Design method and device of corn sheller

A design method and threshing machine technology, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems of belt connection power output, slow granule separation speed, low production efficiency, etc., and achieve large propulsion and continuous Good, easy to process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

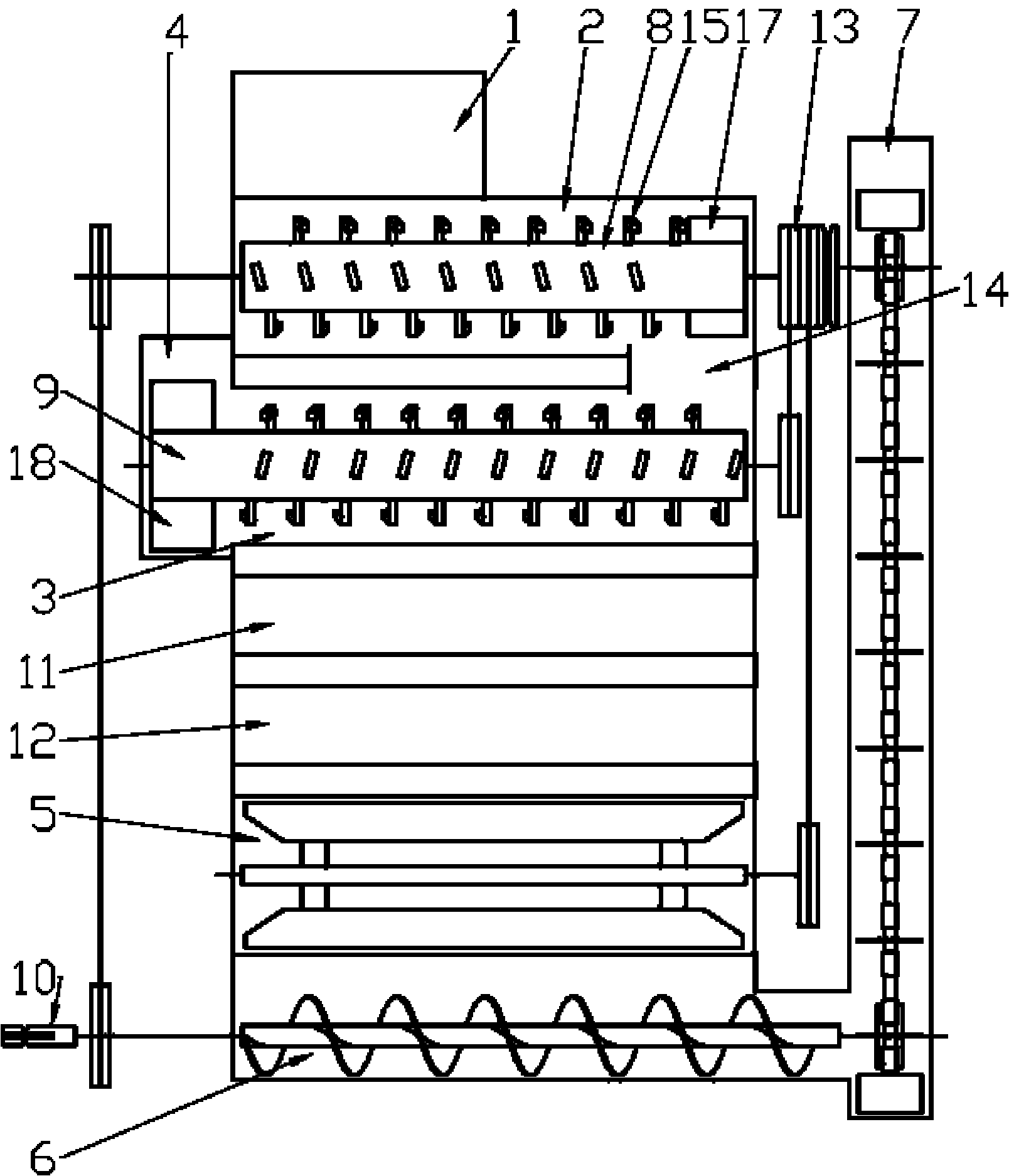

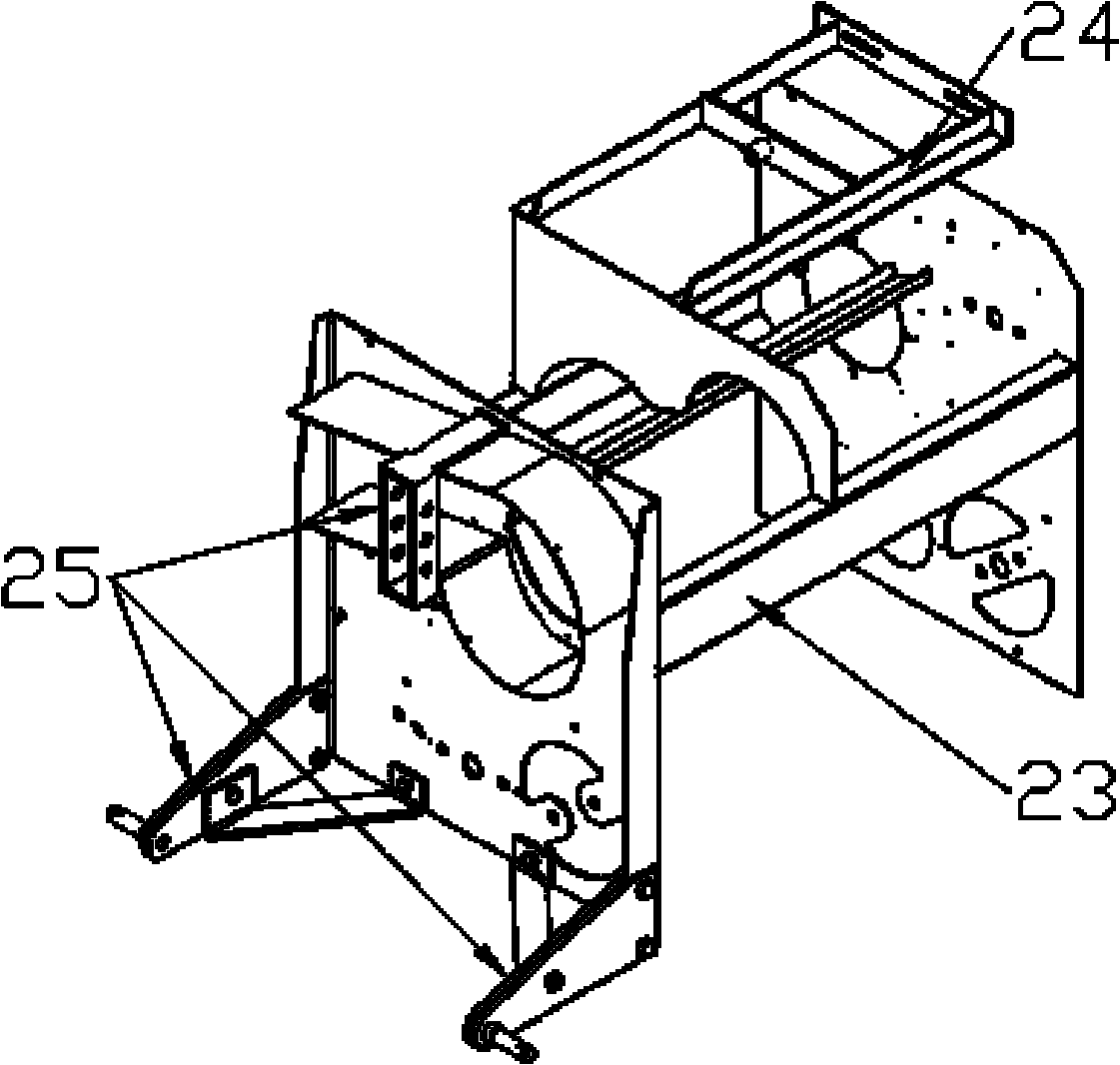

[0029] Embodiment 1: Its power transmission mechanism, threshing mechanism, conveying mechanism, impurity cleaning mechanism and frame five major structures and the connection relationship between these five parts are basically similar to known technology, or with patent No. 02145589.9 corn thresher The structure is basically the same, and the difference is that the roller of its threshing mechanism has sieve holes 16, and the longitudinal direction of the sieve holes 16 is longer than the horizontal direction, and the length and width ratio is 1.1:1 to 5:1. In this way, the throughput is increased while ensuring the quality of the pellets. Patent No. 02145589.9 corn thresher is easily blocked by corn husks and the like.

