Patents

Literature

46results about How to "Solve repair problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Laser cladding Co-based alloy powder for conductor roll

InactiveCN101187022ASolve repair problemsImprove performanceMetallic material coating processesChemical compositionAlloy substrate

Provided is cobalt-based alloy powder for laser cladding electricity conducting roller, the weight percentages of the chemical components of the material are that Cr is 24-30%, W is 6-10%, Mo is 3-6%, Ni takes 6-12%, Fe holds 2-10%, Mn is 0.5-2%, Si holds 0.2-2%, V is 0.1-0.6%, B takes 0.3-1.5%, C holds 0.5-2.5%, Y2O3 is 0-0.5%, Hf takes 0-0.5%, La2O3 holds 0-0.5%, Ce is 0-0.5%, and the rest is Co. The invention has the advantages that with multiple strengthened methods, the alloy substrate is strengthened and the crystal boundary quality is improved, which enables the alloy to achieve perfect combination property, thereby achieving medium rigidity and relatively high intensity of the alloy, simultaneously forming self-fluxing alloy and reducing alloy melting point, and increasing properties of oxidation resistance, abrasion resistance, corrosion resistance, and certain electricity conduction.

Owner:SHENYANG DALU LASER TECH

Gradient alloy material and method for laser strengthening of copper plate of crystallizer of continuous casting machine

InactiveCN103805813AImprove toughnessStrong metallurgical bondMetallic material coating processesWear resistantHigh-temperature corrosion

The invention provides a gradient alloy material and method for laser strengthening of a copper plate of a crystallizer of a continuous casting machine. The method comprises the following steps: enabling transition of a nickel-based alloy material and a substrate on the working surface of a narrow chromium zirconium copper plate of the crystallizer by a laser cladding technology; and then cladding a special cobalt-based alloy material on the nickel-based alloy transition layer to form a new gradient alloy layer on the working surface of the narrow chromium zirconium copper plate of the crystallizer, wherein the gradient alloy layer is resistant to high temperature corrosion and wear resistant and is of an ultrafine and high-toughness metallographic structure. The cobalt-based alloy material is the novel cobalt-based alloy material prepared from the cobalt-based alloy by adding Hf, B and Si elements on the basis of satellite, and then properly lowering down the melting point of the alloy. Compared with the prior art, the gradient alloy material and method have the beneficial effects that the resistance to high-temperature corrosion and the wear resistance of the working surface of the narrow plate of the crystallizer are improved, the laser repair and reproduction of a crystallizer out of work are realized, and the use performance of the crystallizer can also be recovered and improved; in addition, the problem due to the repair of a chromium zirconium copper crystallizer out of work can be effectively solved; the quality of a casting blank is improved; the casting cost of steel per ton can be decreased.

Owner:鞍山煜宸科技有限公司

Method for repairing converter supporting ring

The invention relates to a method for repairing a converter supporting ring. The method comprises the following steps that (1) an old converter supporting ring is disassembled, and a transmission side trunnion and a non-transmission side trunnion assembly are obtained; (2) a tangential key on the transmission side trunnion is removed; (3) a large gear on the transmission side trunnion is dismounted; (4) new supporting ring fan-shaped sections are designed and made optimally; (5) two trunnion assemblies are repaired and the ends of the trunnion are sealed; (6) the two trunnion assemblies and the two fan-shaped sections are assembled on site; (7) the two trunnion assemblies and the two fan-shaped sections are welded and annealed on site. The method is used for repairing the converter supporting ring, greatly shortens the manufacturing period of the supporting ring, guarantees repairing quality and saves a great number of spare part expenses for enterprises.

