Patents

Literature

112results about How to "Simple fix" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

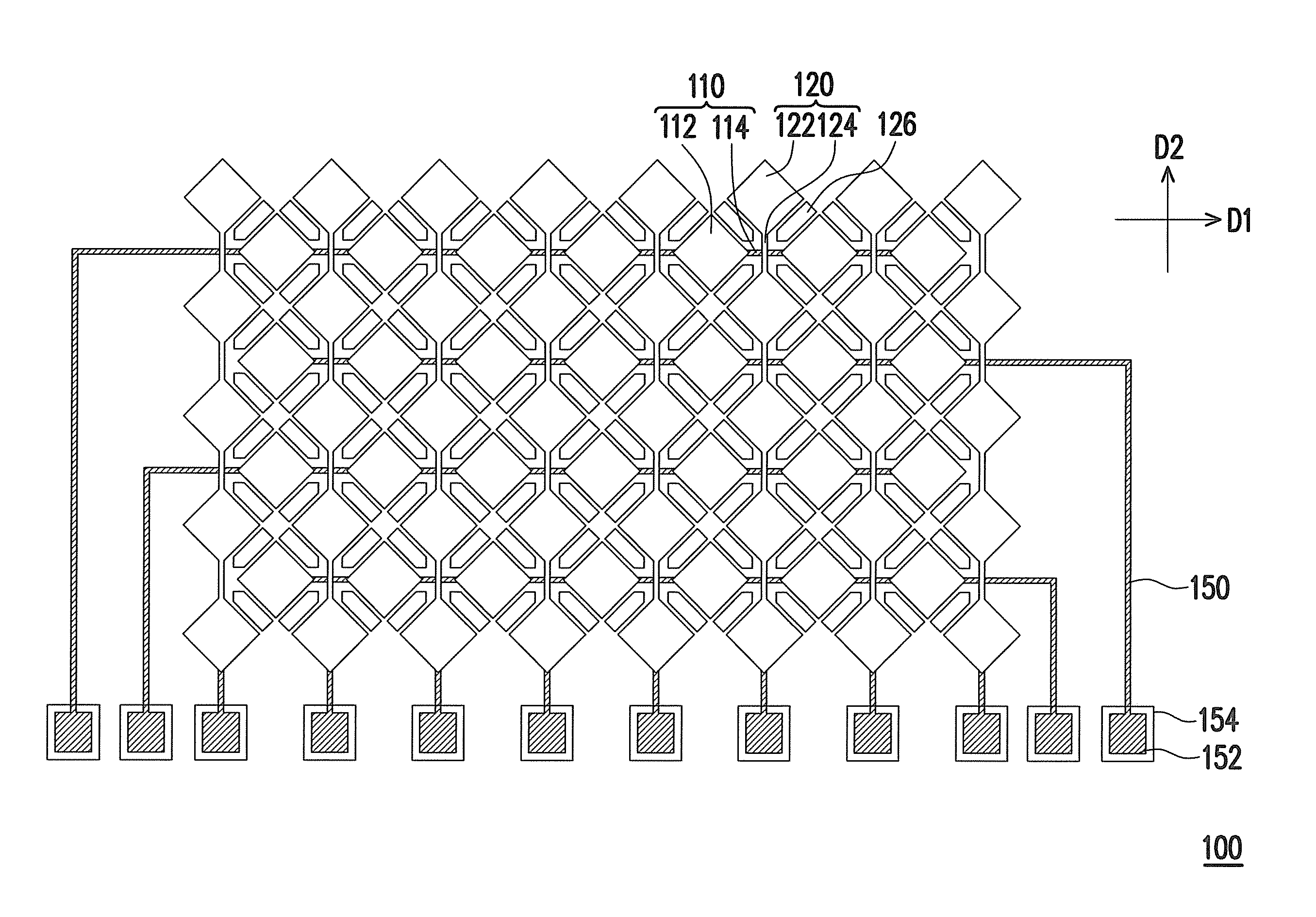

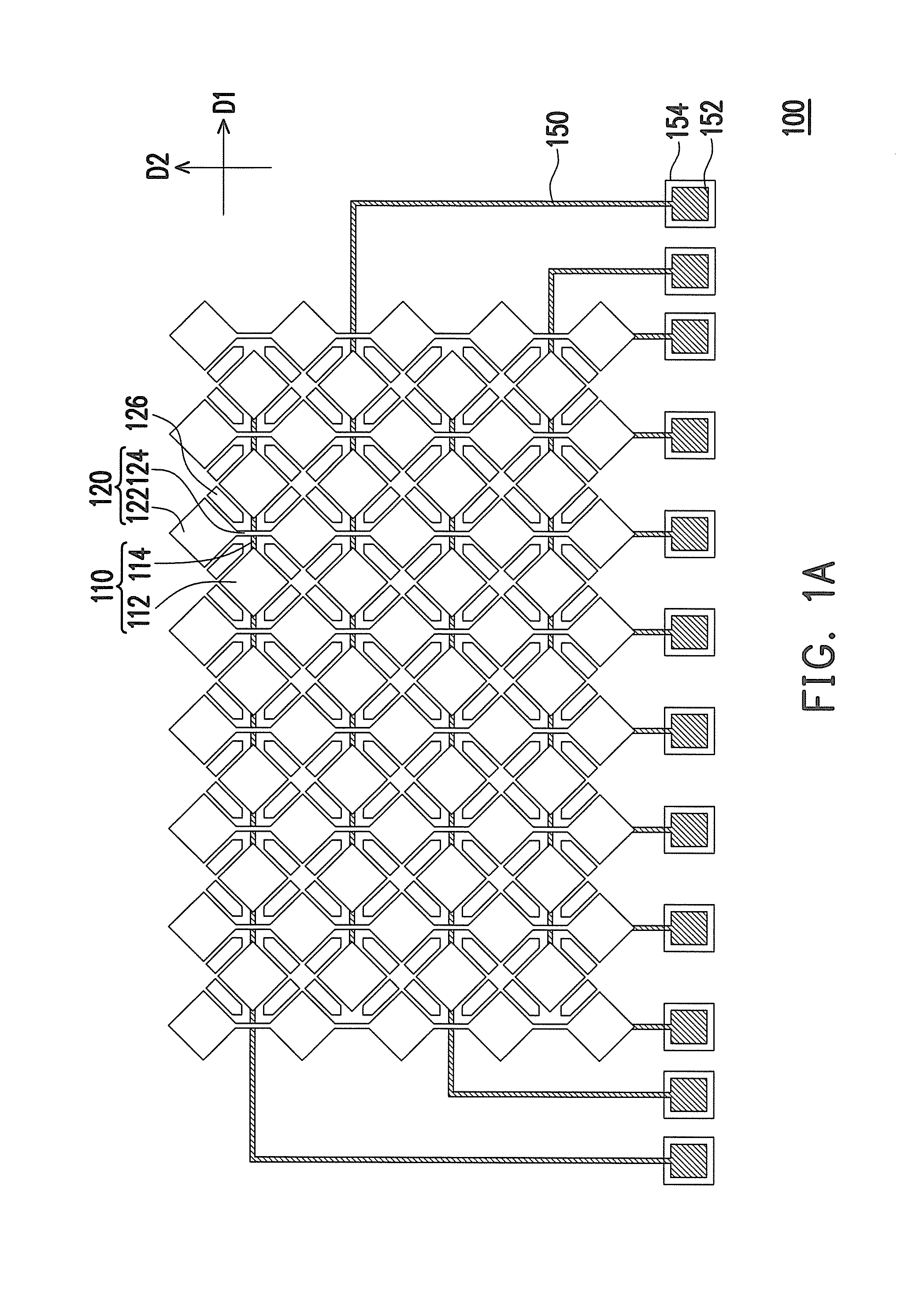

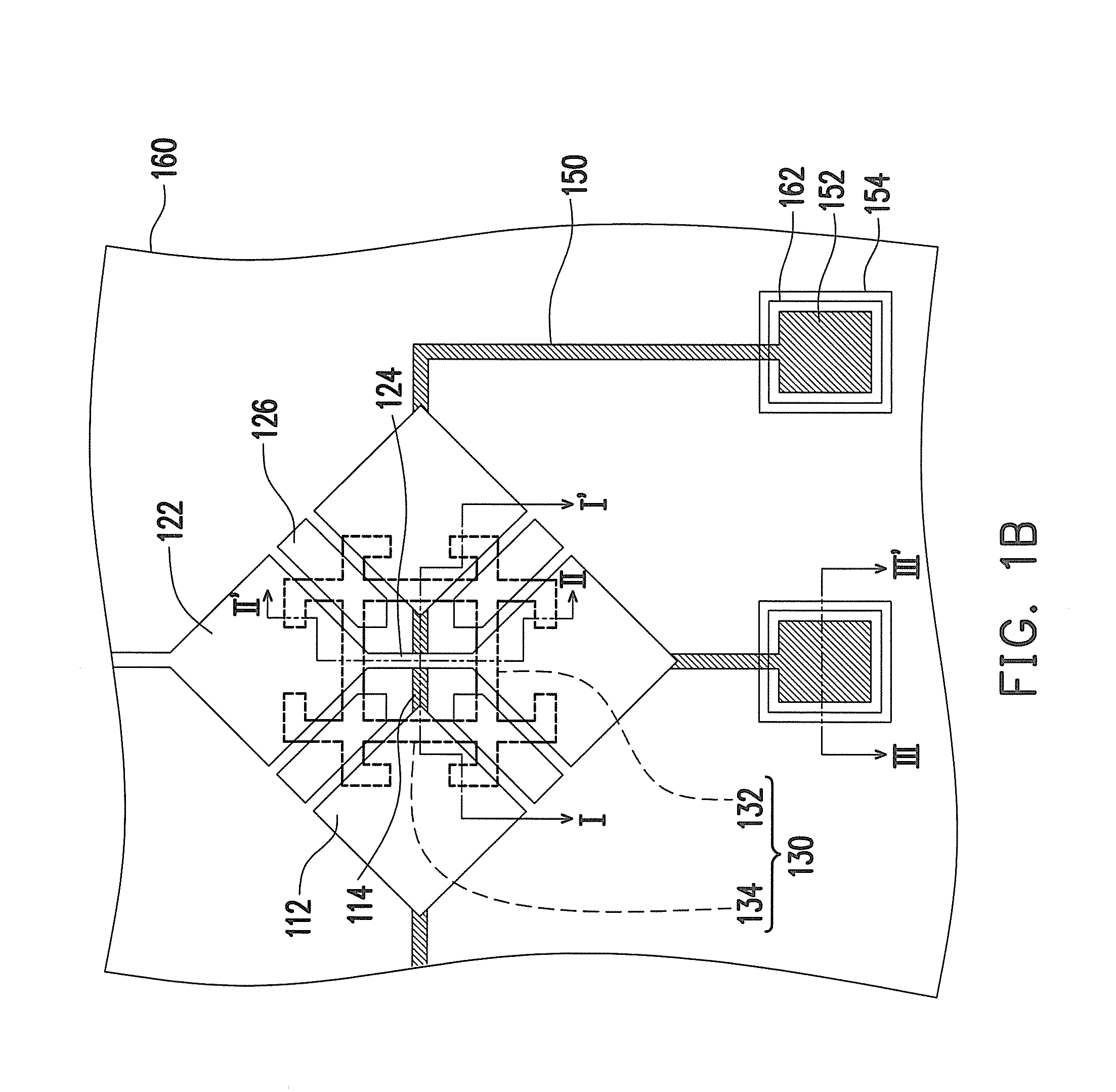

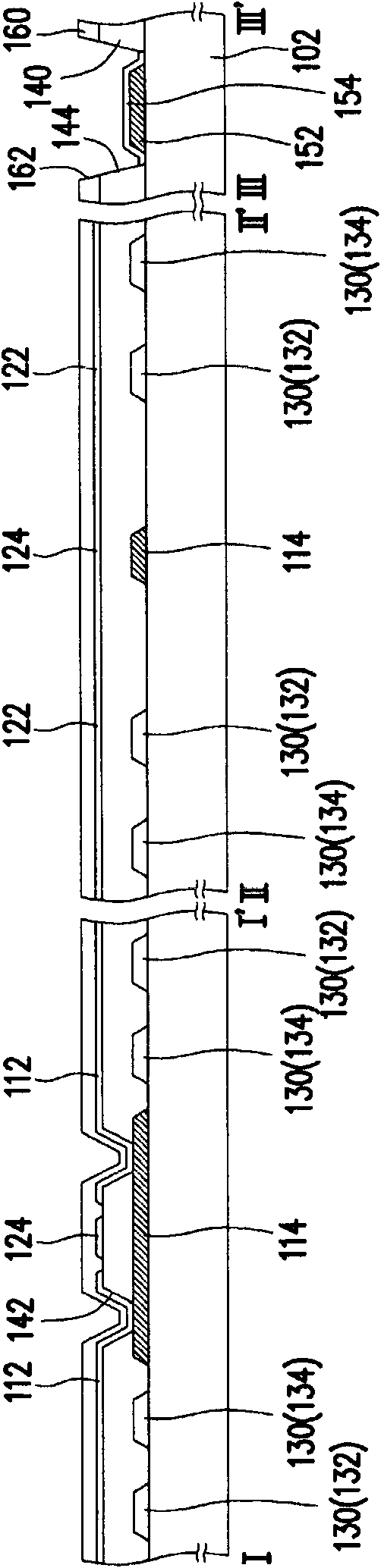

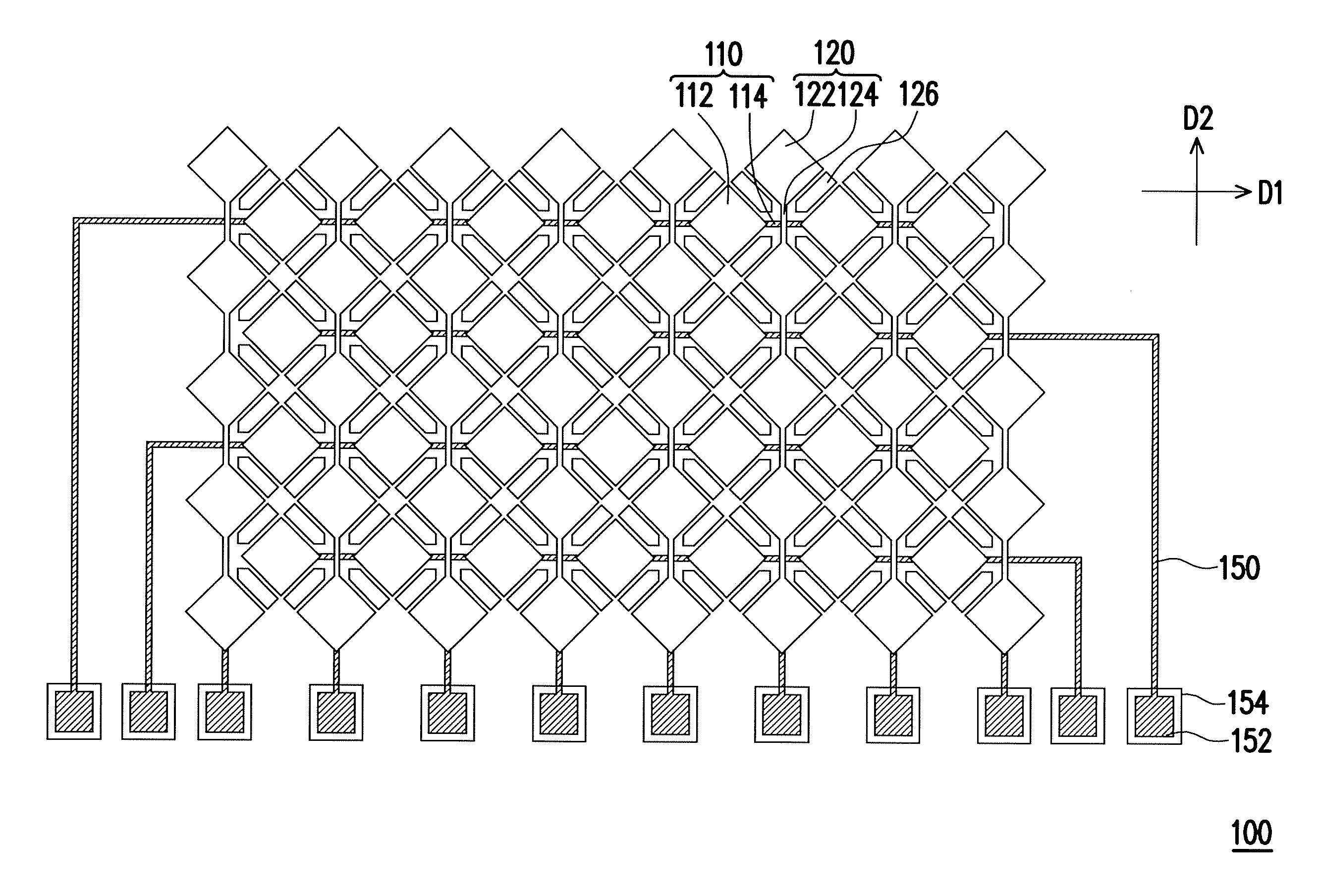

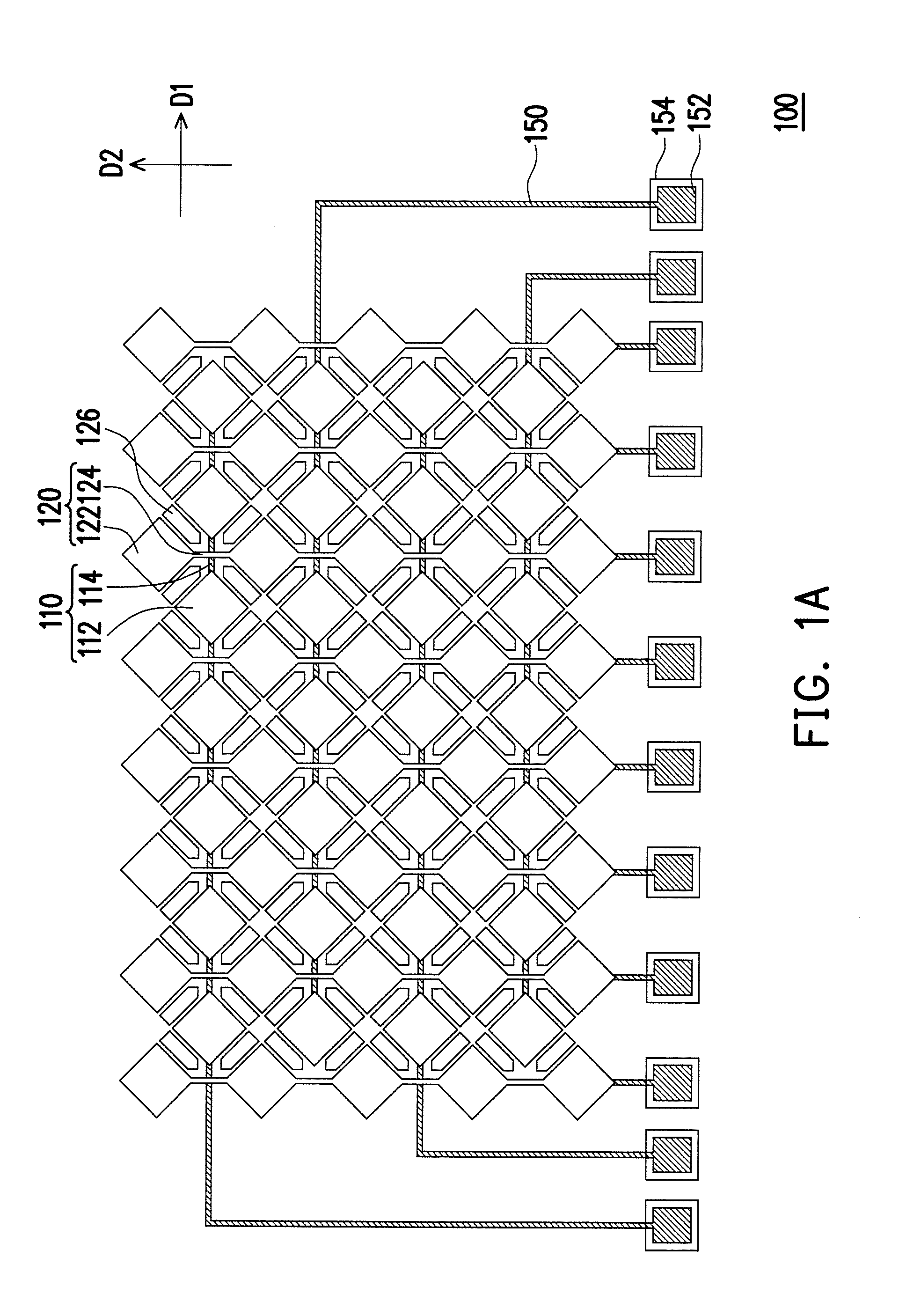

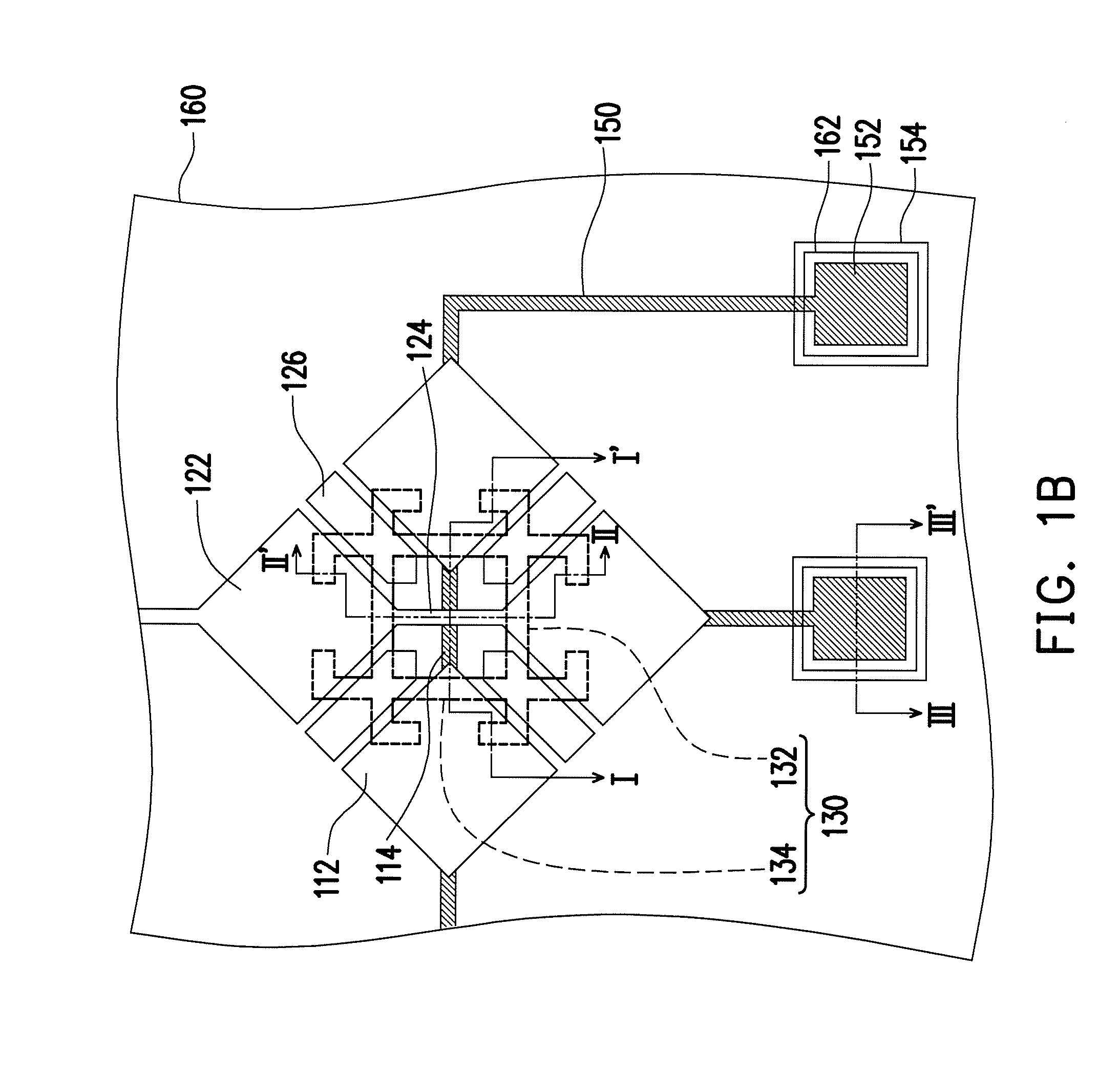

Touch panel and repairing method thereof

InactiveUS20120081300A1Good yieldSimple fixLine/current collector detailsInput/output processes for data processingTouch panelRepair method

