Minisize linear driver based on dimorphic crystal piezoelectric film

A linear actuator, piezoelectric film technology, applied in micro manipulators, fluids using vibration, manipulators, etc., can solve problems such as inability to work, reduced output speed, and difficulty in miniaturization, achieving low cost, increased speed, and improved drive. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A preferred embodiment of the present invention is described as follows in conjunction with accompanying drawing:

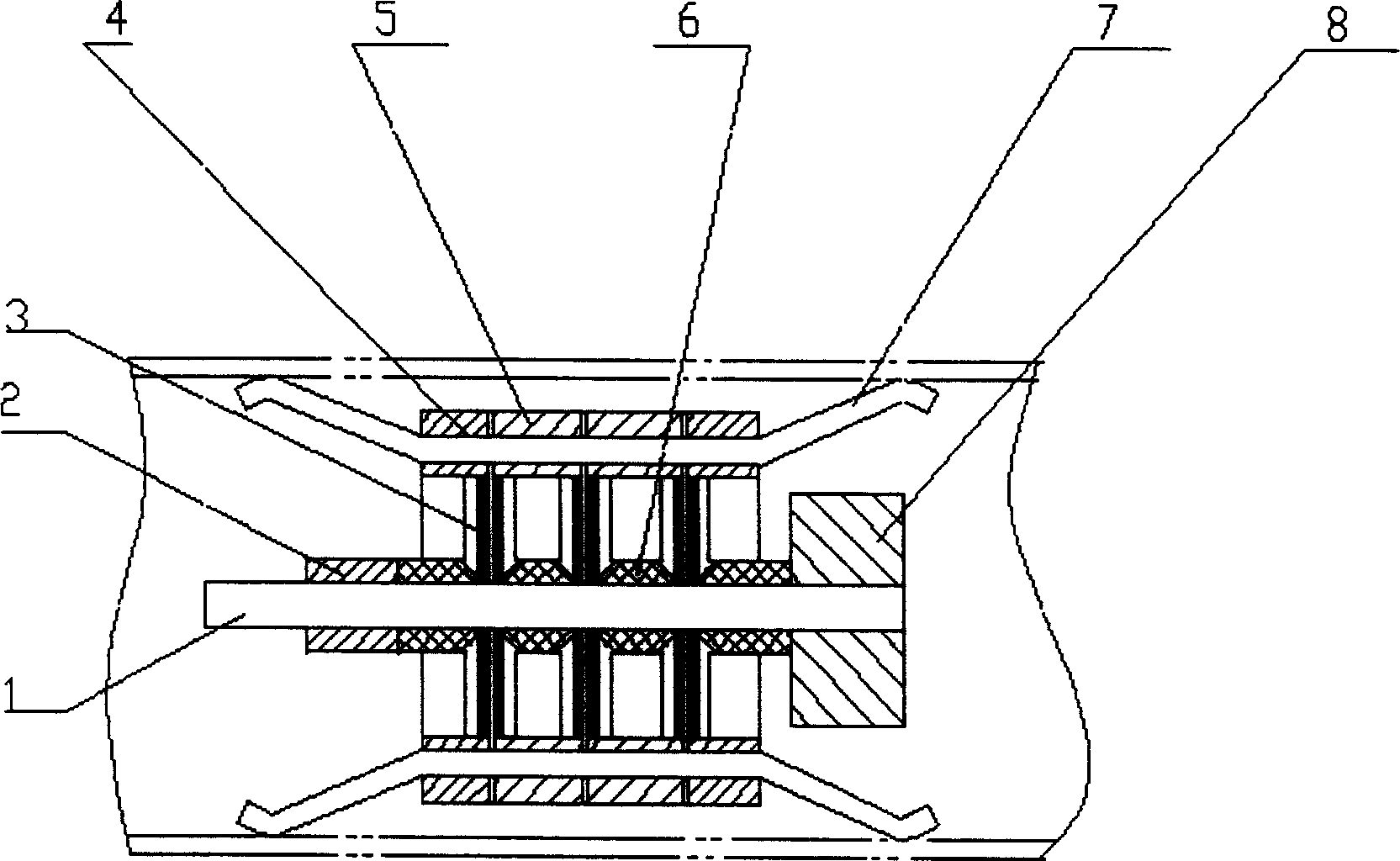

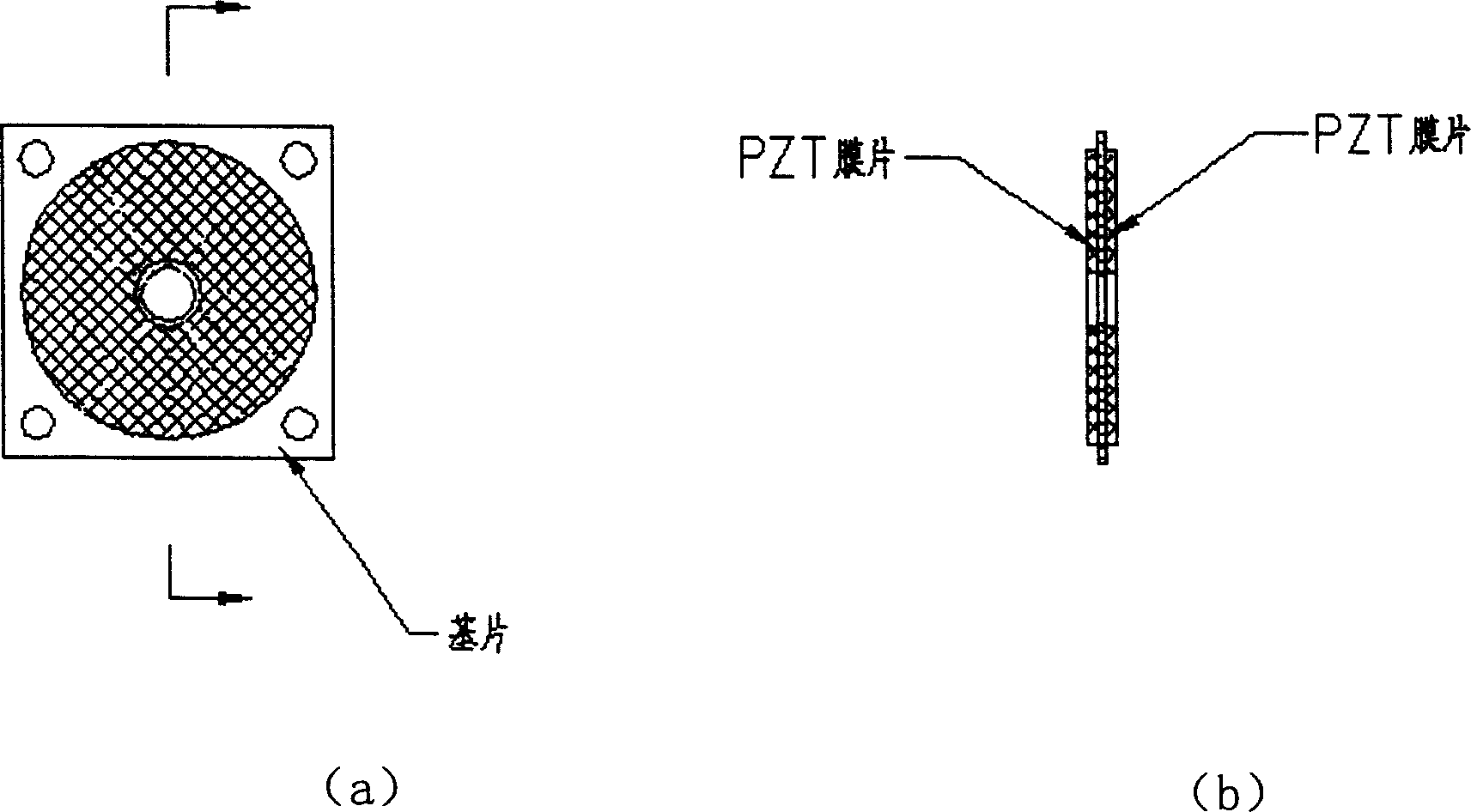

[0030] see figure 1 , the miniature linear actuator based on the double crystal piezoelectric film consists of the following parts: central shaft 1, fixed sleeve 2, double crystal piezoelectric film 3, end rigid frame 4, middle rigid frame 5, insulating isolation sleeve 6, elastic support feet 7. Inertial mass block 8.

[0031] The inertial mass 3 is set on one end of the central axis 1, several bicrystalline piezoelectric films 3 are set on the middle of the central axis, and the sheets are separated by an insulating spacer 6, and the fixed sleeve 2 is separated from the other end of the central axis 1. One end is inserted, and the spacer sleeve 6 is pressed tightly, so that each bicrystalline piezoelectric film 3 is tightened along the axis direction of the central axis 1, and then the fixed sleeve 2 is welded to the central axis 1. The middle rigid fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com