Owner:甘肃酒钢集团西部重工股份有限公司

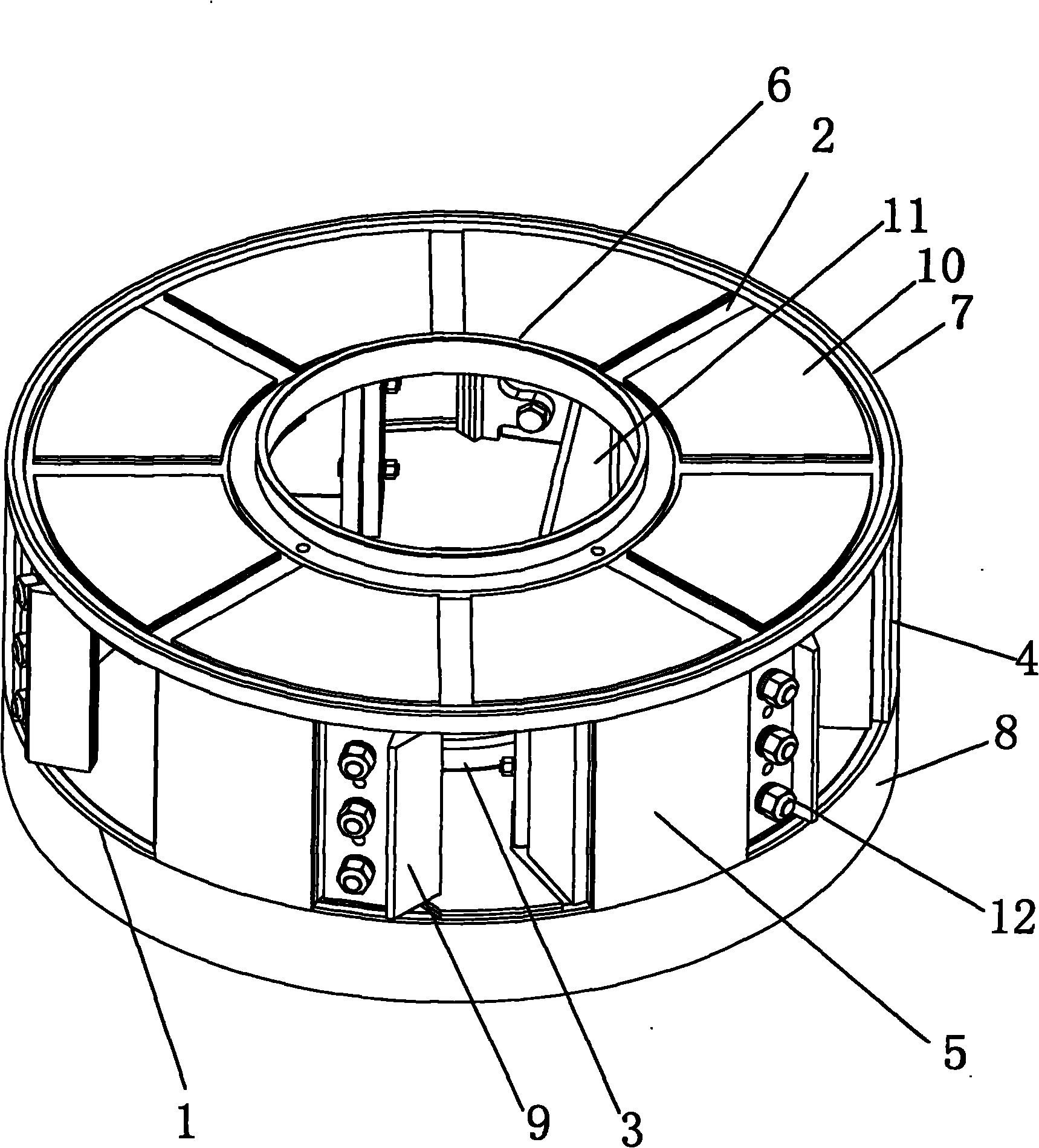

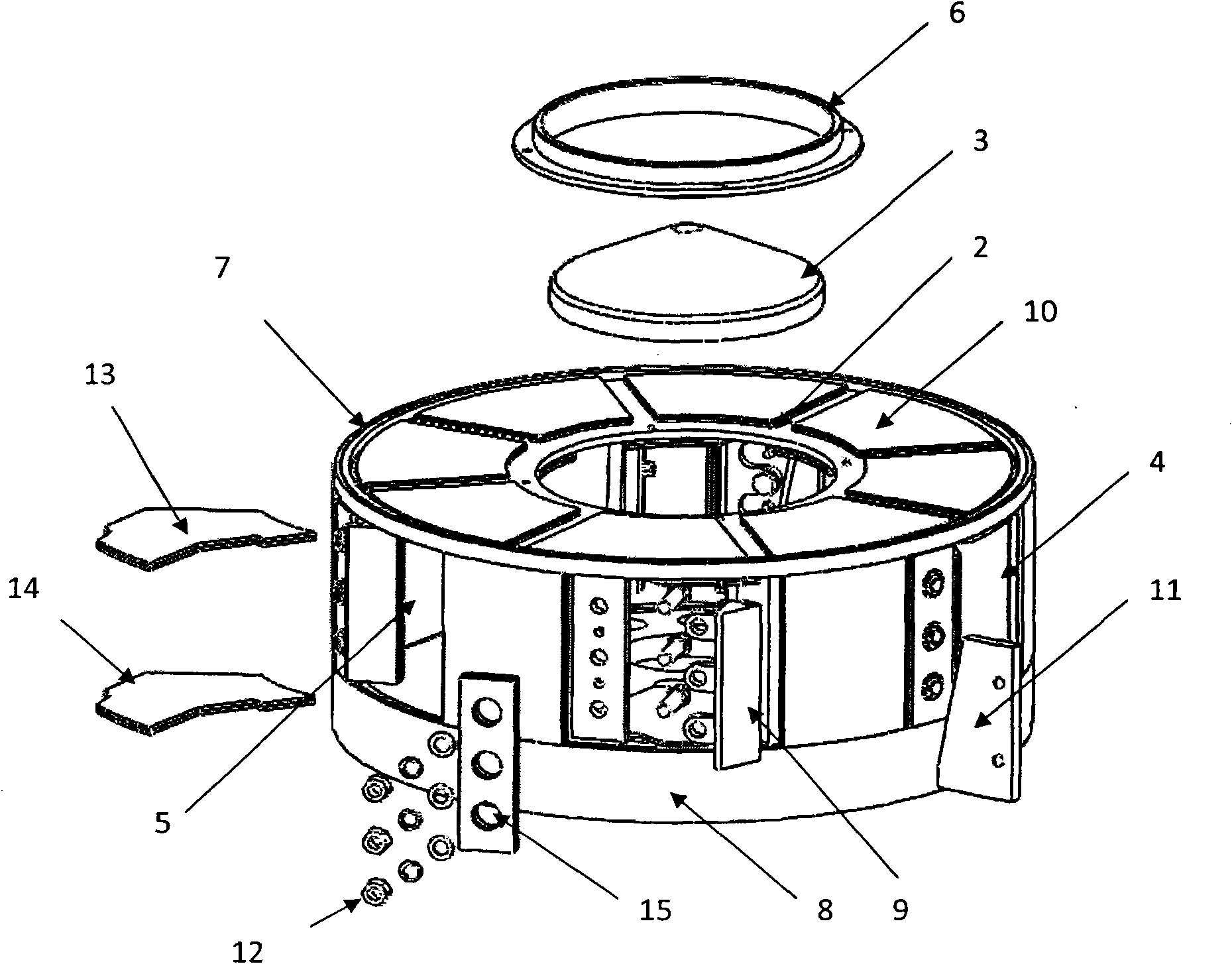

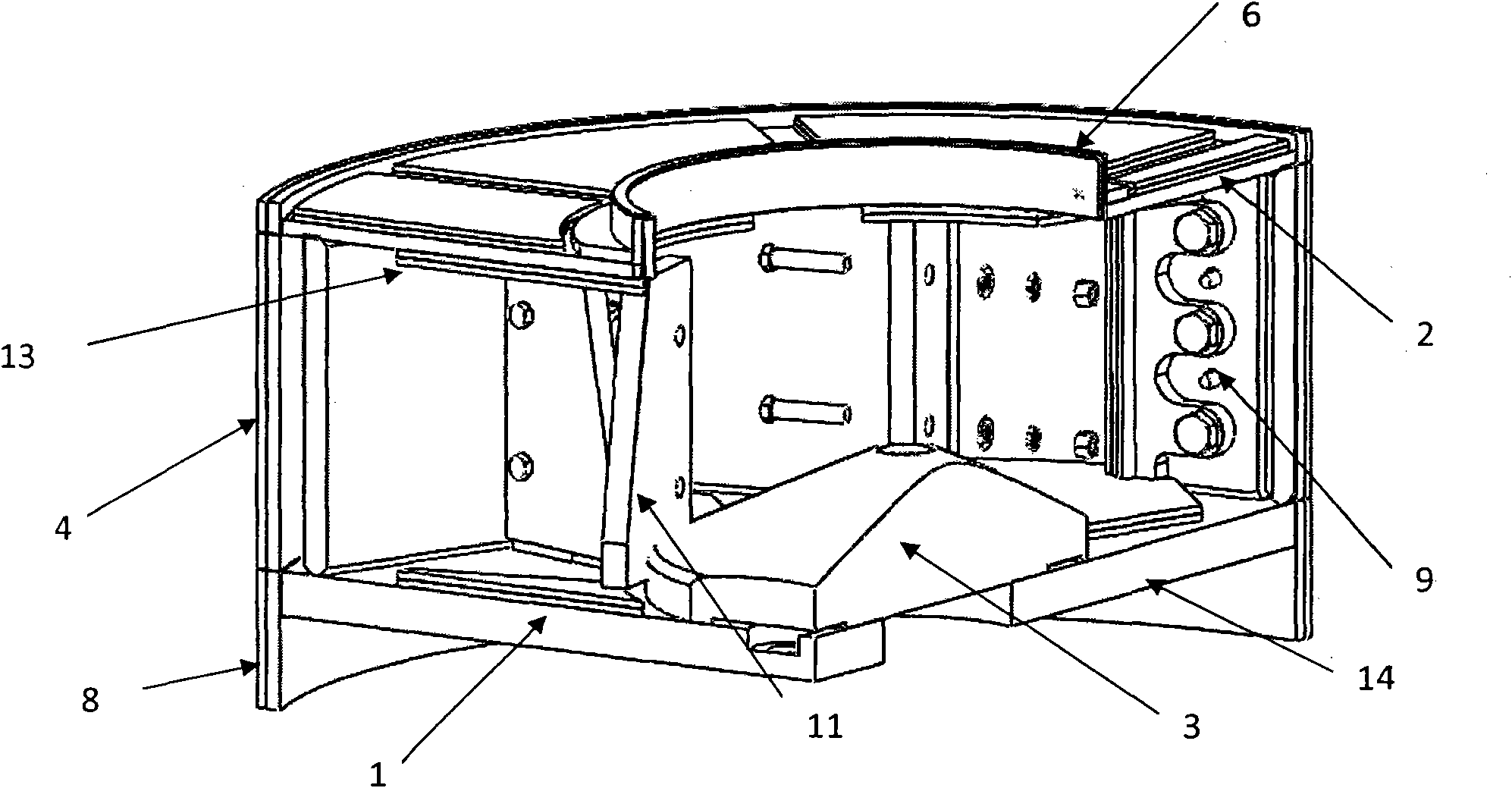

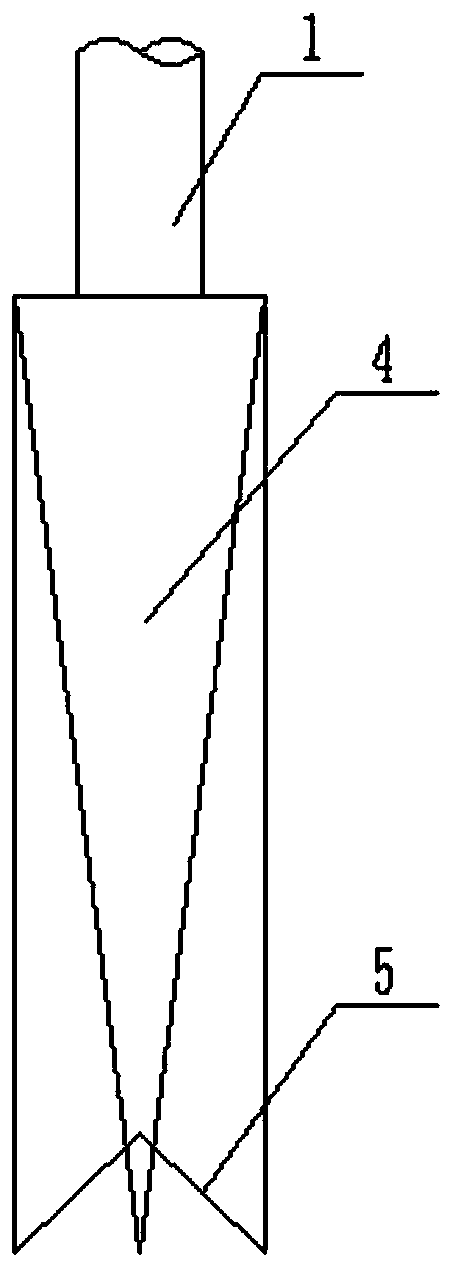

Structure type impeller breaker

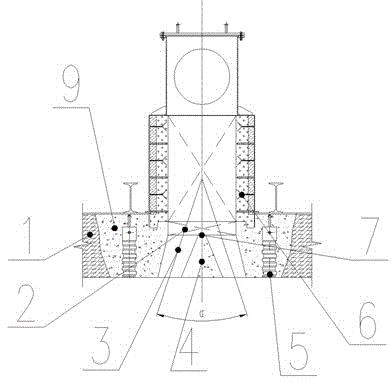

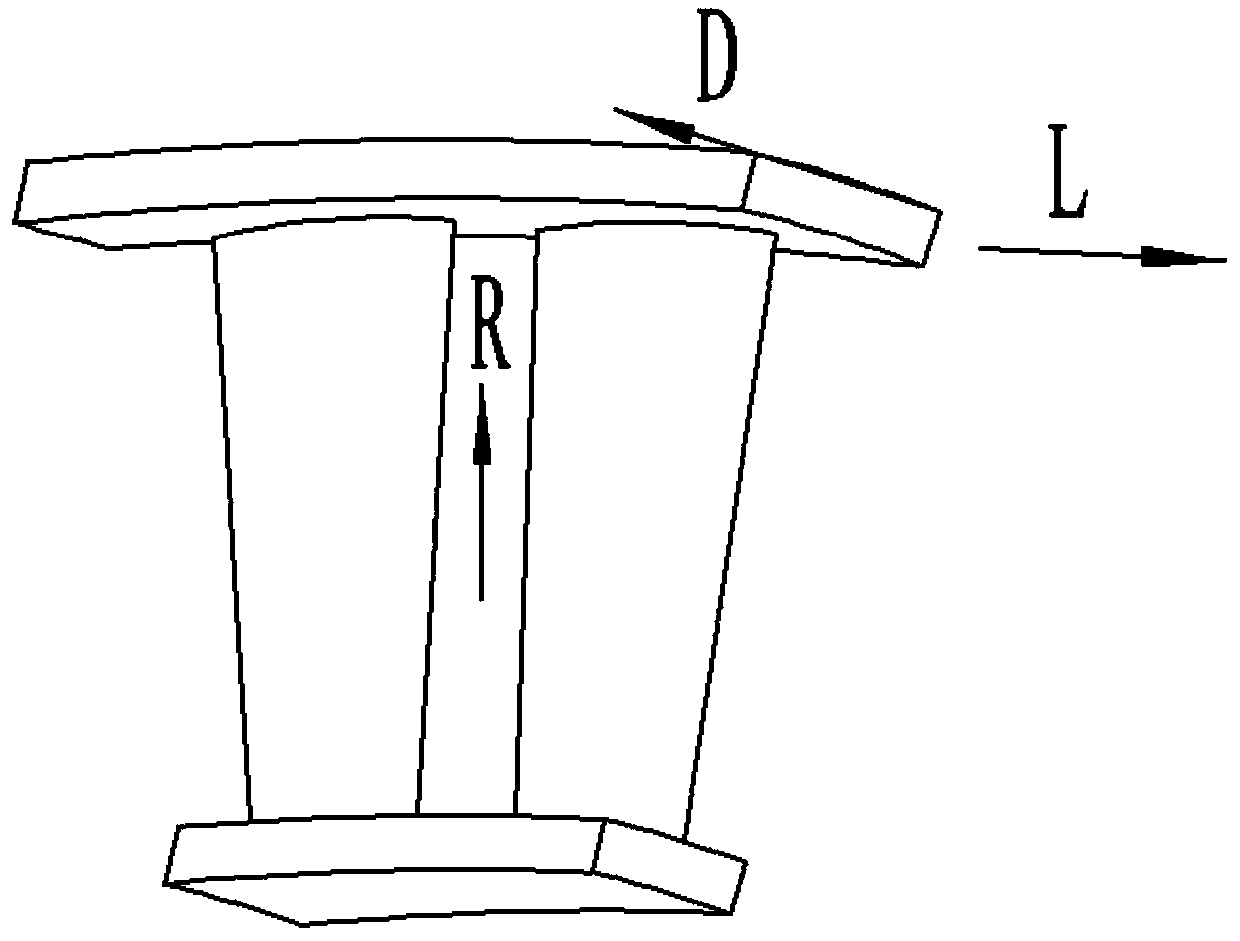

The invention relates to a structure type impeller breaker, comprising a rotor; the structure type impeller breaker is characterized in that: the rotor comprises a bottom plate (1), a ring-shaped top plate (2), a material dividing cone (3) and a plurality of connection plates (4); the material dividing cone (3) is fixed on the bottom plate (1) by a fastening piece, the connection plates (4) are arranged between the bottom plate (1) and the ring-shaped top plate (2), and a material blowing opening (5) is formed between the adjacent connection plates (4); a discharging outlet protecting ring (6) is arranged at the center of the ring-shaped top plate (2), an upper protecting ring (7) is welded at the outer ring of the ring-shaped top plate (2), a lower protecting ring (8) is welded at the outer ring of the bottom plate (1), and a wear resistant material layer is arranged on the outer surface of the connection plate (4); a replaceable injection orifice lining plate (9) is arranged at the same sides of all material blowing openings (5), and an upper padding plate (13) and a lower padding plate (14) are respectively welded on the upper and lower surfaces of the material blowing opening (5). The structure type impeller breaker radically solves the difficult problem that a rotor wear-out part is hard to be used repeatedly after being worn out, a great amount of raw material can be saved and the cost is reduced.

Owner:NANJING ZHONGDA BUILDING MATERIAL EQUIP MFG

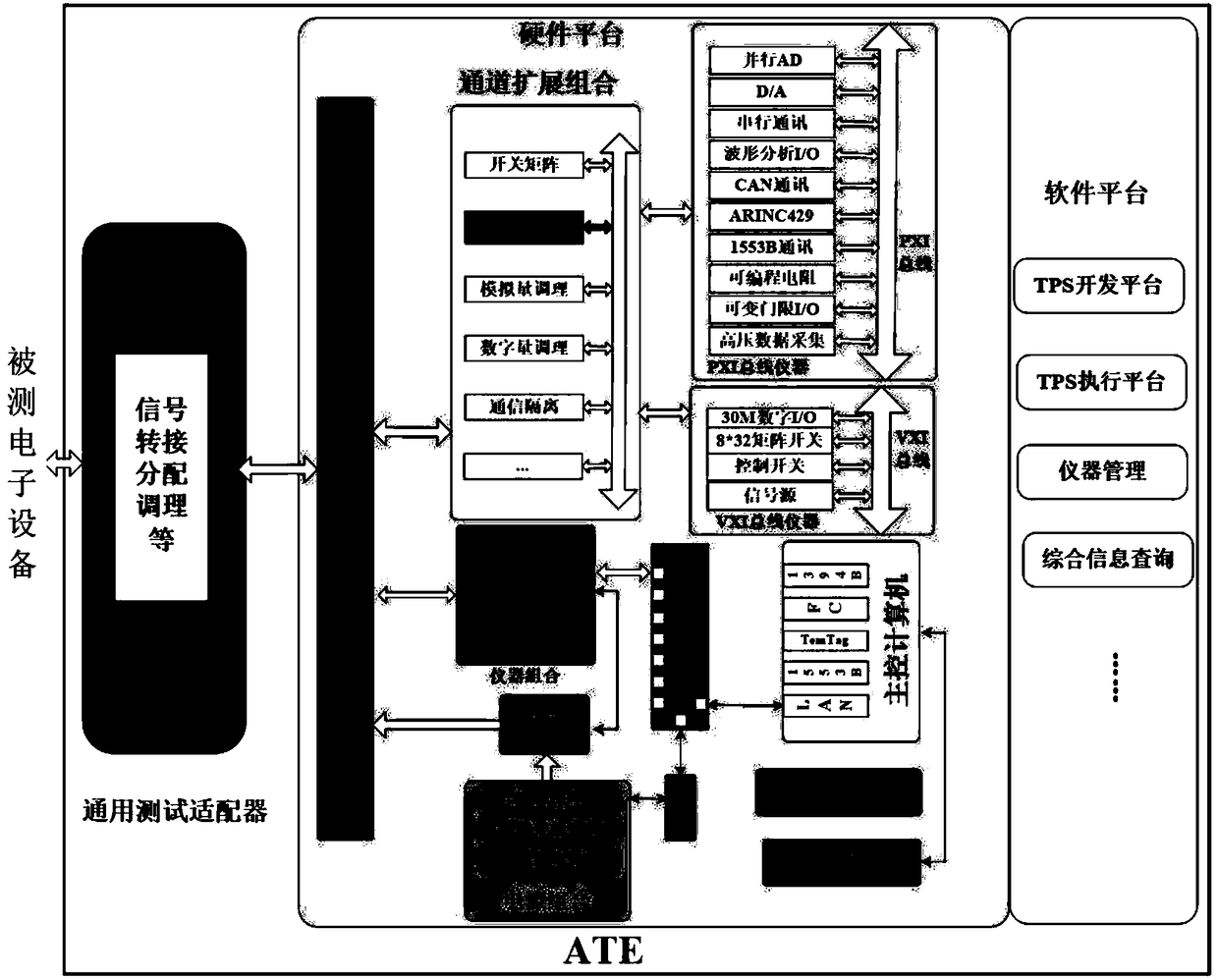

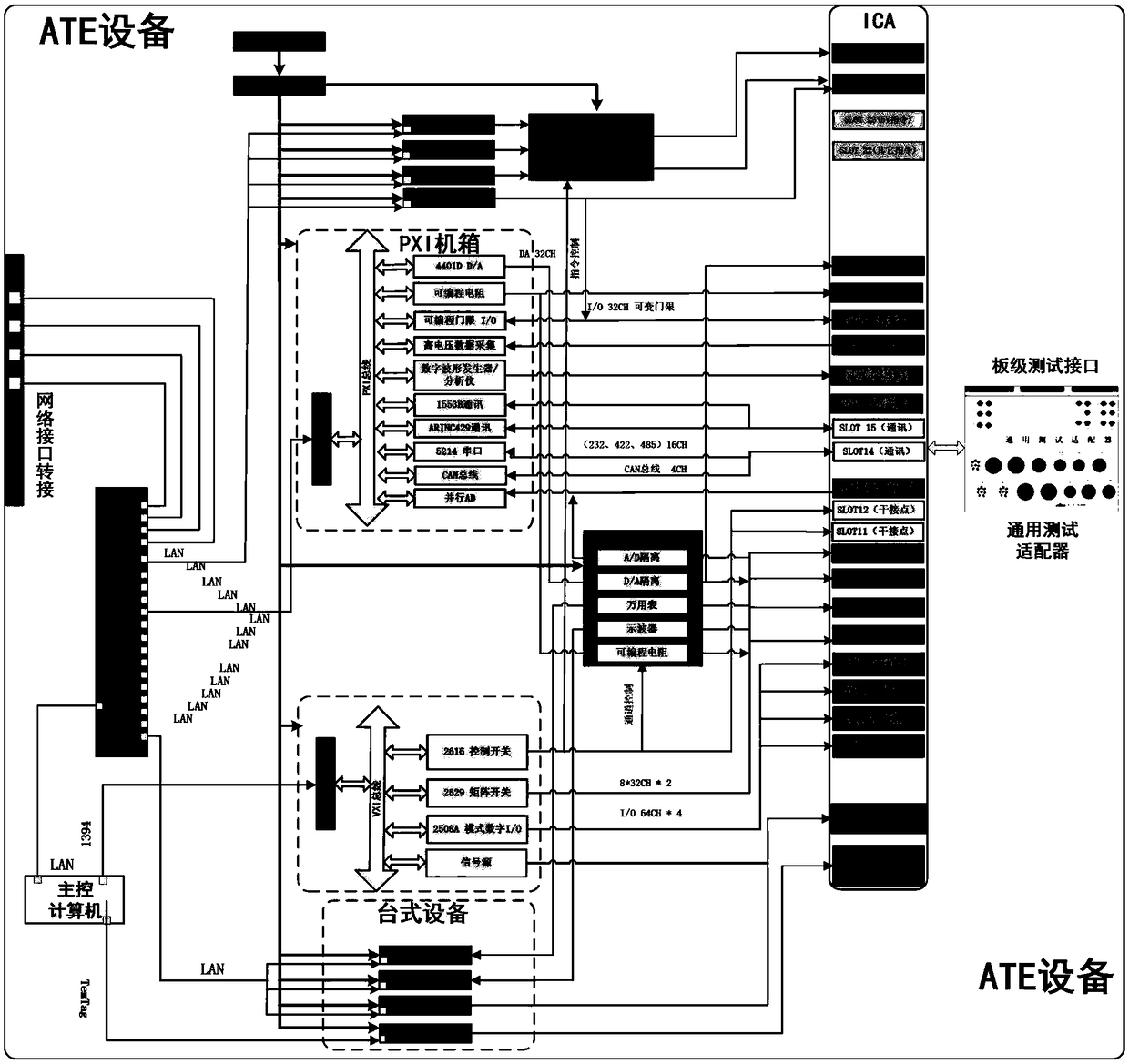

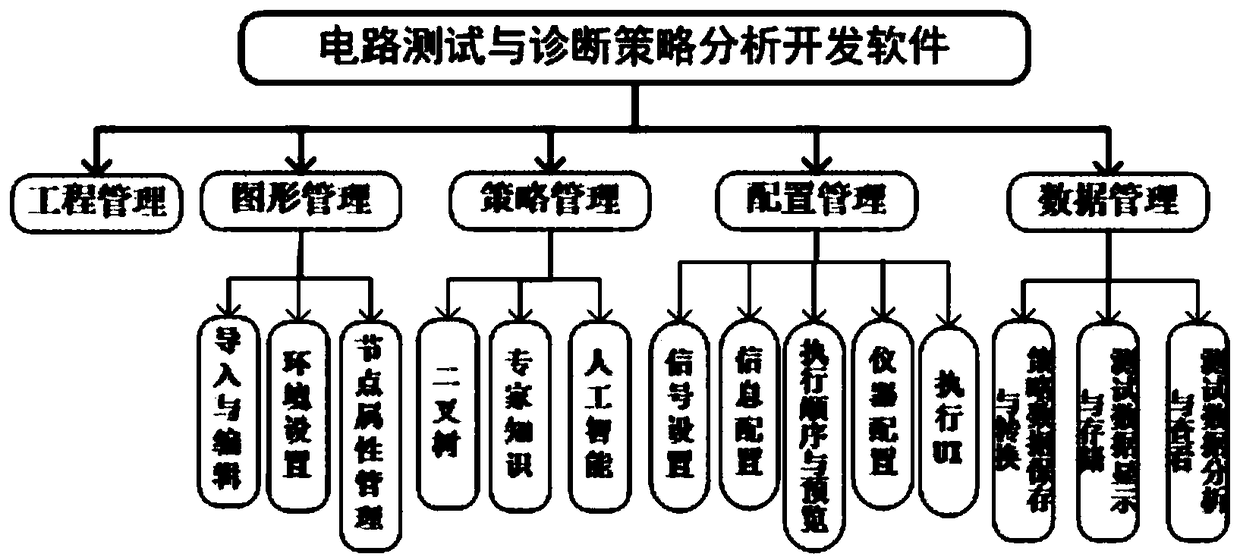

Intelligent test device for medium and low frequency circuits and test method therefor

InactiveCN109298317ATroubleshootingSolve repair problemsAutomated test systemsSoftware systemReusability

The invention relates to an intelligent test device for medium and low frequency circuits and a test method therefor. The test device comprises a universal test adapter for mating with an electronic device to be tested, and an ATE device for mating with the universal test adapter. The ATE device comprises a main control computer, a PXI and VXI bus instrument combination, an LXI-C / GPIB desktop instrument, a combined power supply, an electronic control combination, a channel expansion combination, a common test signal interface ICA, and a self-test adaptive device. The specific steps are as follows: (1) test generation; (2) test simulation; and (3) fault diagnosis. Compared with the prior art, the fault diagnosis and repair difficulty of a circuit board in the active equipment are solved, the universality, the reusability and the convenience of the equipment provide the beneficial effects for intelligent testing of the circuit board, and the software system platform and the system thereof can be combined with other software, so that the compatibility of the software is improved.

