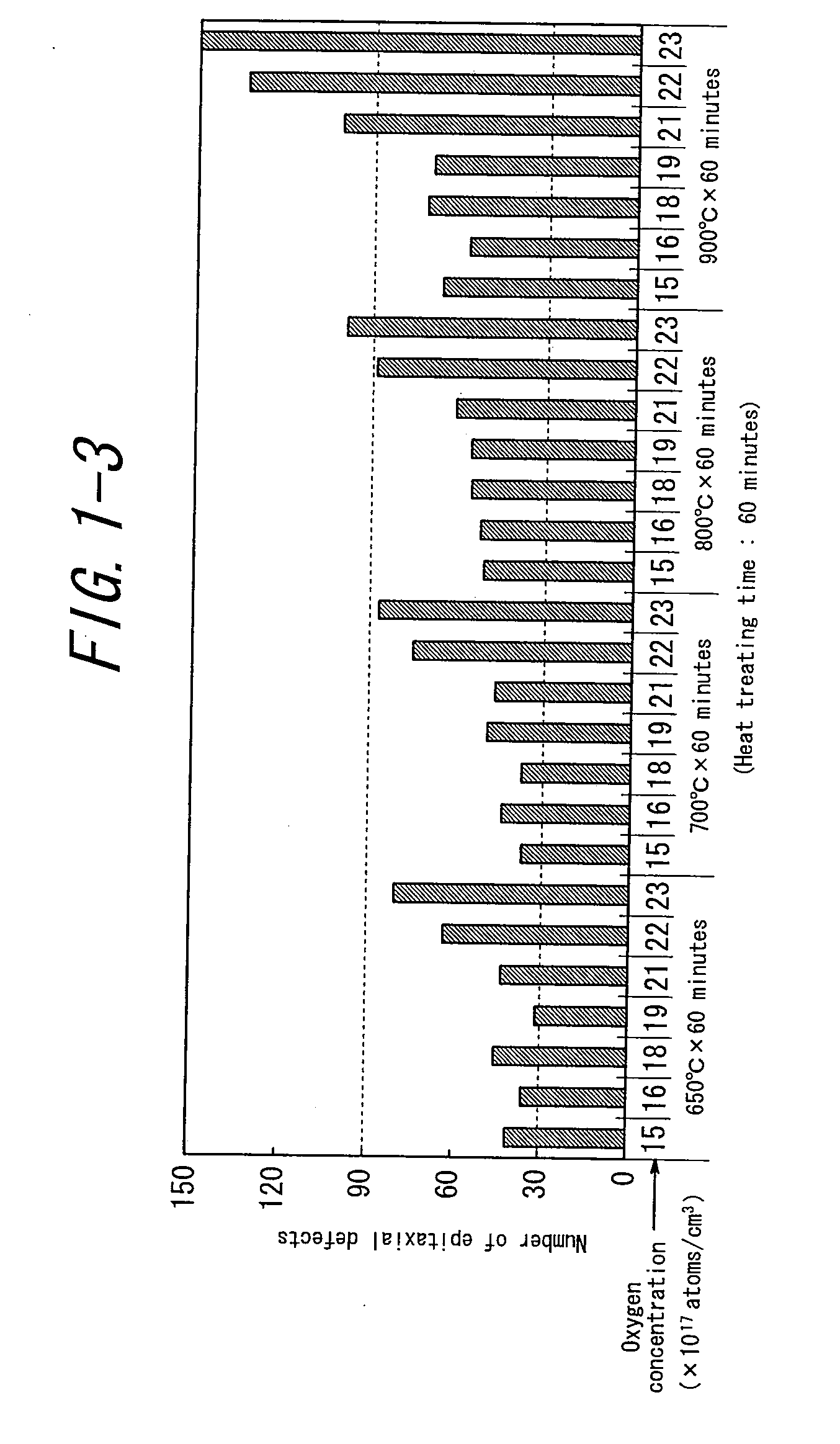

Method of producing epitaxial wafer as well as epitaxial wafer

InactiveUS20110052923A1Increase oxygen concentrationImprove inhalation effectPolycrystalline material growthConductive materialWaferingCzochralski method

An epitaxial wafer is produced by a method comprising steps of growing a silicon single crystal ingot having a given oxygen concentration through Czochralski method, cutting out a wafer from the silicon single crystal ingot, subjecting the wafer to a heat treatment at a given temperature for a given time, and epitaxially growing the wafer.

Owner:SUMCO CORP

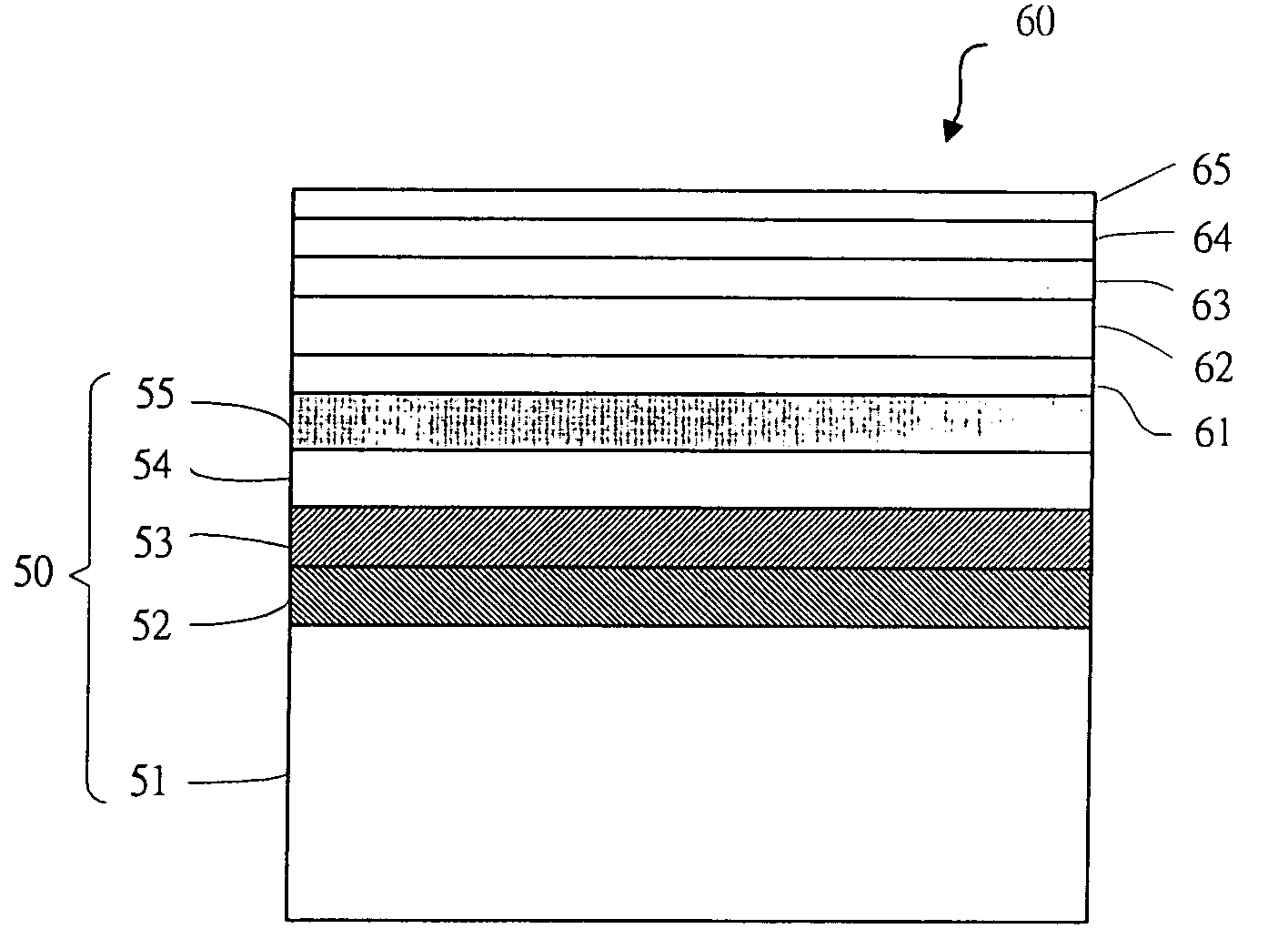

Method for fabricating a compound semiconductor epitaxial wafer

InactiveUS20060011129A1Low occurrenceEliminate stressPolycrystalline material growthFrom chemically reactive gasesDislocationCompound (substance)

The present invention discloses a compound semiconductor epitaxial wafer and its fabrication method. The method comprises the steps of the followings: depositing a first buffer layer of silicon on a silicon substrate; depositing a compound semiconductor second buffer layer on the first buffer layer; growing a compound semiconductor first epitaxy layer on the second buffer layer; reducing the threading dislocation density by a thermal treatment, which is caused by the discrepancy in the lattice constants or in the thermal expansion coefficients of the silicon substrate and the compound semiconductor epitaxy layers; growing a compound semiconductor second epitaxy layer on the first epitaxy layer; and, applying a thermal treatment again. Accordingly, a compound semiconductor epitaxy layer with excellent crystal quality is obtained.

