A method for repairing the titanium infiltration layer of the reactor in the production process of sponge titanium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

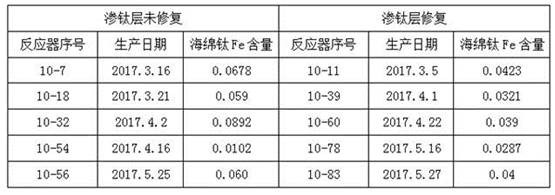

Examples

Embodiment Construction

[0018] The present invention is described in further detail below in conjunction with the examples, but is not used as the basis for any limitation of the invention.

[0019] A method for repairing a titanium infiltrating layer of a reactor in a titanium sponge production process, comprising the following steps:

[0020] (1) Clean the interior of the reactor to be repaired, use D40-D200 solvent oil: titanium powder = 2:1 to mix into a paste, and use a brush to brush the parts of the reactor to be repaired, with a coating thickness of 0.4-0.8mm ;

[0021] (2) The brushed reactor is assembled with a large cover in the preparation section, and the reactor is evacuated and negatively charged by the Roots pump, and then flushed with argon to a slightly positive pressure;

[0022] (3) After the evacuation and argon flushing are qualified, put the reactor into the furnace of the distillation stage for use at the cold end. The temperature of the reactor at the cold end is controlled ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com