Owner:国营芜湖机械厂

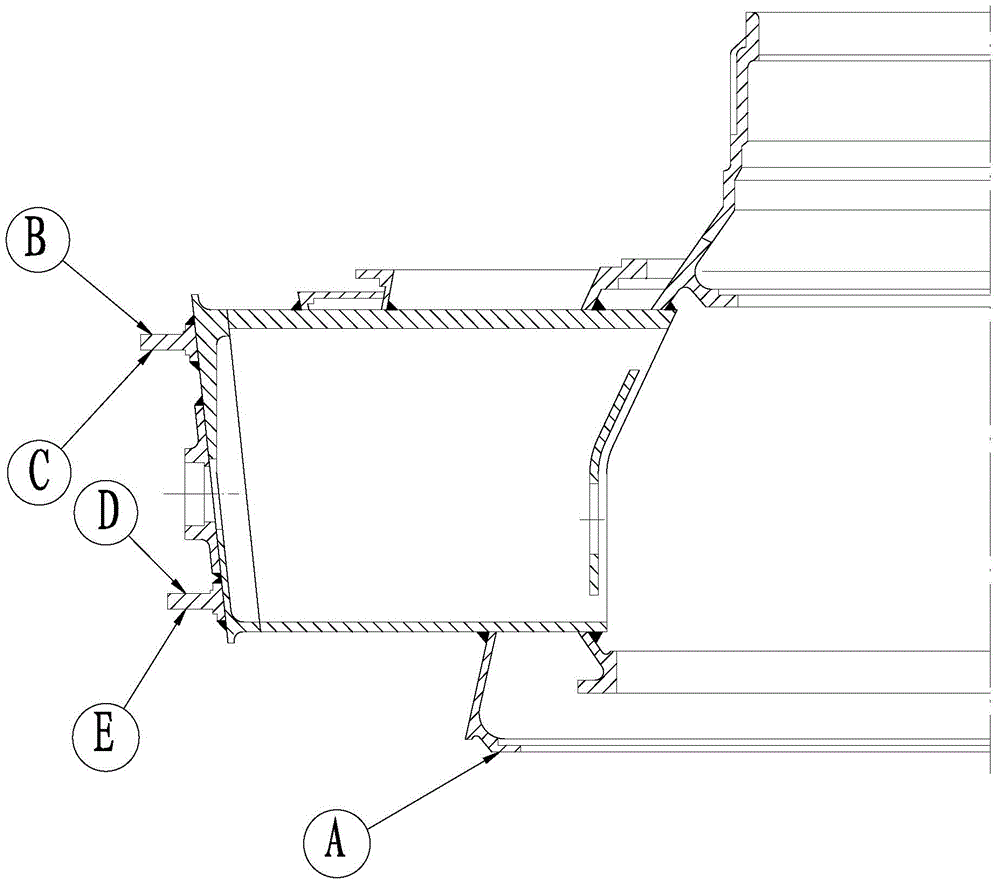

Intermediate casing ring repairing method

The invention relates to an intermediate casing ring repairing method, and belongs to the technical field of maintenance of a component of an aero-engine. A hanging ring and an intermediate casing body is connected through a threaded pin, the hanging ring cannot be directly disassembled when the repaired, so that cracks in the hanging ring cannot be directly subject to welding repair on the intermediate casing body under the limitation of a hanging ring material, a structure and positions of the cracks of the hanging ring, the intermediate casing body is directly deformed during welding repair, and the intermediate casing body can be scrapped under serious conditions. According to the intermediate casing ring repairing method, a problem that the traditional intermediate casing ring is difficult to repair, and the method of completely disassembling the hanging ring from the intermediate casing body is provided; the intermediate casing body is not influenced during disassembly of the hanging ring, the disassembled hanging ring is subject to welding repair outside the intermediate casing body, and then the welding-repaired hanging ring is accurately installed into the intermediate casing body, so that the repair of the hanging ring of the intermediate casing is realized, the scrapping of the intermediate casing is avoided, and repair cost is reduced at the same time.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Special cobalt-based wear-resistant alloy powder for laser remanufacture of drilling jar

ActiveCN102220580AImprove performanceHigh hardnessMetallic material coating processesLaser beam welding apparatusWear resistantAlloy

The invention relates to special cobalt-based wear-resistant alloy powder for laser remanufacture of a drilling jar. The powder is characterized by comprising the following components in percentage by weight: 0.6-1.0% of C, 32-36% of Cr, 7.5-9.5% of W, 3.0-3.6% of Mo, 0.8-1.2% of Ni, 0.2-0.6% of Mn, 2.0-2.4% of Si, 1.2-2.0% of Fe, 1.6-2.2% of B, 0.1-0.2% of Ce, 0.25-0.4% of Hf, 0.06-0.1% of Zr and the balance of Co. The cobalt-based wear-resistant alloy powder provided by the present invention is exclusively used in laser-cladding large-area failure working surfaces of the shaft journal of the drilling jar; and by cladding the alloy powder material, the drilling jar is restored to use, and the oxidation resistance, corrosion resistance and erosion and wear resistance are improved, thus effectively solving the difficulty in the repair of the failure shaft journal of the drilling jar.

Owner:上海大陆天瑞激光表面工程有限公司

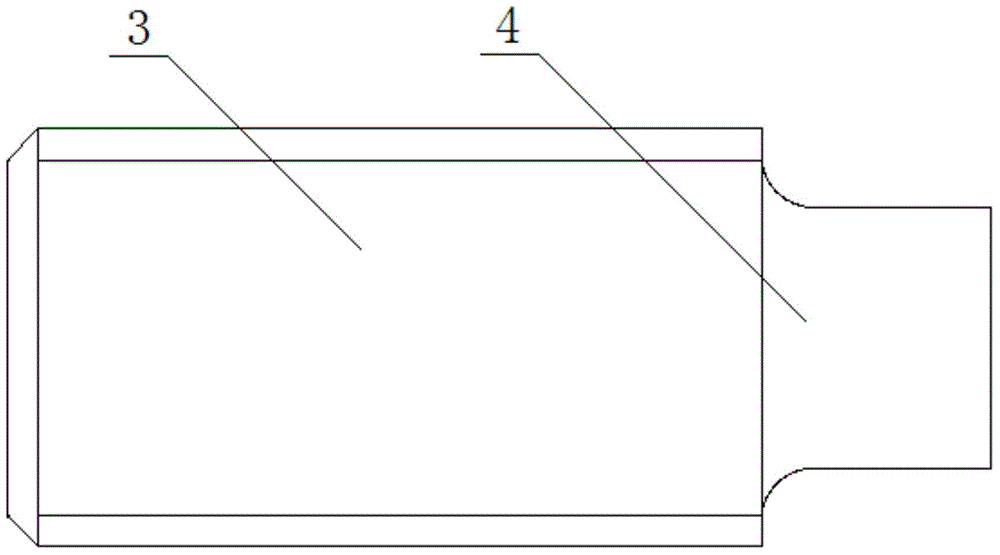

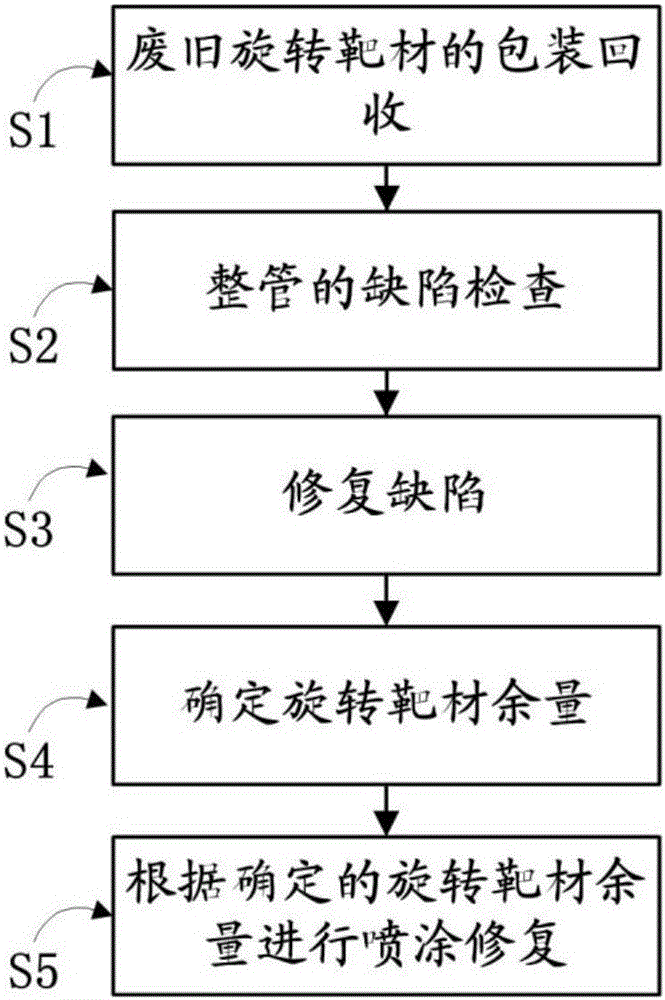

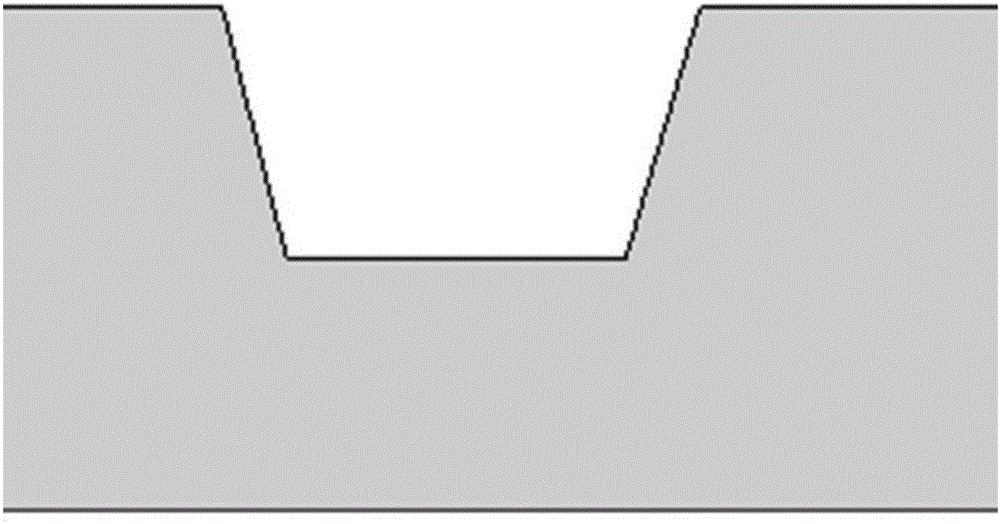

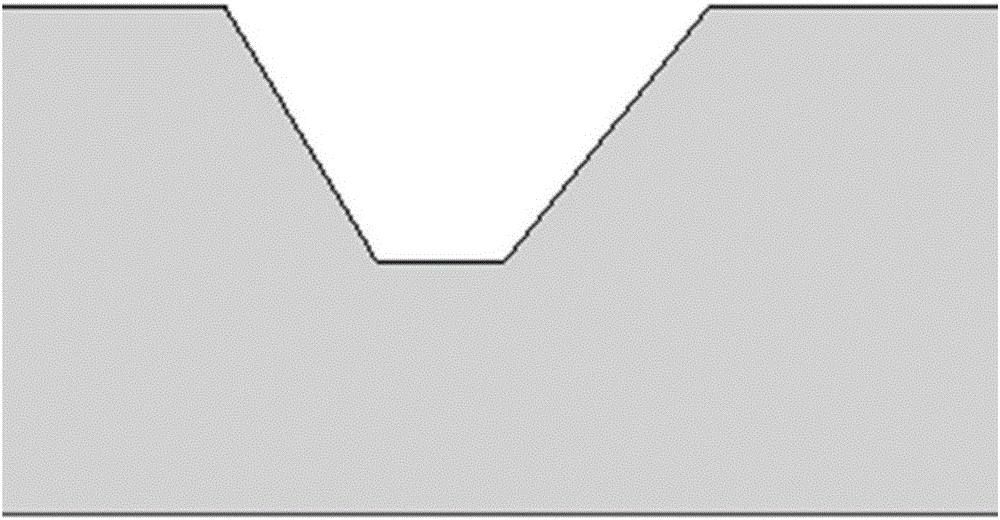

Recycling, repairing and reprocessing method for waste rotating target material

ActiveCN105671501AAchieve recyclingSolve repair problemsMolten spray coatingVacuum evaporation coatingSand blastingEngineering

The invention discloses a recycling, repairing and reprocessing method for a waste rotating target material.The method is used for achieving the technical purposes of recycling, repairing and re-spraying of the waste rotating target material.The method includes the following steps that the waste rotating target material is packaged and recycled; defect inspection of a whole pipe is carried out; defect repairing is carried out; rotating target material allowance is determined; spraying repairing is carried out according to the determined rotating target material allowance.The method has the advantages that the waste rotating target material is recycled and repaired, the earlier-stage processes of base pipe machining, sand blasting, middle layer spraying and the like are omitted, cost is reduced, and reutilization of the target material is achieved; the problem that a defective target material is difficult to repair is solved, scrapping of the whole pipe is avoided, and production efficiency is improved.

