Purification and dust removal device

A dust removal device and a combined technology, applied in the field of printing and dyeing industry, can solve the problems of uneven electric field strength of the dust suction mechanism, easy vibration of the cathode line, small effective area, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

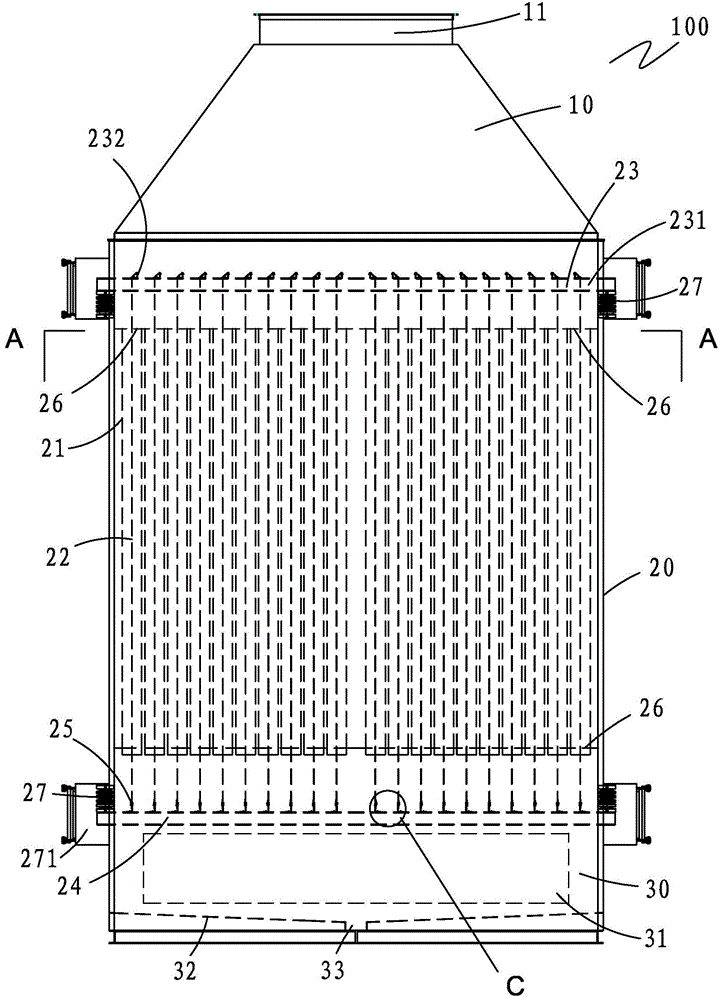

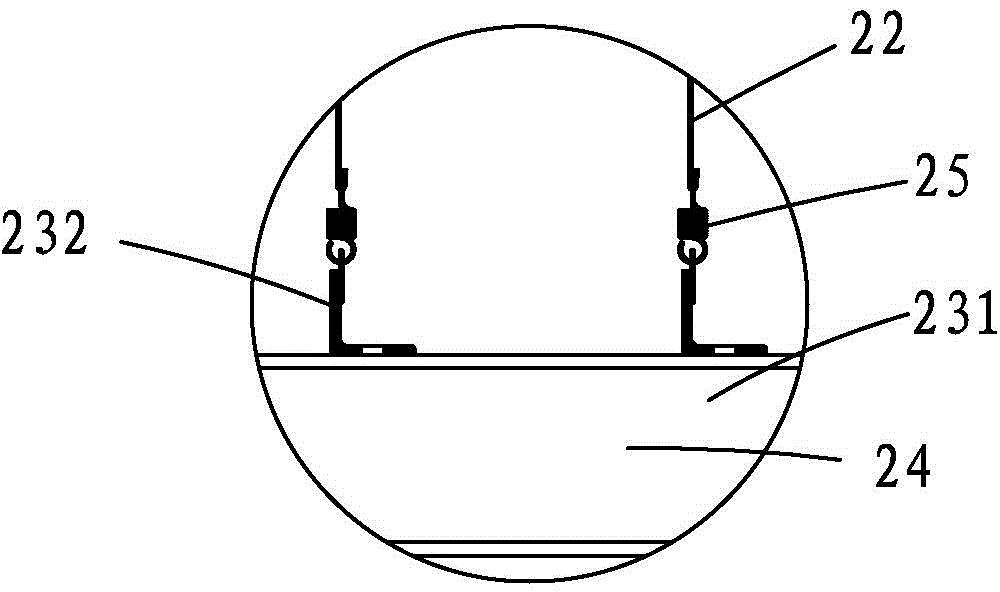

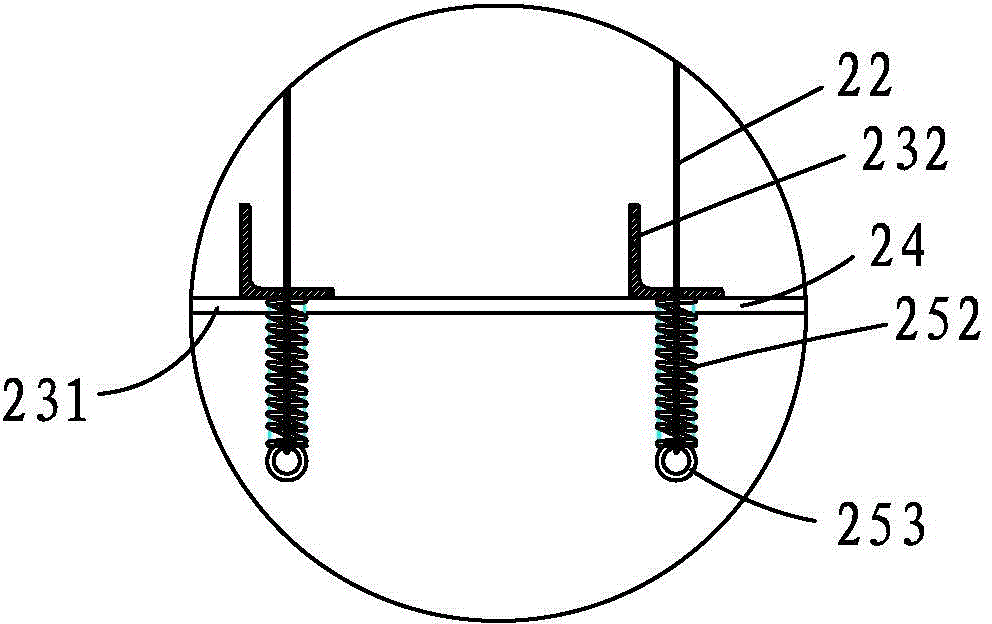

[0026] see Figure 1 to Figure 7 , a purification and dust removal device, the box 100 of the purification and dust removal device includes an upper box 10, a middle box 20 and a lower box 30, the upper box 10 is provided with an air outlet 11, and the lower box The side wall of 30 is provided with an air inlet 31, and the air inlet 31 is provided with at least one defogging plate 311, please refer to Figure 6 and Figure 7 , the defogging plate 311 is composed of a frame 3111 and a plurality of defogging sheets 3112, the upper and lower ends of each of the defogging sheets 3112 are fixed on the frame 3111, and the defogging sheets 311 are composed of two The two surfaces are integrally formed and form an included angle α, and the range of the included angle is 90°≤α≤160°. When the exhaust gas passes through the defogging plate, the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com