Embodiment 2

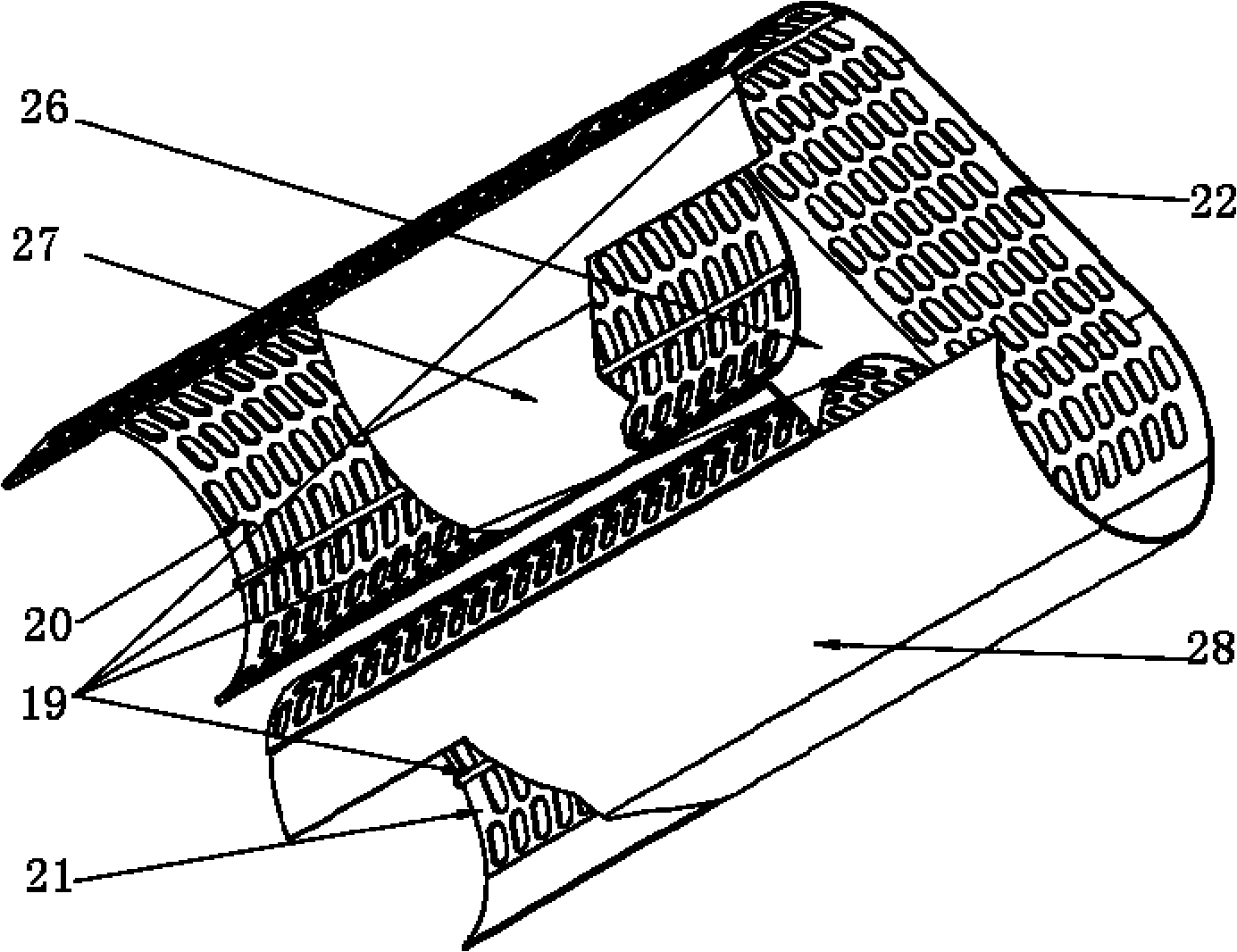

[0030] Embodiment 2: It is basically the same as Embodiment 1, except that its threshing mechanism has a plurality of protrusions 19 evenly distributed on the inner surface of the roller with screen holes 16 .

Embodiment 3

[0031] Embodiment 3: It is also basically the same as Embodiment 1, the difference is that the nail teeth 15 distributed on the main roller 8 and the auxiliary roller 9 are composed of a tooth column and a tooth tail, the top of the tooth column has a tooth tail, and the cross section of the tooth column is a circle The cross-section of the tooth tail is rectangular, and the angle between the tooth column and the tooth tail is selected at 70-85 degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com