Owner:广州市尤特新材料有限公司

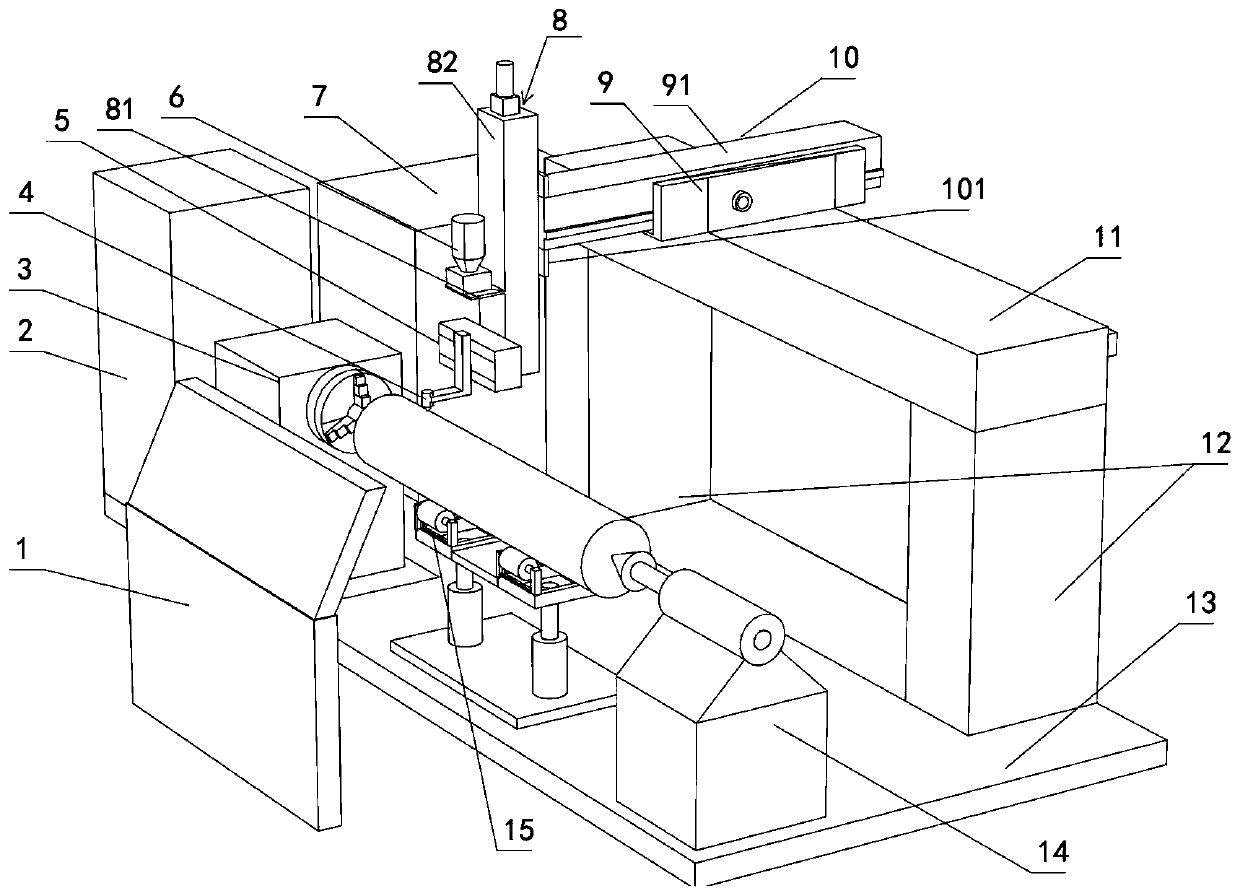

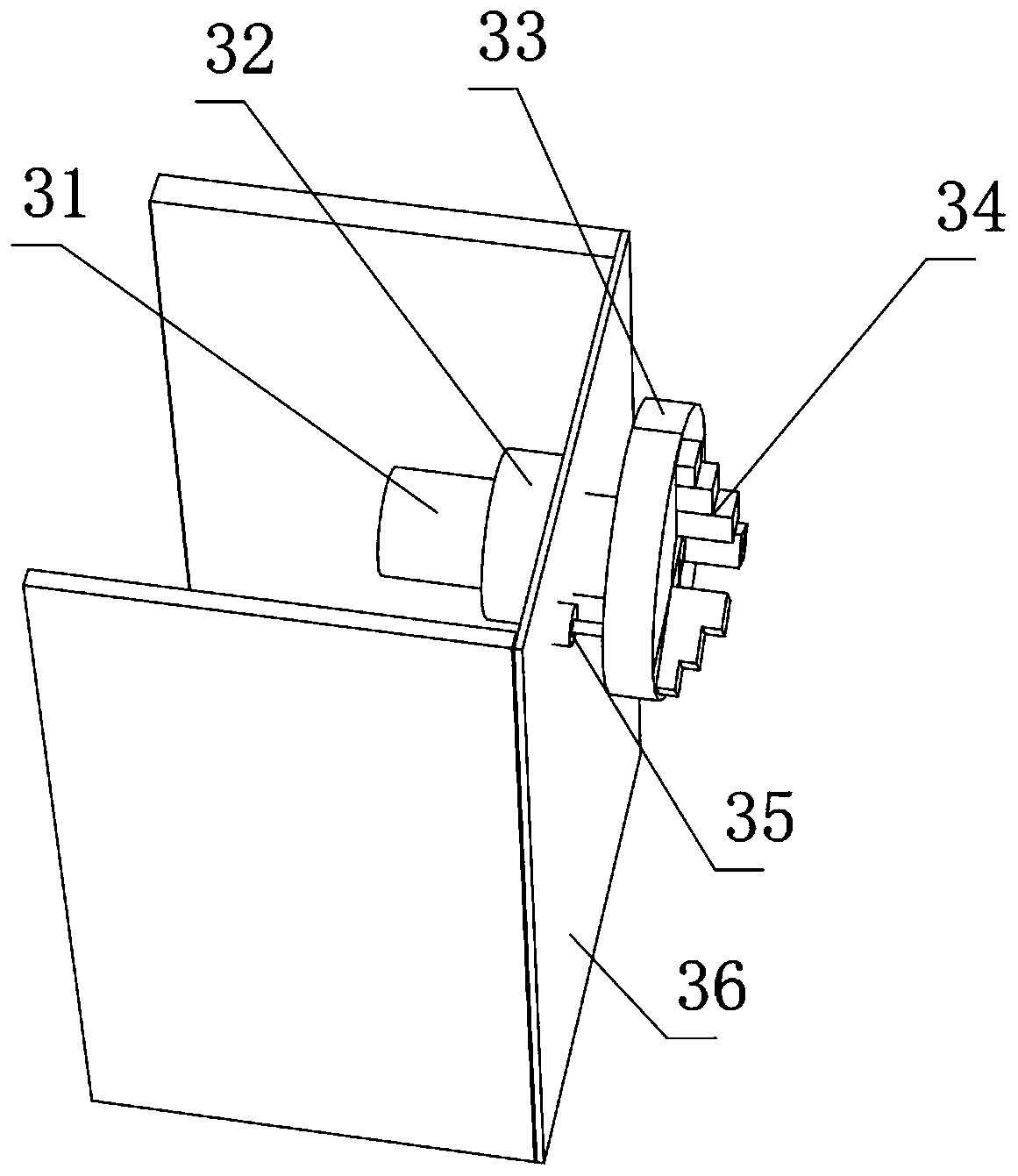

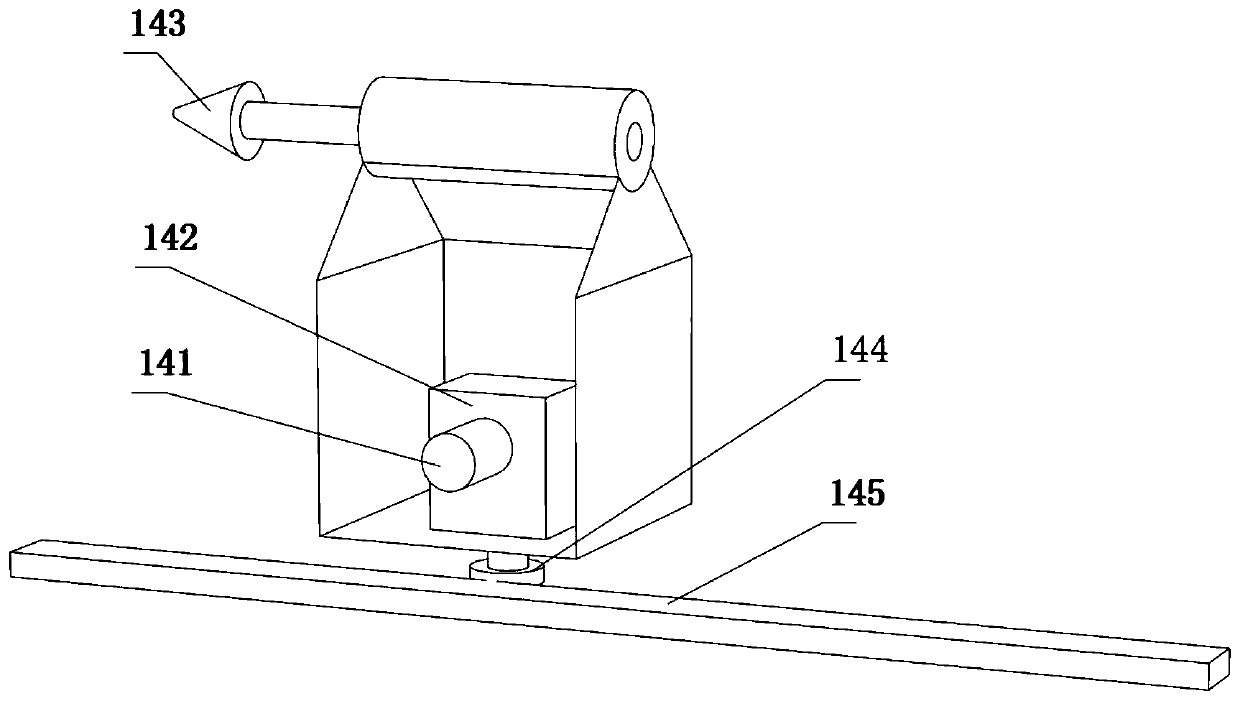

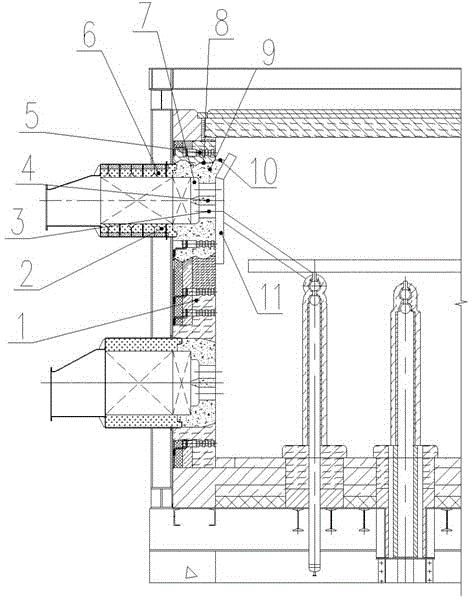

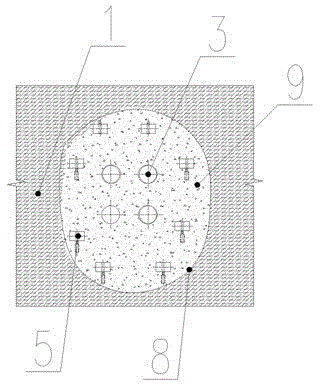

Hydraulic prop roller surface plasma surfacing welding machine

The invention provides a hydraulic prop roller surface plasma surfacing welding machine which comprises a plasma welding gun, a workpiece turntable case, an X-axis transverse moving device, a Y-axis longitudinal moving device, a Z-axis lifting moving device, a powder feeder, a swinging device, a frame cross beam, machine frame double columns, an equipment base, a movable tailstock, a shading screen, an electric control cabinet and a power integrated cabinet. High-power plasma arc is utilized for melting alloy powder, a plasma surfacing welding process is adopted to replace a high-pollution chromium electroplating process, compared with laser cladding, the machine has the advantages of being low in investment, low in operation cost, easy and convenient to operate and wide in surfacing welding material range, has great application potential in the coal machine remanufacturing field, and effectively solves the problem of repairing the outer surfaces of a waste pillar plunger and a middlecylinder by the most economical means.

Owner:武汉高力热喷涂工程有限责任公司

High-temperature-resistant oxidation coating nickel-based alloy powder for laser cladding

InactiveCN110331397AImprove performanceLow melting pointMetallic material coating processesRare-earth elementCrack resistance

The invention discloses a high-temperature-resistant oxidation coating nickel-based alloy powder for laser cladding, and the powder mainly comprises the following chemical components: Ni, Cr, Mo, W, Co, V, Fe, Si, Mn, and at least two of rare earth elements Y2O3 3, La2O3 3, Ce and Hf in proper amount. The invention fundamentally solves and improves the crack resistance, the formability, the process stability and the component uniformity of the alloy powder in a laser cladding layer, and meets the comprehensive performance requirements of a repair part on the cladding layer, such as oxidation resistance, corrosion resistance, wear resistance, fatigue resistance, moderate hardness and strength, certain conductivity and the like. The powder material can be used for laser cladding of the conductive roller part of the key equipment of a electrogalvanizing unit, solves the repairing problem of the conductive roller after corrosion and abrasion, and provides an effective and convenient methodfor successfully repairing the invalid conductive roller part in the metallurgical industry.

Owner:扬州安泰威合金硬面科技有限公司

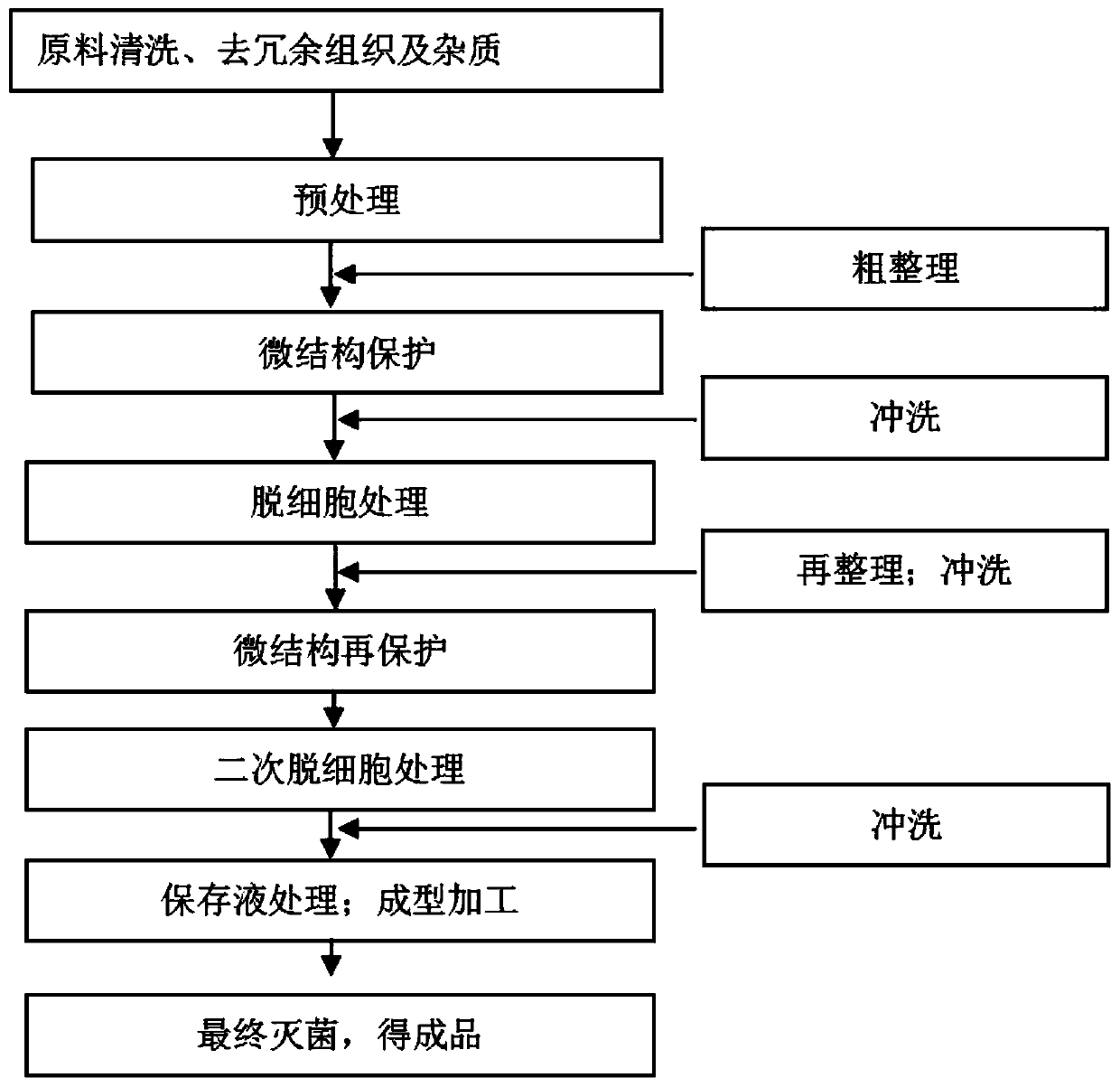

Marine-derived bionic cartilage material and preparation method thereof

InactiveCN110193096AReduce the risk of transmissionAbundant resourcesTissue regenerationProsthesisMedicineNetwork structure

The invention discloses a marine-derived bionic cartilage material and a preparation method thereof, which belong to the field of a medical material. The marine-derived bionic cartilage material is obtained by decellularizing a marine-derived cartilage material by a special process, and has a natural bionic cartilage structure, which can be used for cartilage repair to induce cartilage regeneration; and the preparation method of the marine-derived bionic cartilage material comprises the steps of pretreatment of raw materials, rough finishing, decellularization, re-finishing, preservation liquid pretreatment, molding and the like. The marine-derived bionic cartilage material prepared by the method of the invention has the natural network structure and good mechanical strength, and is a lowimmunogenic bionic extracellular matrix scaffold material, which can solve the problem of clinical cartilage repair; moreover, the marine-derived bionic cartilage material has low risk of carrying andspreading the zoonotic virus, rich resources and low cost, and can fill the market blank of cartilage repair products and has profound social significance.

