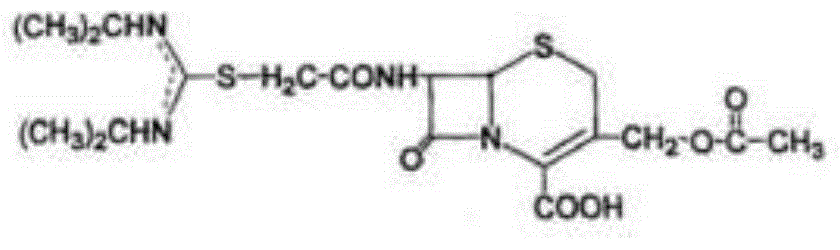

Cefathiamidine compound

A technology of cefathiamidine and compounds, which is applied in the field of cefathiamidine compounds, can solve problems such as unsatisfactory results, and achieve the effects of low incidence of adverse reactions, low polymer content, and significant antibacterial activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] [Example 1] Preparation of Cefathiamidine Compound

[0052] 1) Get 10kg of cefathiamidine crude product, add it in 30L mixed solvent A at 35°C, stir and dissolve to obtain the crude product solution, wherein said mixed solvent A is composed of propylene glycol, tetrahydrofuran and water in a volume ratio of 2:1: 5 prepared mixed solvent;

[0053] 2) The crude product solution obtained in step 1) was naturally cooled to room temperature, and then 60 L of ethanol was added to the crude product solution at a speed of 15 L / min under stirring at a speed of 55 r / min to form a turbid solution;

[0054] 3) Adjust the stirring speed to 15r / min, then add 90L of mixed solvent B to the turbid solution obtained in step 2) at a speed of 5L / min, after the addition is completed, cool down to 0°C, and crystals will precipitate out. Mixed solvent B is a mixed solvent prepared from acetone and N-methylpyrrolidone at a volume ratio of 3:1;

[0055] 4) Stand still in an environment with a...

Embodiment 2

[0060] [Example 2] Preparation of Cefathiamidine Compound

[0061] 1) Take 10kg of cefathiamidine crude product, add in 35L mixed solvent A at 45°C, stir and dissolve to obtain the crude product solution, wherein said mixed solvent A is composed of propylene glycol, tetrahydrofuran and water in a volume ratio of 3:1:7 Prepared mixed solvent;

[0062] 2) The crude product solution obtained in step 1) was naturally cooled to room temperature, and then 175 L of ethanol was added to the crude product solution at a speed of 25 L / min under stirring at a speed of 65 r / min to form a turbid solution;

[0063] 3) Adjust the stirring speed to 25r / min, then add 280L of mixed solvent B to the turbid solution obtained in step 2) at a speed of 10L / min, after the addition is completed, cool down to 5°C, and crystals are precipitated. Mixed solvent B is a mixed solvent prepared from acetone and N-methylpyrrolidone at a volume ratio of 8:1;

[0064] 4) Stand still in an environment with a tem...

Embodiment 3

[0068] [Example 3] Preparation of Cefathiamidine Compound

[0069] 1) Take 10kg of cefathiamidine crude product, add it in 32L mixed solvent A at 40°C, stir and dissolve to obtain the crude product solution, wherein said mixed solvent A is composed of propylene glycol, tetrahydrofuran and water in a volume ratio of 2.5:1: 6 mixed solvent prepared;

[0070] 2) The crude product solution obtained in step 1) was naturally cooled to room temperature, and then 96L of ethanol was added to the crude product solution at a rate of 20 L / min under stirring at a speed of 60 r / min to form a turbid solution;

[0071] 3) Adjust the stirring speed to 20r / min, and then add 160L of mixed solvent B to the cloudy solution obtained in step 2) at a speed of 8L / min. Mixed solvent B is a mixed solvent prepared from acetone and N-methylpyrrolidone at a volume ratio of 5:1;

[0072] 4) Stand still in an environment with a temperature of 2° C. for 3 hours, filter, wash the filter cake with absolute et...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com