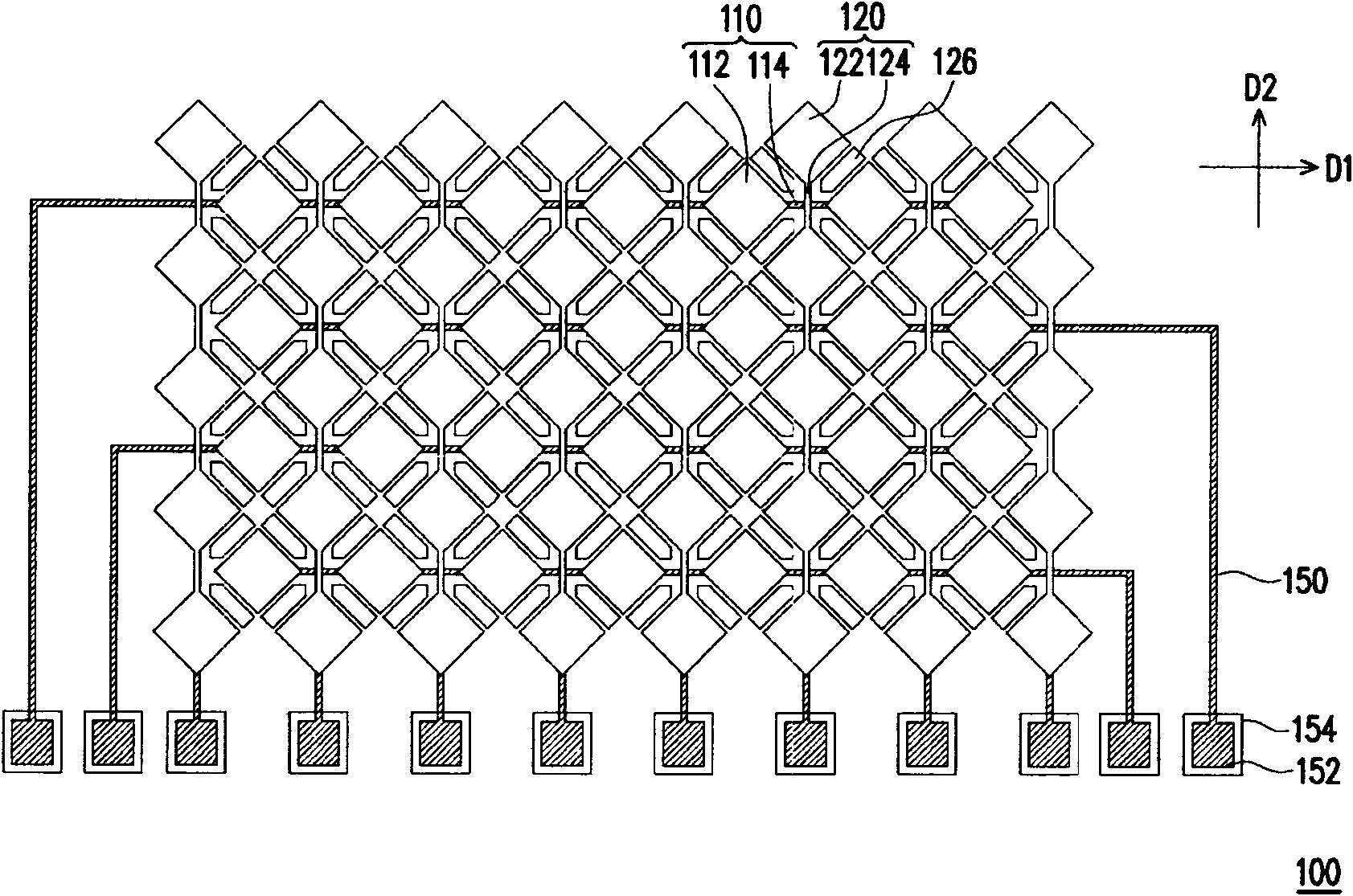

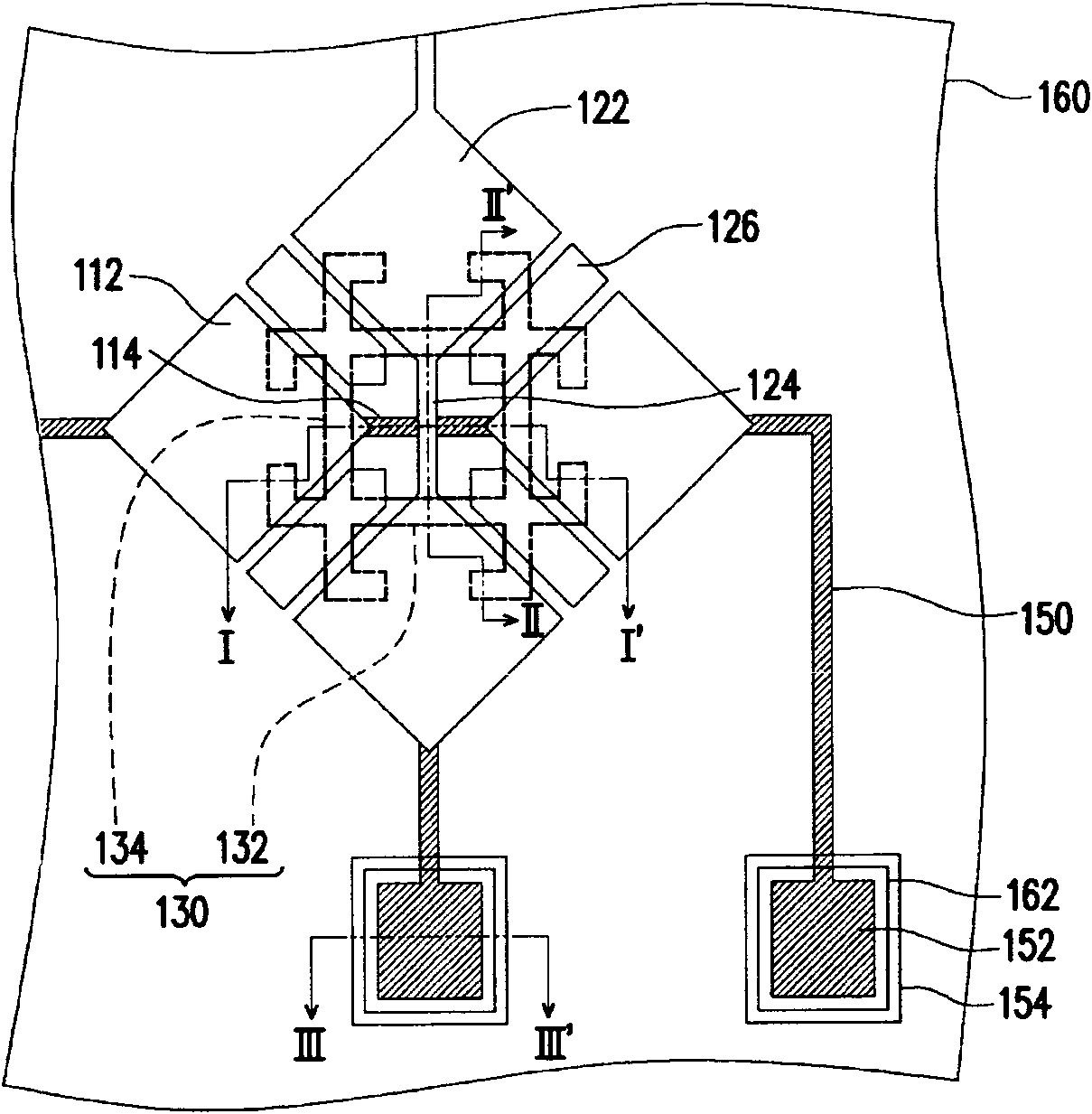

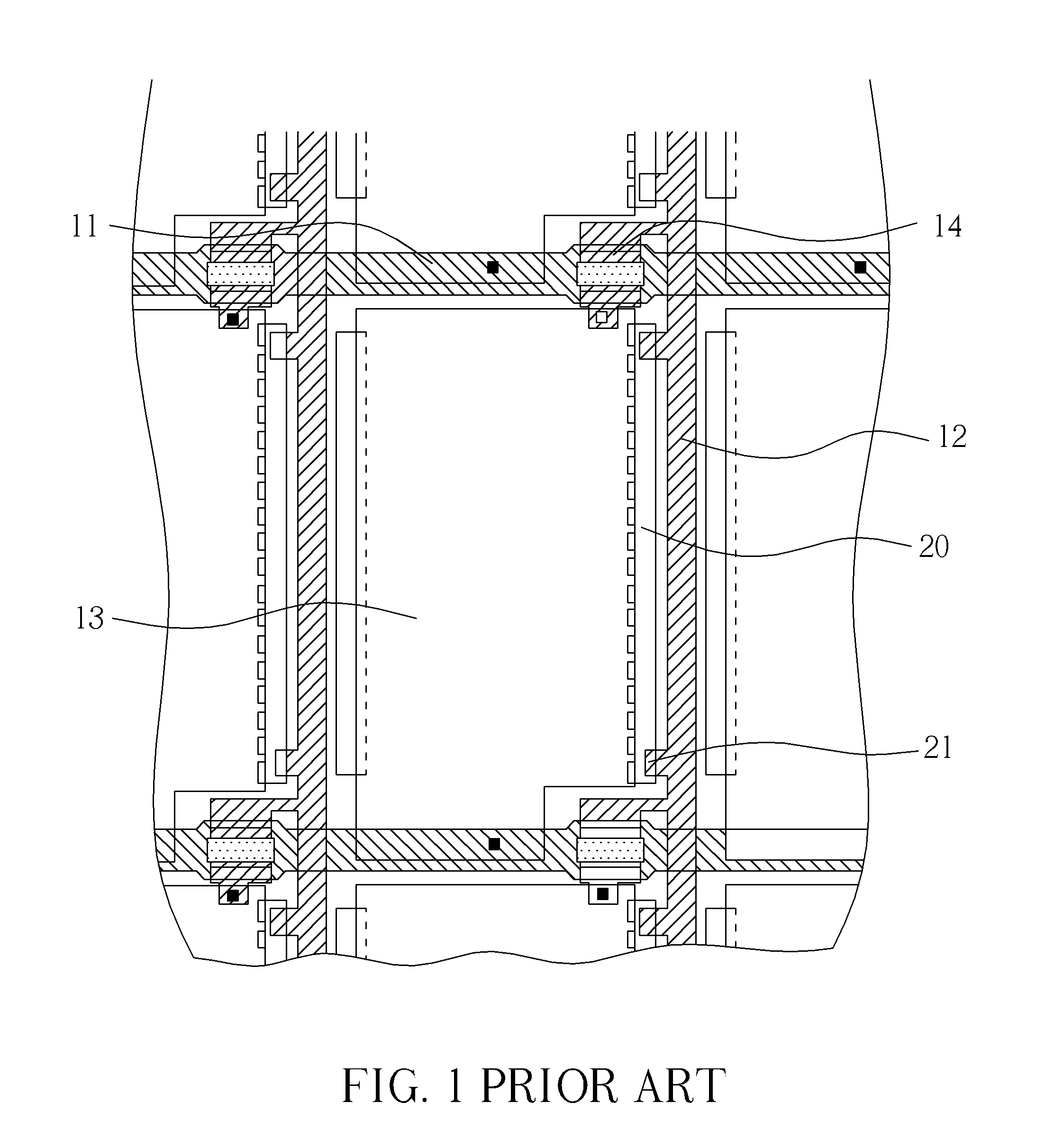

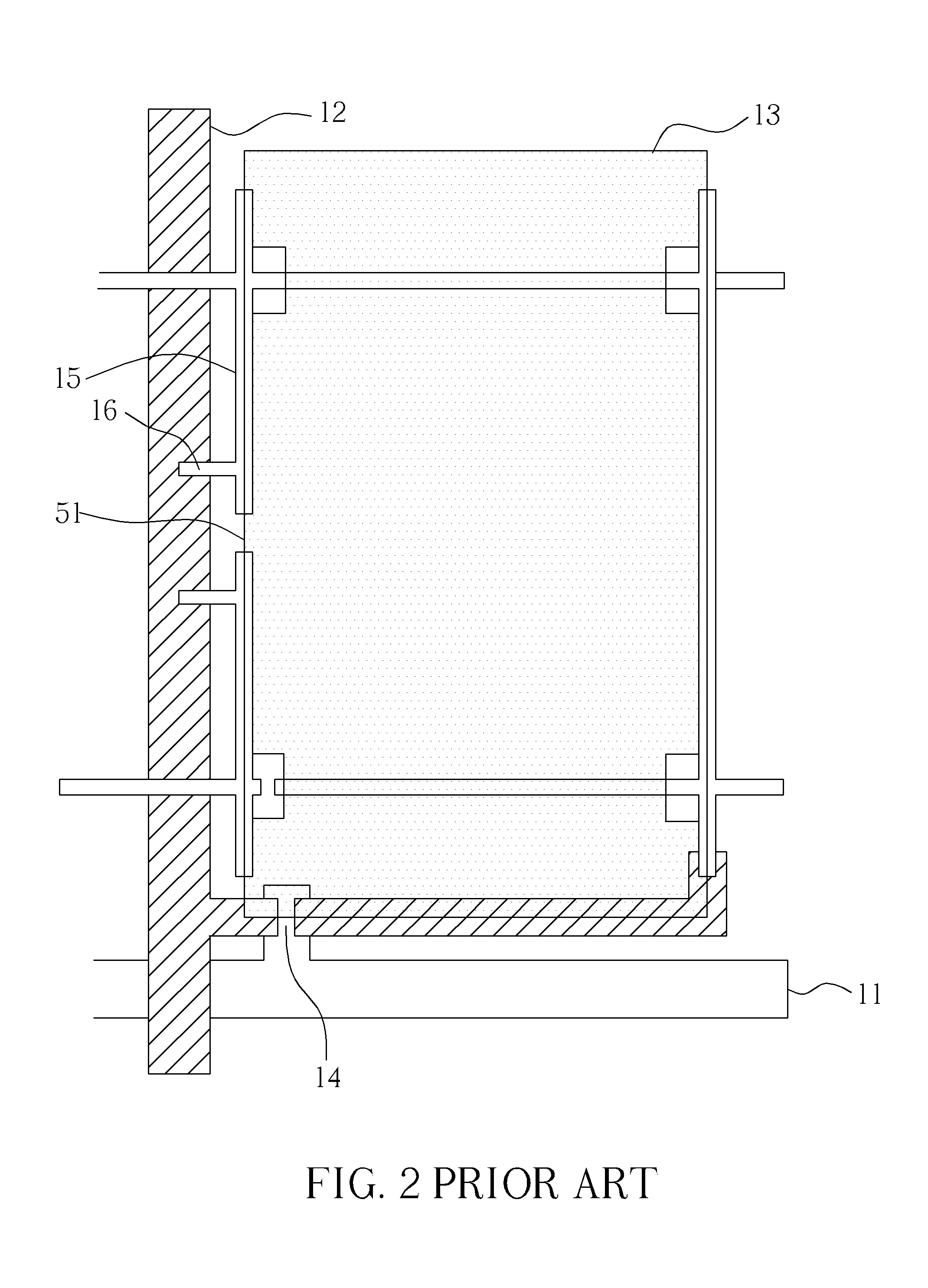

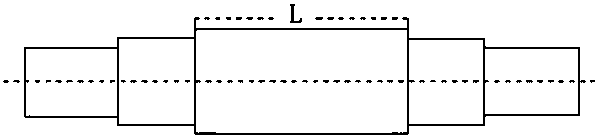

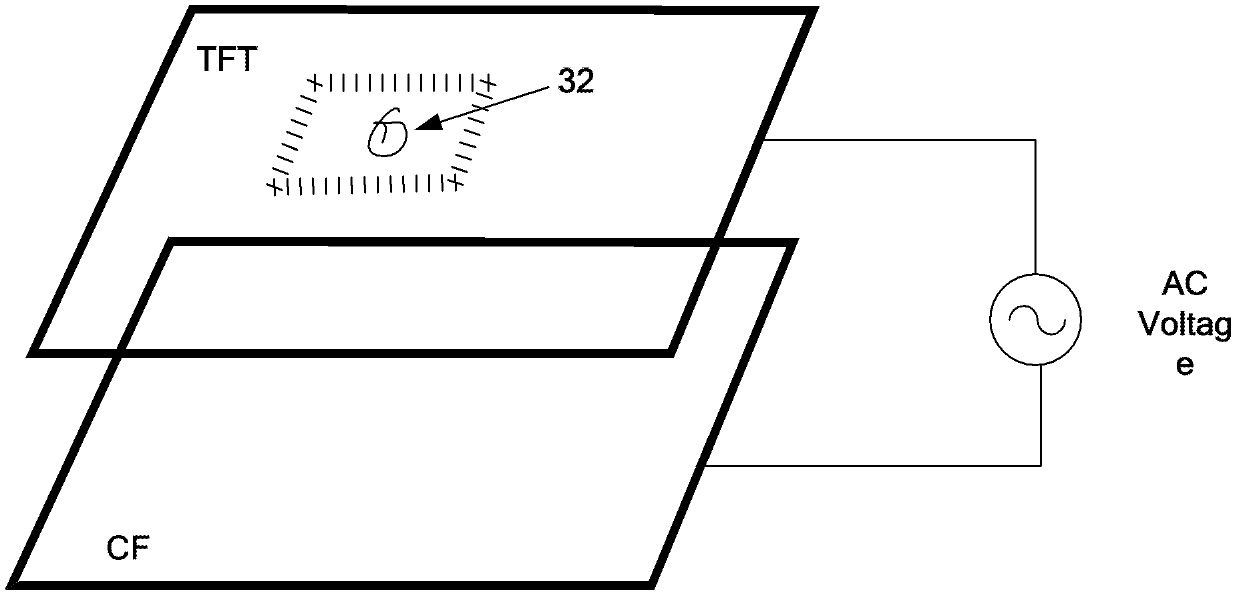

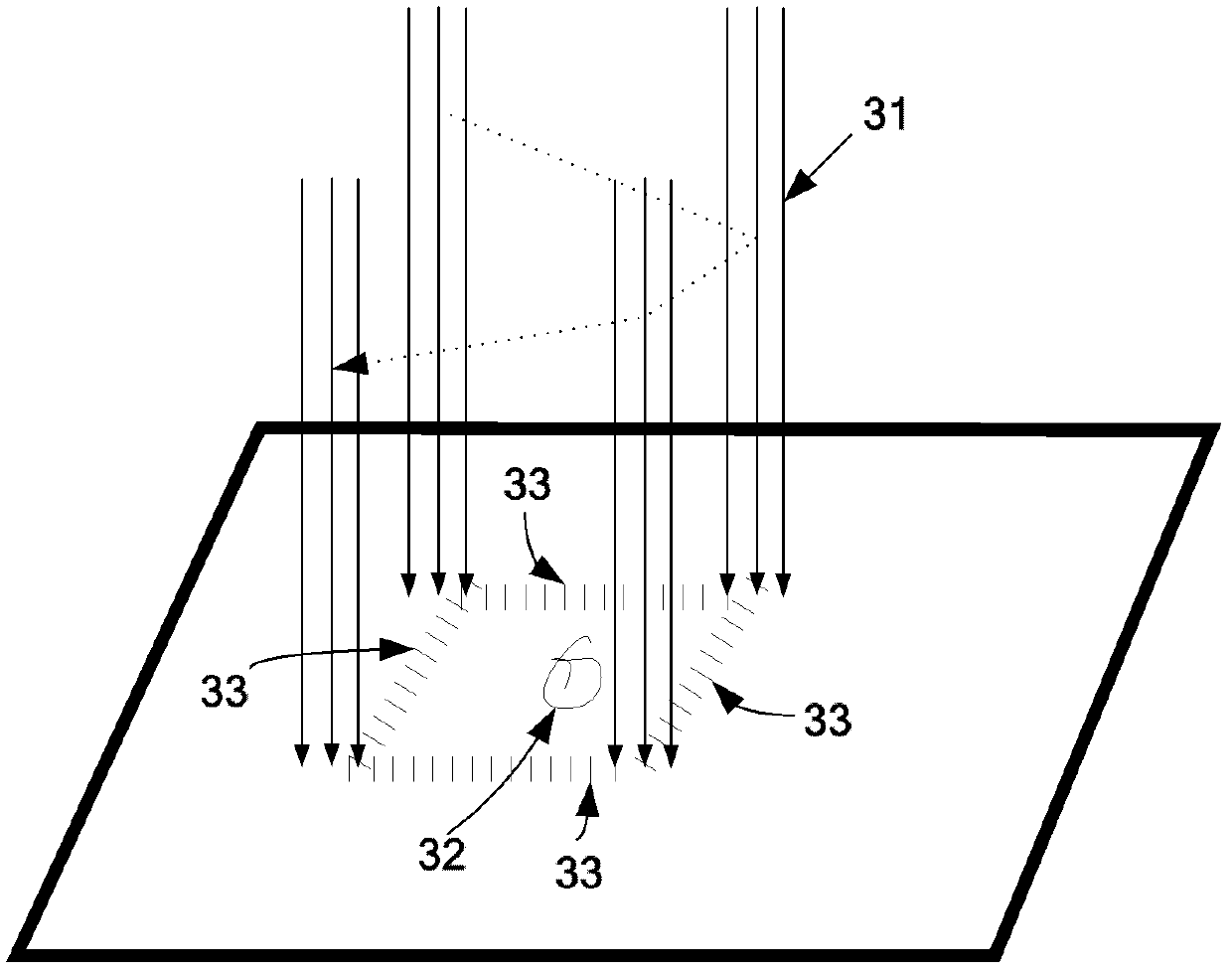

A touch panel including a substrate, a plurality of first and second sensing series, and a plurality of conductive repairing pattern layers is provided. The first sensing series are disposed on the substrate and extended along a first direction. Each of the first sensing series includes a plurality of first sensing pads and first bridge lines, and the first bridge lines serially connect two adjacent first sensing pads. The second