Owner:INST NUCLEAR ENERGY RES ROCAEC

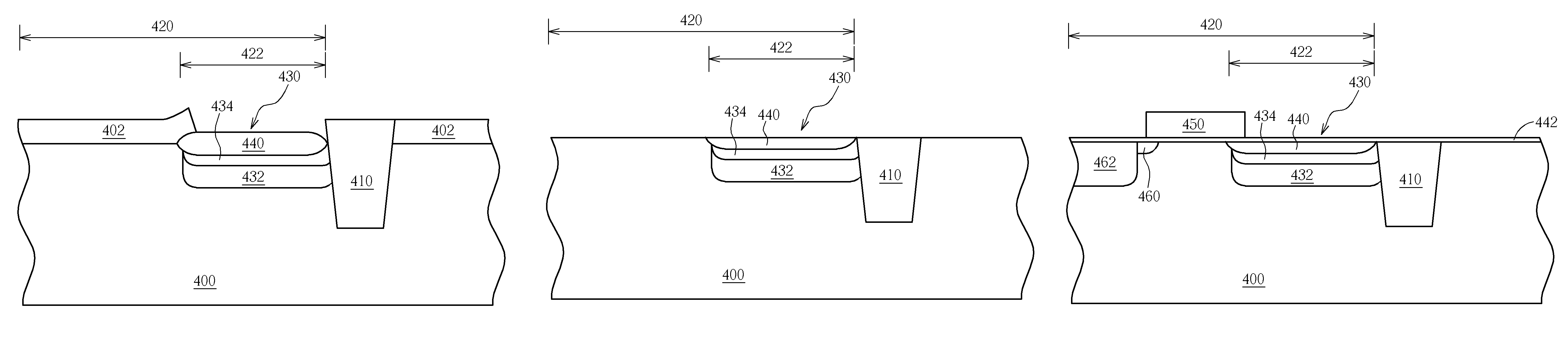

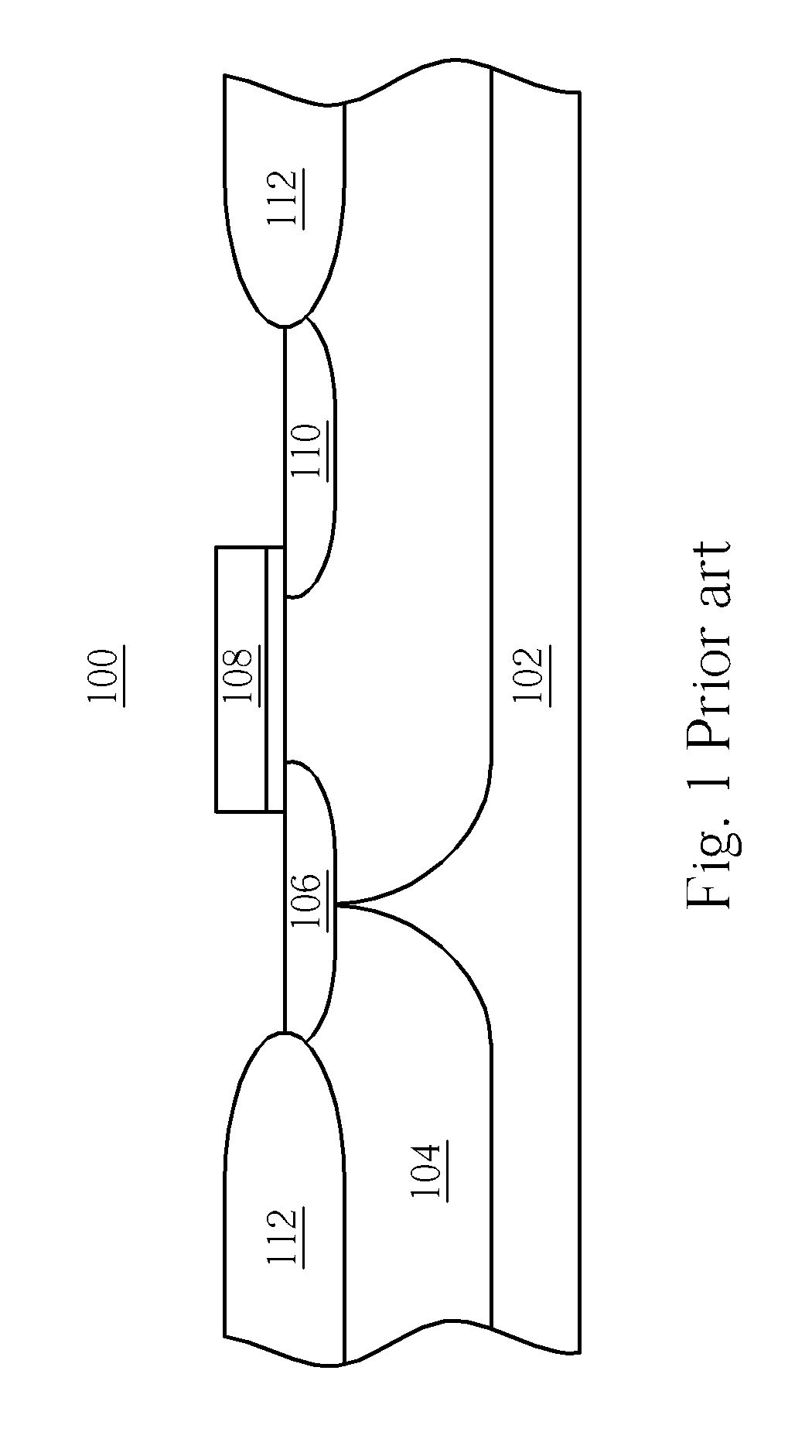

Image sensor device and manufacturing method thereof

A semiconductor substrate is provided on which a plurality of shallow trench isolations (STI) defining a plurality of active areas are formed. The active areas comprise a photo sensing region, and a plurality of photodiodes are formed in each photo sensing region. Then a local oxidation of silicon isolation (LOCOS) layer is formed by performing a LOCOS process. Thereafter a plurality of gates are respectively formed in each active area, where the gates partially overlap the LOCOS layer. Finally doped regions are formed in the semiconductor substrate where the gate does not cover the LOCOS layer.

Owner:MARLIN SEMICON LTD

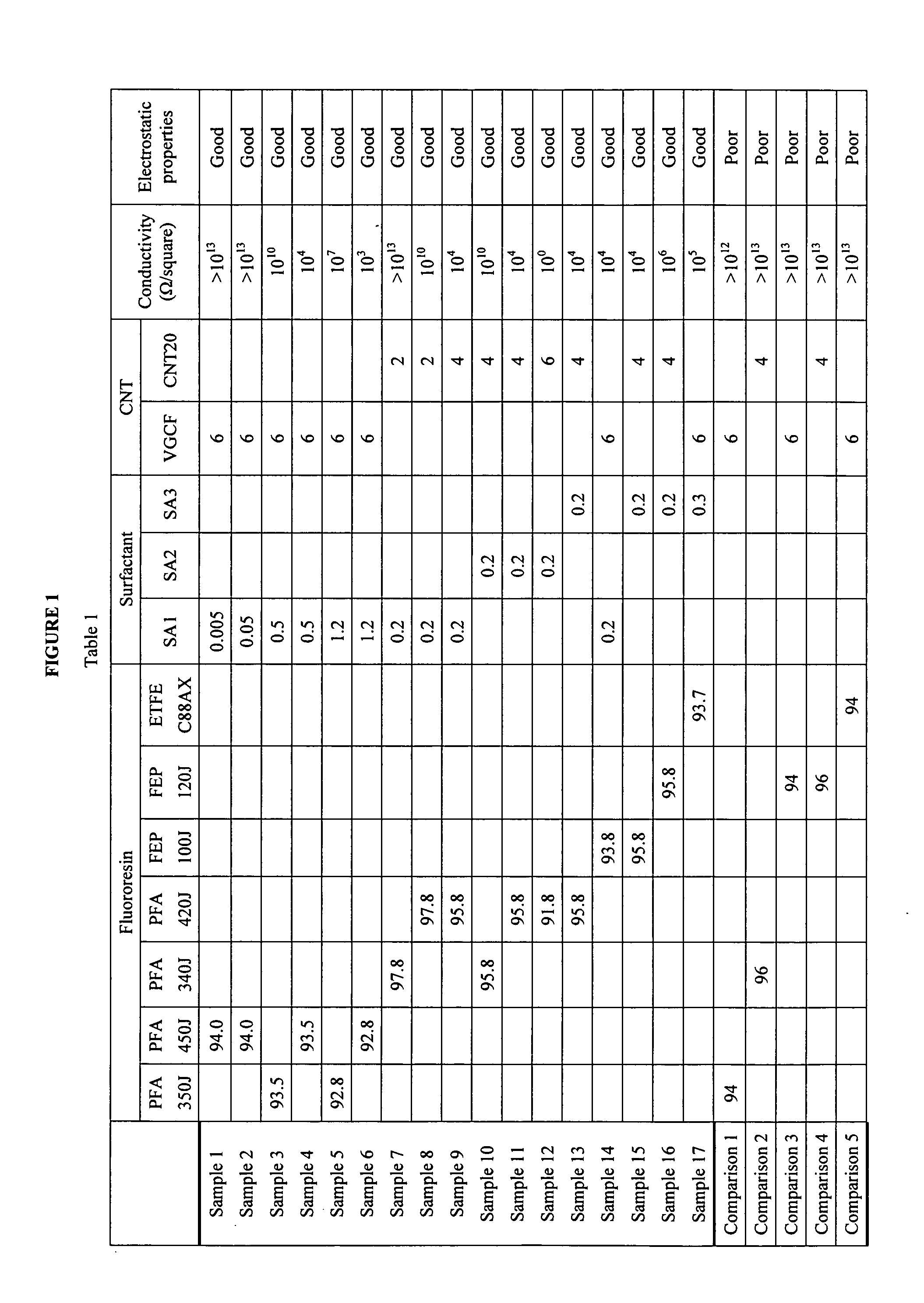

Fluororesin composition

InactiveUS20050159540A1Shedding from the fluororesin is reducedImprove conductivityMaterial nanotechnologyFibre treatmentCarbon nanotubePolymer chemistry

A fluororesin composition comprising a mixture of a fluororesin and carbon nanotubes whose surfaces have been treated with a fluorine-based surfactant is described. The fluororesin composition of the present invention has enhanced conductivity, electrostatic charge properties, and other electrical properties.

Owner:JUNKOSHA

Actinic ray-sensitive or radiation-sensitive resin composition, and, resist film, pattern forming method, electronic device manufacturing method, and electronic device, each using the composition

ActiveUS20140287363A1Occurrence be very lowPattern roughnessPhotosensitive materialsPhotomechanical exposure apparatusChemistryActinic Rays

Disclosed are an actinic ray-sensitive or radiation-sensitive resin composition including (A) a compound capable of generating an acid by irradiation of actinic rays or radiation, and (B) a resin of which solubility in an alkali developer increases by being decomposed by the action of an acid, and, a resist film, a pattern forming method, an electronic device manufacturing method, and an electronic device, each using the composition, wherein the actinic ray-sensitive or radiation-sensitive resin composition contains at least one type of a specific compound represented by General Formula (A-I) and at least one type of a specific compound represented by General Formula (A-II) as the compound (A).