Owner:SHANGHAI SIXTH PEOPLES HOSPITAL

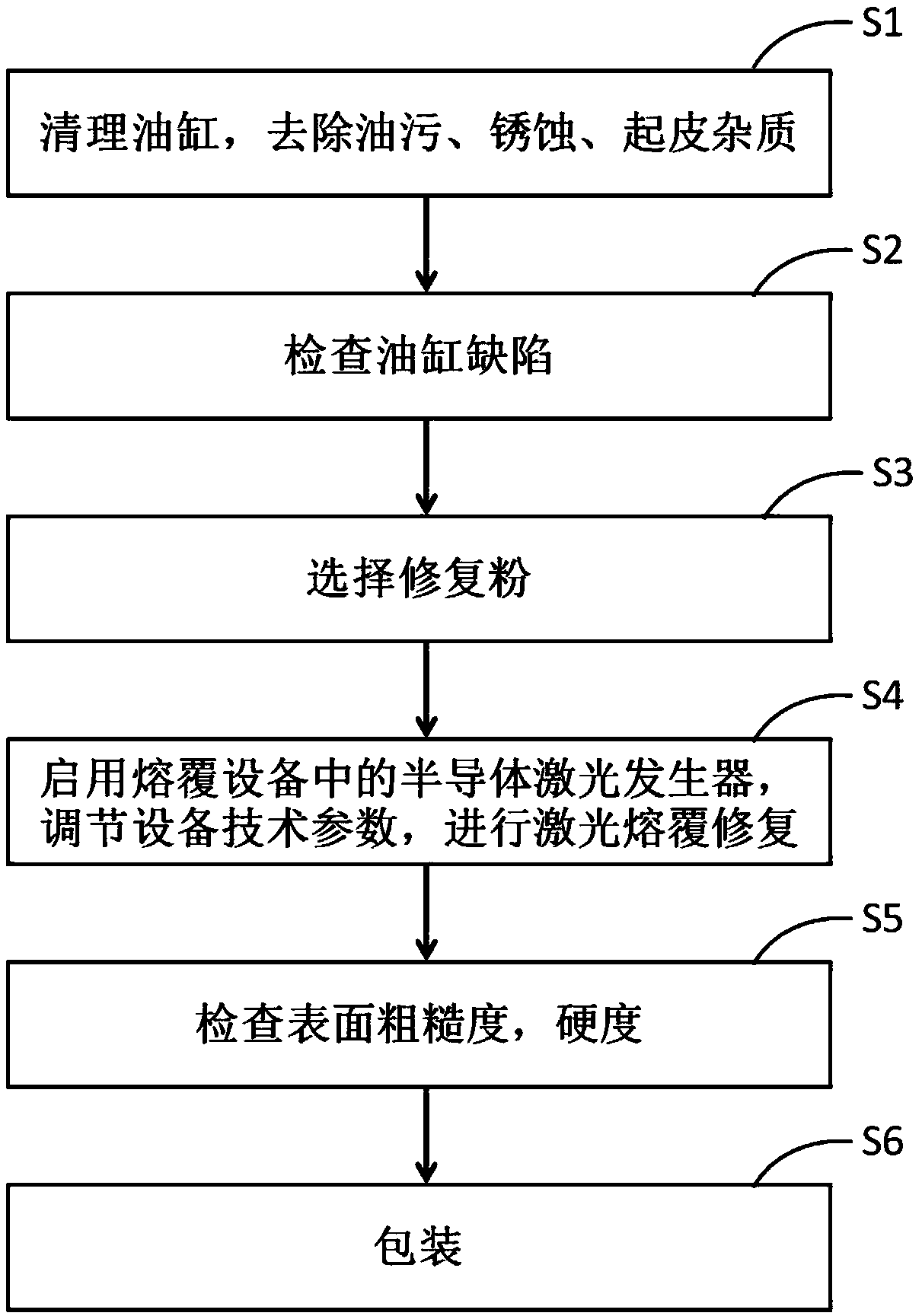

Laser cladding repairing method of mine hydraulic support and repairing powder

InactiveCN109023358AHigh hardnessSolve repair problemsMetallic material coating processesNiobiumContamination

The embodiment of the invention discloses a laser cladding repairing method of a mine hydraulic support and a repairing powder. The laser cladding repairing method of the mine hydraulic support comprises the steps of cleaning an oil cylinder and removing oil contamination, corrosion and peeling impurities; checking oil cylinder defects; selecting the repairing powder; starting a semiconductor laser generator in cladding equipment to adjust technical parameters of the equipment so as to carry out laser cladding repairing; checking surface roughness and hardness; and packaging. The repairing powder comprises chromium, carbon, boron, silicon, nickel, molybdenum, niobium and iron. According to the laser cladding repairing method of the mine hydraulic support, the repairing difficult problem ofthe oil cylinder is solved, the production efficiency is enhanced by 40%, materials are saved by about 20%, and the quality qualified ratio reaches 95%. The repairing powder has the advantages of high hardness, HRC (Rockwell hardness) of 50-60, corrosion resistance and improvement of welding and cladding performance.

Owner:宁夏昀启昕机械再制造有限公司

Method for online repair of regenerative burner nozzle of heating furnace

The invention discloses a method for online repair of a regenerative burner nozzle of a heating furnace and belongs to the technical field of heating furnace maintenance. The method is used for online repair of the damaged regenerative burner nozzle of the heating furnace. According to the technical scheme, the shape and angle of the burner nozzle are designed according to the heating capacity of a regenerative burner; meanwhile, a burner internal mold provided with reinforcing ribs is arranged, an old nozzle of the heating furnace and a peripheral furnace wall are dismantled when the heating furnace is blown out, the burner internal mold is placed in the furnace wall, an external mold is erected on the outer side of the furnace wall, a discharging port is formed in the top of the external mold, and micro-expansion refractory castable is adopted for pouring; after demolding, the heating furnace can be used after being dried normally. By the adoption of the method, the damaged regenerative burner nozzle of the heating furnace can be repaired quickly, all furnace walls of the heating furnace do not need to be dismantled, heating furnace maintenance time is shortened, and the construction cost of the heating furnace is reduced; meanwhile, the heating capacity of the regenerative burner of the heating furnace can be adjusted, so that the heating furnace supplies heat more balanced and reasonable, and the heating capacity and temperature uniformity of the heating furnace are improved.

Owner:TANGSHAN IRON & STEEL GROUP

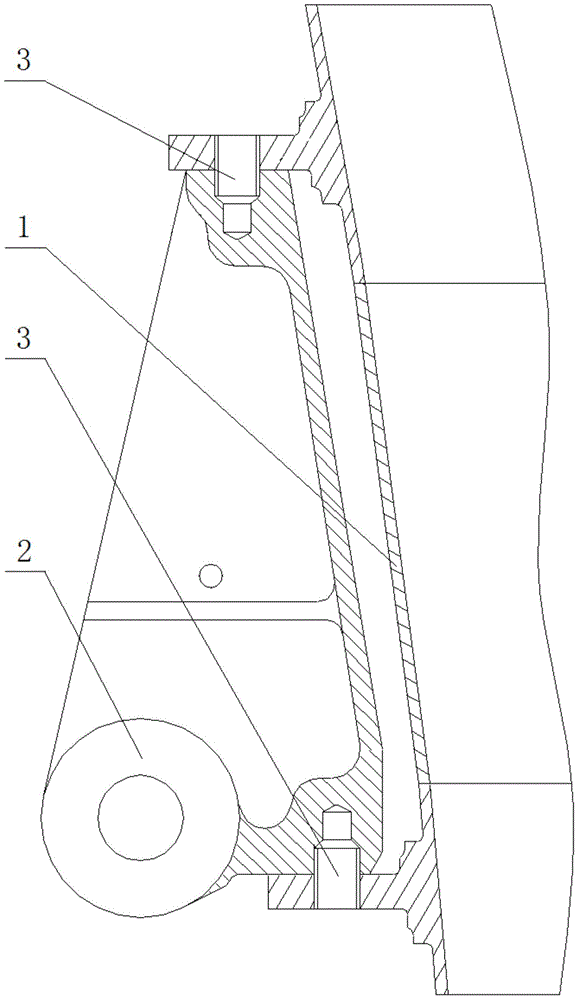

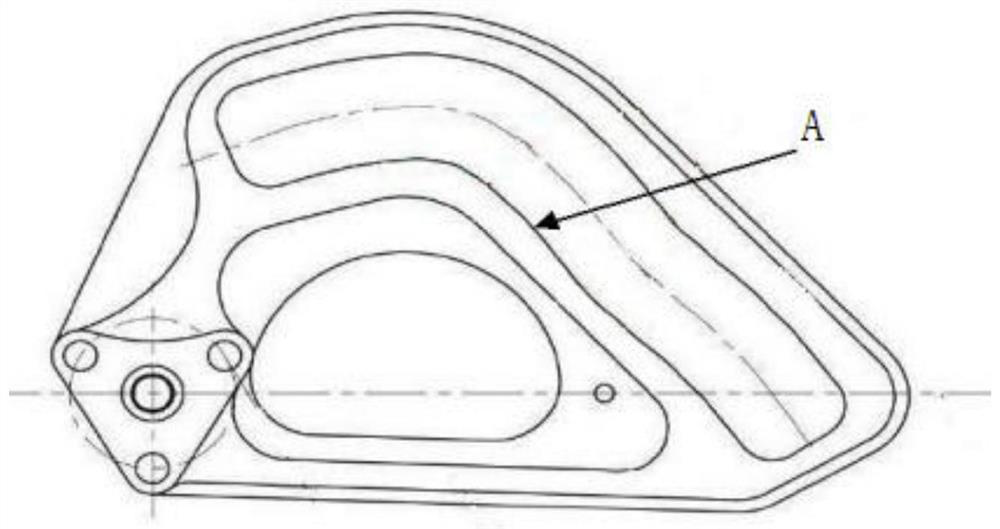

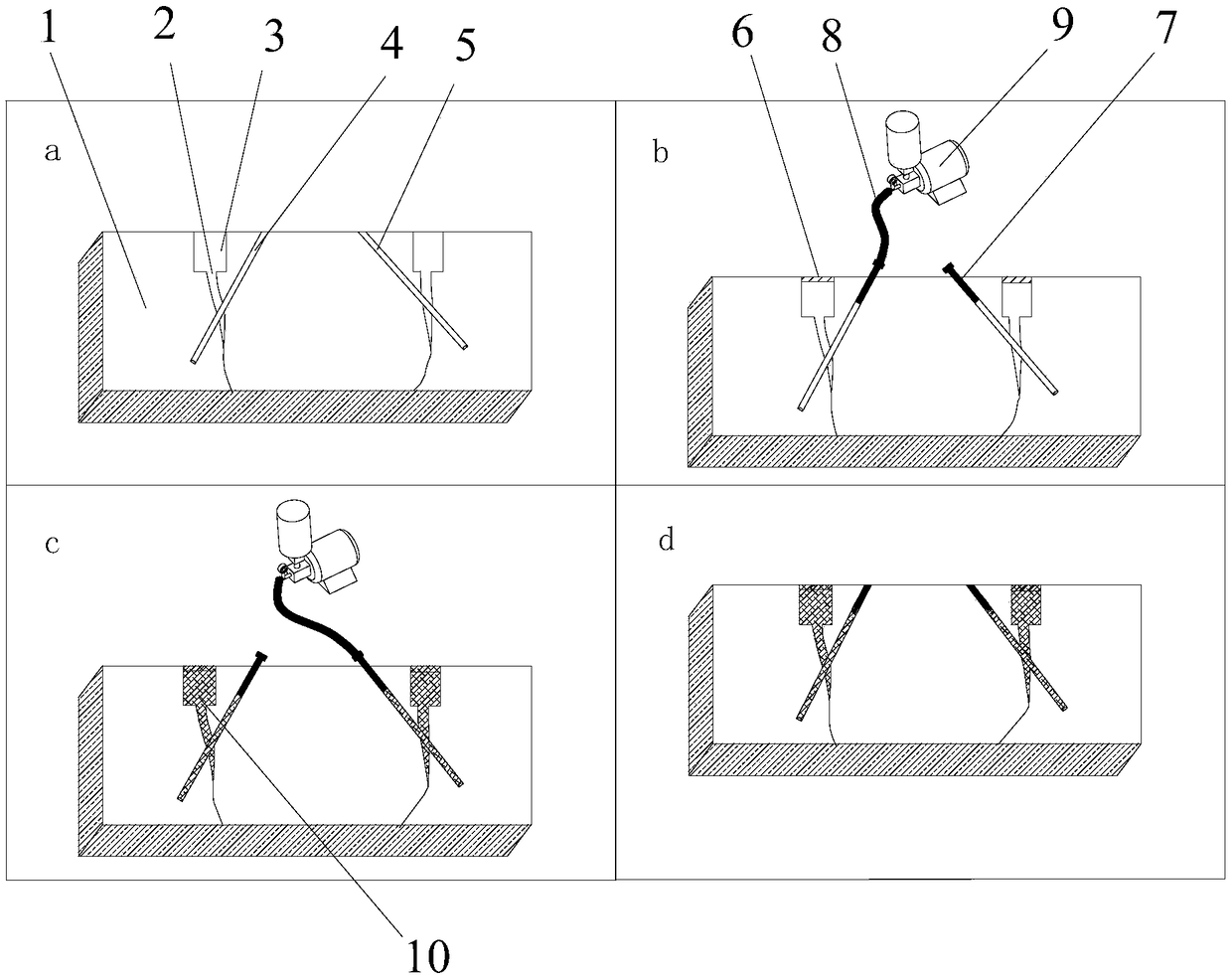

Guiding blade mold and design method for contraction thereof

ActiveCN111570726ASolve mold opening interferenceSolve repair problemsFoundry mouldsFoundry coresReduction treatmentContraction rate

The invention provides a guiding blade mold and a design method for contraction thereof. The method comprises the steps that: Step 1: a determined guiding blade mold is enlarged as a whole according to a contraction rate of chord lengths of an upper marginal plate and a lower marginal plate, and an enlarged guiding blade mold is obtained; and Step 2: the length of a blade body in the enlarged guiding blade mold and the length of the blade body after being enlarged according to the contraction rate thereof are compared; when the length of the blade body in the enlarged guiding blade mold is smaller than the length of the blade body after being enlarged according to the contraction rate thereof, the length of the blade body is first extended, reduced thickness of the upper marginal plate andthe lower marginal plate is caused at the same time, and then thickening treatment is conducted to the upper marginal plate and the lower marginal plate; when the length of the blade body in the enlarged guiding blade mold is larger than the length of the blade body after being enlarged according to the contraction rate thereof, the length of the blade body is first shortened, increased thicknessof the upper marginal plate and the lower marginal plate is caused at the same time, and then thickness reduction treatment is conducted to the upper marginal plate and the lower marginal plate; andtherefore, the design of contraction of the guiding blade mold is completed and manufacturing of the guiding blade mold is conducted.