sensing series are disposed on the substrate and extended along a second direction. Each of the second sensing series includes a plurality of second sensing pads and second bridge lines, and the second bridge lines serially connect two adjacent second sensing pads. Each conductive repairing pattern layer electrically floating locates around the crossover region of the first and second sensing series. Two adjacent sensing pads are connected by the conductive repairing pattern layer after a repair procedure is finished.

Owner:AU OPTRONICS CORP

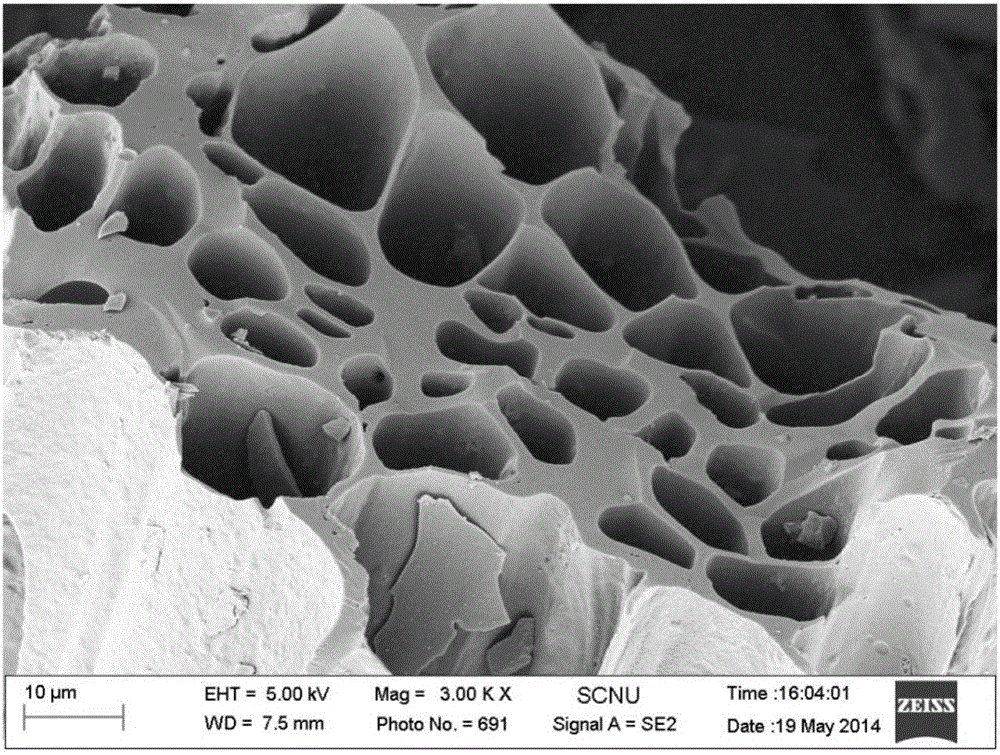

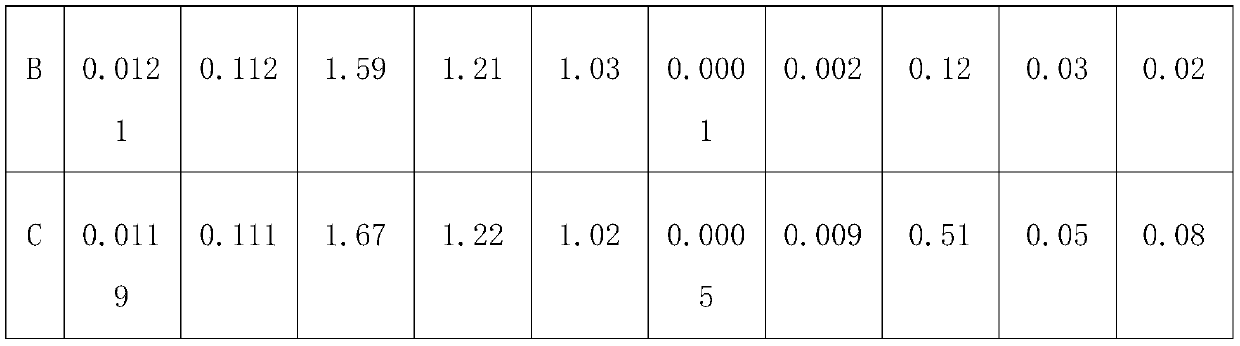

Preparation and application for heavy metal chromium contaminated soil remediation material