Owner:FUJIFILM CORP

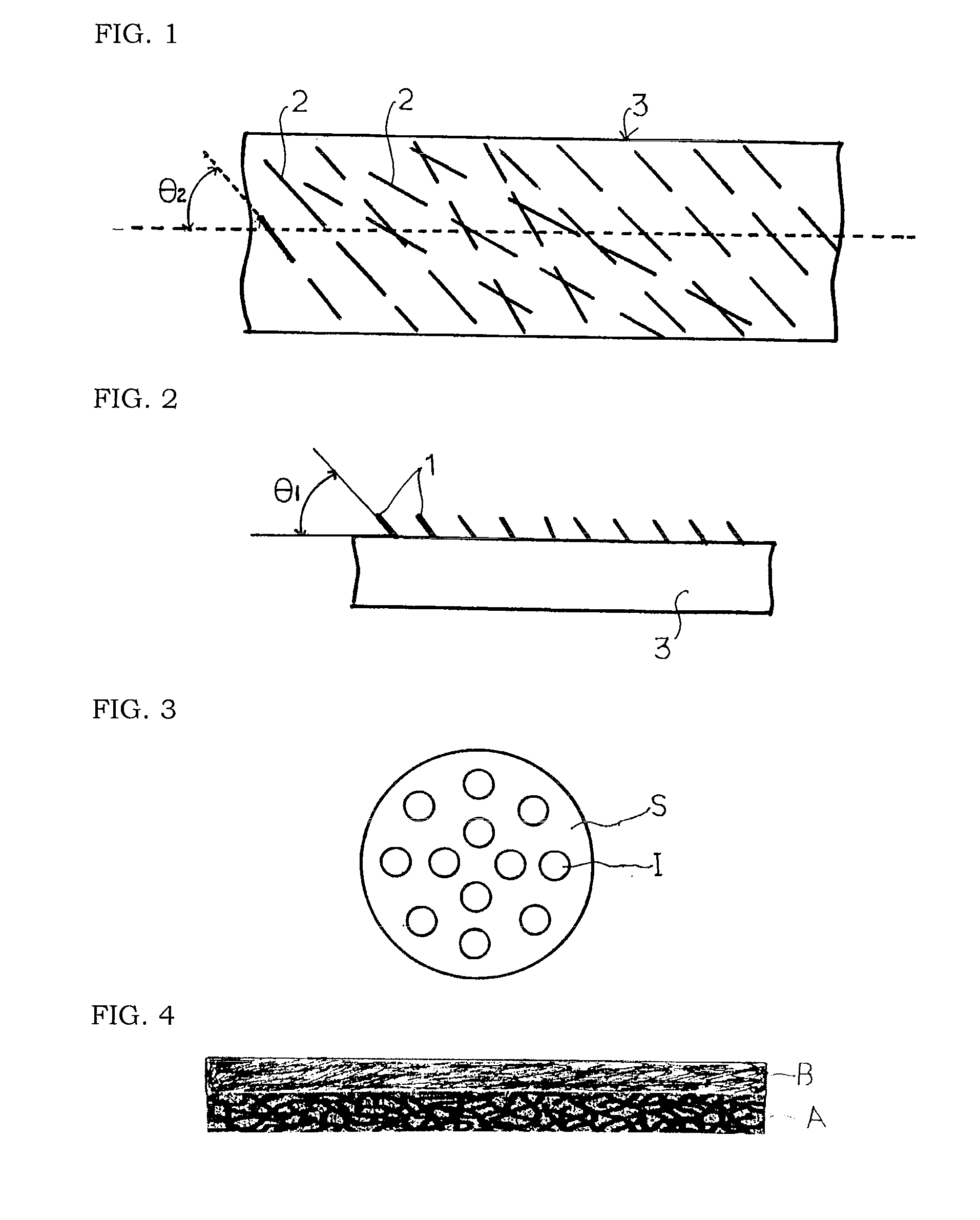

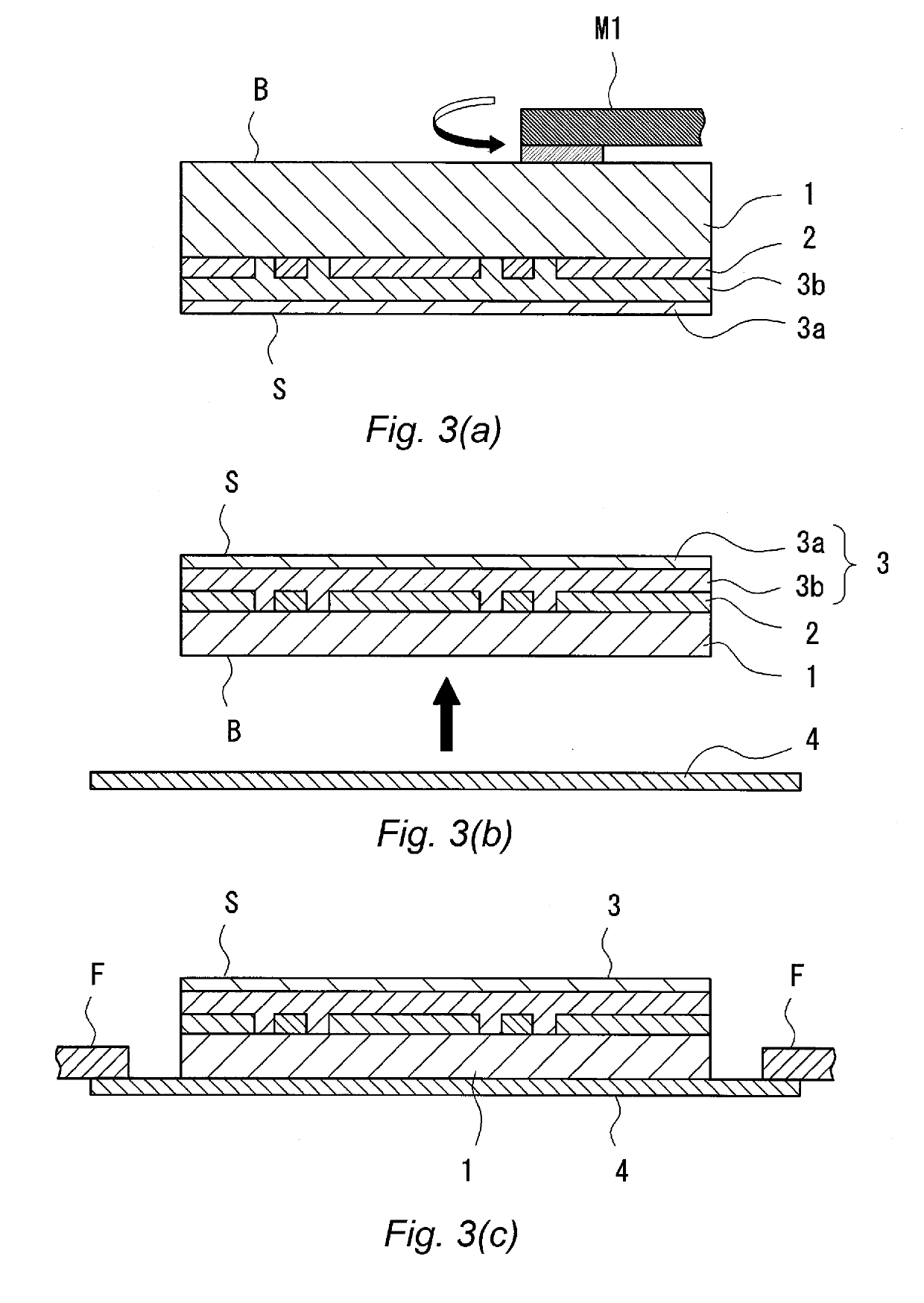

Polishing pad and method of manufacturing the same

InactiveUS20100173573A1Occurrence is very lowImprove surface uniformityAbrasion apparatusPretreated surfacesFlat glassFiber

Disclosed are a polishing pad used in a CMP process of a planar material such as a silicon wafer, plate glass for a display, etc. and a method for manufacturing the same. The polishing pad comprises a non-woven fabric consisting of ultrafine fibers and elastomeric polymer impregnated into the fabric, on which the ultrafine fibers are raised and arranged to simultaneously satisfy the following conditions (I) to (III) such that the ultrafine fibers are oriented in a longitudinal direction to a central axis:The polishing pad of the present invention includes ultrafine fibers, which are arranged at a relatively wide orientation angle and have pores formed therebetween without requiring alternative processes for forming the pores, thus, exhibits excellent polishing performance and low occurrence of scratches during a polishing process.

