Static mixer for ethylene and oxygen

A static mixer, ethylene technology, used in fluid mixers, mixers, transportation and packaging, etc., can solve the problems of unsatisfactory mixing effect of olefin and oxygen, and achieve simple structure, increased pressure drop, and uniform speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

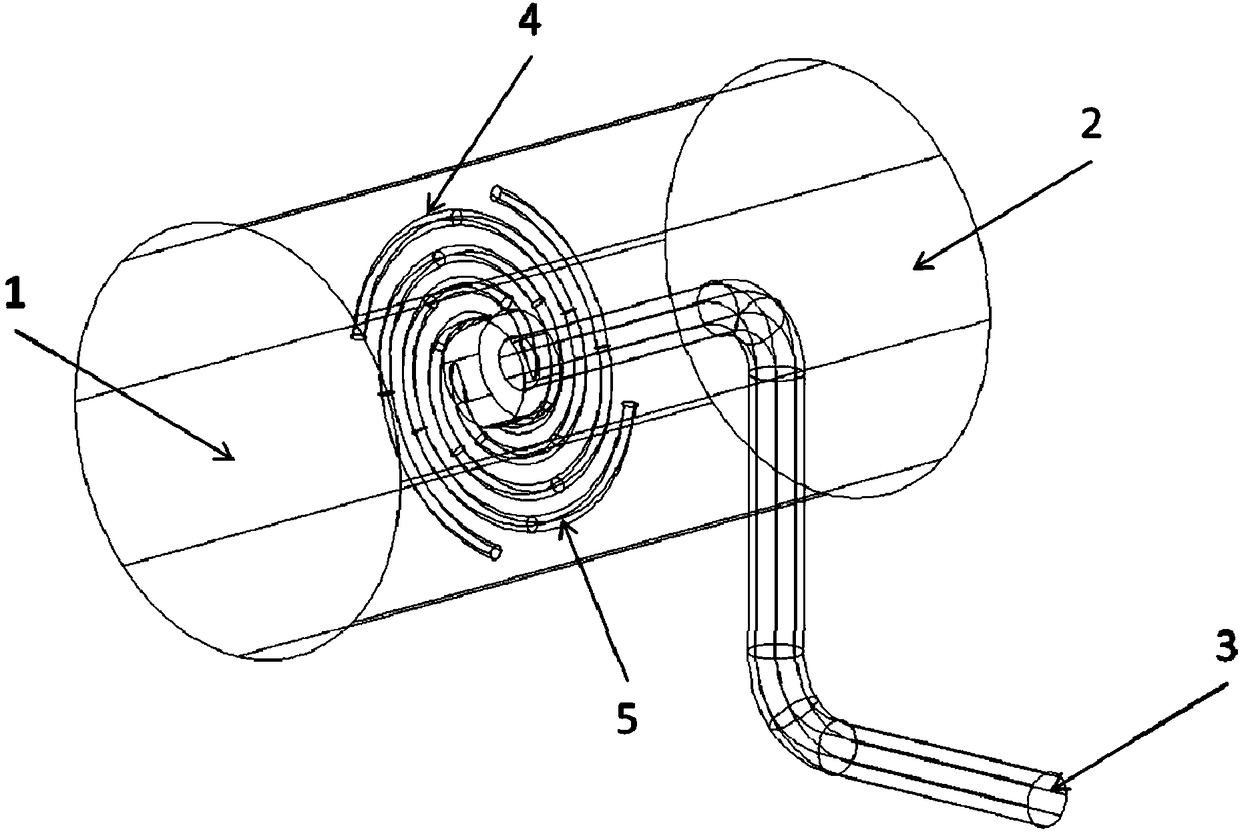

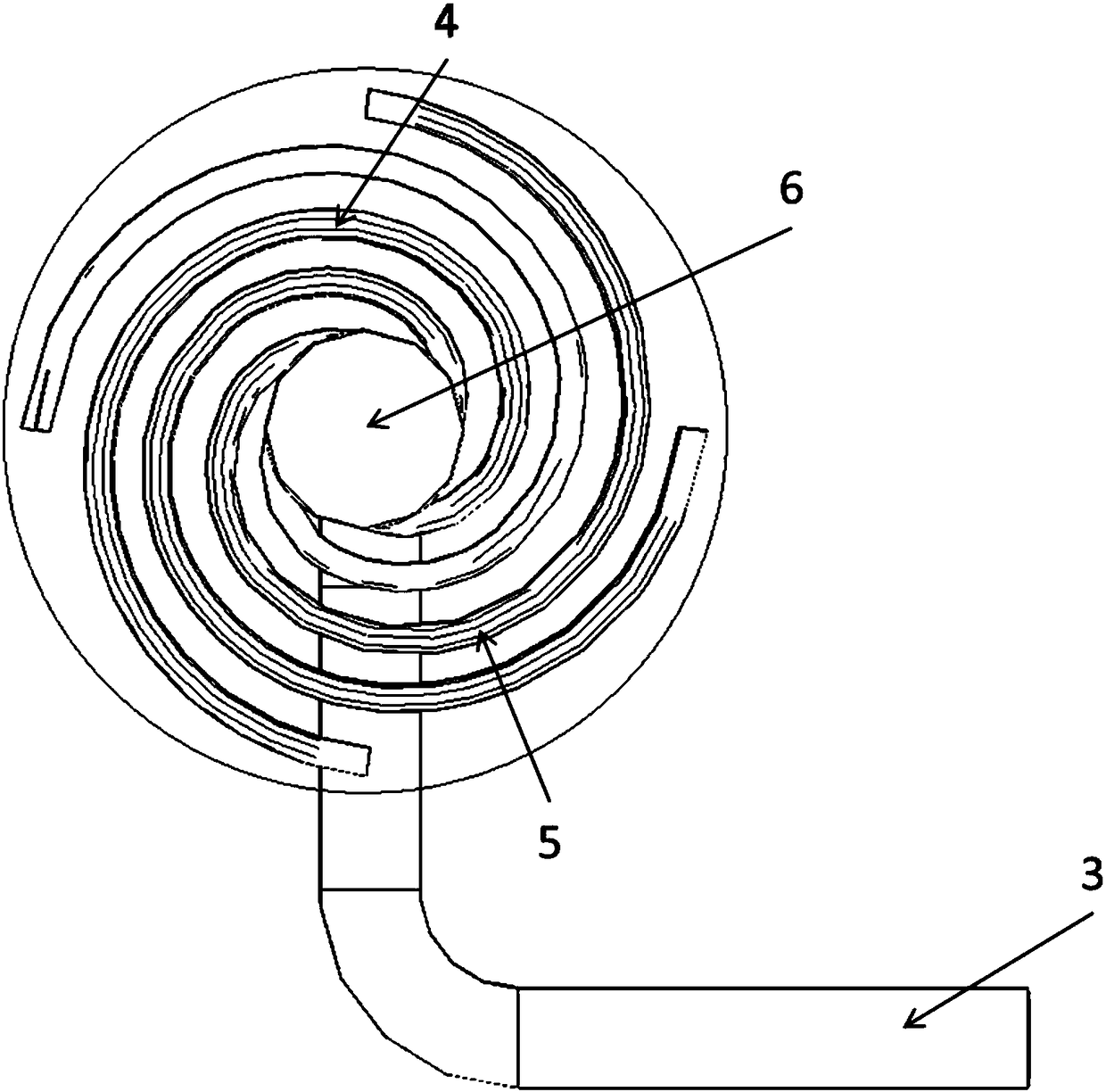

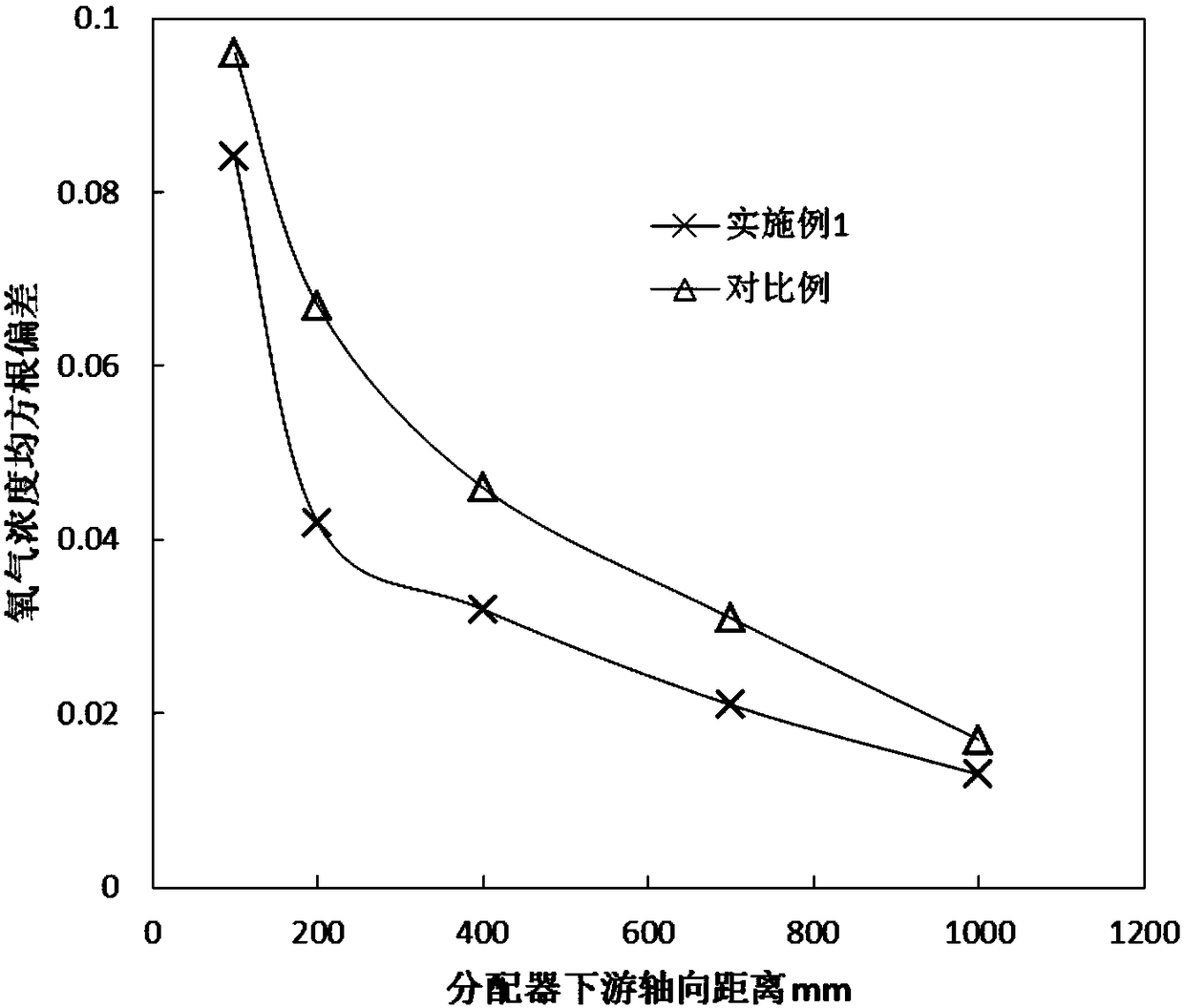

[0023] A static mixer of ethylene and oxygen, such as figure 1 , 2 As shown, the olefin enters the mixing zone along the main channel, and the oxygen passes through the wall of the olefin main channel and enters the central oxygen distributor of the mixing chamber. Ethylene mixes quickly and evenly.

[0024] The structural parameters of the online mixing equipment mixer are as follows:

[0025] use figure 1 with figure 2 For the mixer of ethylene and oxygen shown, the internal diameter of the olefin main pipeline is DN1100, the diameter of the oxygen pipeline is DN150, the central oxygen distributor is a sphere with a diameter of 250, the diameter of the spiral distribution pipe is DN80, and the number