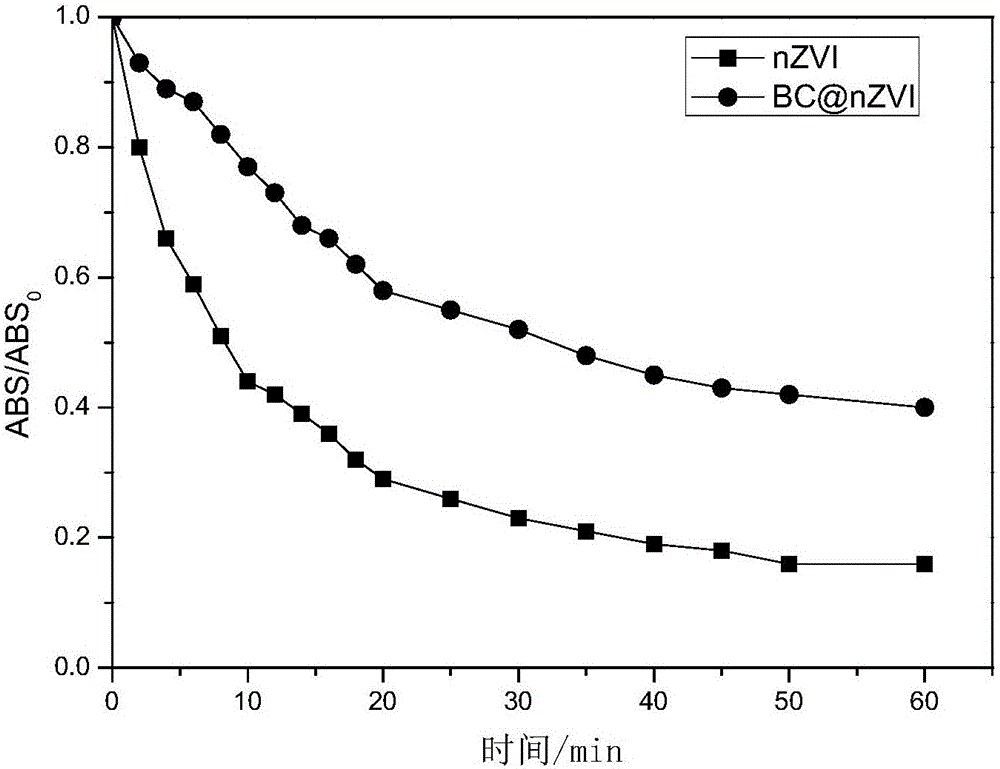

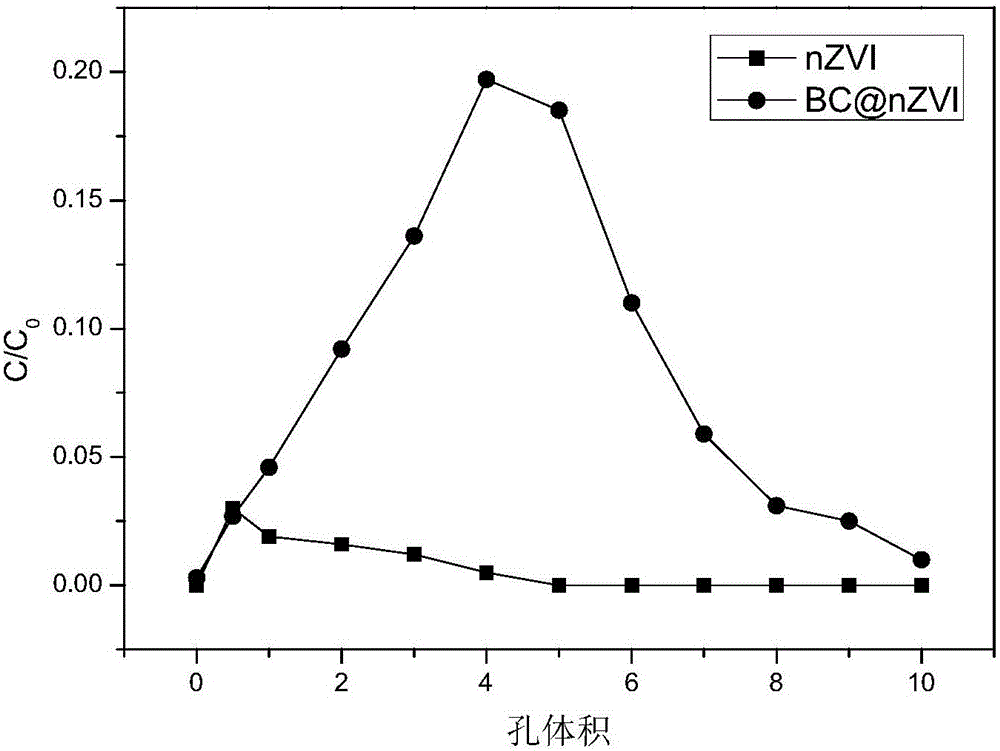

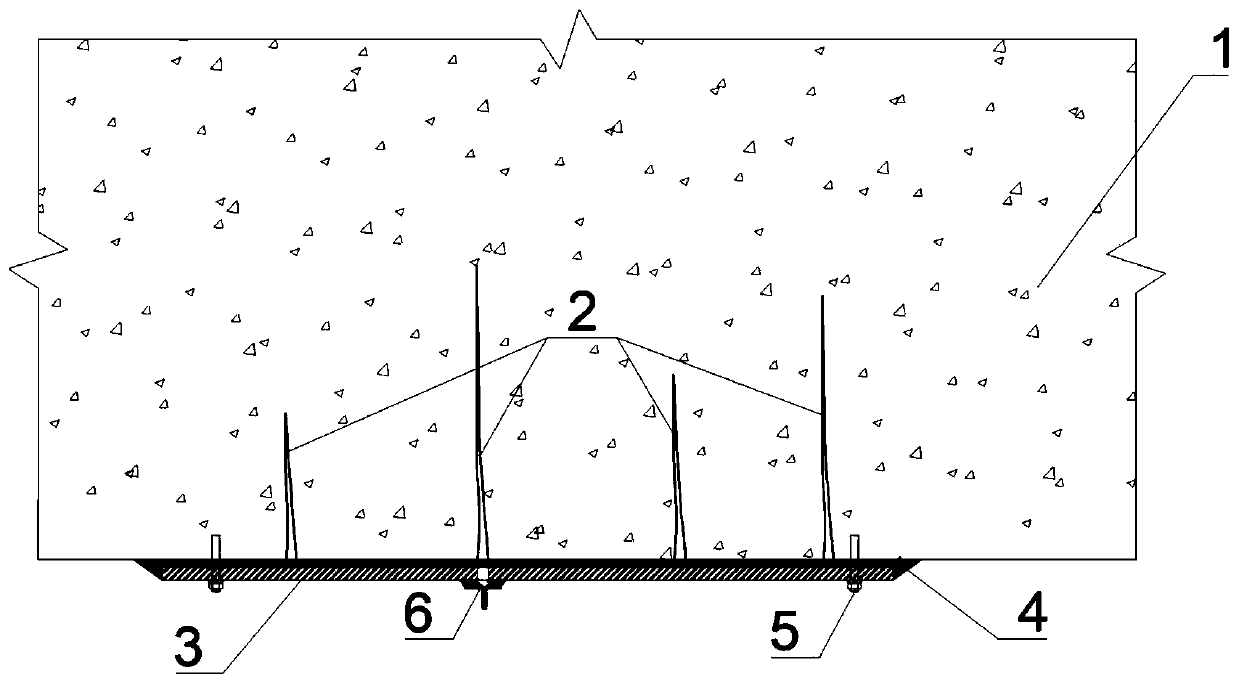

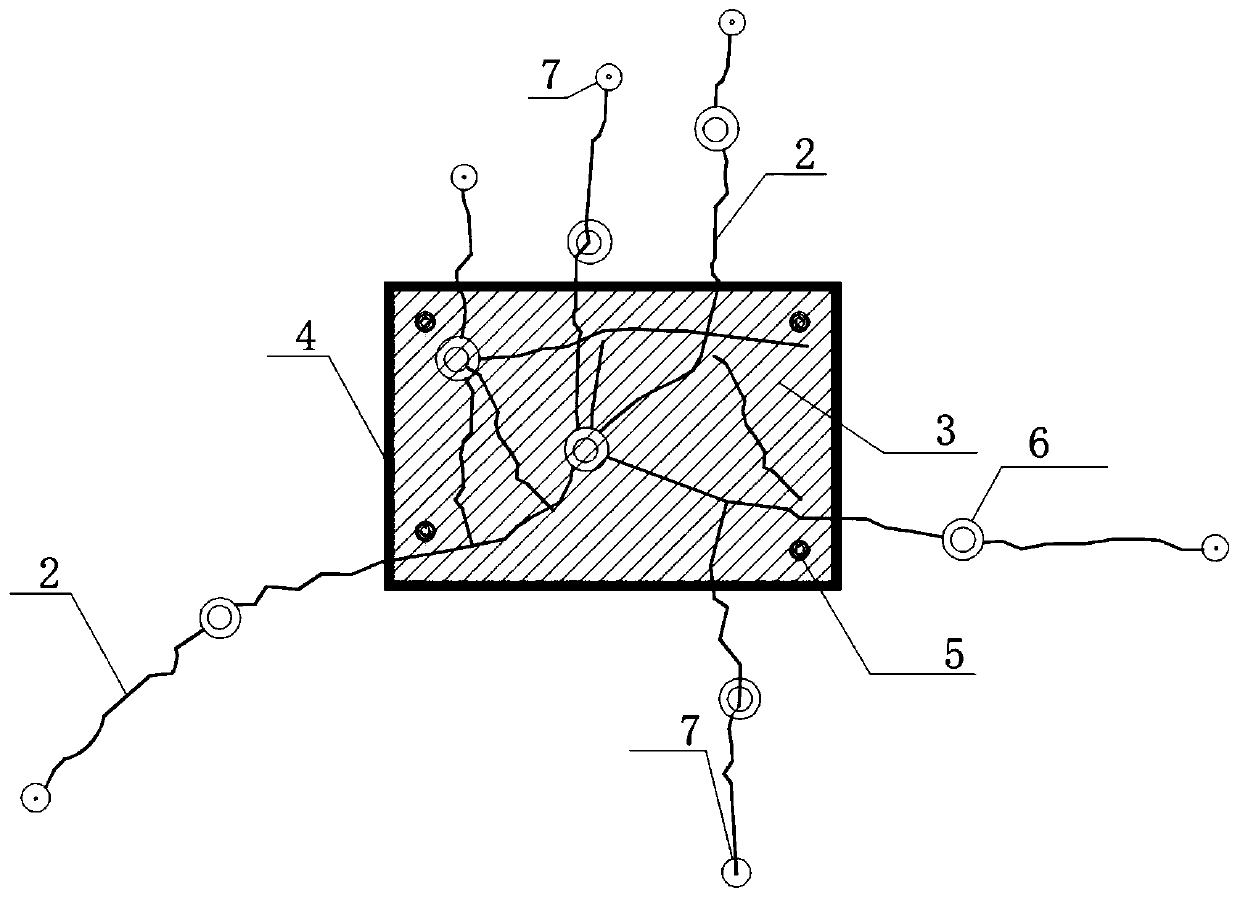

ActiveCN105013811AImprove repair efficiencyImprove stabilityContaminated soil reclamationOrganic fertilisersFerrous saltsCarbon particle

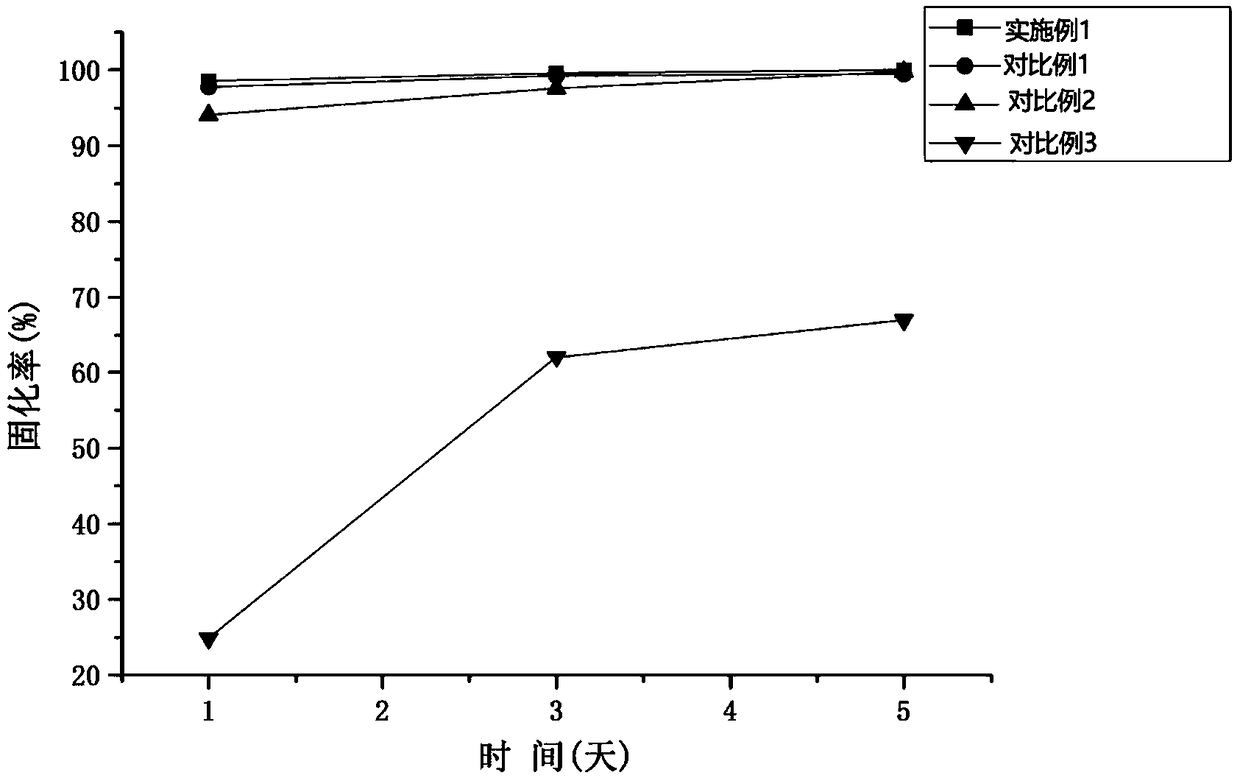

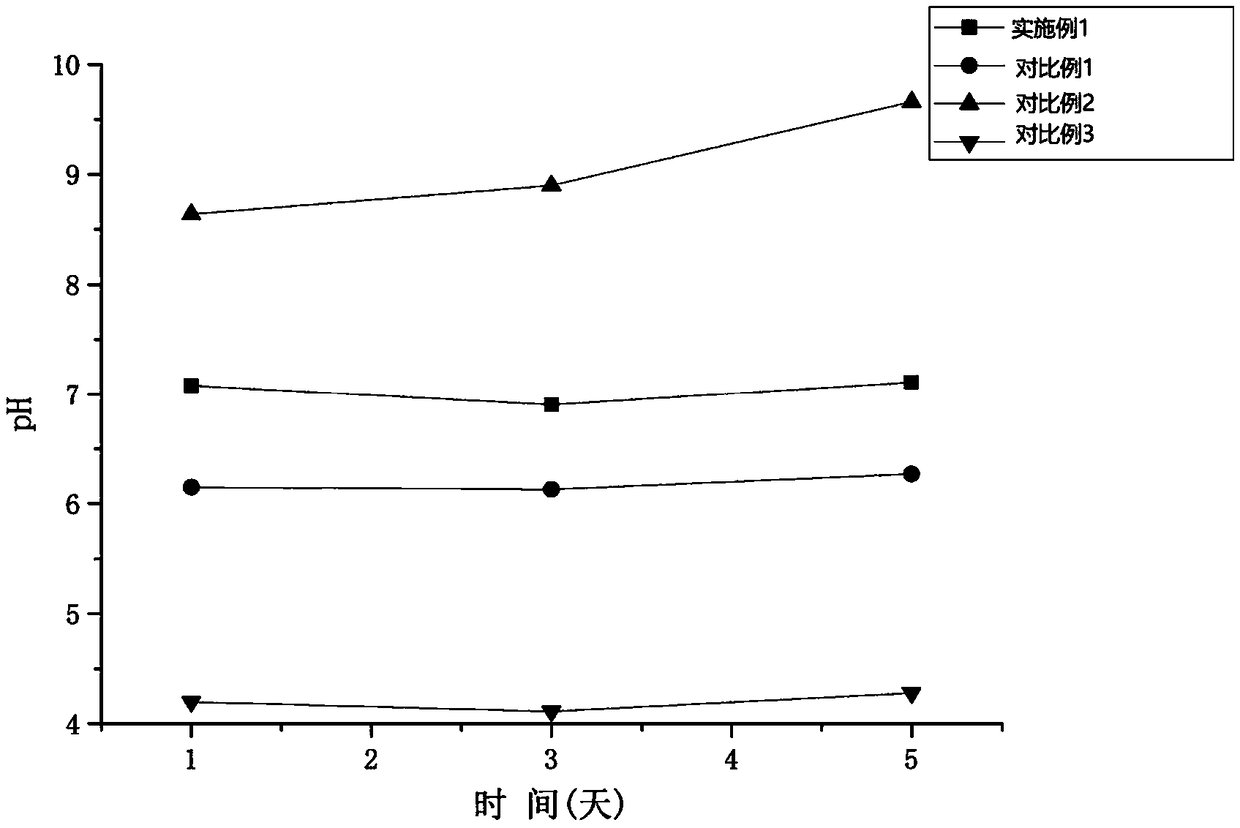

The invention discloses preparation and an application for a heavy metal chromium contaminated soil remediation material. Preparation for biological carbon particles comprises the following steps: 1) cleaning, drying and crushing agriculture waste to obtain a substance A; and 2) placing the substance A under a protective atmosphere to deoxidize and carbonize, and grinding and sieving carbonize products to obtain the biological carbon particles. Preparation for supported type nano zero-valent iron particles comprises the following steps: 1) preparing ferrite into a solution; 2) adding biological carbon particles into the solution, and uniformly mixing the biological carbon particles with the solution; and 3) dissolving a reducing agent into a solvent to obtain a mixture, adding the mixture into the system in the last step under the protective atmosphere, stirring the mixture, sufficiently reacting the mixture, separating nano zero-valent iron, washing, drying and grinding the nano zero-valent iron to obtain the supported type nano zero-valent iron particles. The invention further discloses the application of the supported type nano zero-valent iron particles to remediating chromium contaminated soil in situ. The in-situ remediation method for the heavy metal chromium contaminated soil comprises the following steps: adding the supported type nano zero-valent iron particles into soil, uniformly mixing the supported type nano zero-valent iron particles, adding deoxygenated water, and carrying out remediation. The remediation material prepared by the preparation disclosed by the invention is high in efficiency of remediating the chromium contaminated soil, and capable of improving the soil structure and improving the soil fertility.