Owner:KOLON IND INC

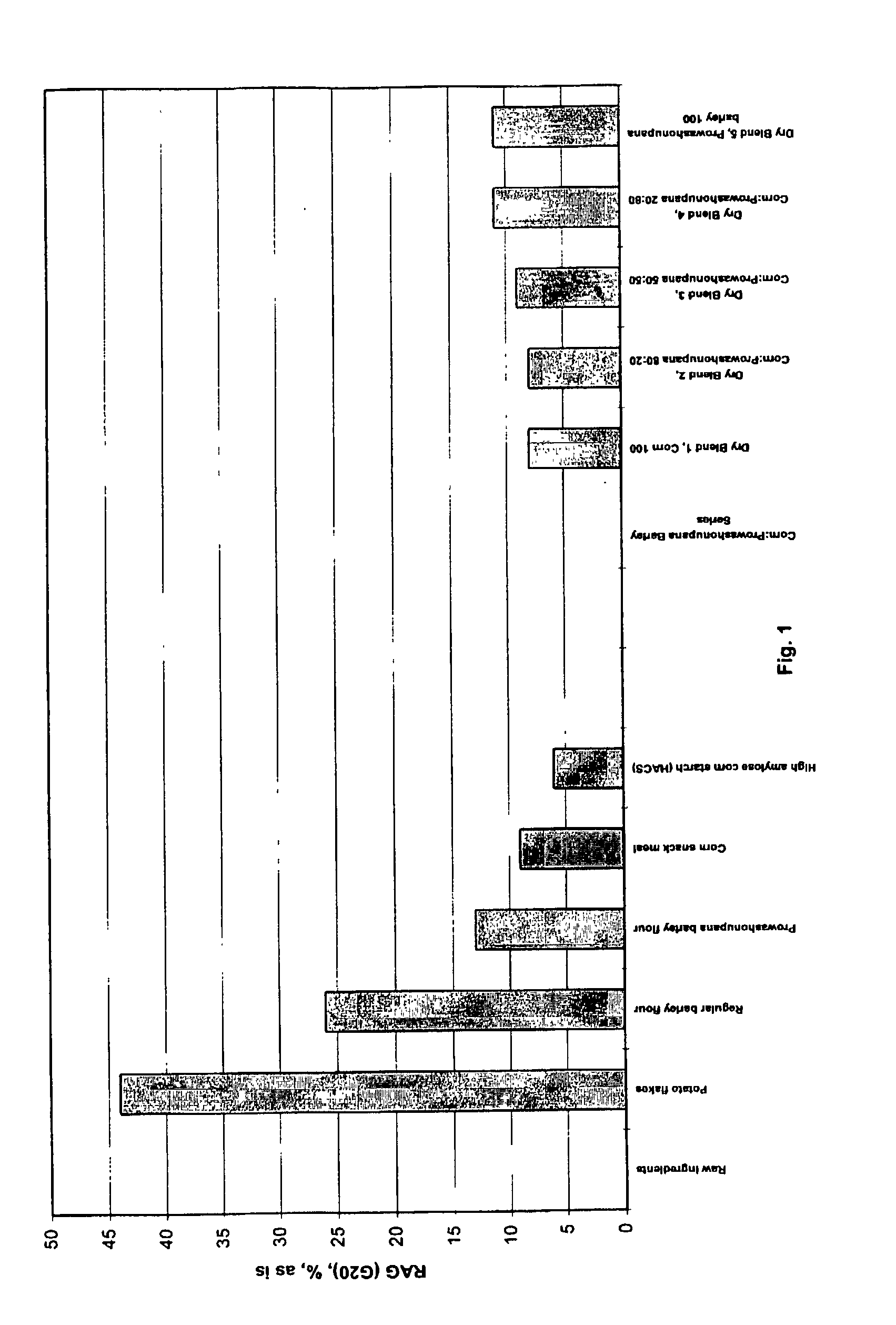

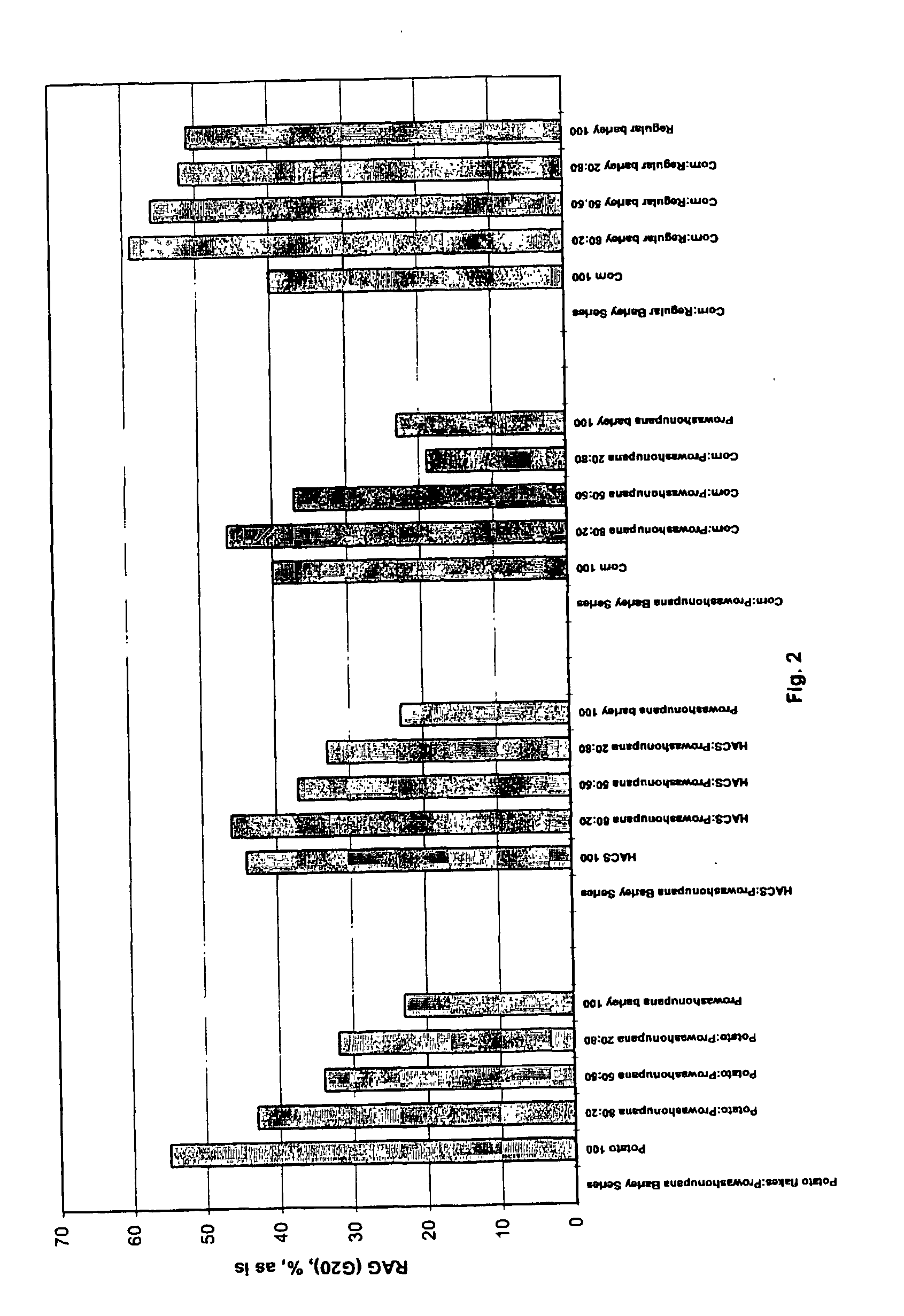

Method and composition related to low glycemic index foods

InactiveUS20030087018A1Low RAGGood for healthDough treatmentBaking mixturesMarkedly elevated IgED-Glucose

The present invention relates to a method for using Prowashonupana barley to produce a food product comprised primarily of the Prowashonupana barley. The resultant food product is desired because, when consumed, it does not contribute to significantly elevated glycemic indices in a host, as indicated by the rapidly available glucose (RAG) assay.

Owner:ARDENT MILLS

Method for manufacturing p-type group III nitride semiconductor, and group III nitride semiconductor light-emitting device

ActiveUS7537944B2Occurrence is very lowAdequate carrier concentrationPolycrystalline material growthLaser detailsDopantCharge carrier

An object of the present invention is to provide an efficient method for manufacturing a p-type group III nitride semiconductor that has adequate carrier concentration and a surface with a low occurrence of crystal damage. The inventive method for manufacturing a p-type group III nitride semiconductor comprises: (a) growing a group III nitride semiconductor containing a p-type dopant at 1000° C. or higher in an atmosphere containing H2 gas and / or NH3 gas; and (b) after the growth of the group III nitride semiconductor, substituting the H2 gas and NH3 gas with an inert gas at a temperature higher than 800° C. while reducing the temperature.

Owner:TOYODA GOSEI CO LTD

Process for the production of aromatic diisocyanates in the gas

ActiveUS8399702B2Simple and economical processIncreased space-time yieldIsocyanic acid derivatives preparationOrganic compound preparationPolymer scienceAliphatic amine

Aromatic diisocyanates are produced by reacting in the gas phase the corresponding primary aromatic diamine with phosgene. The phosgene and the primary aromatic diamine are reacted within a mean residence time of from 0.05 to 15 seconds. The aromatic diamine used contains less than 0.05 mole % overall of aliphatic amine containing no keto groups, per mole of primary amino groups.

