Mould for eliminating fishhook flaws of tile-shaped permanent magnetic ferrite and manufacture method of mould

A permanent magnet ferrite and tile-shaped technology, which is applied in the field of mechanical mold manufacturing, can solve problems such as waste and affecting the performance parameters of magnet materials, and achieve the effects of convenient operation, specific scheme, and reduced magnetic flux leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

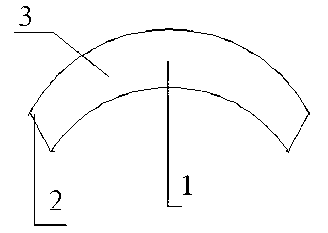

[0009] A tile-shaped mold, the tile-shaped abrasive tool includes a mold body, the surface of the lower mold is provided with a non-magnetic layer, and the non-magnetic layer includes an inner arc surface 1, platforms 2 on both sides of the inner arc surface, and a space between the inner arc surface and the platform. The transition zone 3, the thickness ratio of the inner arc surface 1, platform 2, and transition zone 3 is 2:3:1, and the non-magnetic layer is welded or affixed to the surface of the lower die of the tile-shaped mold. The mold manufacturing method for ferrite fishhook cracks comprises the following steps: the ferrite pre-fired material is wet crushed to 0.5-1.5u by ball milling to make permanent magnet ferrite powder. The shaped magnet mold is compressed into a green body by pumping water and magnetizing orientation, and then undergoes a sintering and grinding process. After the lower mold base is made according to the size of the blank, a layer of non-magnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com