Owner:师大清远环境修复科技有限公司

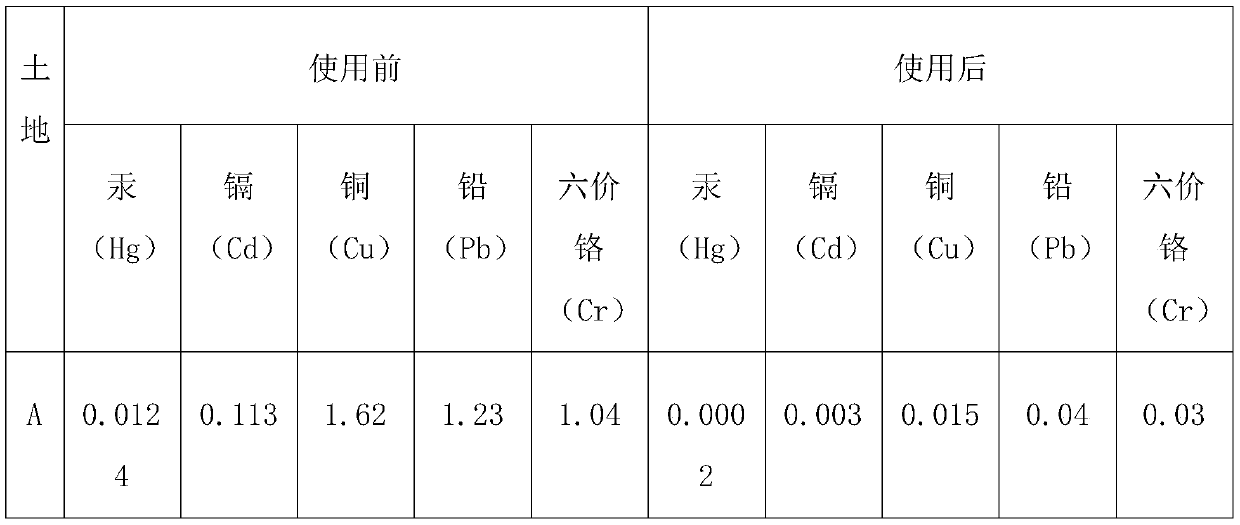

Passivator for repairing mercury polluted soil, mercury polluted soil repairing method and application

InactiveCN106281332AReduce contentAvoid failureContaminated soil reclamationOrganic fertilisersSulfur containingPollution

The invention provides a passivator for repairing mercury polluted soil. The passivator is prepared from a sulfur-containing reagent and an iron-containing reagent which are stored separately in a mass ratio of 1:5-5:1, wherein the sulfur-containing reagent is one or more of sulfur, sulfide, hydrosulfide, polysulfide and thiosulfate, and the iron-containing reagent is one or more of zero-valent iron, ferrous sulfate and hydrate thereof, ammonium ferrous sulfate and hydrate thereof, ferric sulfate, ferrous chloride and hydrate thereof, ferric chloride and hydrate thereof, polyferric chloride, poly ferrous sulfate, ferroferric oxide and ferric oxide. The sulfur-containing reagent and the iron-containing reagent in the passivator for repairing mercury polluted soil are stored separately, so that invalidation of effective ingredients of mercury in soil caused by reactions generated by mixing can be avoided. The passivator is wide in raw material source and low in cost. The repairing method is simple and feasible, is not sensitive to the soil type, has a remarkable repairing effect for various forms of mercury, does not have secondary pollution, and can be used for repairing cadmium, lead, zinc, copper or nickel heavy metal polluted soil.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

Passivating agent used for arsenic polluted soil restoration, arsenic polluted soil restoration method, and application of passivating agent

InactiveCN106336869AReduce dosageLow implementation costContaminated soil reclamationOrganic fertilisersRestoration methodPollution

The invention provides a passivating agent used for arsenic polluted soil restoration. The passivating agent comprises calcium oxide, an iron-containing reagent and calcium sulfate / calcium sulfate hydrate which are separately stored, and also comprises general purpose portland cement, calcium oxide accounts for 0.5-5% of the mass of arsenic polluted soil to be restored, the iron-containing reagent accounts for 0.5-5% of the mass of the arsenic polluted soil to be restored, the calcium sulfate / calcium sulfate hydrate accounts for 0.5-5% of the mass of the arsenic polluted soil to be restored, and the general purpose portland cement accounts for 1-10% of the mass of the arsenic polluted soil to be restored. Reagent raw materials adopted by the passivating agent used for arsenic polluted soil restoration have wide sources and low cost, the calcium sulfate / calcium sulfate hydrate and the iron-containing reagent have synergism, and addition of the calcium sulfate / calcium sulfate hydrate substantially reduces the use amount of the iron-containing reagent and reduces the engineering enforcing cost. An arsenic polluted soil restoration method provided by the invention is simple, is easy to implement, is insensitive to the type of soil, can be used for most of arsenic polluted soils, and has the advantages of wide application range, high arsenic polluted soil restoration efficiency, obvious restoration effect and no secondary pollution.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

Touch panel and repair method thereof

ActiveCN101984391AImprove yieldSimple fixInput/output processes for data processingComputer scienceTouch panel

The invention discloses a touch panel and a repair method thereof. The touch panel comprises a substrate, a plurality of first sensing universal serial buses, a plurality of second sensing universal serial buses and a plurality of conductive repair pattern layers, wherein the first sensing universal serial buses are configured on the substrate, extend in the first direction, and comprise a plurality of first sensing pads and a plurality of first bridging lines; each first bridging line is used for connecting every two adjacent first sensing pads in series; the second sensing universal serial buses are configured on the substrate, extend in the second direction, and comprise a plurality of second sensing pads and a plurality of second bridging lines; each second bridging line is used for connecting every two adjacent second sensing pads in series; the first direction is different from the second direction; the first sensing universal serial buses are electrically insulated from the second sensing universal serial buses; the conductive repair pattern layers are positioned close to the junctures of the first and second universal serial buses; and the conductive repair pattern layers are electrically floated, and can connect every two adjacent sensing pads after the repair movement finishes.

Owner:AU OPTRONICS CORP

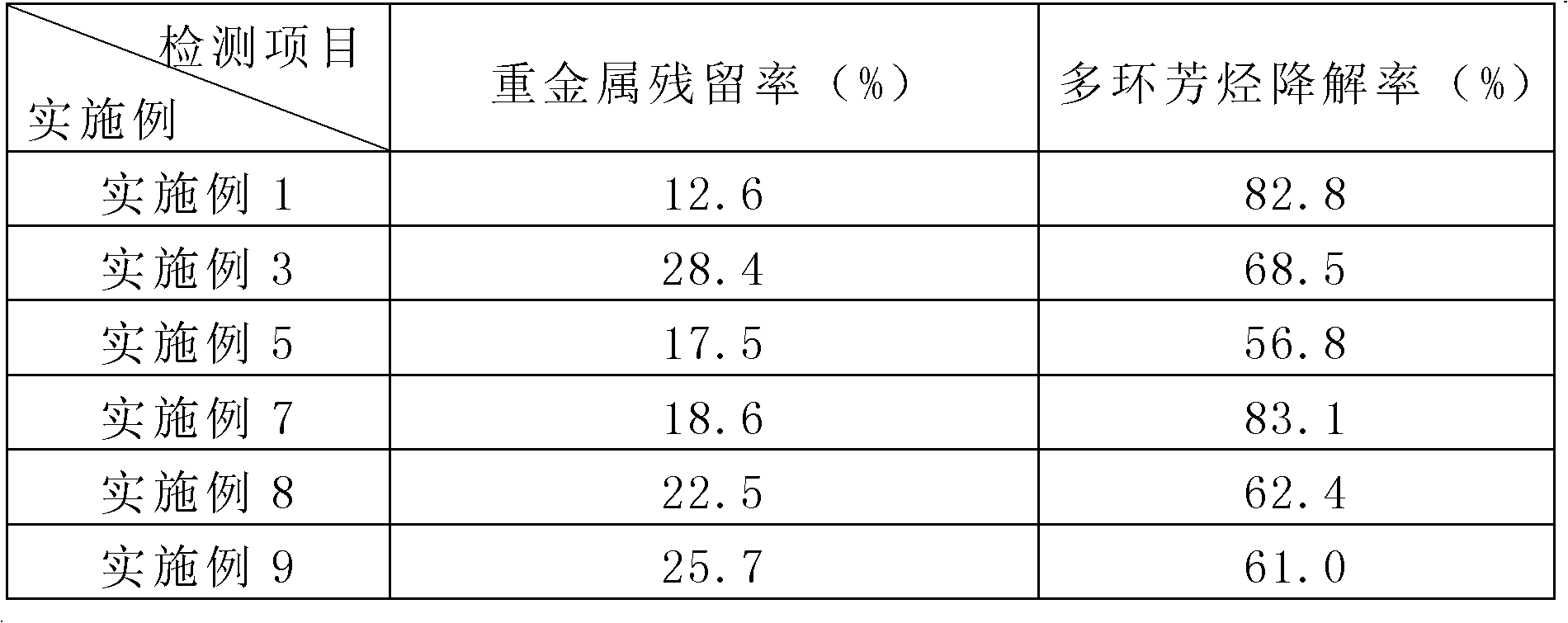

New method for combined remediation of compound contaminated soil

InactiveCN102319729ASimple fixGood repair effectContaminated soil reclamationContaminated soilsHumic acid

The invention relates to a new method for combined remediation of compound contaminated soil, which belongs to the technical field of regeneration of the contaminated soil. The method comprises the following steps: adding humic acid and activated sludge into the compound contaminated soil, adding water, then regulating the pH value to 6.0-8.5, controlling the culture temperature at 15 DEG C-40 DEG C, and performing remediation for 1-6 days so as to get the soil subjected to remediation. The method has the advantages that the used raw materials are easy to get, the production process is simpleand easy to operate, the remediation method is simple, the remediation effect on the compound contaminated soil is better, the residual rate of heavy metals in the soil and the residual rate of polycyclic aromatic hydrocarbons are lower after the remediation, and the degradation effect is obvious.

Owner:杭州韦尔茂通环境技术有限公司

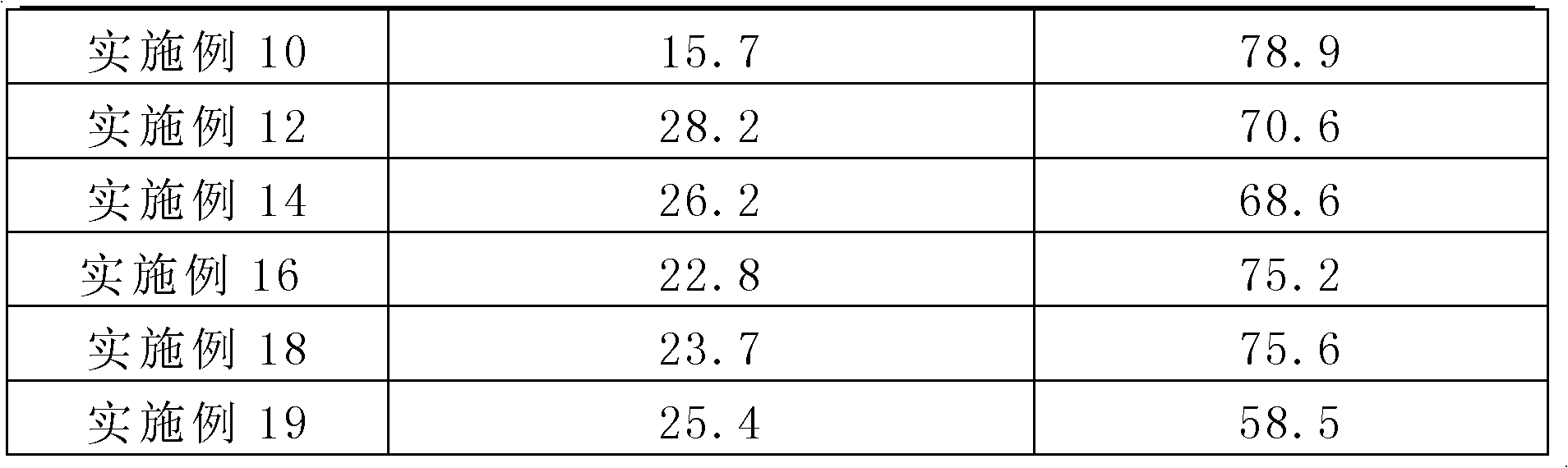

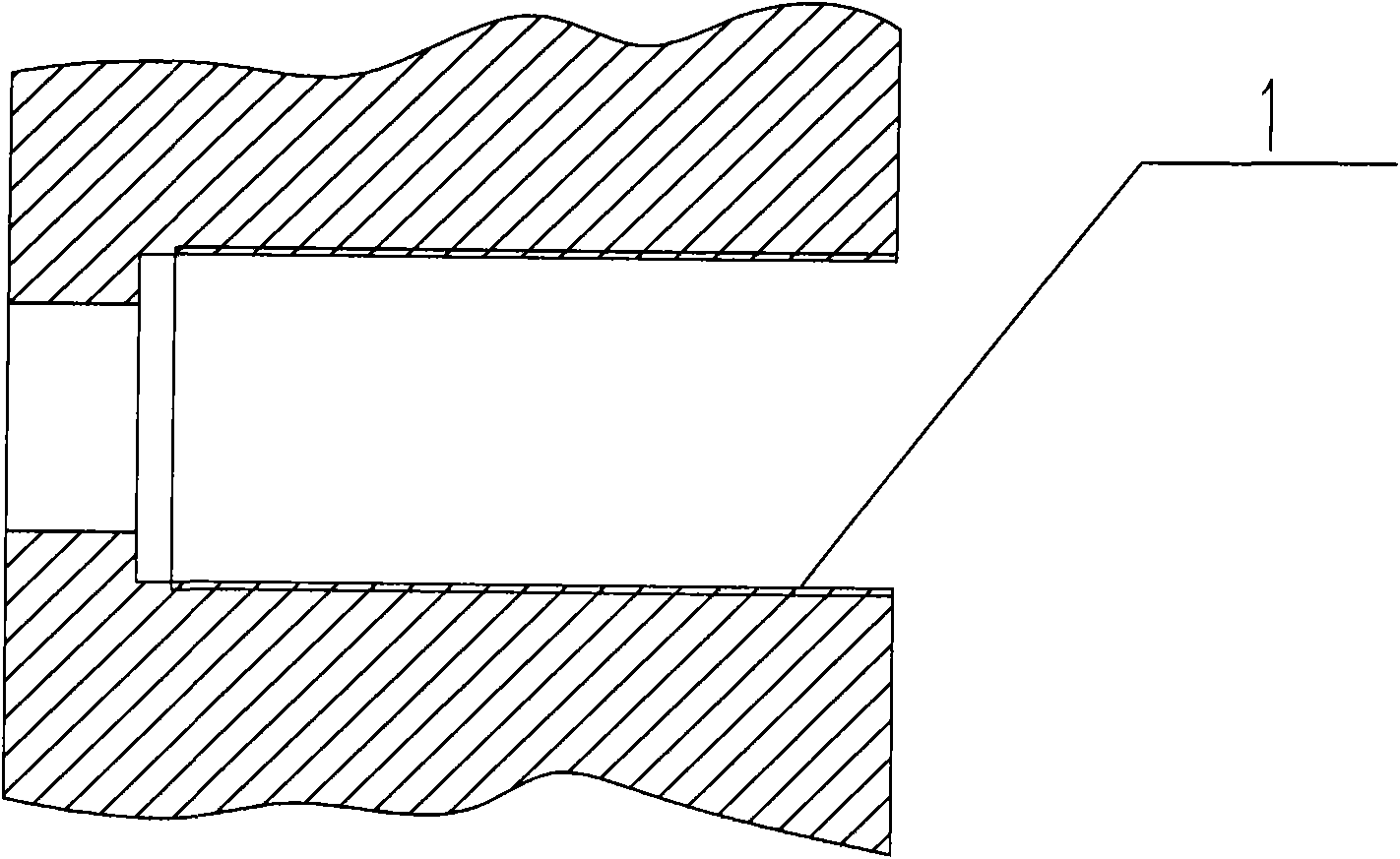

Array substrate of liquid crystal display device and repair method thereof

InactiveUS20110194041A1Avoid scrappingSimple fixSolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayEngineering

A repair method for an array substrate of a liquid crystal display device includes, providing an array substrate for a liquid crystal display device, detecting a line defect of a signal transmitting wire and locating the line defect, performing a removal process to remove a shielding layer covering two ends of the line defect and the shielding layer extending to a common line adjacent to the line defect, performing a deposition process to deposit a connecting metal layer the region where the shielding layer is removed, and performing a cutting process to cut outer ends of the common line adjacent to the line defect to form a common line section. The signal transmitting wire forms an electrical circuit with the common line section.