Owner:AECC AVIATION POWER CO LTD

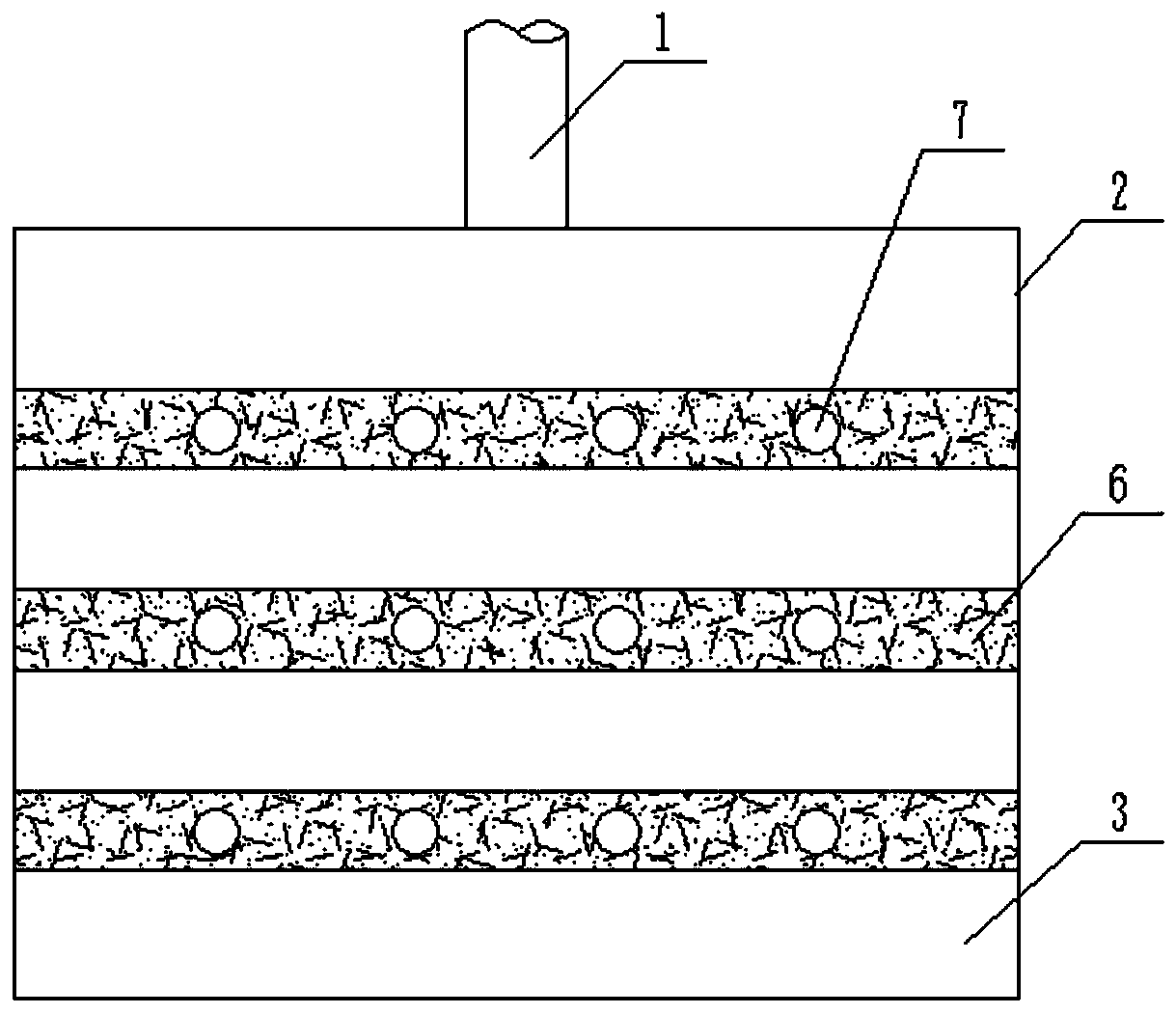

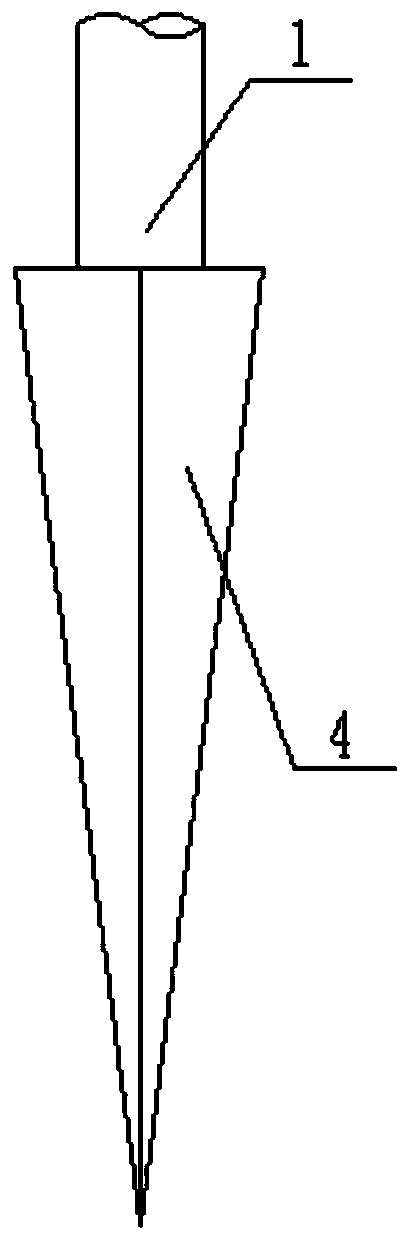

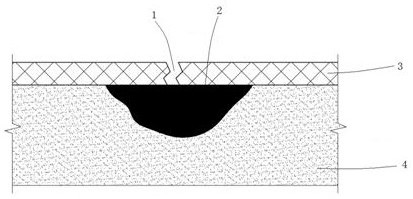

Shield tunnel pipe piece fracture blockage device and construction method

PendingCN110966025AAvoid the risk of sheddingReduce risk of sheddingUnderground chambersTunnel liningArchitectural engineeringStructural engineering

The invention discloses a shield tunnel pipe piece fracture blockage device. The device comprises an iron box, a reserved grouting pipe and rubber sleeves, wherein the iron box comprises a top plate,a pair of first side plates, a pair of second side plates and a base plate; the pair of the first side plates are relatively fixed on the two sides of the top plate; the pair of the second side platesare V-shaped and relatively fixed on the other two sides of the top plate; the base plate is reversely V-shaped and fixed on the bottom edges of the pair of the first side plates; multiple reserved grouting holes are symmetrically formed in the pair of the first side plates; a grouting hole is formed in the top plate; the iron box is made of a flexible steel piece; the reserved grouting pipe is in vertical sealing communication with the grouting hole; and multiple rubber sleeves are provided and sleeved at the outer periphery of the iron box for sealing and covering the multiple reserved grouting holes. The invention further discloses a shield tunnel pipe piece fracture blockage construction method. The device not only can achieve the pipe piece fracture blockage purpose, but also can form wedged bodies in pipe piece fractures to effectively reduce the blockage material falling risk.

Owner:CCCC SECOND HARBOR ENG

Two-stage unsupported construction method used for repairing damaged hydraulic concrete beams

Owner:南京瑞迪建设科技有限公司

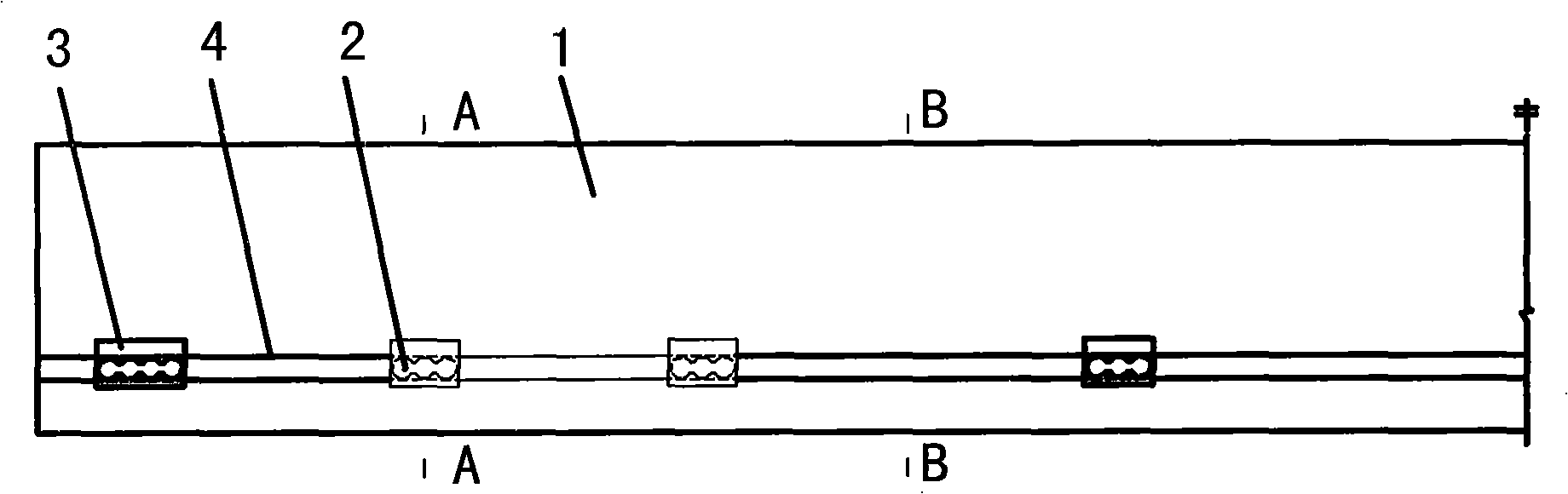

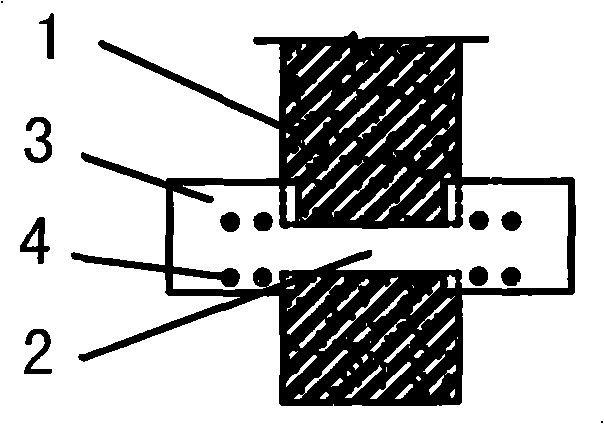

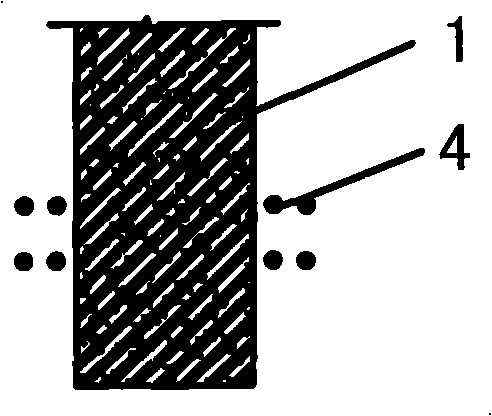

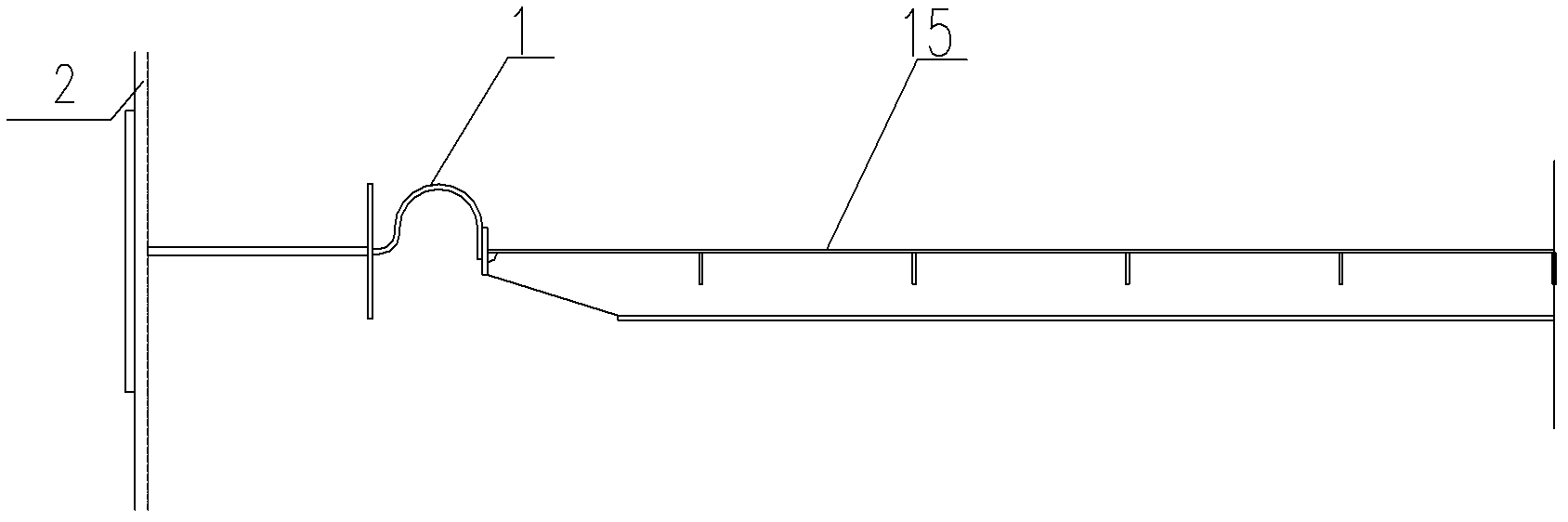

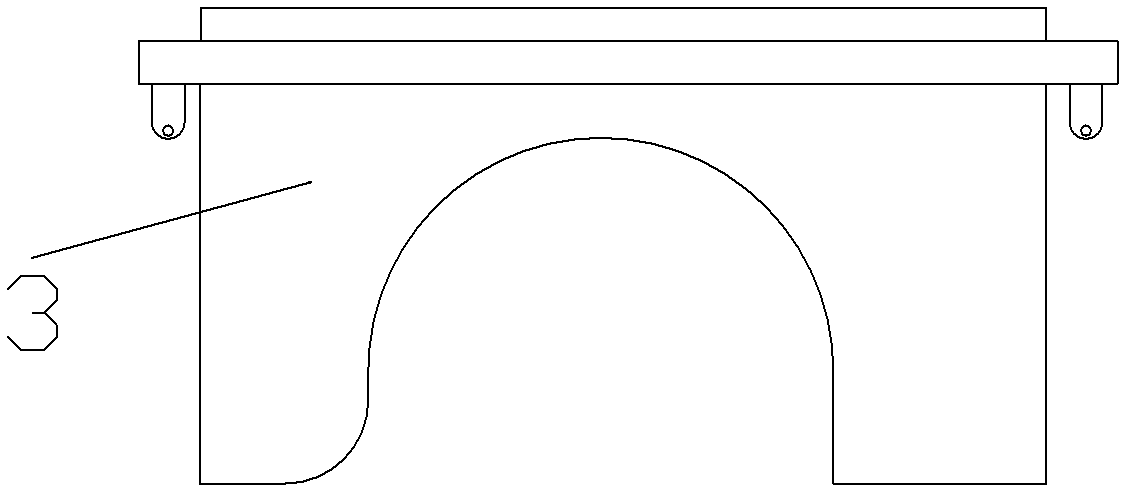

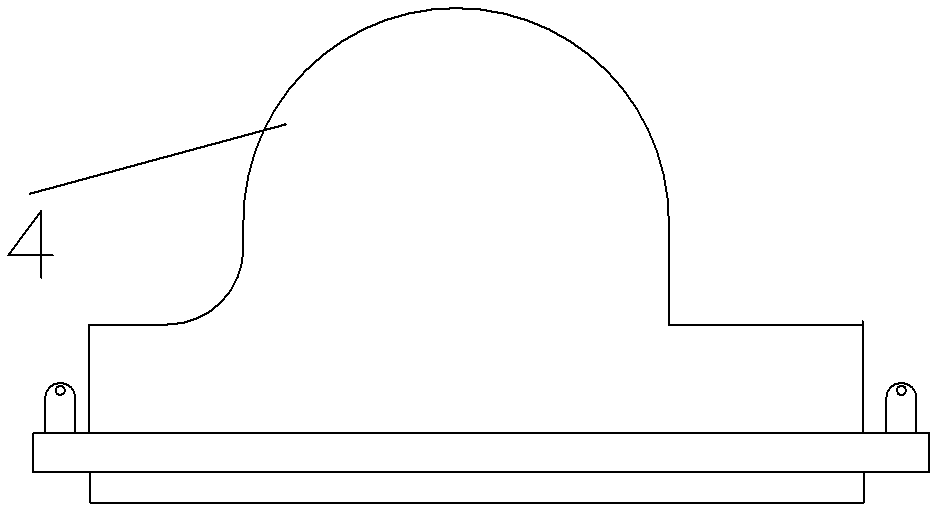

Method and device for forming U-shaped elastic knot by cold pressing

InactiveCN102319774ASolve the need for repairSolve the disadvantages of large shape differencesShaping toolsBatch productionSeries production

The invention relates to a method and a device for forming a U-shaped elastic knot by cold pressing. The method and the device are characterized in that the elastic knot is formed by adopting one-time pressing of a pressing die; the pressing die is produced by using a pressing machine and mainly comprises an upper die and a lower die; the upper die is of a gate-type structure; an arched concave part is arranged in the middle of the upper die; a protruded part in the middle of the lower die is mutually matched with the arched concave part of the upper die; the top end of the upper die is formed by splicing an upper die base plate with a plurality of upper die rib plates; and the bottom end of the lower die is formed by splicing a lower die base plate with a plurality of lower die rib plates. According to the method and the device, the U-shaped elastic knot can be formed by pressing at one time without rework; and the method and the device have the advantages of high efficiency, batch production, favorable forming quality and high forming identical degree of products.