Owner:COVESTRO DEUTSCHLAND AG

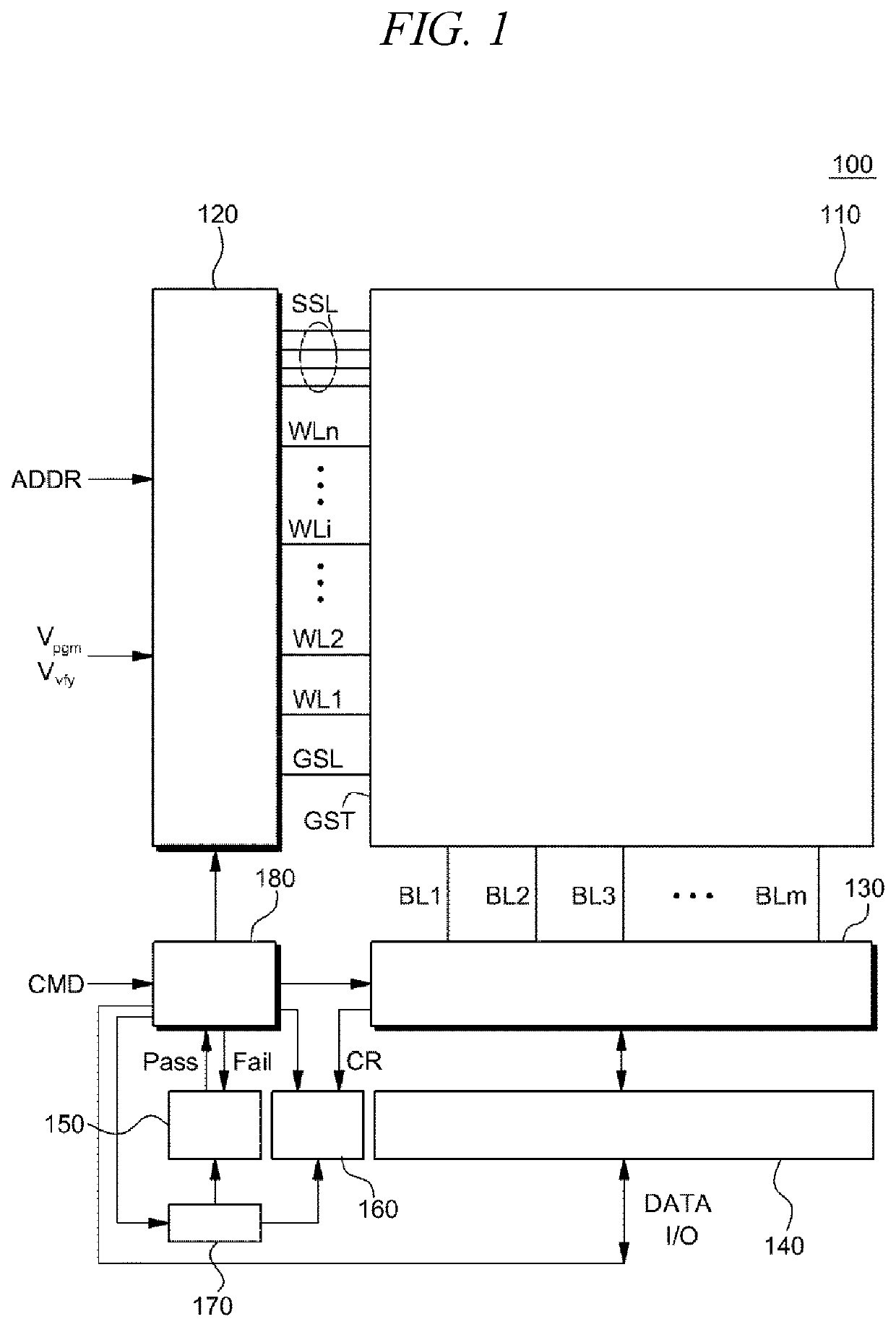

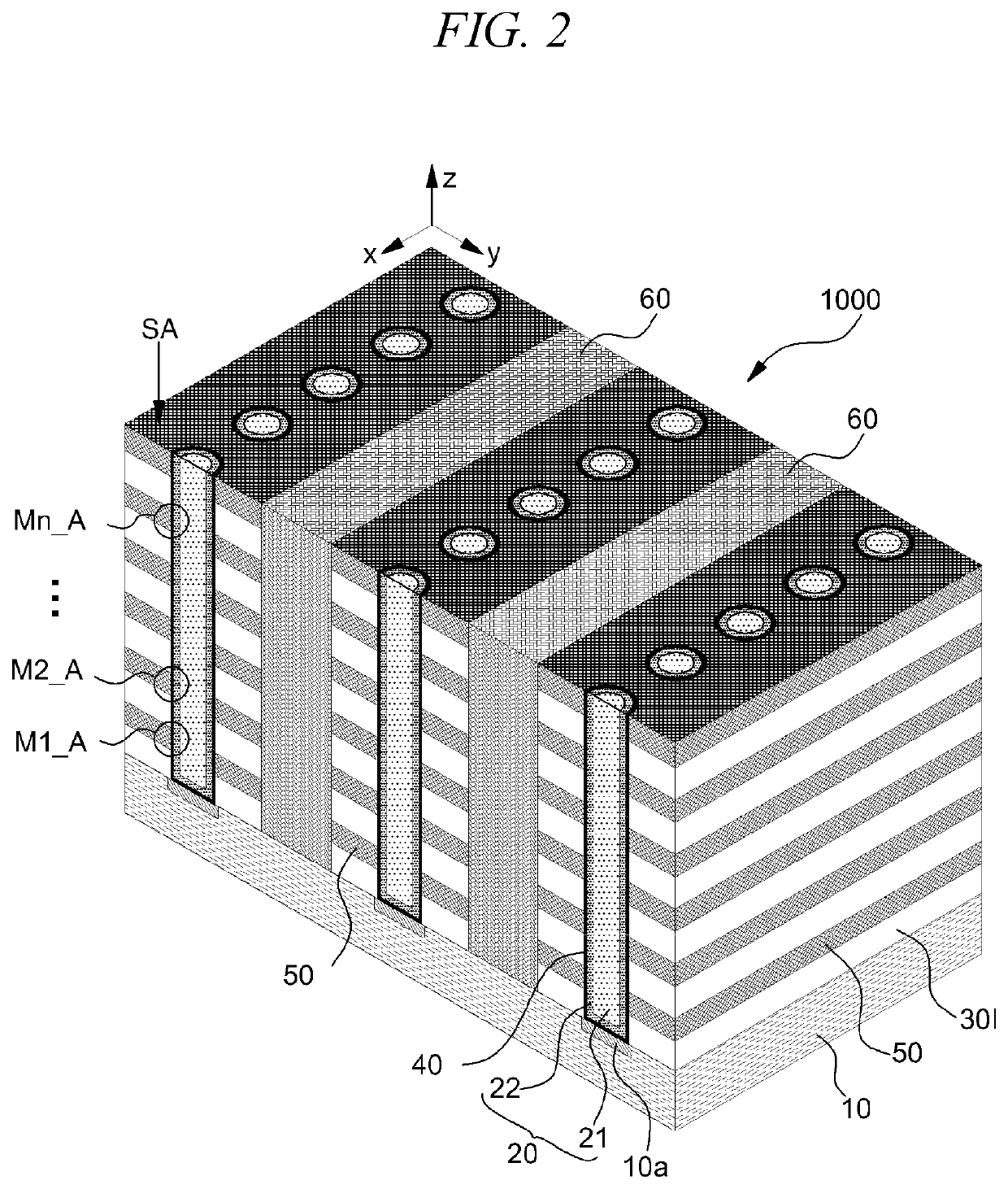

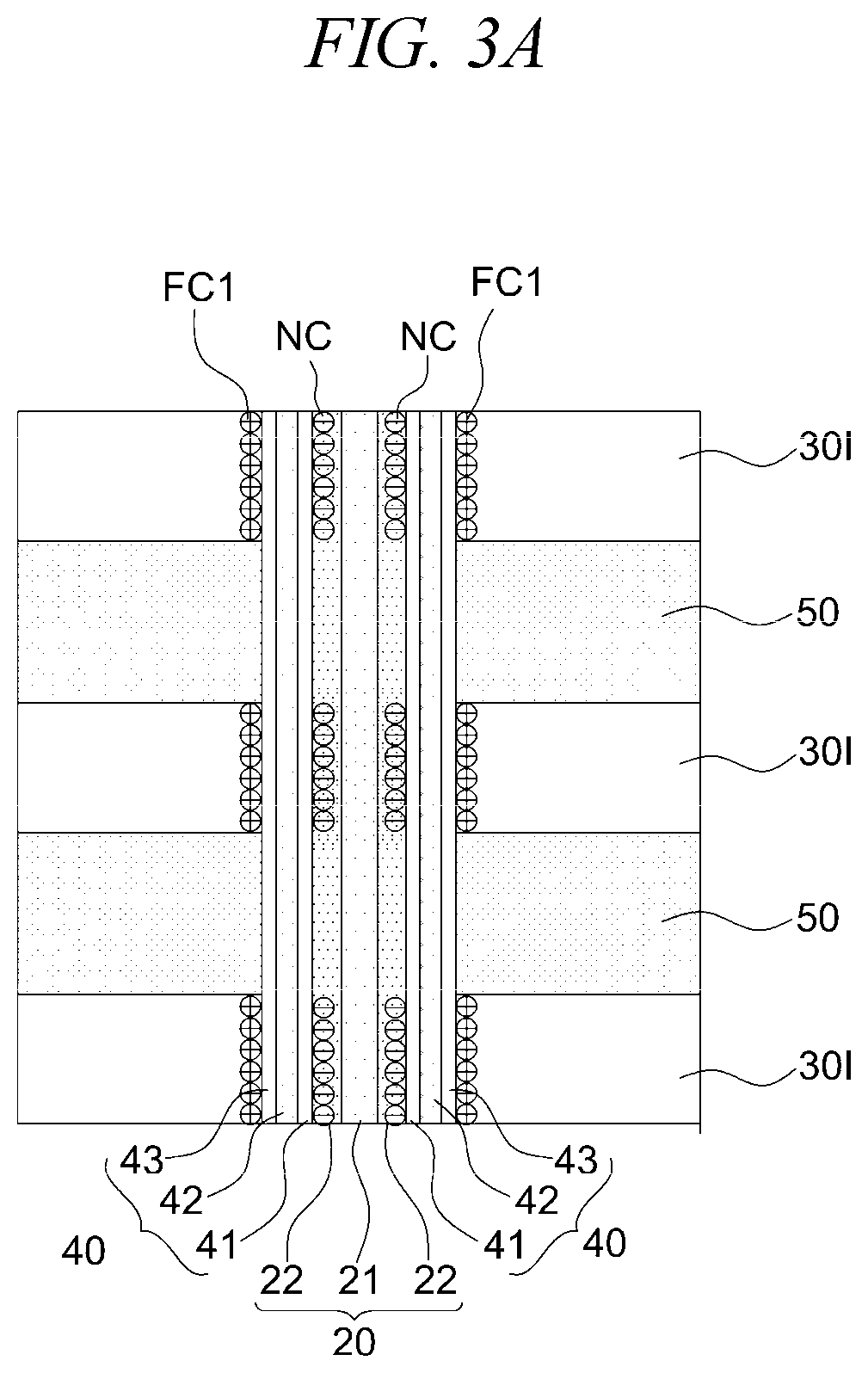

3-dimensional NAND flash memory device, method of fabricating the same, and method of driving the same

ActiveUS20210288070A1Reduce additionalEasy to integrateSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringCondensed matter physics

A 3-dimensional flash memory device and methods of fabricating and driving the same are provided. The device includes: a channel layer extending over a substrate in a first direction perpendicular to a surface of the substrate; an information storing layer extending along a sidewall of the channel layer in the first direction; control gates each surrounding, the channel layer, with the information storing layer between the channel layer and the control gates; an insulating layer being between the control gates in the first direction and separating the control gates from each other; a fixed charge region disposed at an interface of the insulating layer and the information storing layer or in a portion of the information storing layer between the control gates in the first direction; and a doped region induced by the fixed charge region and disposed at a surface of the channel layer facing the fixed charge region.

Owner:SK HYNIX INC +1

Polyethylene resin composition, laminate comprising same, and medical container using laminate

ActiveUS20160237263A1Excellent transparency and flexibility and barrier property and cleanlinessOccurrence is very lowFlexible coversWrappersLow-density polyethyleneLinear low-density polyethylene

Provided are: a polyethylene laminate that exhibits excellent flexibility, barrier properties, and cleanliness (a low occurrence of fine particles), that does not deform even after sterilization treatment at 121° C., and that maintains high transparency; and a medical container using same. The medical container is configured by layering: an outer layer and an inner layer that comprise from 20 to 80 wt % of a high-density polyethylene (A) having specific properties, from 0 to 50 wt % of a linear low-density polyethylene (B1), and from 5 to 40 wt % of an ethylene-based polymer (C); and an intermediate layer that comprises from 10 to 40 wt % of the high-density polyethylene (A) and from 60 to 90 wt % of the linear low-density polyethylene (B1).

