Single-phase cylindrical linear vibration motor

A linear vibration, single-phase circular technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of low output per unit volume and complex structure, achieve high propulsion force density, simple and solid structure, and improve the effective magnetic flux. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

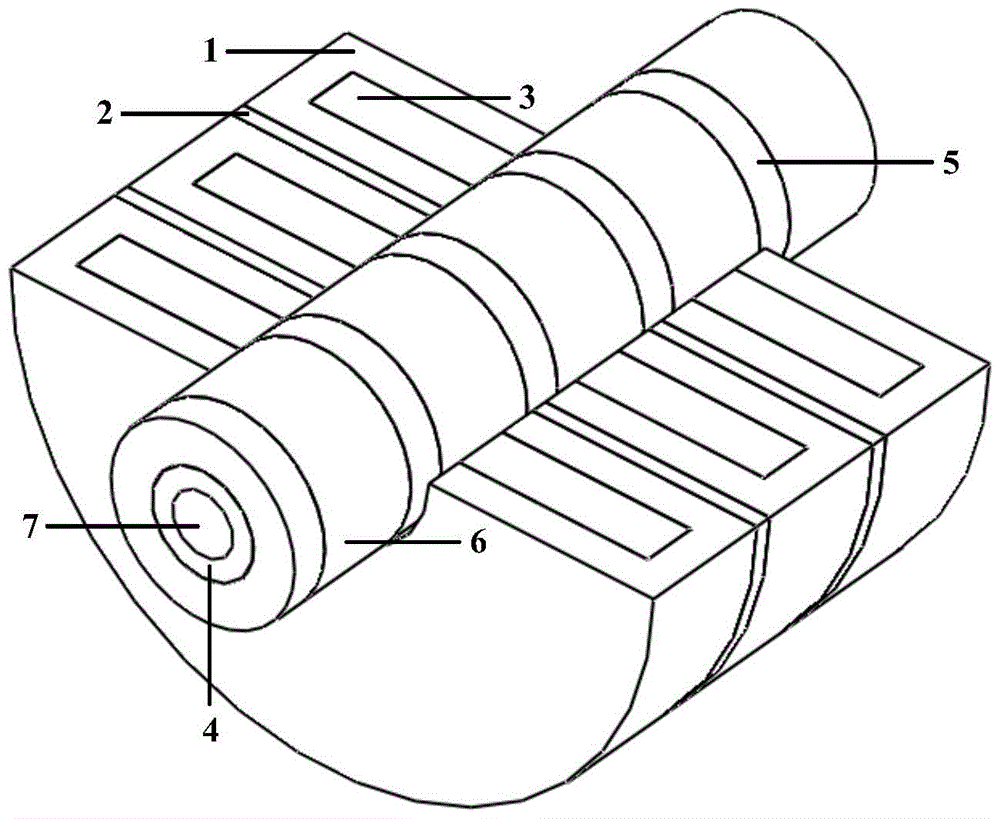

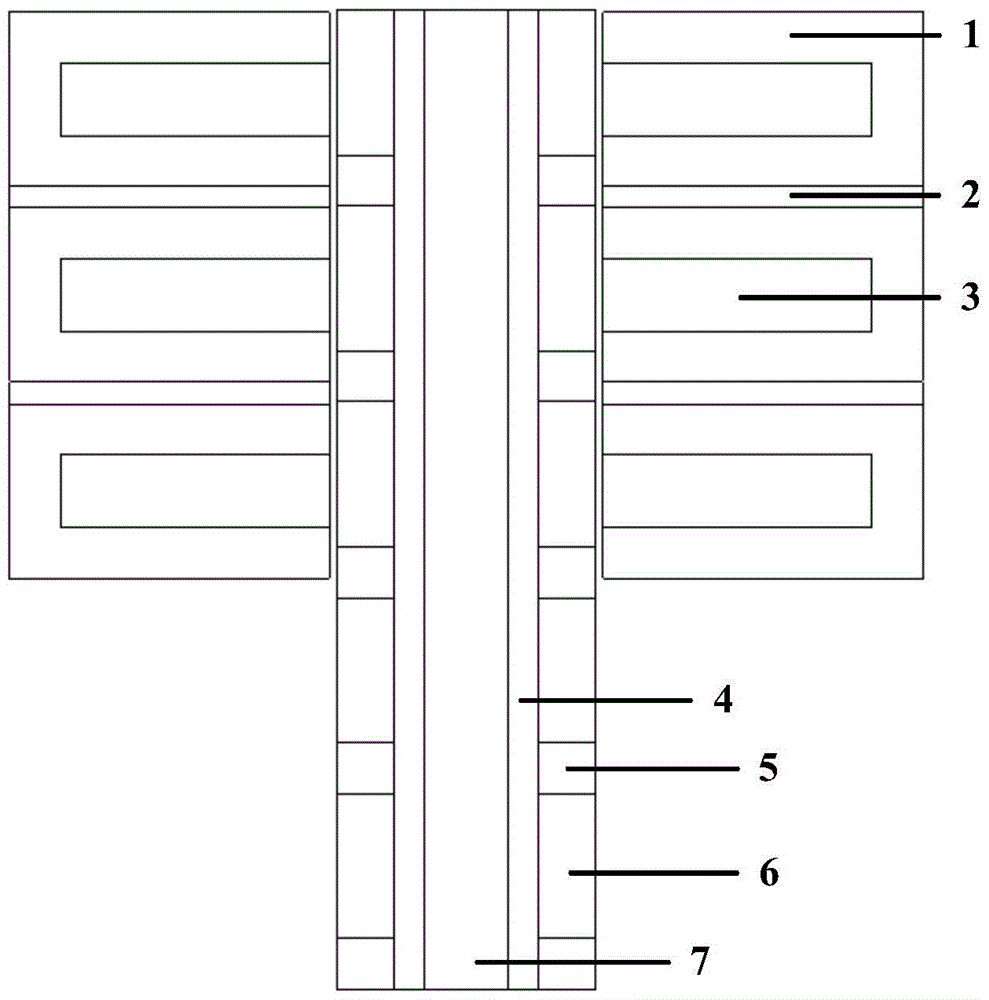

[0028] like figure 1 and figure 2 As shown, the single-phase cylindrical linear vibration motor of the present invention includes: a motor stator, a motor mover, and a bearing 7 .

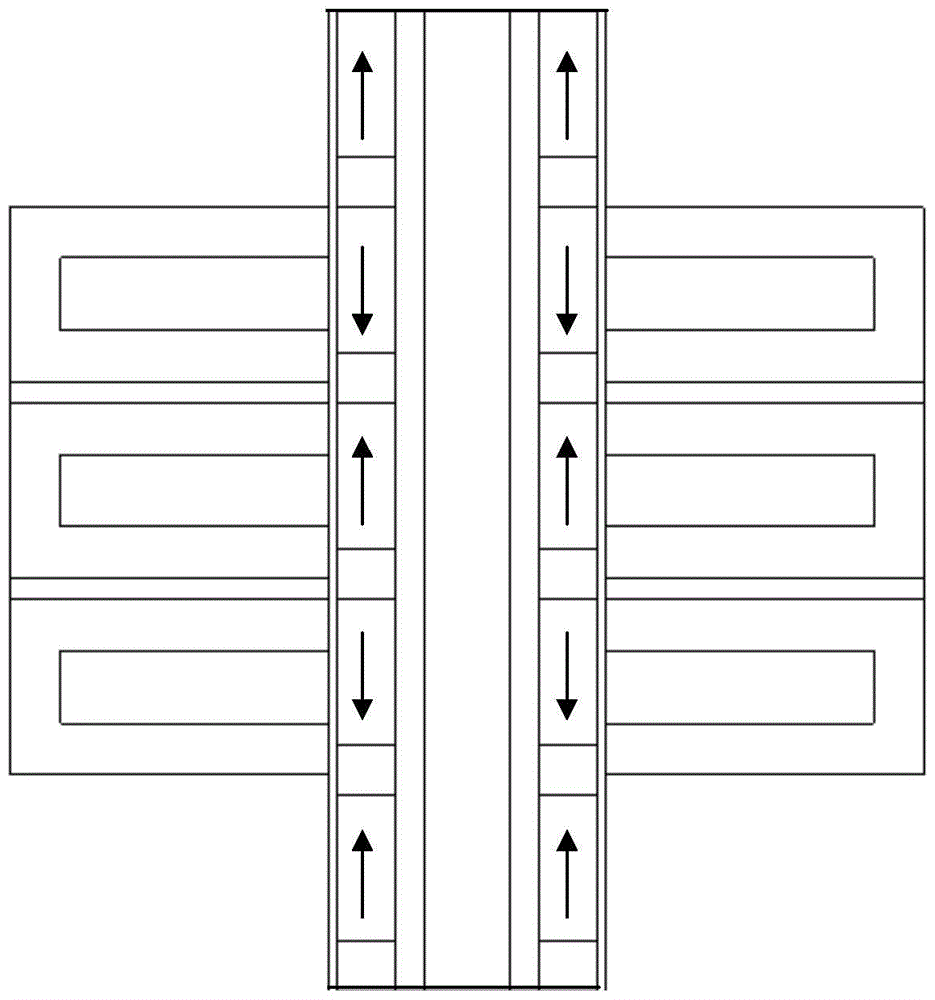

[0029] The motor stator includes three U-shaped stator cores 1, two non-magnetic conductive rings 2 and three concentric winding coils 3; among the three U-shaped stator cores 1, a non-conductive The magnetic conduction rings 2 are spaced apart, pressed and fixed; the three concentric winding coils 3 are embedded in the U-shaped slots of the three U-shaped stator cores 1, and the concentric winding coils 3 are wound on the inner wall of the U-shaped stator slot; Among the three concentric winding coils 3, the head end of the first concentric winding coil is connected to the positive pole of the power supply, the tail end is connected to the head end of the second concentric winding coil, and the tail end of the second concentric winding coil is connected to the third The first ends of the concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com