Air flow orientating propelling system

A propulsion system and airflow technology, which is applied to the components of pumping devices for elastic fluids, non-variable-capacity pumps, pump devices, etc., can solve the problems of inability to fix the airflow direction, poor guiding performance, and low propulsion force, etc. Achieve the effect of large propulsion, strong airflow guiding performance and strong driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

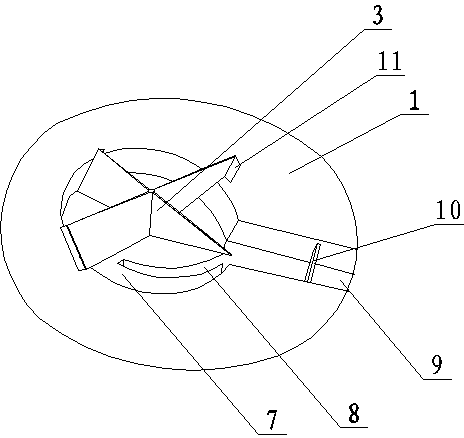

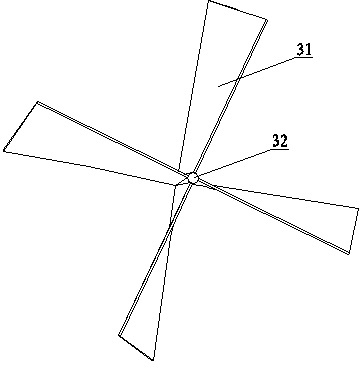

[0030] Specific implementation mode one: see figure 1 with figure 2 The airflow directional propulsion system of the present invention comprises a propeller body 1 and a blade torque propeller 3, the blade torque propeller 3 is installed above the propeller body 1, and the transmission shaft 32 of the blade torque propeller 3 is placed on the propeller body 1 is connected to the power system at the bottom, and the tail of the propeller main body 1 is provided with an airflow dredging outlet 9, and the top of the propeller main body 1 has a circular air compression chamber 7, and the blade torque propeller 3 is located in the circular air compression chamber 7, the circular air compression chamber 7 communicates with the airflow dredging exhaust port 9, the blade torque propeller 3 includes a plurality of paddle blades 31 and a transmission shaft 32, and the plurality of paddle blades 31 are annularly arrayed on the outer wall of the transmission shaft 32 above, and the conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com