Owner:CENTURY DISPLAY (SHENZHEN) CO LTD

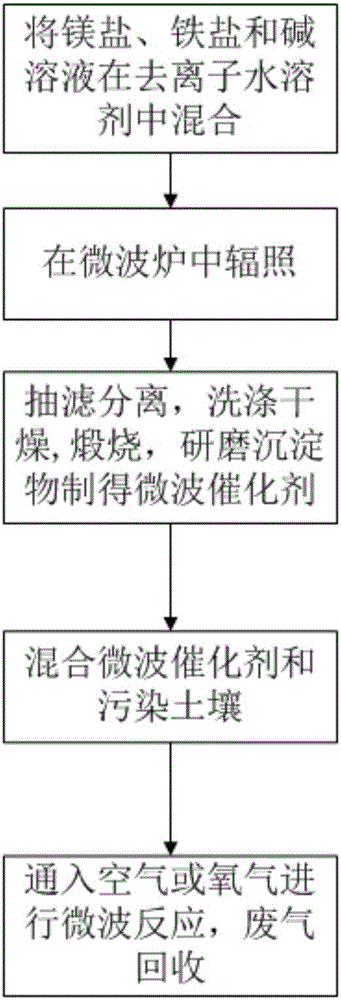

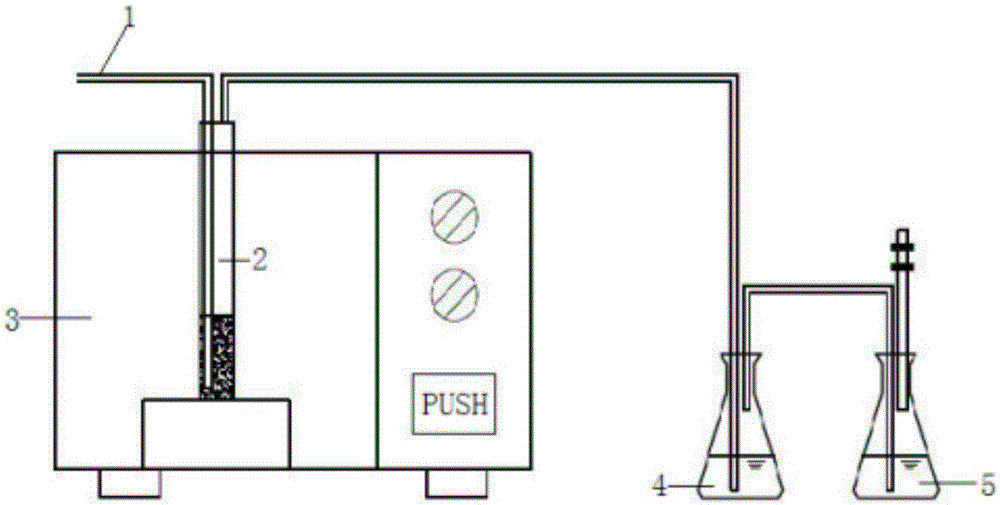

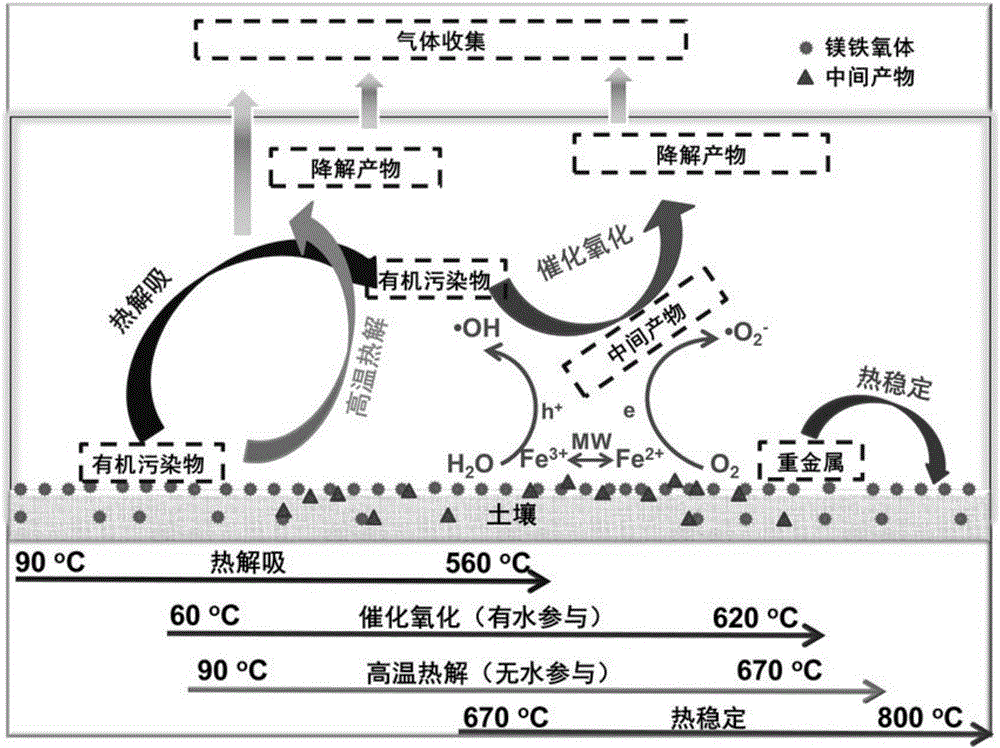

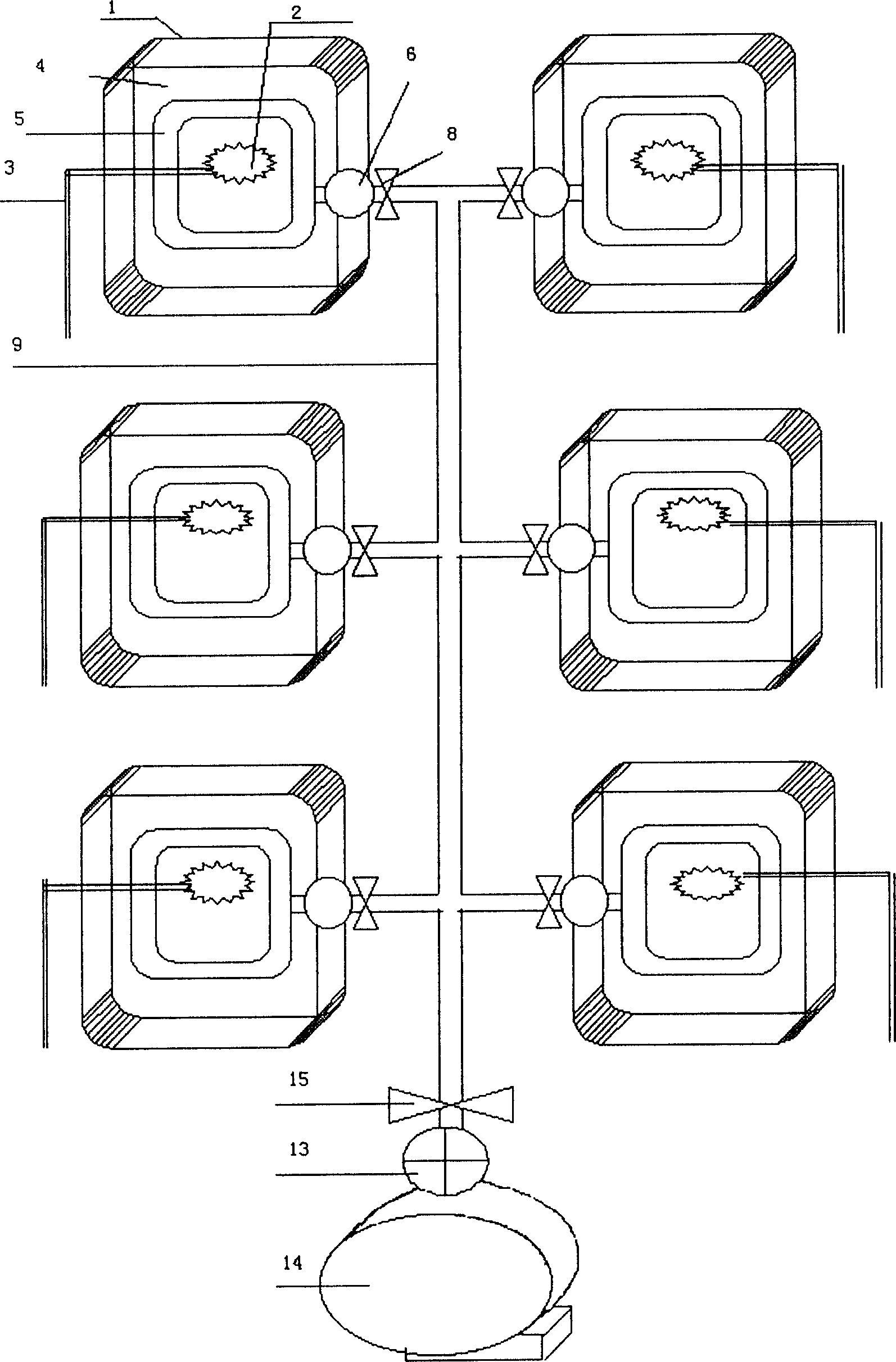

Microwave catalytic remediation method for organic matter-heavy metal compound contaminated soil

The invention belongs to the technical field relevant to soil remediation and particularly relates to a microwave catalytic remediation method for organic matter-heavy metal compound contaminated soil. The microwave catalytic remediation method for the organic matter-heavy metal compound contaminated soil comprises the steps that magnesium salt, ferric salt and aqueous alkali are added into deionized water and then mixed and stirred; turbid liquid is irradiated in a microwave oven; suction filtration is conducted on the turbid liquid after a reaction so that sediment can be separated out, and the sediment is washed and dried; a microwave catalyst is obtained through cooling and grinding after calcination; the microwave catalyst and the contaminated soil are mixed; the mixture is placed in a microwave reactor, and oxygen or air is led into the microwave reactor for a microwave reaction; and gas generated during the reaction is collected at the same time, and thus required remediation of the contaminated soil is completed. By the adoption of the microwave catalytic remediation method for the organic matter-heavy metal compound contaminated soil, the contaminated soil can be remediated in the way that environment protection is facilitated, quality control is convenient and the efficiency is high; and the microwave catalyst is used for adsorbing heavy metal ions in the contaminated soil and degrading organic matter in the contaminated soil, and meanwhile secondary pollution is avoided by collecting waste gas.

Owner:HUAZHONG UNIV OF SCI & TECH +2

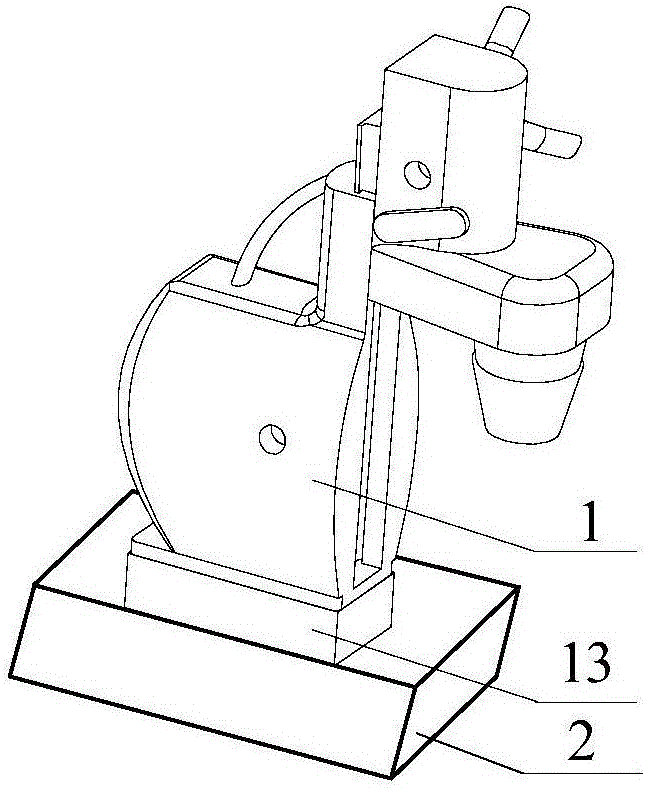

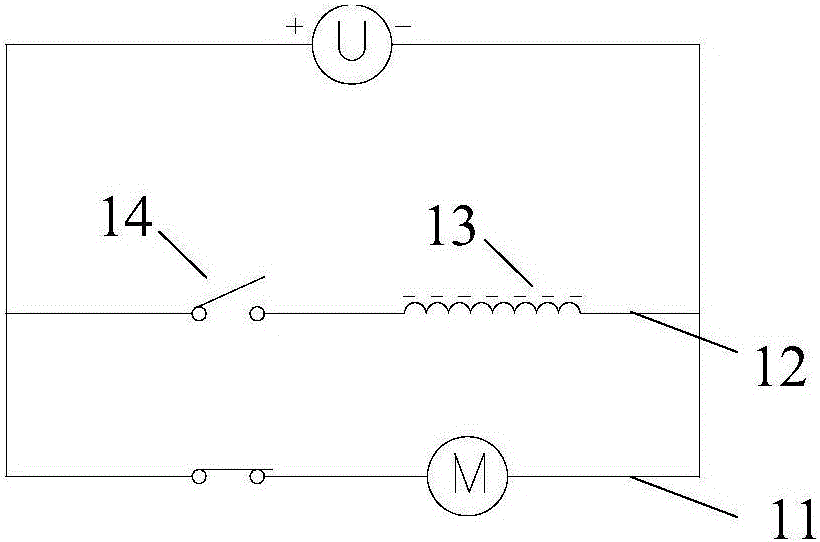

Threaded hole repairing method and device

The invention provides a threaded hole repairing method and device. The device comprises a demagnetizing magnetic drill and a position adjuster, wherein the position adjuster is arranged on a bogie and can move in the transverse direction and the longitudinal direction on a first plane; the first plane is parallel to the cross section of a threaded hole to be repaired in a tumbler axle box on the bogie; the demagnetizing magnetic drill is fixed on the position adjuster and can move along with movement of the position adjuster; a drill bit of the demagnetizing magnetic drill is positioned above the threaded hole to be repaired; the demagnetizing magnetic drill comprises a power supply access and a magnetizing access; the power supply access is used for providing power for the drill bit of the demagnetizing magnetic drill; the magnetizing access is used for magnetizing a magnet block of the demagnetizing magnetic drill; a demagnetizing switch is arranged in the magnetizing access; and when the threaded hole is repaired, the demagnetizing switch is in a switch-on state. The invention provides the threaded hole repairing method and device, the repairing method is simple, and the cost is relatively low.

Owner:CRRC TANGSHAN CO LTD

Repairing method for broken and defected bronze ware culture relic

ActiveCN105149862AFlexible adjustmentSimple fixWelding/cutting media/materialsWelding/soldering/cutting articlesLight energyEngineering

The invention belongs to the field of archaeology and particularly relates to a repairing method for a broken and defected bronze ware culture relic. The repairing method includes the following steps that firstly, treatment before repairing is conducted; secondly, a repairing model is established; thirdly, a packaging die is prepared; fourthly, welding powder is configured; fifthly, die assembling is conducted; sixthly, power is loaded; seventhly, repairing is conducted; eighthly, aftertreatment is conducted. According to the repairing method, due to an exothermic reaction of self-propagating powder, high-temperature metal liquid with basic components consistent with those of the bronze ware culture relic is obtained, the metal liquid is solidified to be in a specific shape in the packaging die and is firmly metallurgically bonded to a base body, and therefore the repairing of the broken and defected bronze ware culture relic is achieved. According to the repairing method for the broken and defected bronze ware culture relic, filler metal components can be flexibly adjusted according to basic components of bronze ware or special requirements, equipment of the repairing method is simple, energy such as electric energy and light energy does not need to be consumed in the repairing process, the repairing cost is low, the repairing method is suitable for repairing various forms of broken and defected bronze ware culture relics, universality is good, the repairing speed is high, efficiency is high, and field operation can be achieved.