Owner:WUHAN YIYE STEEL STRUCTURE

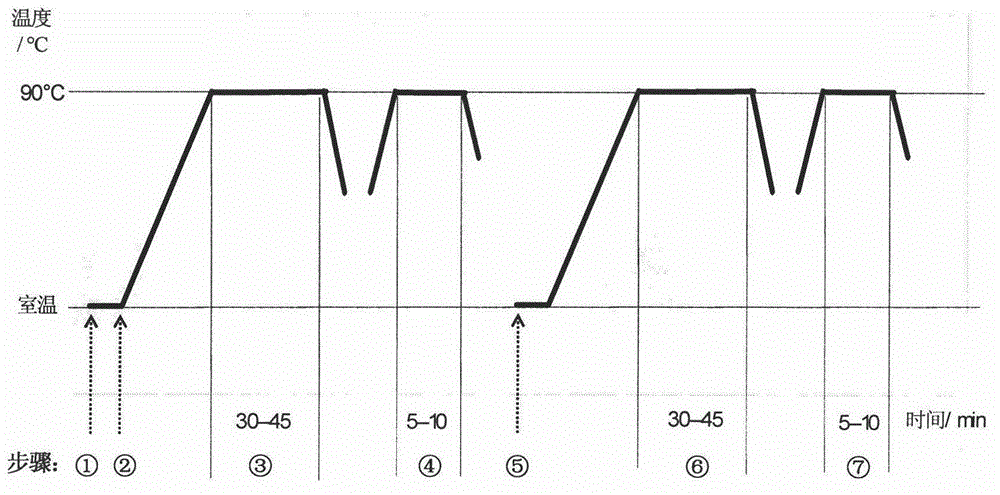

Method for stripping organic fluorine waterproof agent

InactiveCN104532555AImprove permeabilityGood emulsificationDry-cleaning apparatus for textilesVegetal fibresThermal waterFluorine

The invention discloses a method for stripping an organic fluorine waterproof agent. The method specifically comprises the following steps: (1) preparing a working solution; (2) putting a plus material needed to be returned for repair into the working solution, heating to more than 95 DEG C, and boiling for 30-45 minutes; (3) washing for 5-10 minutes by using hot water at the temperature of more than 90 DEG C; (4) preparing a fresh working solution; (5) putting the plus material treated in the step (3) into the fresh working solution prepared in the step (4), heating to more than 95 DEG C, and treating for 20-30 minutes; and (6) finally, washing for 5-10 minutes by using hot water at the temperature of more than 90 DEG C. By adopting the method disclosed by the invention, while organic fluorine is stripped from a fabric, an excellent hydrophilic property is brought to the fabric, so that a good basis is laid for returning defective cloth for repair; and besides, experiences prove that the method disclosed by the invention also has a very good effect of stripping fluorine-free waterproof agents.

Owner:JIANGSU NEW REBA TECH CO LTD

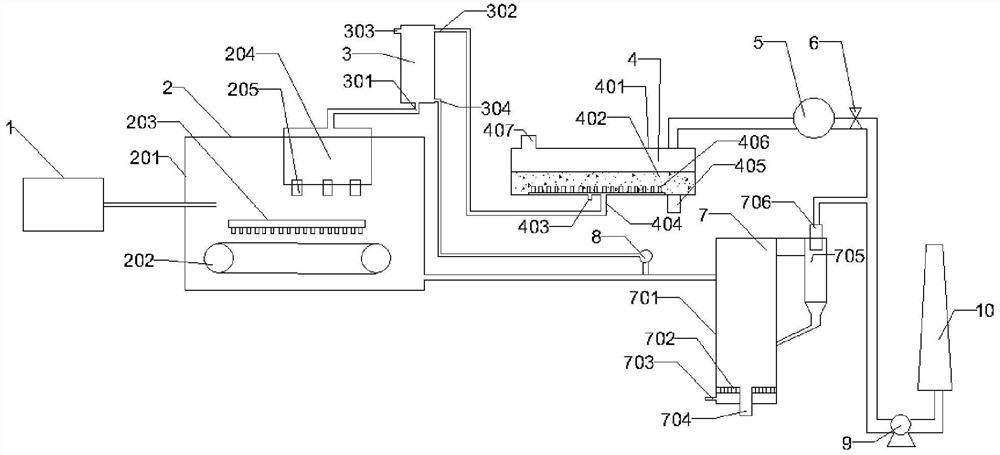

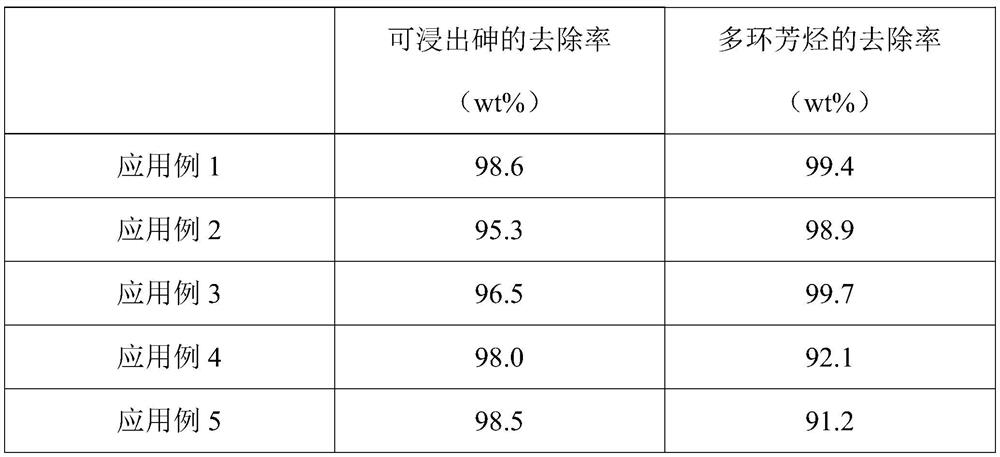

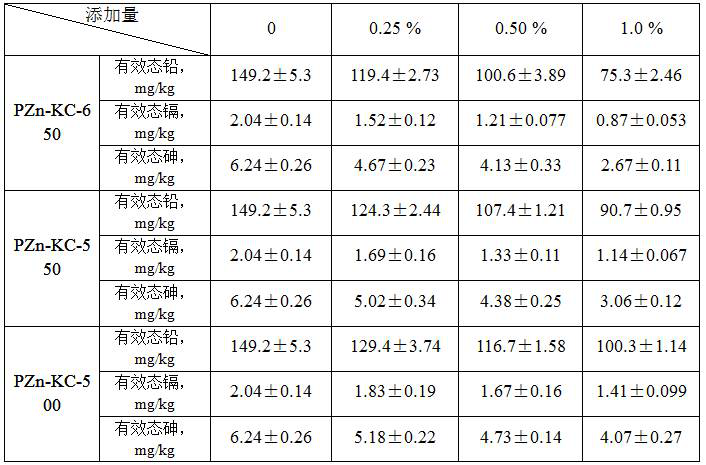

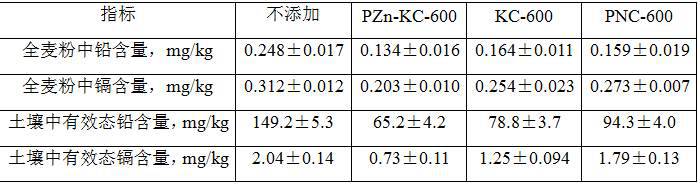

Device and method for repairing soil with organic matter-heavy metal combined contamination

PendingCN112007945AGood curing effectHigh removal rateUsing liquid separation agentContaminated soil reclamationEnvironmental chemistrySoil science

The invention provides a device for repairing soil with organic matter-heavy metal combined contamination. The device comprises a crushing unit, a microwave unit, an oxidation unit, an activation unitand a flue gas treatment unit which are connected in sequence, and further comprises a fluidization reaction unit connected with the microwave unit. According to the invention, microwave, oxidation,activation and fluidization treatment technologies are integrated, and soil with organic matter-heavy metal combined contamination can be repaired; and a method utilizing the device is simple to operate, good in heavy metal solidification effect and high in organic matter removal rate, and particularly can be used for repairing soil with high organic matter concentration.

Owner:GUANGDONG J TECH ENVIRONMENT SCI CO LTD

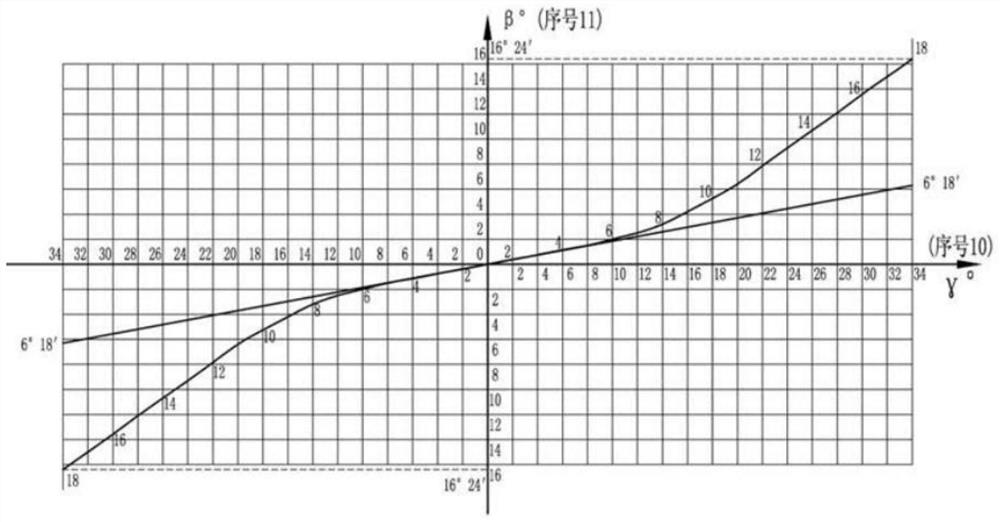

Laser cladding repairing method for abrasion of circular arc curved surface of cam of airplane control system

PendingCN112159979ASolve repair problemsQuality improvementMetallic material coating processesControl systemCam

The invention relates to the field of airplane part repairing, in particular to a laser cladding repairing method for abrasion of a circular arc curved surface of a cam of an airplane control system.The laser cladding repairing method comprises the following specific steps of S1, damage distribution inspection; S2, repairing design; S3, process material analysis; S4, repairing through laser cladding; S5, polishing and finishing after repairing; S6, inspection after polishing; S7, assembly inspection; and S8, motion inspection. According to the laser cladding repairing method, the repairing problem of the nonlinear relation of the circular arc curved surface is solved, the technical blank of circular arc curved surface repairing based on the nonlinear relation is filled up, and compared with the traditional technology, the laser cladding repairing method has the remarkable technical progress; and by tracking the using condition of the repaired cam, it is verified that the adopted repairing method and process are safe and reliable, and the remarkable effects of improving the cam quality and reducing the cost are achieved.

Owner:国营芜湖机械厂

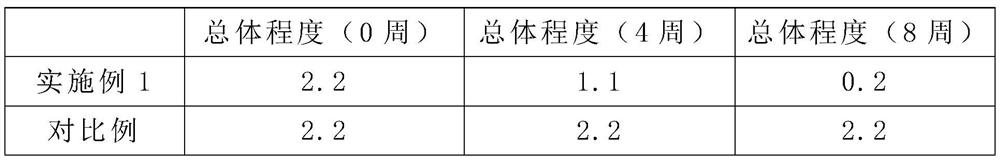

Preparation method of microecologically balanced probiotic microspheres based on traction structure

ActiveCN112870148ASolve repair problemsImprove protectionCosmetic preparationsToilet preparationsBiotechnologyMicrobiology

The invention discloses a preparation method of microecological balance probiotic microspheres based on a traction structure, probiotic composite microspheres are formed by taking a probiotic compound as an active core layer and taking multilayer composite hyaluronic acid as a coating shell, the multilayer composite hyaluronic acid contains tetrahydromethylpyrimidine carboxylic acid, and the specific preparation method is provided. According to the invention, the problem of difficulty in repairing a microbial barrier is solved, a physical-biological dual repairing system is formed by utilizing a physical water retention system of the probiotic compound and the hyaluronic acid, the protection effect of skin is greatly improved, and meanwhile, a physical repairing system of a water anion system is formed by utilizing the tetrahydromethylpyrimidine carboxylic acid, so that the protection effect is greatly improved.