Owner:TOSOH CORP

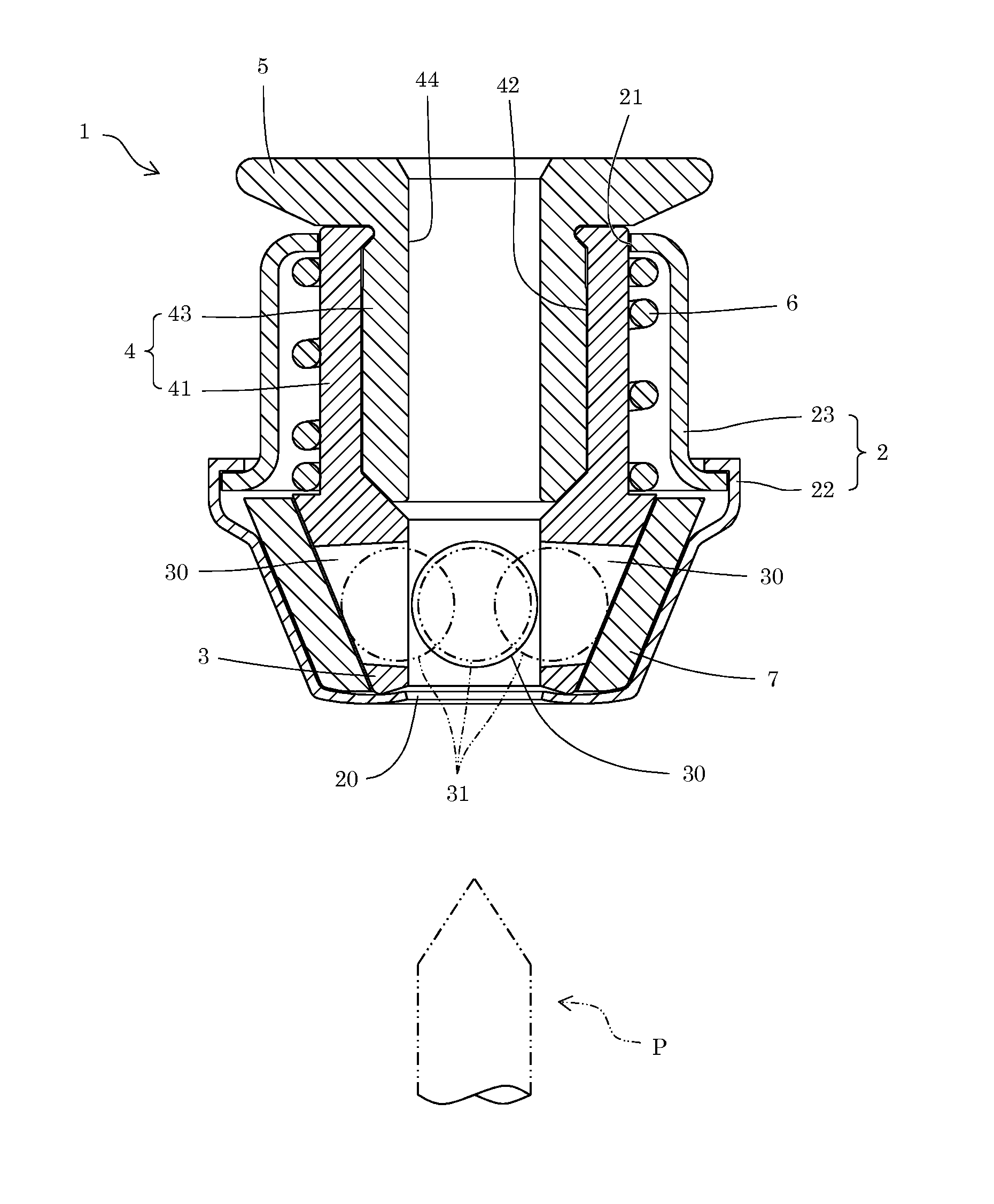

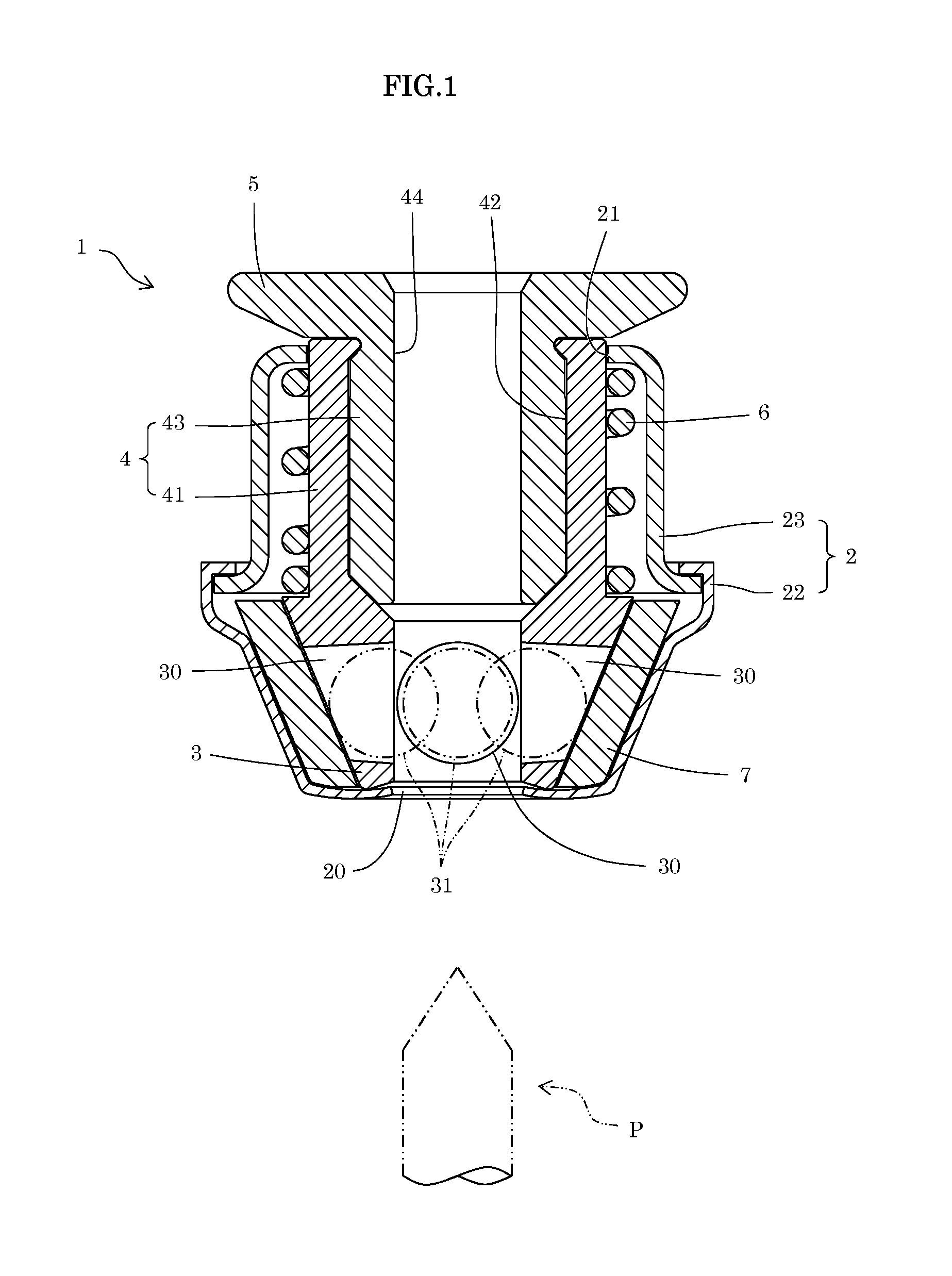

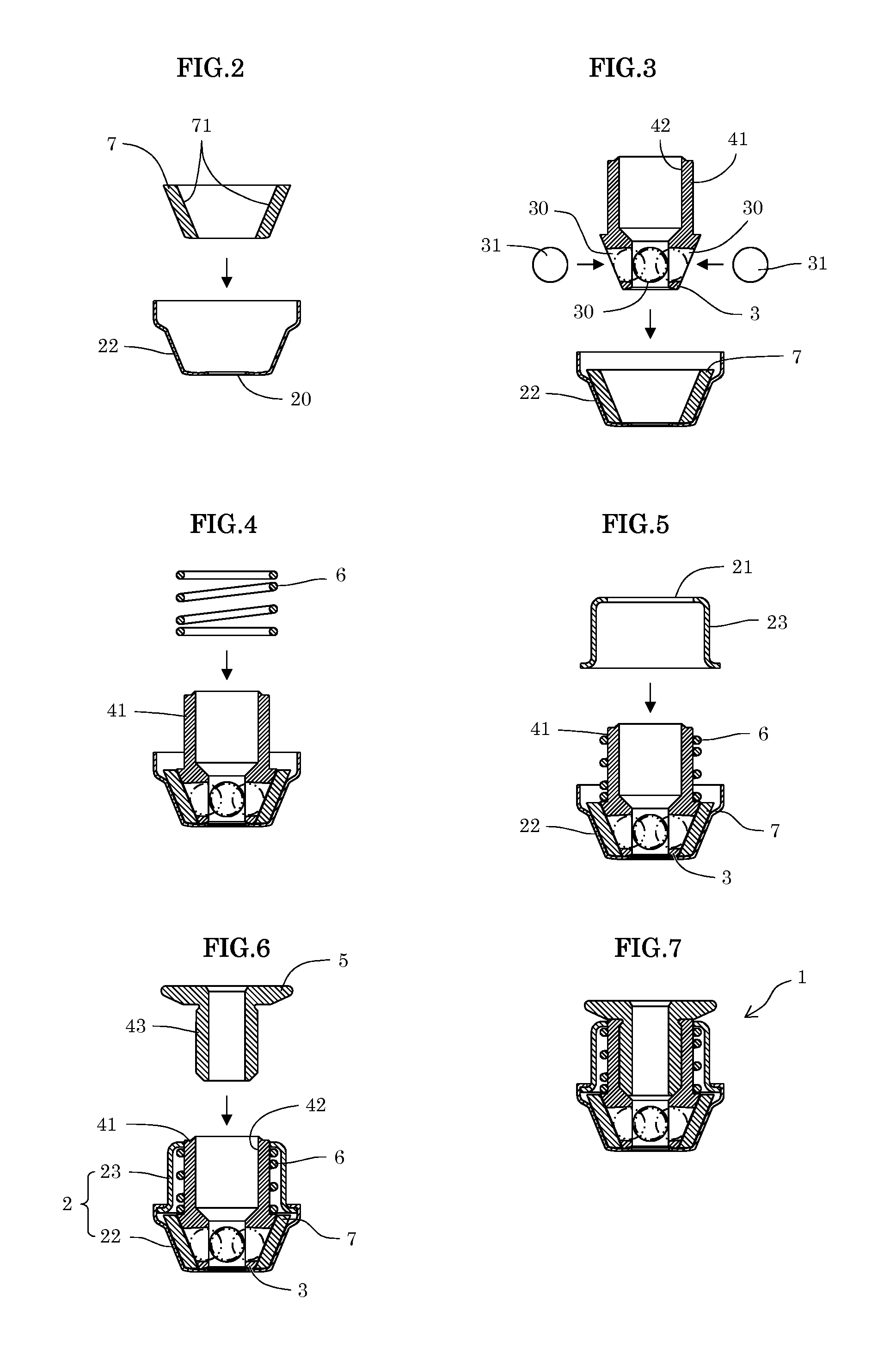

Fastener For Ornament With Pin

InactiveUS20140023454A1Improve machinabilityYield ratio can be improvedMedalScarvesYield ratioBiomedical engineering