Owner:WUHAN UNIV

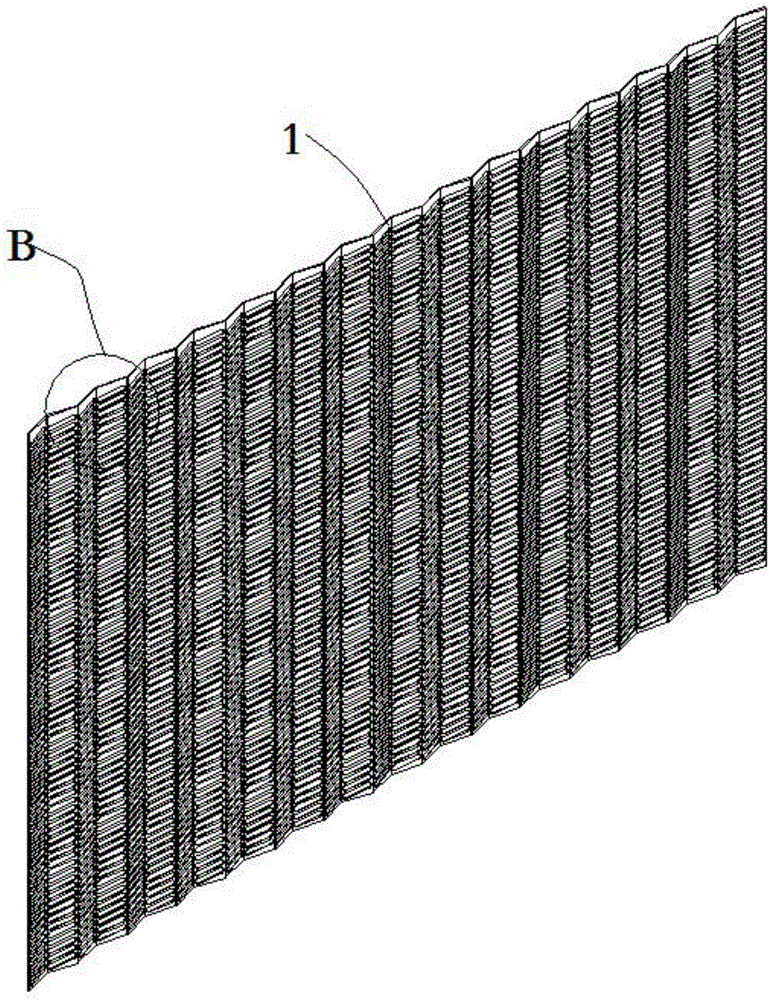

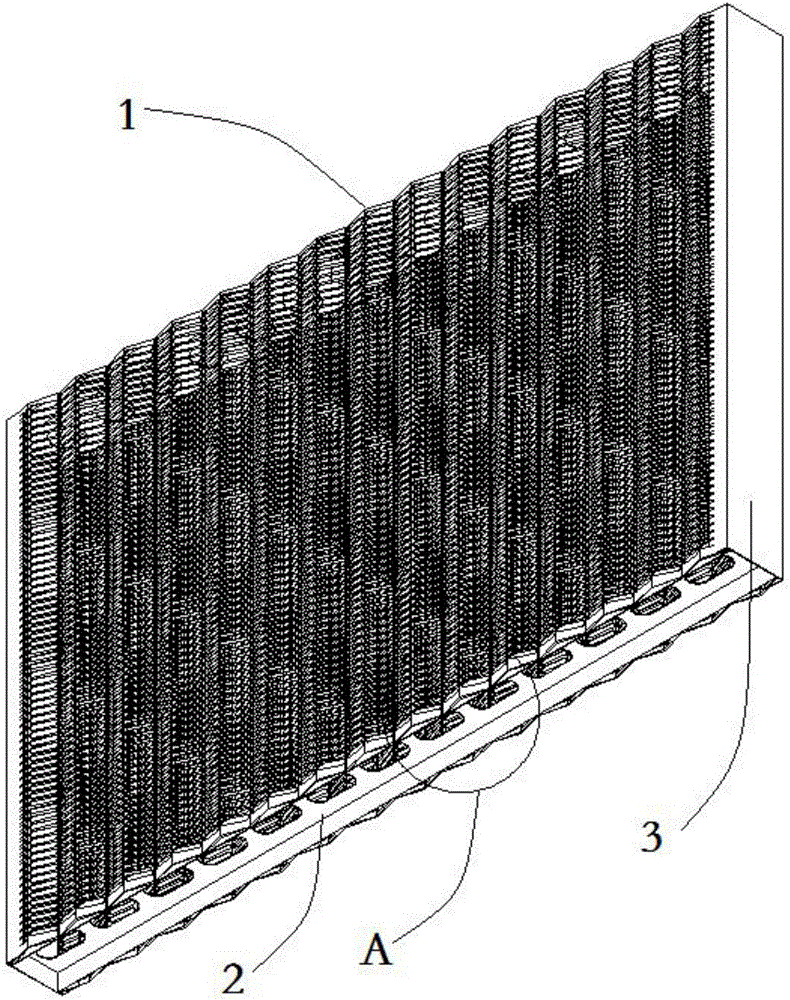

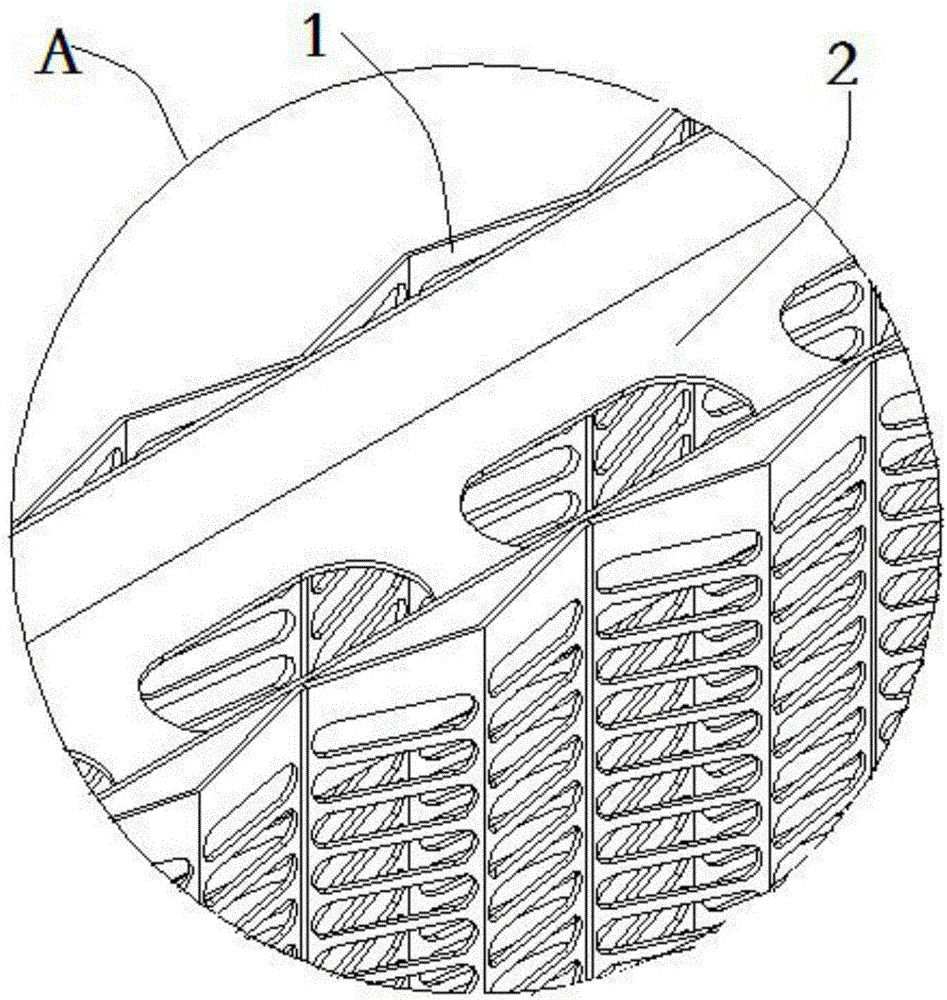

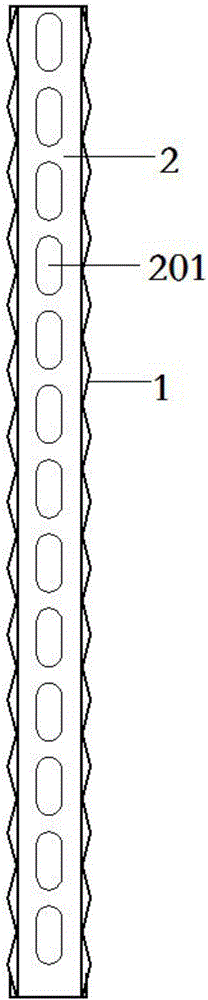

Soil remediation adsorption net and remediation method thereof

InactiveCN106111691ARepair pollutionPermanently removedContaminated soil reclamationFiberHazardous substance

The invention discloses a soil remediation adsorption net and a remediation method thereof. The soil remediation adsorption net comprises a net plate. The net plate is formed by pressing an adsorption material and is in a wave shape. The thickness of the net plate is 2-5 mm. Strip-shaped filter holes are evenly formed and distributed in the surface of the net plate. An inclination angle of 10-15 degrees is formed between each strip-shaped filter hole and a corresponding wavy folded edge of the net plate. The adsorption material is prepared from ion exchange fibers and attapulgite powder, wherein the weight ratio of the ion exchange fibers to the attapulgite powder is 2-4:1-1.5. The remediation method comprises the step that the adsorption net is embedded into the soil with the depth being 15-25 cm for 15-30 days. The adsorption net is prepared from the attapulgite powder and the exchange fibers and applied to government and remediation of soil pollution. The remediation method is simple and fast and suitable for industrial production. Harmful substances in the soil can be removed permanently through adsorption and exchange, the purpose of remedying soil pollution is achieved, the leaching concentration of the harmful substances in the soil is lowered, and the mobility and poisoning degree of heavy metal in the soil are reduced.

Owner:安徽金联地矿科技有限公司

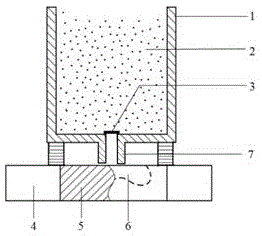

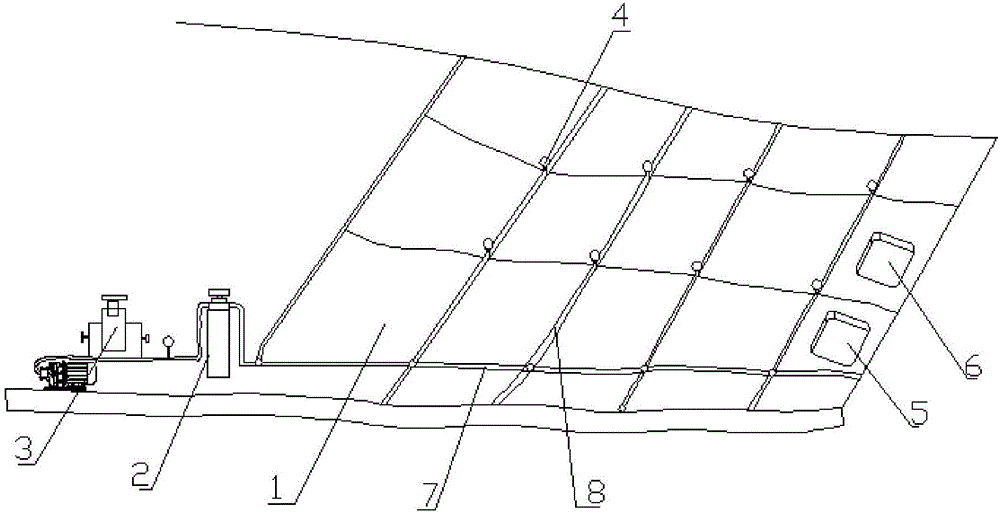

Biological restoring method for contaminative soil and equipment therefor

InactiveCN1569350ASimple process conditionsSimple fixContaminated soil reclamationRecovery methodPollution soil

The invention relates to a recovery technology for contaminated soil, which concretely is a recovery method and appliance for contaminated soil. The method puts in fertilizer according to the weight of the contaminated soil, in the material, C:N:P=80-120:9-11:1-2, 1-5% solid bacteria agent and 14-25% water, the pH value is adjusted to 6-8, they are put into the pile corroding pool after being blended. The device is canopy type structure, in which there has a pile corroding pool, on which there is the contaminated soil piles, there has a penetration resisting layer under the pool, there has a water pipe for assembling nozzle above the pool, in the pool there also has ventilation pipe distributed with ventilation apertures, which are connected to the fan; there lays with plastic cloth on the canopy. The invention is easy to be controlled, and it has no contamination.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

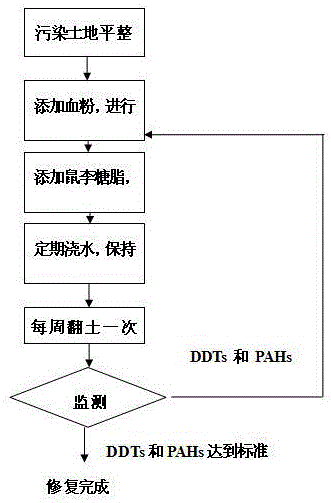

Method for restoring anofex-polycyclic aromatic hydrocarbon composite polluted soil by biological agent

InactiveCN105903759AHigh activityIncrease the number ofContaminated soil reclamationPolycyclic aromatic hydrocarbonBiological agent

The invention relates to a polluted soil restoring method, and concretely relates to a method for restoring anofex-polycyclic aromatic hydrocarbon composite polluted soil by a biological agent. The method utilizes the degradation effect of indigenous microorganisms on pollutants, and is a method for in situ restoration of anofex-polycyclic aromatic hydrocarbon composite polluted farmland soil by a biological surfactant rhamnolipid reinforced blood powder, the blood powder is added to stimulate the indigenous microorganisms in order to activate the activity of the indigenous microorganisms, and the biological surfactant rhamnolipid is used to realize a compatibilization effect on organic pollutants and enhance degradation of DDTs and PAHs in the soil in order to realize restoration of DDTs and PAHs pollution in the soil; and the blood powder is added to the DDTs-PAHs composite polluted soil according to a ratio of the blood powder to the polluted soil of 5g / 1000g, and the blood powder and the polluted soil are uniformly mixed. The method for in situ restoration of anofex-polycyclic aromatic hydrocarbon composite polluted farmland soil by the biological surfactant rhamnolipid reinforced blood powder has the characteristics of low cost, easy operation, large-area application, small environment risk and wide application prospect.

Owner:SHENYANG UNIV

House refuse burning fly ash curing stabilization gel material and repairing method using the same

InactiveCN106396444ASolve the most pressing problemsSave raw materialsSolid waste managementCement productionAdditive ingredientFly ash

The invention provides a house refuse burning fly ash curing stabilization gel material. The material is prepared from 55-85% by mass of mineral waste residues, 5-25% by mass of a clinker, 0-10% by mass of sodium chloride, 0-10% by mass of gypsum and 2-8% by mass of an alkaline exciting agent. The house refuse burning fly ash curing stabilization gel material is prepared from cheap and easily available raw materials through simple and easy processes, is insensitive to ingredients of house refuse burning fly ash, can be used for curing stabilization treatment on most of fly ash, has obvious curing effects, guarantees heavy metal long-term stability, effectively prevents fly ash-caused secondary pollution on the environment, and solves existing pressing issues of the waste incineration plant and fly ash-caused damage to environmental protection and human body health.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

Heavy-metal-polluted soil remediating method

InactiveCN106111689ASimple fixRemediation of soil heavy metal pollutionContaminated soil reclamationOrganic fertilisersIon exchangeIon

The invention discloses a heavy-metal-polluted soil remediating method. The remediating method includes the following steps that ethylene glycol and ethylene diamine are sequentially added into a certain quantity of polyvinyl alcohol fibers, and a reflux reaction is conducted in a stirred state to obtain an intermediate product; the intermediate product is washed with water and placed into a mixed solution of ethylene glycol, aminopyridine and chloroethane, stirring is conducted at the normal temperature to conduct a reaction, a product is washed with water, hydrochloric acid and water in sequence to be neutral after the reaction, and ion exchange fibers are obtained; and attapulgite powder is added into the ion exchange fibers according to the weight ratio of (2-4):(1-1.5), a uniform mixture is obtained, the uniform mixture is rolled to be formed or placed in a net bag and then buried in heavy-metal-polluted soil, and the uniform mixture is taken out of the soil after adsorption and exchange. The fibers used as the matrix are compounded with the attapulgite powder, the uniform mixture is applied to treating and remediating heavy-metal-polluted soil, and the remediating method is simple, rapid and suitable of industrial production.

Owner:安徽金联地矿科技有限公司

Insulation restoration method for generator rotor magnetic pole

ActiveCN102306988AImprove insulation performanceImprove the insulation levelApplying solid insulationRestoration methodMagnetic poles

The invention discloses an insulation restoration method for a generator rotor magnetic pole. The method comprises the following steps of: (1) disassembling a rotor magnetic pole coil, a core and insulators which are assembled together; (2) checking, sorting out and washing each disassembled part to clean up dirt on each part; (3) painting insulating paint on the coil and the insulators respectively; (4) sleeving a part of insulators on the core, painting glue on the insulators, assembling the coil on the core and sealing a seam between the coil and the core by using the glue; (5) arranging the other part of insulators on the coil, sealing gaps on the two end parts of the coil and painting the glue on the insulators; (6) arranging a pressing tool on the assembled magnetic pole for pre-pressing, and cleaning up residual glue on the magnetic pole; and (7) performing standing, and loosening and taking the pressing tool down after the glue painted on the magnetic pole is cured. By the method, the overall insulation level of the generator rotor magnetic pole is improved.

Owner:CHN ENERGY DADU RIVER REPAIR & INSTALLATION CO LTD

Remediation agent and remediation method for heavy metal contaminated soil

InactiveCN111362746ALow toxicityPromote growthAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersSodium phosphatesOsmolyte

The invention relates to the technical field of soil remediation, in particular to a remediation agent and remediation method for heavy metal contaminated soil. The remediation agent for the heavy metal contaminated soil comprises 2-16 parts of humic acid, 5-10 parts of succinic acid, 5-20 parts of sawdust, 2-10 parts of bentonite, 10-20 parts of sodium polyacrylate, 5-10 parts of honeycomb briquette ash, 5-20 parts of seaweed residues, 2-10 parts of zeolite, 5-10 parts of nano hydrogel, 10-30 parts of charcoal, 10-20 parts of Fe-Mn binary oxide, 5-10 parts of sodium pyrophosphate and 2-10 parts of microorganism mixed bacteria. The remediation agent is good in repairing effect and low in cost. The remediation method for remediating the heavy metal contaminated soil through the remediationagent is simple, heavy metal in the soil can be efficiently solidified, and the water quality grade of the soil penetrating fluid is improved.

Owner:WEIFANG UNIV OF SCI & TECH

Restoration method for chromium-contaminated soil

InactiveCN105950160ARepair pollutionReduce contentCation exchanger materialsOrganic fertilisersFiberRestoration method

The invention discloses a restoration method for chromium-contaminated soil. The restoration method comprises the following steps: taking a proper amount of fibers, adding the fibers into organic alcohol, adding an amination agent, performing refluxing reaction under a stirring state, washing products with water, airing the products, then adding organic alcohol and a chloride-containing solvent, stirring at a room temperature, adding the amination agent for reaction, removing the solvent after reaction is finished, and sequentially washing products with water and hydrochloric acid until the products are neutral, thereby obtaining ion-exchange fibers; performing rolling molding on the ion-exchange fibers or feeding the ion-exchange fibers into a mesh bag, burying the ion-exchange fibers into the chromium-contaminated soil, and removing the ion-exchange fiber ion-exchange fibers from the soil after adsorbing and exchanging, thereby removing chromium-contaminated heavy metals in the soil. The restoration method is simple and rapid, and is applicable to industrial production; by virtue of adsorption and exchange, the heavy metals in the soil can permanently removed, so that the purpose of restoring the heavy metal pollution of the soil is achieved.

Owner:MAANSHAN ZHONGCHUANG ENVIRONMENTAL PROTECTION TECH CO LTD

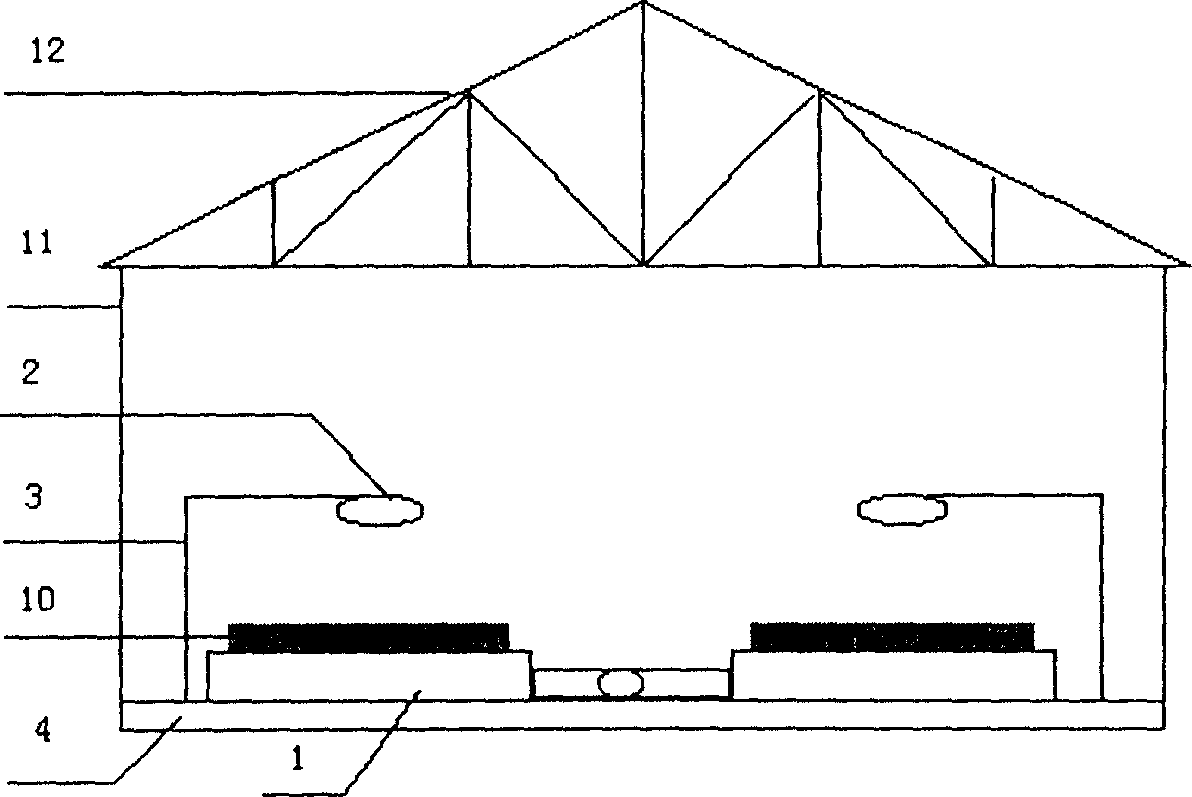

Soil remediation method

InactiveCN106670220AReduce acidity and alkalinitySimple structureContaminated soil reclamationAlkalinityWater storage

The invention discloses a soil remediation method. The soil remediation method comprises soil and water, wherein a soil remediation device is arranged on the soil; the soil remediation device comprises a water pumping device, a water sprinkling device, a clean water pool and a water storage pool, wherein the clean water pool is connected with the water pumping device; the water pumping device is connected with the water sprinkling device; the water pumping device is connected with the clean water pool and the water sprinkling device through a water pipeline; and soil remediation is carried out by virtue of water. The soil remediation method disclosed by the invention is simple, convenient to operate, capable of weakening the acidity and alkalinity of the soil, improving the structure of the soil and bringing many nutrients to the soil, low in soil improvement cost, environment-friendly, economic and reasonable, and pollution-free in soil remediation; and the sustainable development of the soil is realized through many times of progressive improvement and remediation.

