Minisize linear driver based on dimorphic crystal piezoelectric film

A technology of linear actuators and piezoelectric films, applied in the direction of micro-manipulators, fluids that use vibration, and manipulators, can solve problems such as inoperability, reduced output speed, and difficulty in miniaturization, and achieve low cost, increased speed, and improved drive. speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A preferred embodiment of the present invention is described as follows with reference to the drawings:

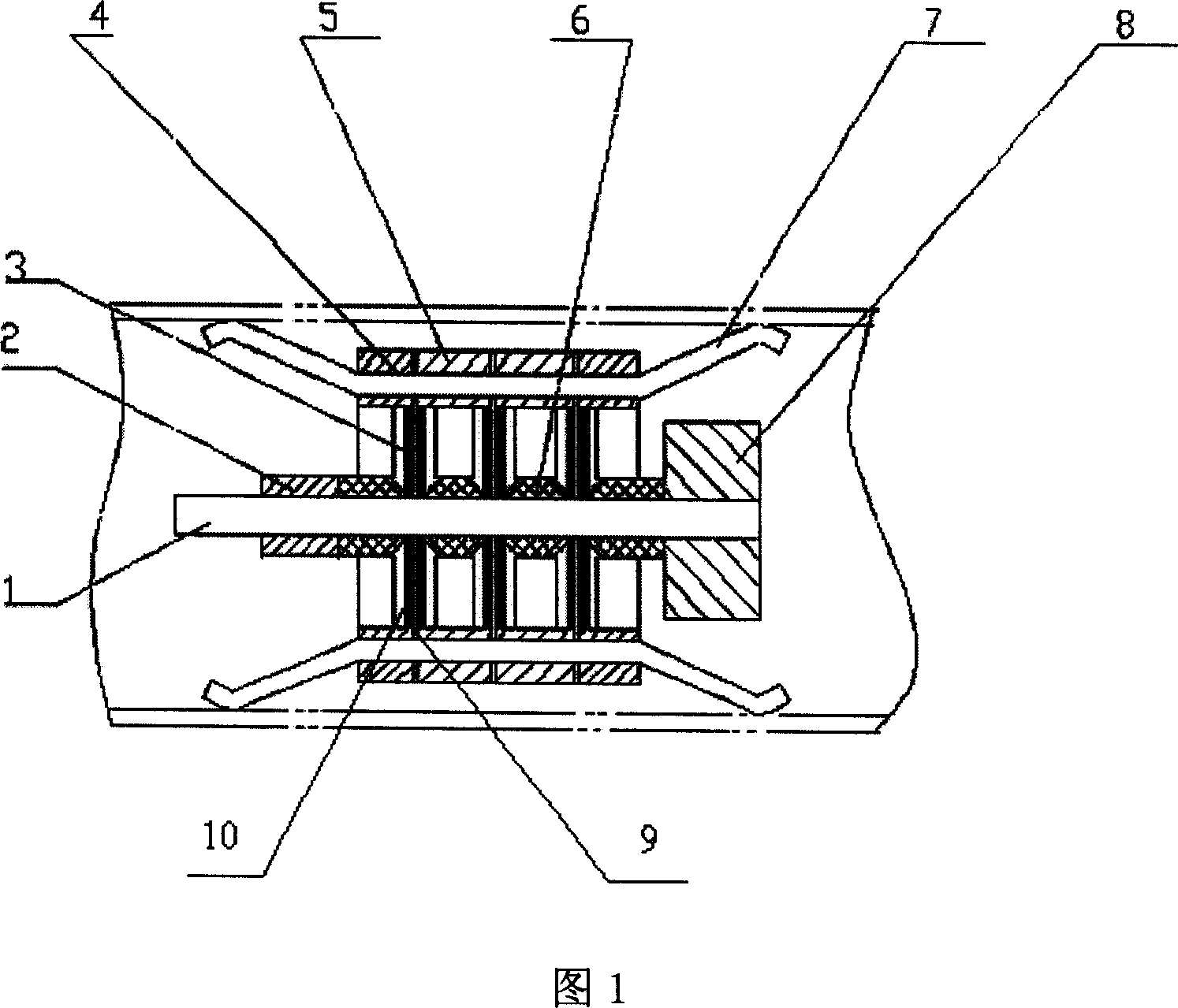

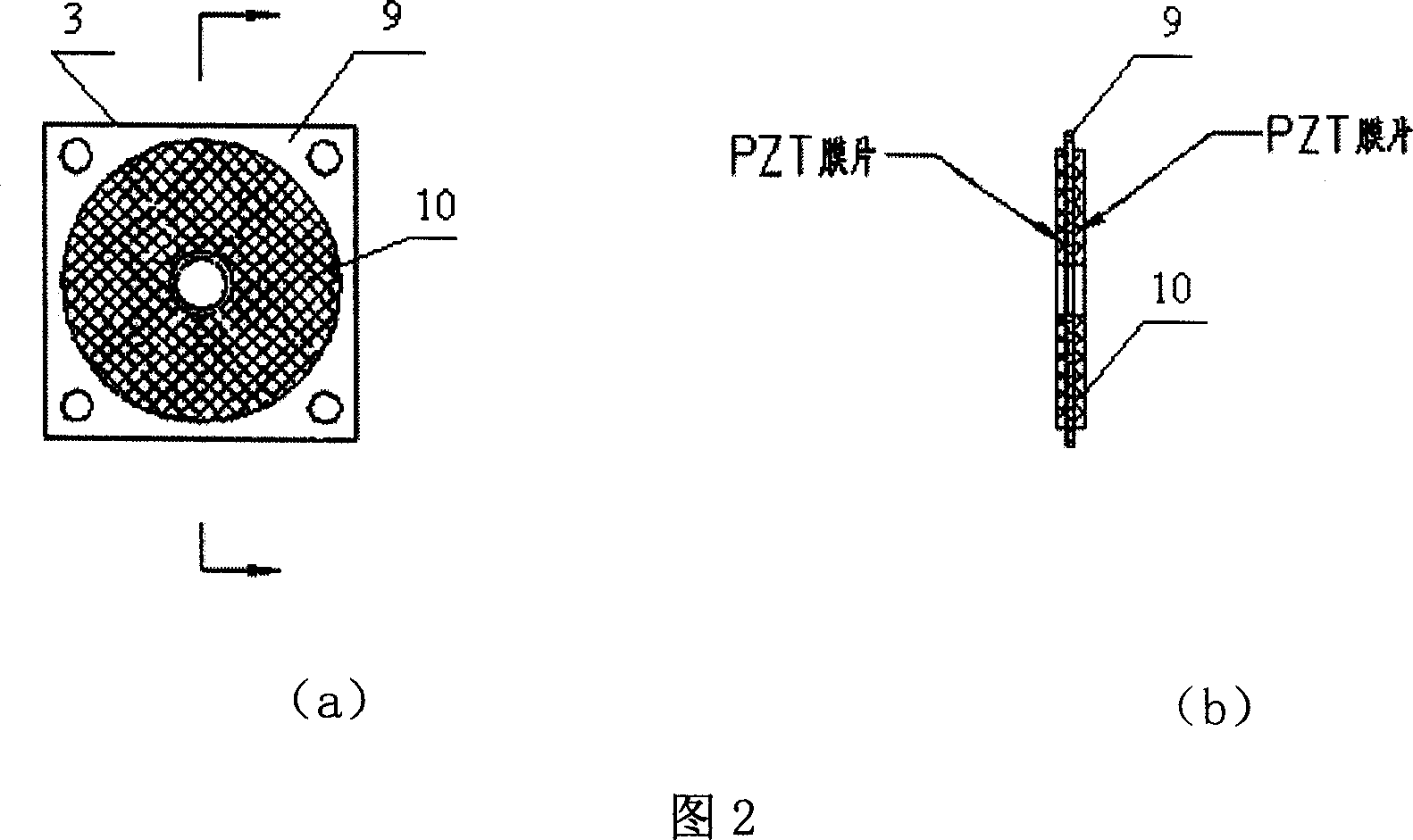

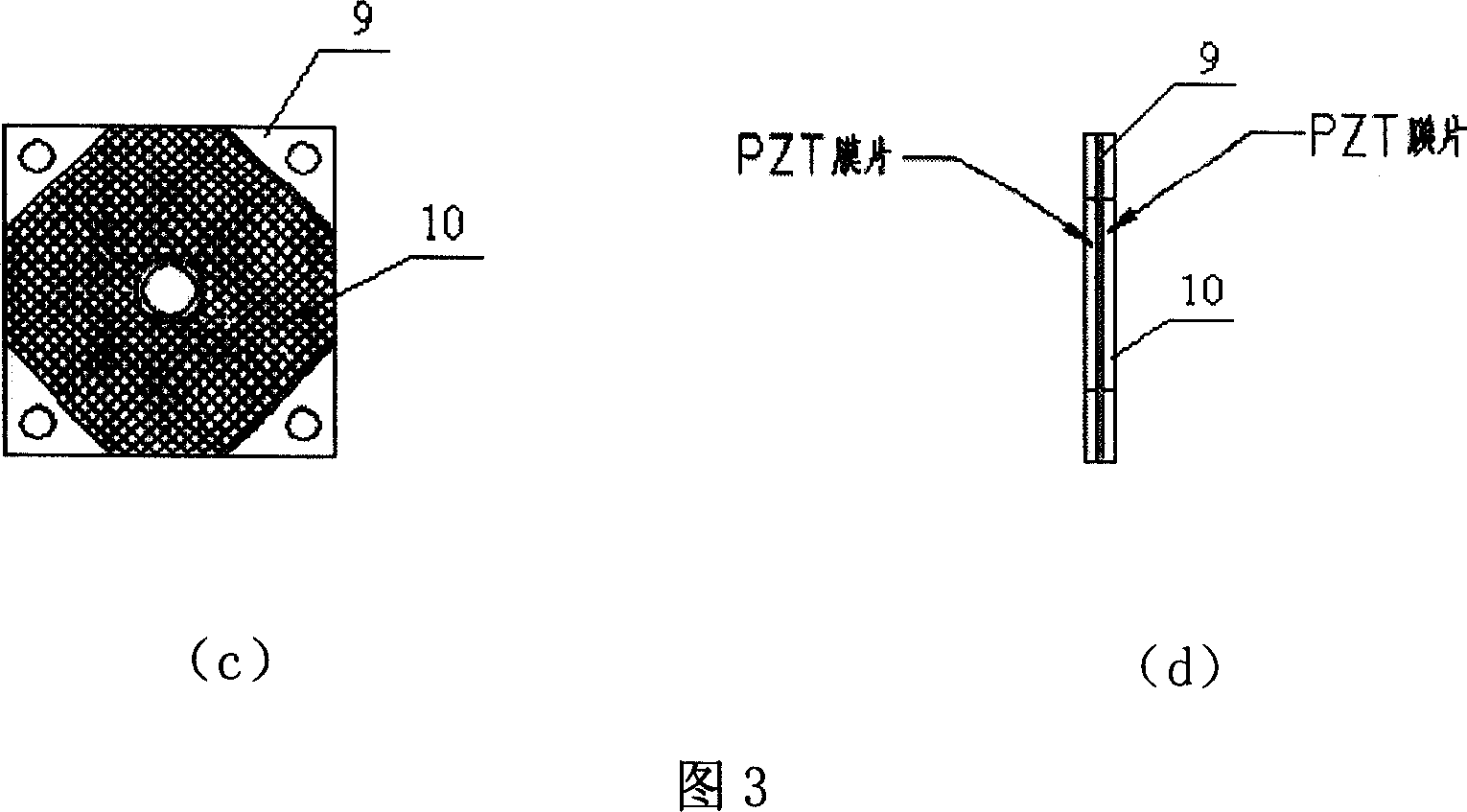

[0030] Referring to Figure 1, the miniature linear actuator based on dual-crystal piezoelectric film has the following components: central shaft 1, fixed sleeve 2, dual-crystal piezoelectric film 3, end rigid frame 4, middle rigid frame 5, insulating sleeve 6, Elastic support foot 7, inertial mass 8.

[0031] The inertial mass 3 is sleeved on one end of the central shaft 1, several bimorph piezoelectric films 3 are sleeved in the middle of the central shaft, and the plates are separated by an insulating isolating sleeve 6, and the fixed sleeve 2 is separated from the other side of the central shaft 1. One end is sleeved, and the isolating sleeve 6 is pressed tightly, so that the bimorph piezoelectric films 3 are fastened along the axial direction of the central shaft 1, and then the fixed sleeve 2 is welded to the central shaft 1 to close. The middle rigid frame 5 separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com