Efficient ducted propeller

A ducted propeller and high-efficiency technology, applied in ship propulsion, ship parts, ships, etc., can solve problems such as affecting the normal navigation of ships, easy to get stuck in water and grass debris, etc., to increase propulsion, reduce possibility, and improve work. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

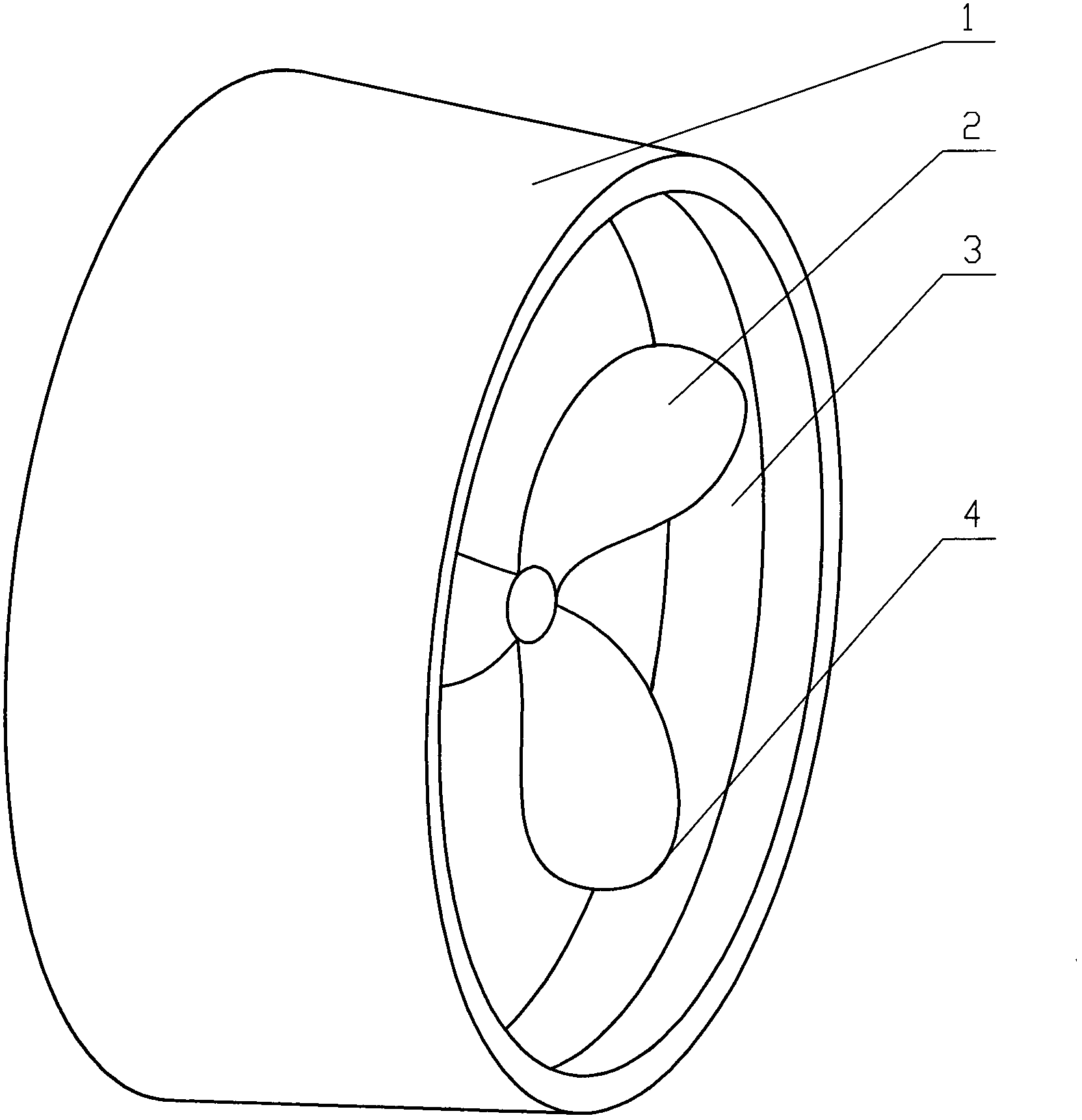

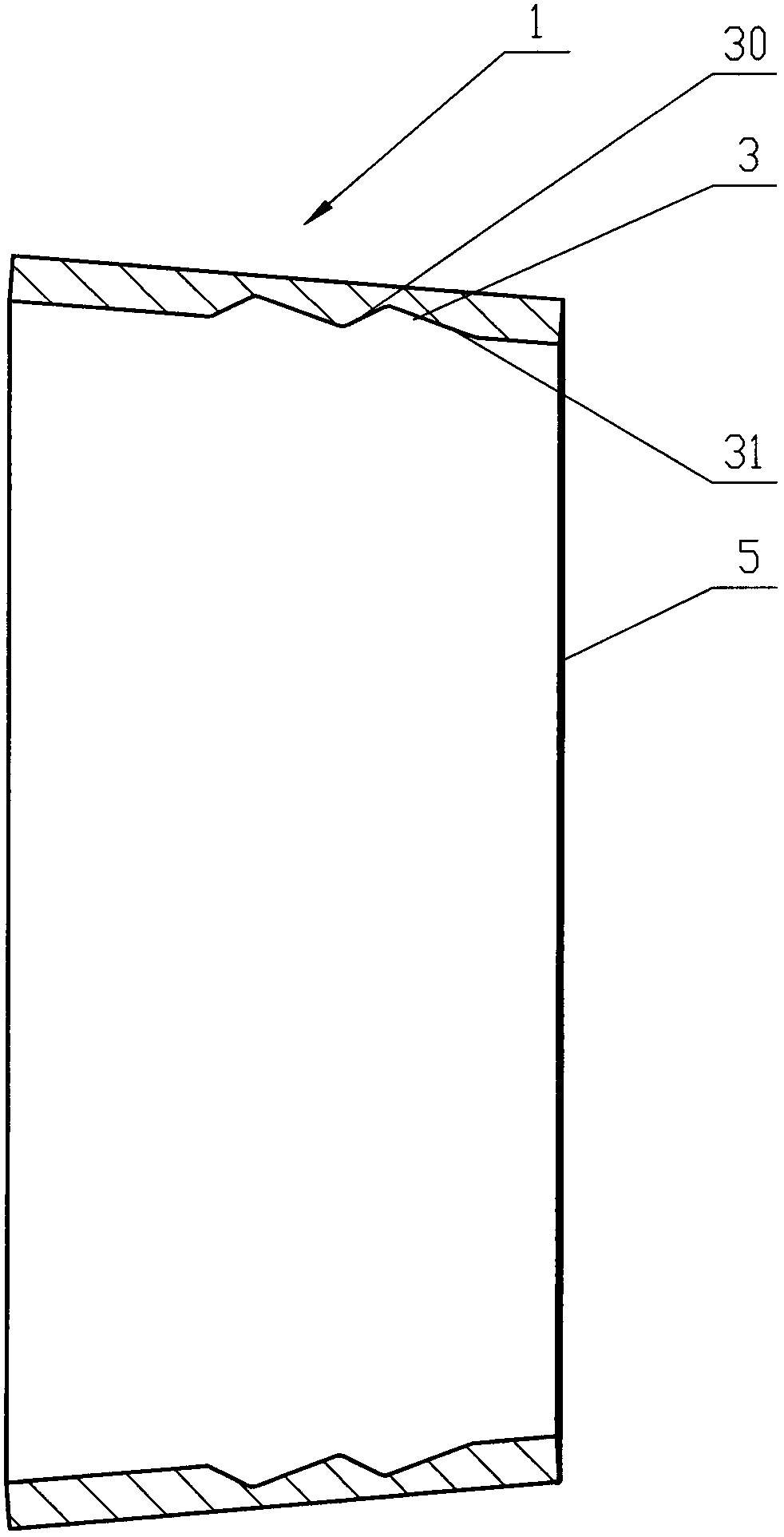

[0014] See figure 1 , the present invention includes a conduit 1 and a paddle 2 , wherein the inner surface of the conduit 1 is provided with a groove 3 , and the position of the groove 3 corresponds to the peripheral position of the tip 4 of the paddle 2 . See figure 2 The groove 3 of the conduit 1 includes a front end part 31 and a rear end part 30, the front end part 31 is close to the small-diameter end 5 of the conduit 1, there is a slope between the front end part 31 and the rear end part 30, and the slope of the front end part 31 is smaller than the rear end The inclination of the part 30 is to facilitate the discharge of sundries and increase the propulsive force of the propeller; the groove 3 may include a plurality, the number of which is set according to the manufacturing cost of the propeller and the load of the ship.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com