of spiral distribution pipes is 3, divided into The piping inlets are evenly distributed in the cross-section of the olefin main pipeline, the angle between adjacent spiral distribution pipes is 120 degrees, the average flow velocity in the distribution pipes is 12m / s, and ...

Embodiment 2

[0039] According to the conditions and steps described in embodiment 1, the structural parameters of the online mixing equipment mixer are as follows:

[0040] The structural parameters of the online mixing equipment mixer are as follows:

[0041] use figure 1 with figure 2 For the mixer of ethylene and oxygen shown, the internal diameter of the olefin main pipeline is DN1100, the diameter of the oxygen pipeline is DN150, the central oxygen distributor is a sphere with a diameter of 250, the diameter of the spiral distribution pipe is DN80, and the number of spiral distribution pipes is 5. The pipe inlets are evenly distributed in the cross-section of the olefin main pipe, the angle between adjacent spiral distribution pipes is 72 degrees, the average flow velocity in the distribution pipes is 11m / s, and each spiral distribution pipe has 35 small holes with a diameter of 11mm , the nozzle speed is 45m / s, and the ends of the five spiral distribution pipes converge with the c...

Embodiment 3

[0055] According to the conditions and steps described in embodiment 1, the structural parameters of the online mixing equipment mixer are as follows:

[0056] The structural parameters of the online mixing equipment mixer are as follows:

[0057] use figure 1 with figure 2 For the mixer of ethylene and oxygen shown, the internal diameter of the olefin main pipeline is DN500, the diameter of the oxygen pipeline is DN50, the central oxygen distributor is a sphere with a diameter of 100, the diameter of the spiral distribution pipe is DN32, and the number of spiral distribution pipes is 2, divided into The pipe inlets are evenly distributed in the cross-section of the olefin main pipe, the angle between adjacent spiral distribution pipes is 180 degrees, the average flow velocity in the distribution pipes is 9m / s, and each spiral distribution pipe has 35 small holes with a diameter of 11mm , the nozzle speed is 45m / s, and the ends of the two spiral distribution pipes converge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com