Owner:GUANGDONG IND TECHN COLLEGE

Laser cladding Co-based alloy powder for conductor roll

InactiveCN100575553CSolve repair problemsImprove performanceMetallic material coating processesRare-earth elementAlloy substrate

Owner:SHENYANG DALU LASER TECH

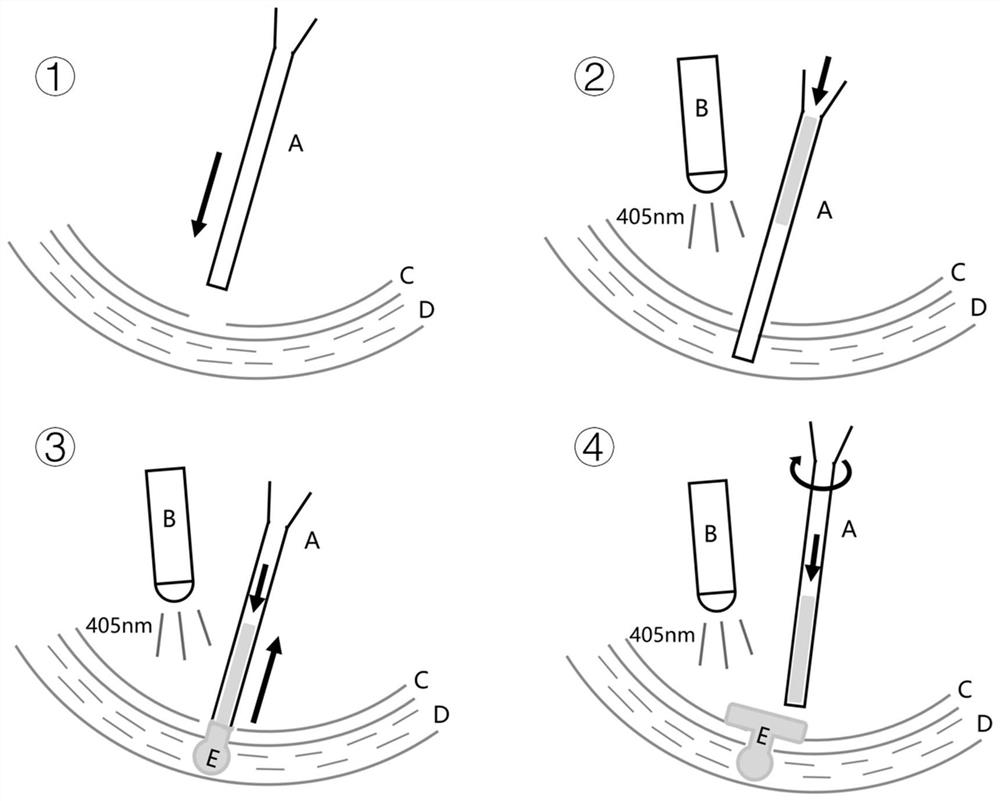

In situ biofabrication method in vivo and its application in tissue repair in vivo

ActiveCN113181427BAchieve fixPromote repair and regenerationTissue regenerationProsthesisTissue repairRepair tissue

The present invention relates to in situ biomanufacturing method in vivo and its application in tissue repair in vivo. The in situ biomanufacturing method in the body provided by the present invention is to transport the photosensitive repair material to the tissue to be repaired in the body through an instrument, fix it as a bioprinting scaffold in the form of a rivet to the tissue to be repaired, and realize the integration of the bioprinting scaffold and the tissue to be repaired by increasing the mechanical force. The good attachment of the repaired tissue solves the problems that the tissue to be repaired is not easy to attach because the tissue to be repaired is located in the deep layer of the body and the surface is wet. The novel photosensitive repair material of the present invention is widely applicable to the in-situ repair of tissues in the body, and the in-situ rapid solidification in the body is riveted with the tissue to be repaired in the form of a hydrogel rivet, and strongly adheres to the tissue. Acrylate is covalently cross-linked with the tissue to be repaired to achieve firm repair and long-term closure of the damaged site, which has a good clinical application prospect.

Owner:TSINGHUA UNIV +1

Probiotic milk ball for promoting micro-ecological balance of skin

ActiveCN112826750ASolve repair problemsImprove protectionCosmetic preparationsToilet preparationsBiotechnologyMicrosphere

The invention discloses a probiotic emulsion ball for promoting skin micro-ecological balance, which is characterized in that a probiotic compound is used as an active core layer, hyaluronic acid is used as a coating shell layer, and shell-core microspheres are formed. The problem that the microbial barrier is difficult to repair is solved, a physical-biological dual repair system is formed by matching the probiotic compound with a physical water retention system of hyaluronic acid, and the skin protection effect is greatly improved.

Owner:广州优科生物科技有限公司

A cobalt-based alloy powder for repairing the nozzle ring of an internal combustion engine supercharger

ActiveCN104233281BHigh hardnessHigh strengthMetallic material coating processesCombustionUltimate tensile strength

Owner:上海大陆天瑞激光表面工程有限公司

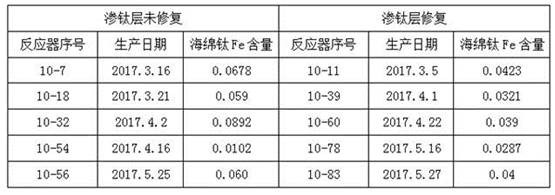

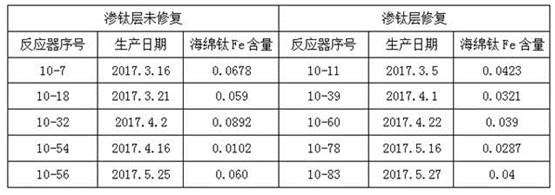

A method for repairing the titanium infiltration layer of the reactor in the production process of sponge titanium

ActiveCN113584325BAvoid damage expansionSolve repair problemsSolid state diffusion coatingPhysical chemistryProcess engineering

The invention relates to a method for repairing a titanium infiltration layer of a reactor in the production process of sponge titanium. The method uses D40-D200 solvent oil and titanium powder mixed with titanium powder to smear the titanium infiltration layer of a reactor to be repaired, and then evacuates the reactor and flushes it with argon. It is then put into the cold end of the distillation stage for use. After the cold end of the distillation is completed, the reactor is put into the hot end of the next round of reduction stage for use, and the repair of the titanium infiltration layer is completed in the process. Combining the invention with production, the reactor titanium infiltration repair and production can be carried out at the same time, which greatly improves the utilization rate of the reactor, saves the power consumption of the separate titanium infiltration process, and avoids the furnace occupation of the separate titanium infiltration process.

Owner:洛阳双瑞万基钛业有限公司

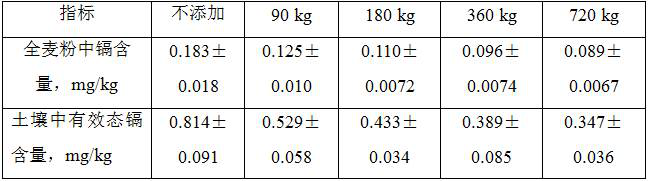

A zinc-rich biochar, its preparation method and its application in passivation restoration of heavy metal polluted soil

ActiveCN112457853BAvoid pollutionSelf-activationAgriculture tools and machinesContaminated soil reclamationSoil heavy metalsCarbonization

The invention relates to a preparation method of zinc-rich biochar, including 1) pretreatment: mixing furfural slag, zinc oxide and water, and then sealing and storing at 20-50°C for 120-240 h; 2) carbonization: Under nitrogen atmosphere, the product obtained in step 1) was heated to 250-450°C for carbonization for 1-3 hours; 3) activation: the temperature was raised to 500-700°C, and activated at a flow rate of carbon dioxide gas of 10-60 mL / min for 0.5-2 hours , and then cooled, that is. The invention realizes the reduction and harmless disposal of furfural slag, reduces environmental discharge and pollution; the biochar obtained in the invention can effectively fix heavy metal pollutants, and has a good repair effect on heavy metal polluted farmland, which is an ideal Low-cost soil heavy metal pollution passivation remediation agent.

Owner:HIGH & NEW TECH RES CENT OF HENAN ACAD OF SCI

Method for repairing reactor titanizing layer in titanium sponge production process

ActiveCN113584325AAvoid damage expansionSolve repair problemsSolid state diffusion coatingProcess engineeringTitanium powder

The invention relates to a method for repairing a reactor titanizing layer in a titanium sponge production process. The method comprises the following steps: mixing D40-D200 solvent oil with titanium powder, smearing a reactor titanizing layer to be repaired, evacuating a reactor, filling the reactor with argon, putting the reactor into a cold end of a distillation stage for use, placing the reactor into a hot end of a next reduction stage for use after operation at the cold end of the distillation stage is finished, and finishing the repair of the titanizing layer in the process. The method is combined with production, the reactor titanizing repair and production can be simultaneously performed, the utilization rate of the reactor is greatly improved, meanwhile, the power consumption of an independent titanizing process is reduced, and the furnace occupation condition of independent titanizing is avoided.

Owner:洛阳双瑞万基钛业有限公司

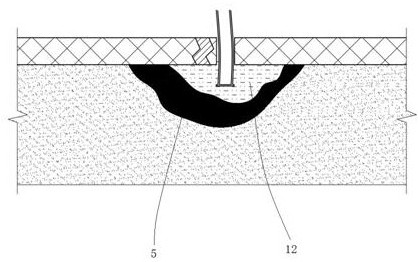

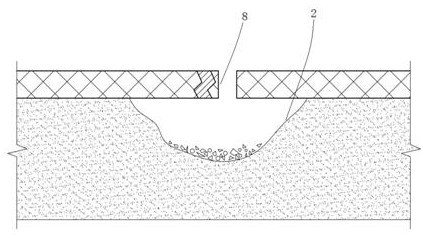

Desilting, grouting and reinforcing method for cracks of pavement with empty bottom

InactiveCN112252111ASolve repair problemsImprove reinforcementPaving detailsRoads maintainenceGeotechnical engineeringStructural engineering

A desilting, grouting and reinforcing method for cracks of a pavement with an empty bottom comprises the following steps: injecting water into a void area at the bottom of a rigid pavement slab, stirring to enable sludge to form slurry, thoroughly pumping out the slurry, and then grouting and reinforcing. According to the method, the plate bottom slurry can be thoroughly removed, the void area canbe completely filled with the grouting slurry, a good crack reinforcing effect is achieved, and the problem that the reinforcing material is difficult to inject due to the fact that the bottom of thevoid road rigid pavement plate is silted is fundamentally solved.

Owner:徐州成瑞建筑科技研究院有限公司

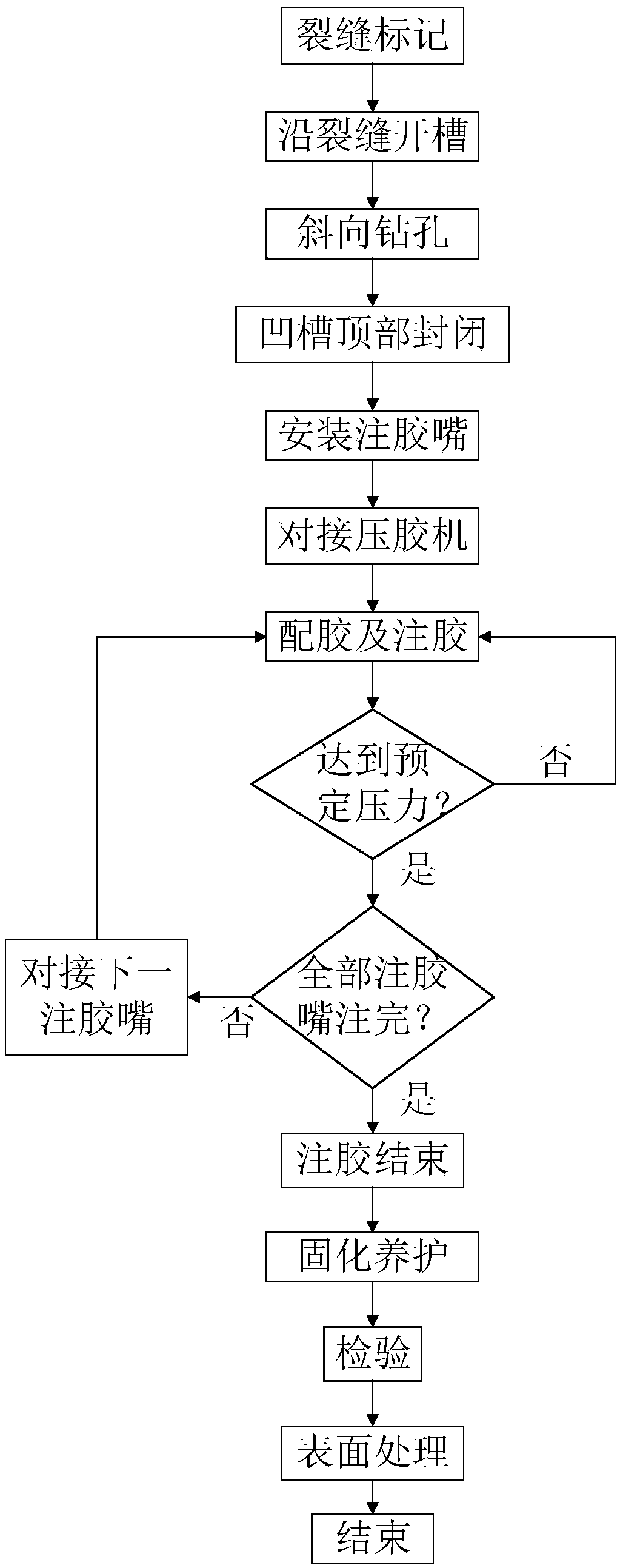

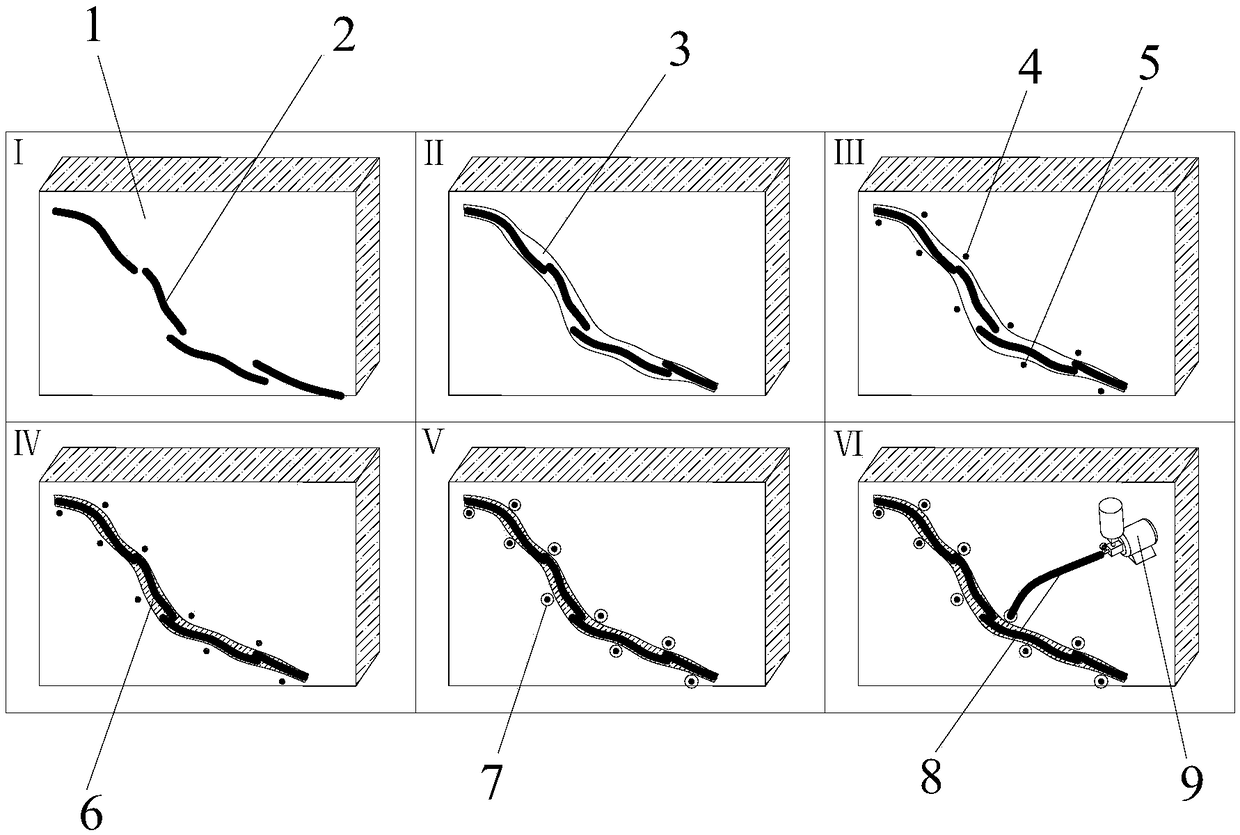

Repairing method of inconstant cracks of concrete building body

InactiveCN108952206ASolve repair problemsImprove repair effectBuilding repairsSurface finishingRepair method

The invention provides a repairing method of inconstant cracks of a concrete building body. The method comprises the steps of step one, crack marking; step two, groove forming along the cracks; step three, hole drilling in oblique directions; step four, groove top sealing; step five, glue injection mouth installing; step six, glue injection; step seven, surface finishing. The method has the advantages that the difficult problem of the repairing of the inconstant cracks on the concrete building body is solved, a communicated space is created for the glue injection process of the cracks so thatglue can completely fill cracking regions, the repairing effect of the inconstant cracks on the concrete building body is significantly improved, the durability and safety of a concrete structure is enhanced, the operation is convenient, construction is easy, the repairing construction efficiency is high, large equipment is not needed, construction can be conducted in various complicated environments, and the cost is lower.

Owner:CHINA RAILWAY 14TH CONSTR BUREAU GRP 4TH ENG +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com