The present invention is to provide a fastener for an ornament having a pin which is excellent in workability on assembly and manufacture and improved in yield ratio, and the fastener of the present invention is characterized that the pin of the ornament is clamped in the fastener and retained between the respective spherical surfaces of a plurality of small balls, wherein a column portion inside a housing is provided with an outer column portion of a cylindrical body which is formed integrally with a pin retaining portion in a direction at which the pin retaining portion is pulled backward and internally has a through hole in the same direction as a direction at which the pin is inserted and an inner column portion of a cylindrical body which is inserted and fixed to the through hole inside the outer column portion, formed integrally with the control lever in a direction at which the control lever is urged and also has a through hole acting as a passage for introducing the pin inserted through the pin passing hole.

Owner:KIKUNAGA ERI

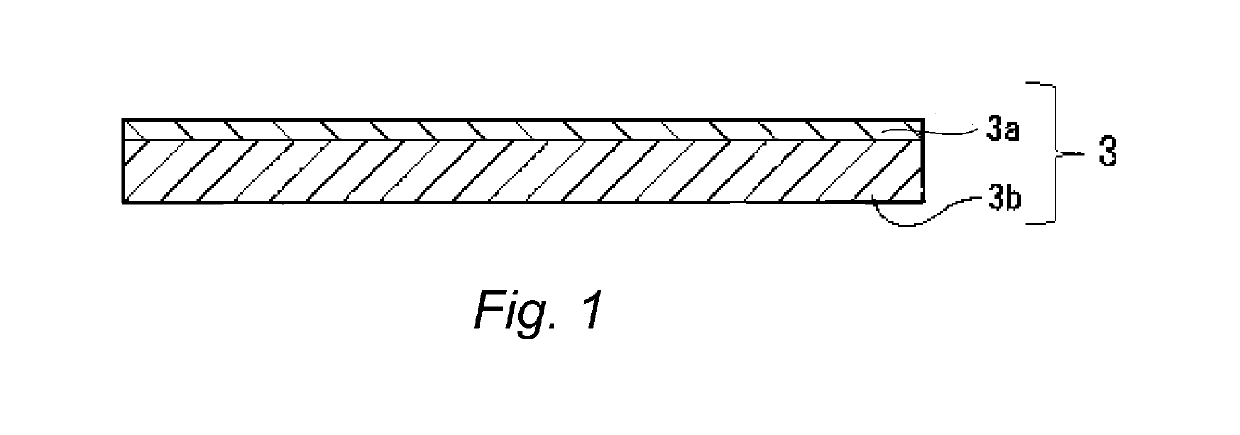

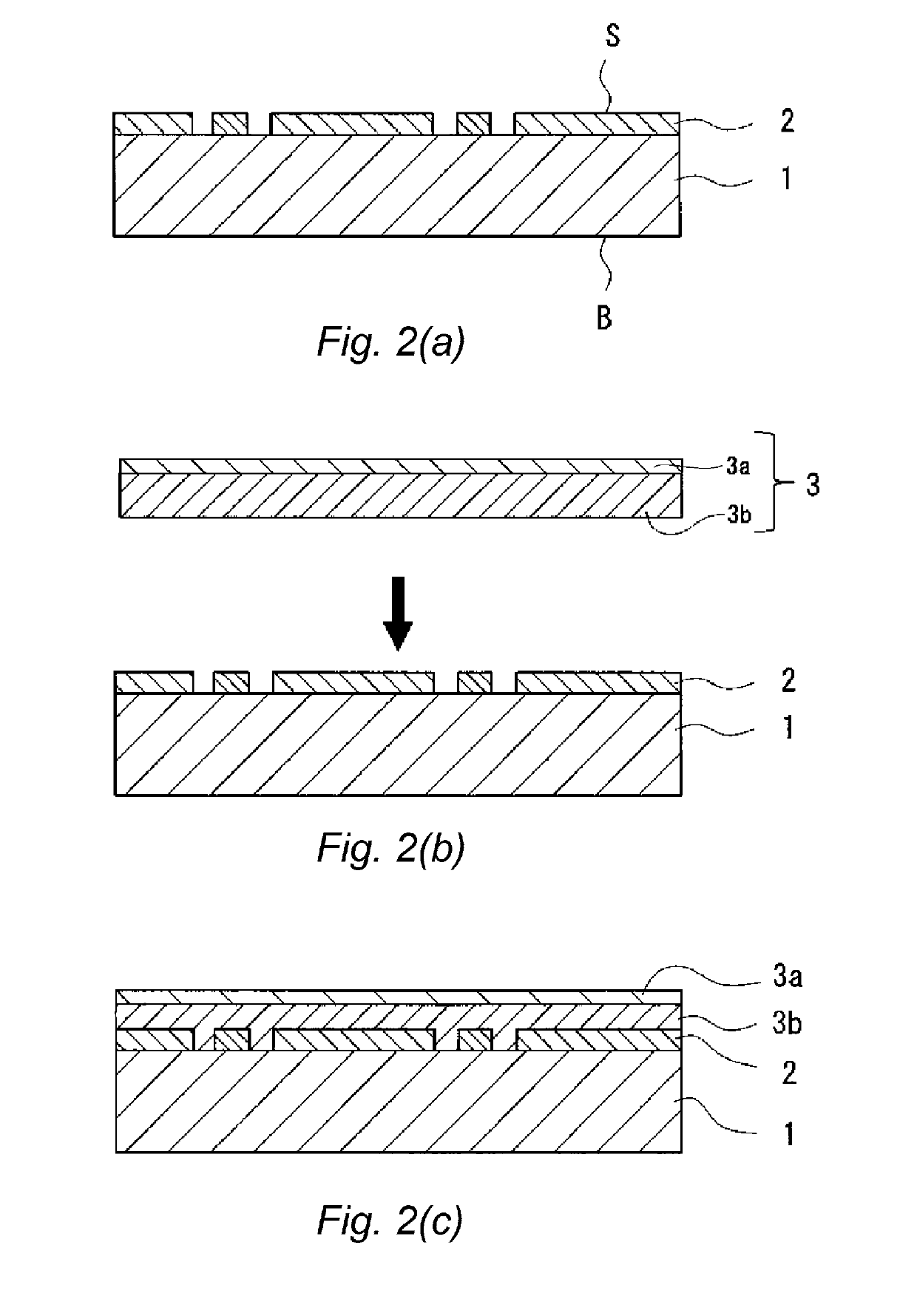

Mask-integrated surface protective tape

ActiveUS20190198378A1Well protective propertyGood peelingFilm/foil adhesivesSolid-state devicesPhysicsEngineering

A mask-integrated surface protective tape for production of semiconductor chips, with the production containing steps (a) to (d), which tape comprises a base film and a mask material layer provided thereon, wherein a wetting tension of the base film on the side from which the mask material layer has been peeled is from 20.0 mN / m to 48.0 mN / m, and wherein a surface roughness Ra of the base film on the side from which the mask material layer has been peeled is within a range from 0.05 μm to 2.0 μm when measured in conformity to JIS B0601,(a) a specific laminating step;(b) a specific peeling step;(c) a specific plasma-dicing step; and(d) a specific ashing step.

Owner:FURUKAWA ELECTRIC CO LTD

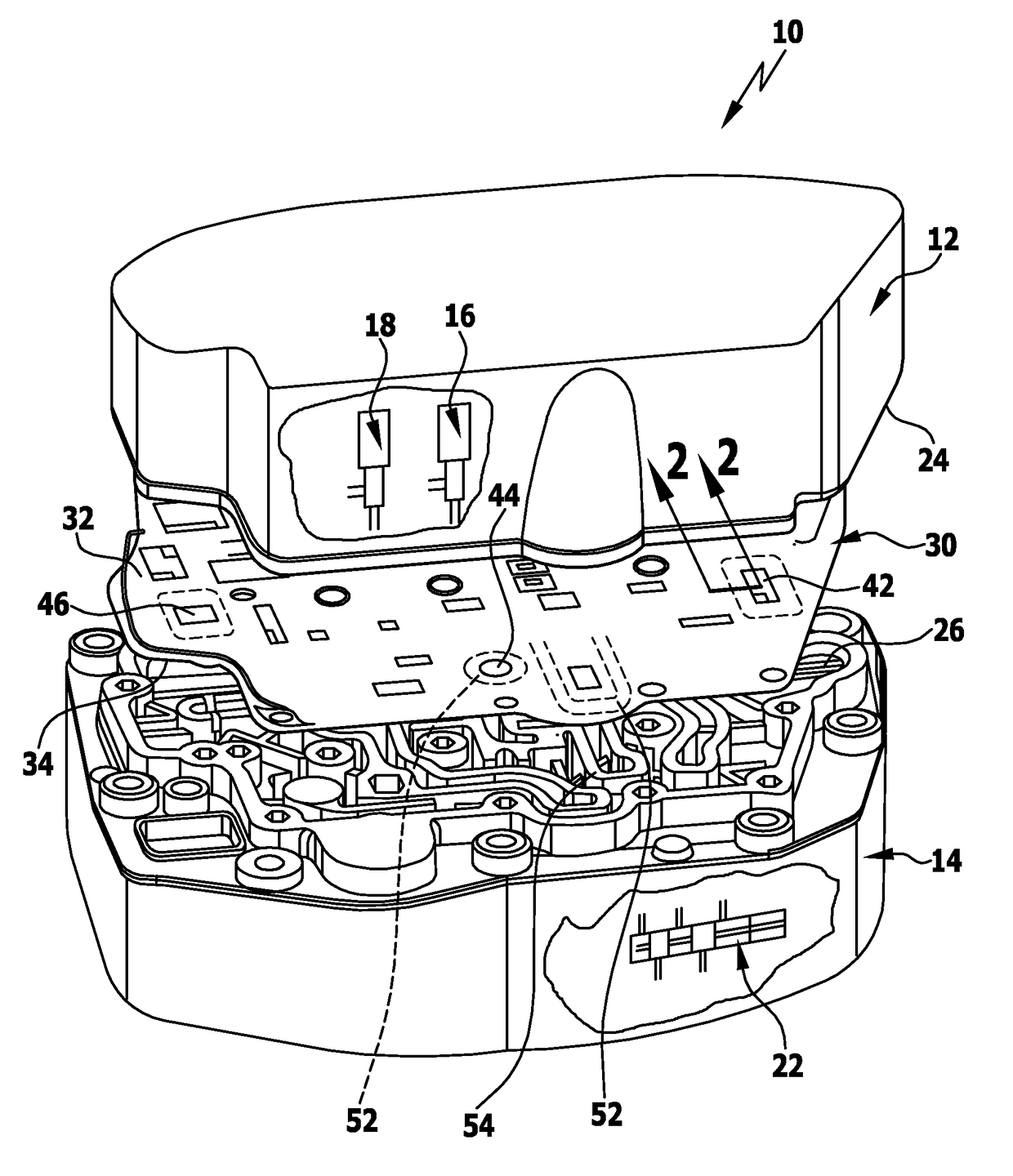

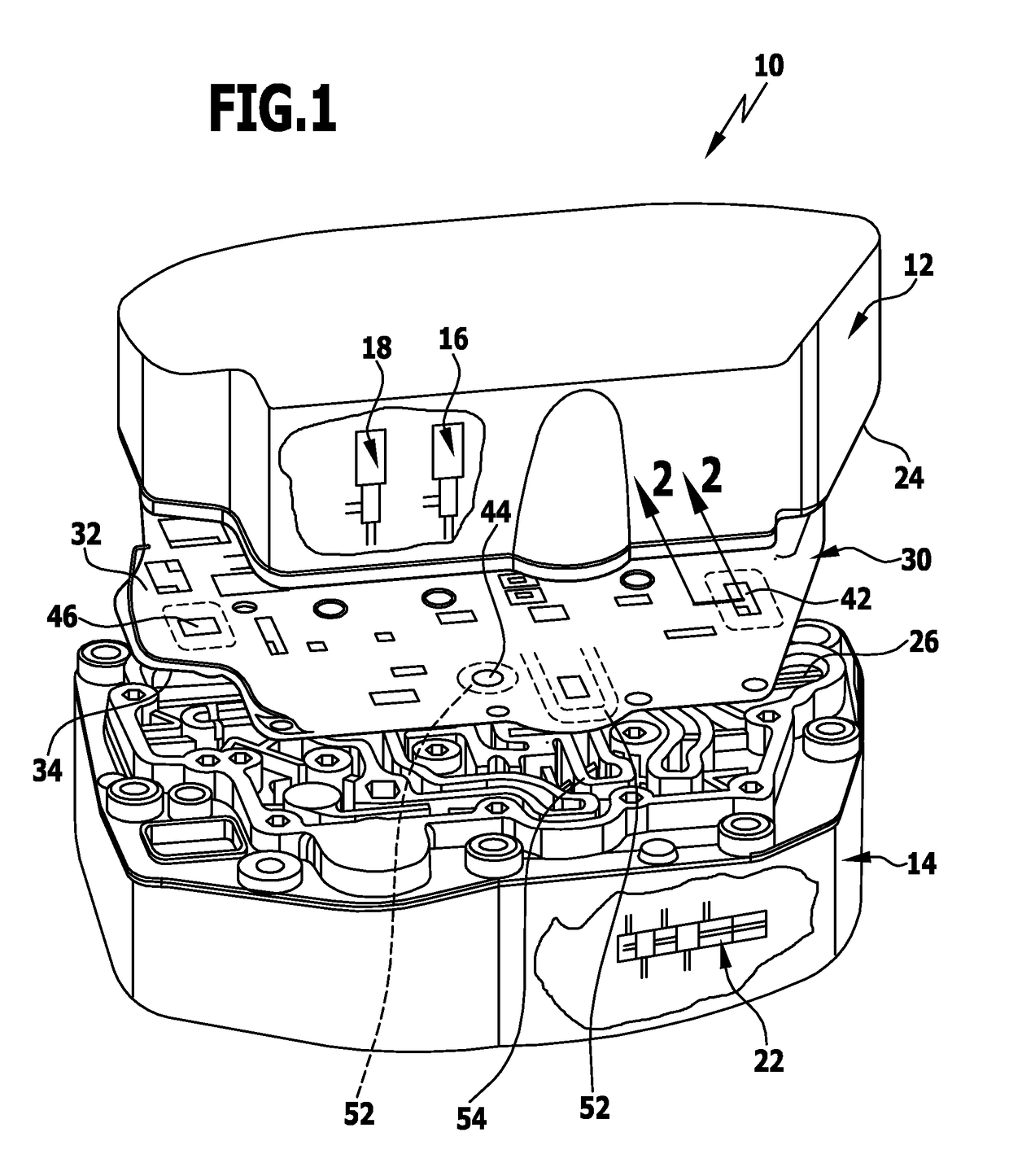

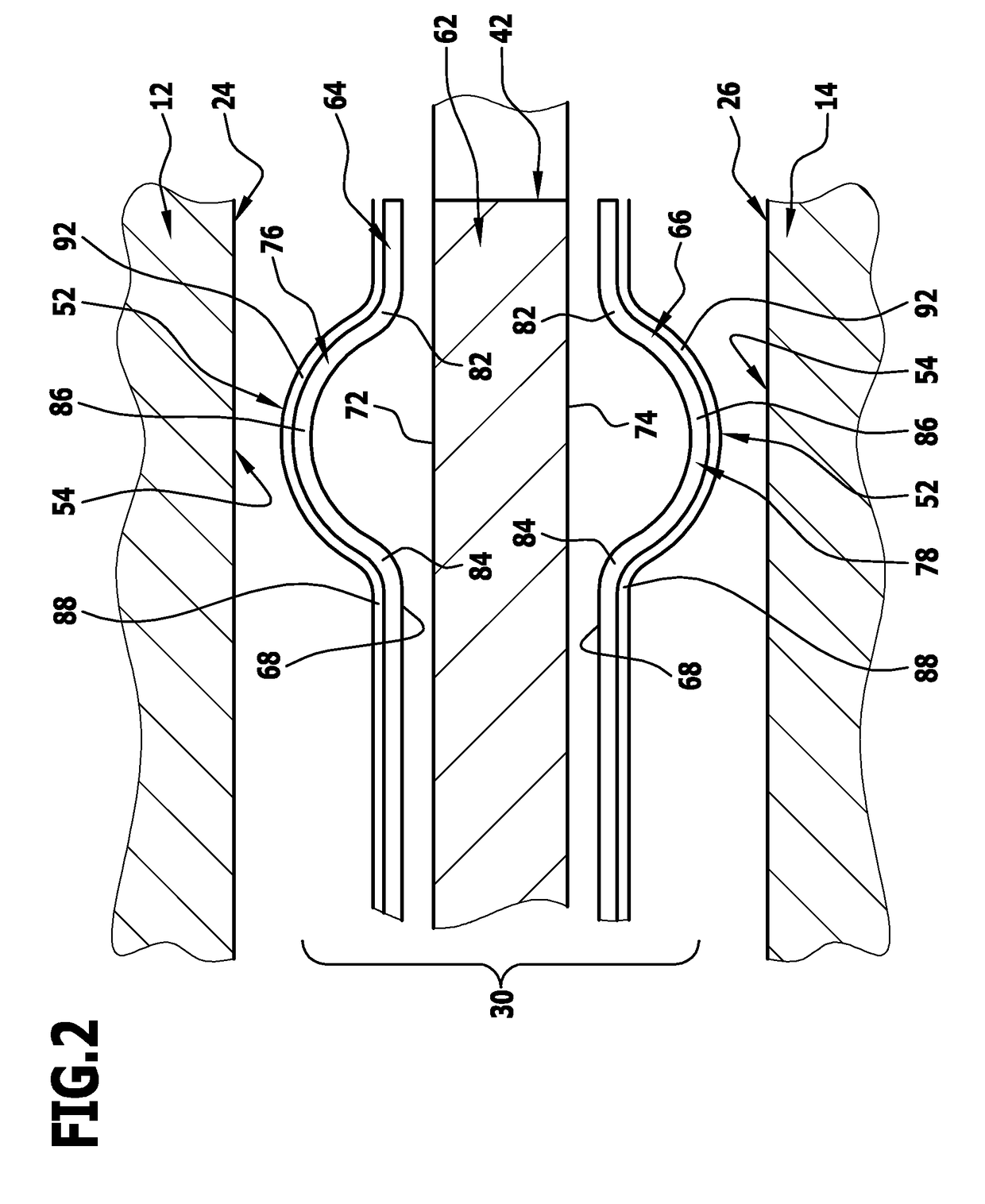

Intermediate plate and control unit for fluid operated consuming devices

InactiveUS20170130823A1Protection materialReduce wearEngine sealsGearing controlMetal coatingEngineering

In order to improve an intermediate plate for the sealing of mutually opposed sealing faces of housing parts of a control unit for fluid-operated consuming devices, comprising two seal surface regions of at least one seal layer which face toward the respective sealing faces and are placeable sealingly thereon, so that a lasting and reliable sealing between the seal surface regions and the sealing faces is ensured, it is proposed that at least one of the seal surface regions is formed by an exposed metal coating which is capable of sliding relative to the sealing faces, for direct contact with the sealing faces.

Owner:ELRINGKLINGER AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com