Owner:苏州千层茧农业科技有限公司

Touch panel and repairing method thereof

ActiveUS20160370900A1Good yieldSimple fixInput/output processes for data processingEngineeringTouch panel

A touch panel including a substrate, a plurality of first and second sensing series, and a plurality of conductive repairing pattern layers is provided. The first sensing series are disposed on the substrate and extended along a first direction. Each of the first sensing series includes a plurality of first sensing pads and first bridge lines, and the first bridge lines serially connect two adjacent first sensing pads. The second sensing series are disposed on the substrate and extended along a second direction. Each of the second sensing series includes a plurality of second sensing pads and second bridge lines, and the second bridge lines serially connect two adjacent second sensing pads. Each conductive repairing pattern layer electrically floating locates around the crossover region of the first and second sensing series. Two adjacent sensing pads are connected by the conductive repairing pattern layer after a repair procedure is finished.

Owner:AU OPTRONICS CORP

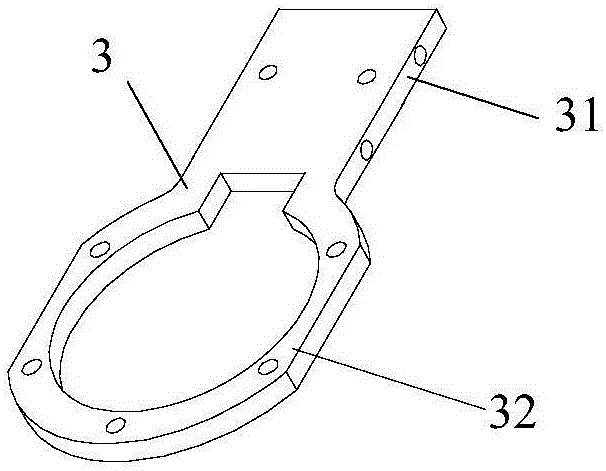

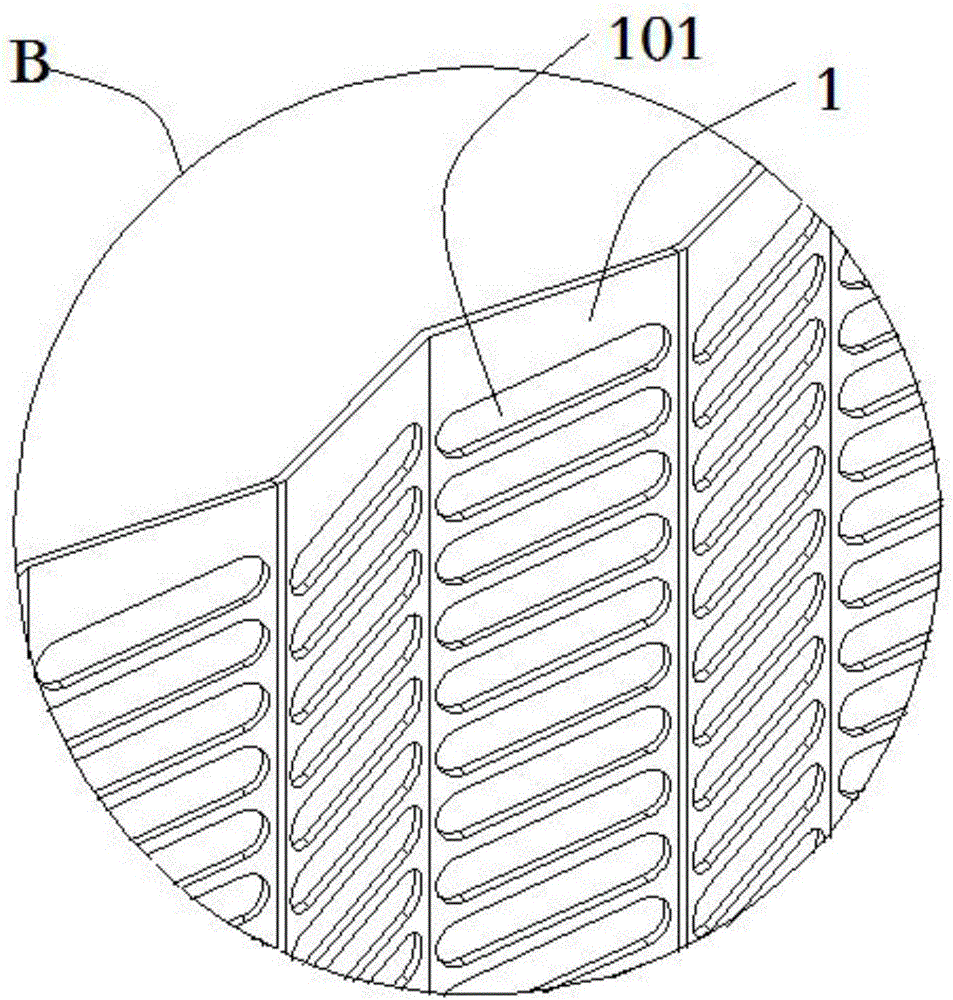

Framework device and remediation method applicable to soil remediation

InactiveCN105880269ARepair pollutionEasy to polluteContaminated soil reclamationSoil remediationEngineering

The invention discloses a framework device applicable to soil remediation. The framework device comprises immersion mesh plates, a main beam and side beams, wherein filter holes are uniformly formed in the surfaces of the immersion mesh plates, and the main beam and the side beams are U-shaped trough plates; through-flow holes are formed in the main beam side by side along the axial direction, one end surface of the main beam is fixed on one surface of one immersion mesh plate side by side, and another immersion mesh plate is fixed on another end surface of the main beam; and two side surfaces of the main beam are blocked through the side beams. The invention further discloses a remediation method applicable to the soil remediation. The framework device is taken as a movable matrix, is filled with an attapulgite adsorption material and is applied to soil control and remediation. The remediation method is simple and rapid and applicable to industrial production; and by virtue of adsorption and exchange, the purpose of remediation of soil pollution is achieved, and the leaching concentration, mobility and toxicity degree of pollutants in soil are decreased.

Owner:安徽金联地矿科技有限公司

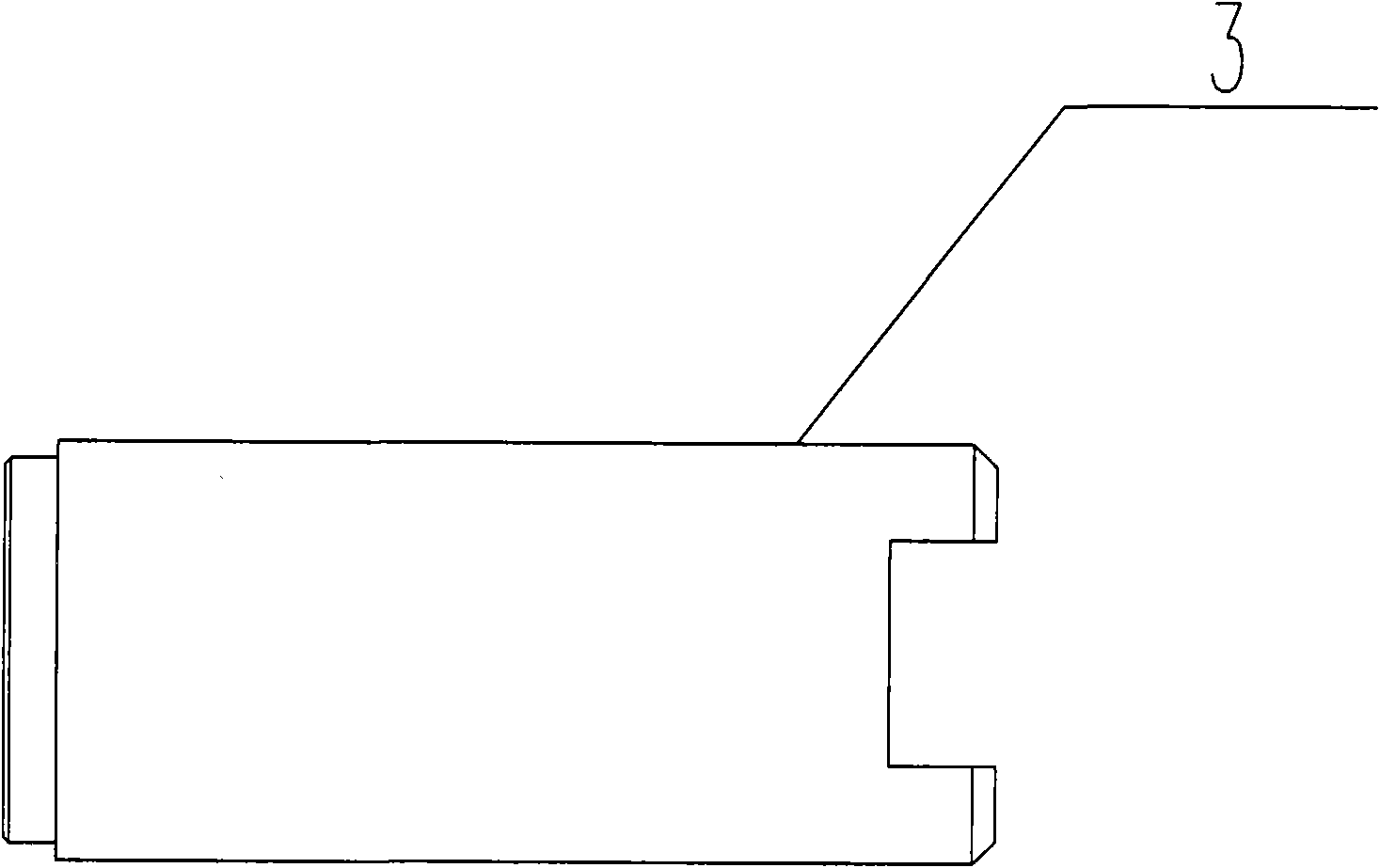

Repairing method for leakage of installation screw hole on installation surface of integration box

The invention relates to the field of mechanical parts repair processes, in particular to a repairing method for leakage of an installation screw hole on the installation surface of an integration box. The repairing method comprises the following steps of: a. reaming the installation screw hole having leakage problem to a screw thread hole; b. turning a matched red copper gasket; c. cleaning the screw thread hole, and placing the red copper gasket to the bottom of the screw hole; d. turning a matched screw sleeve; e. uniformly coating screw thread locking agent on the outside of the screw sleeve and screwing the screw sleeve to the screw thread hole; f. milling the outer end of the screw sleeve to be in parallel with the installation surface of the integration box after the screw thread locking agent is cured; and g. drilling a new installation screw hole on the screw sleeve. The repairing method is simple, practical and convenient, has good effect for the leakage problem of the installation screw hole caused by shrinkage cavity and porousness, avoids scrapping of parts, prolongs the service life of the parts, and greatly saves production cost.

Owner:CRRC QISHUYAN CO LTD

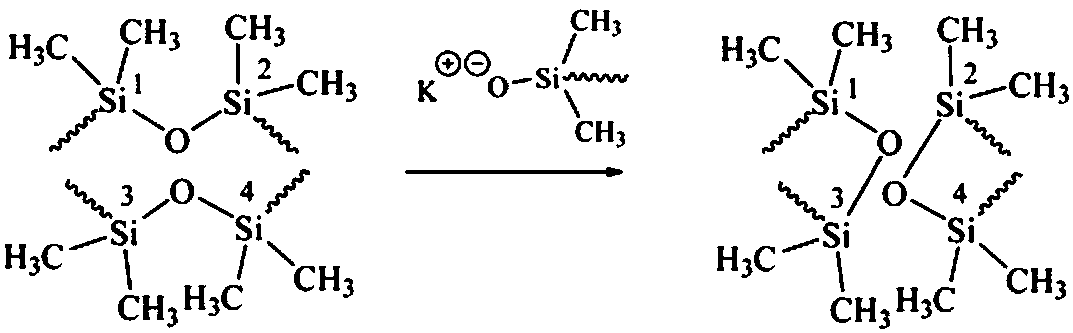

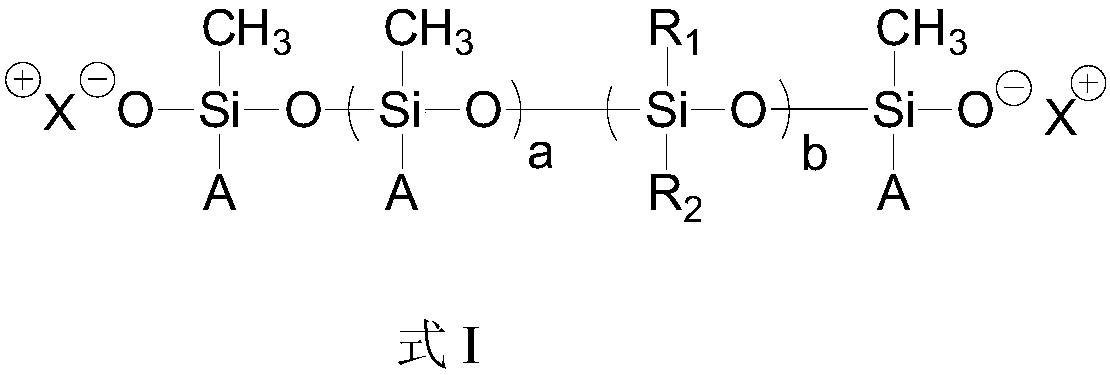

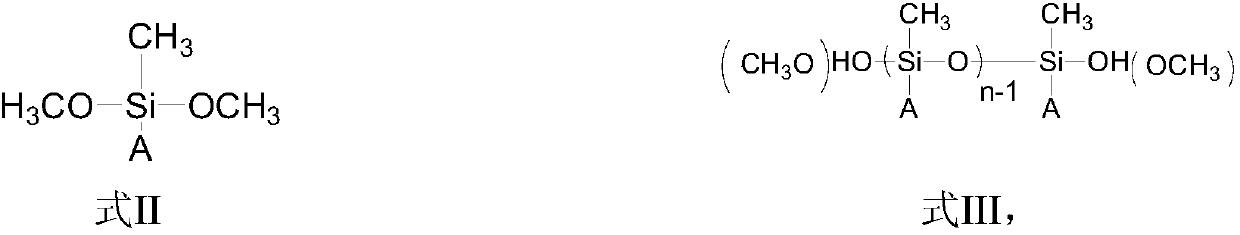

Silanol salt-terminated organo-silicon polyamine curing agent and self-repairing epoxy resin produced therewith

The invention belongs to the technical field of epoxy resin curing agent, and discloses a silanol salt-terminated organo-silicon polyamine curing agent and thermally reversible crosslinking epoxy resin produced therewith. The curing agent is represented as the structure formula (I), wherein polysiloxane terminated with silanol salt serves as a main chain, and a part of or the whole siloxane chainsegment contains an amido functional group. A is aliphatic amino group, R1 and R2 are alkyl group or aryl group, and X is alkali metal salt or ammonium salt; in the structure of the curing agent, theamino group can be subjected to a curing crosslinking reaction with the epoxy resin; and under catalysis with the silanol salt, the polysiloxane chain segment is subjected to a balanced rearrangementreaction, so that an epoxy resin cured material has self-repairing function.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Method for repairing propeller blades of ship

The invention discloses a method for repairing propeller blades of a ship, and belongs to the field of maintenance and repair of main parts used on ships. For a worn blade, the worn part of the guideedge of the blade can be subjected to surfacing through gas welding, and the texture of a used welding wire material is required to be the same as the texture of the propeller, and then the surface ofthe surfacing position is polished. For a defective blade caused by being collided with a hard object, a slightly larger piece of casting material having the same texture as that of the propeller canbe cast in advance according to the shape of the defective part, then match working is conducted through a manual method, a suitable weld chamfer needs to be machined at the weld joint, and then manually welded by using oxygen-acetylene; and finally grinding and trimming are conducted so that the use efficiency of the propeller can be recovered. At the same time, the repairing method is simple and practical, and the repaired blade bodies have the same service life as original blade bodies.

Owner:南通如港船舶配套机械有限公司

Low pressure pouring closing method for concrete grouped cracks

InactiveCN110388087AReduce economic costsReliable sealing qualityBuilding repairsBridge engineeringRepair method

The invention relates to the technical field of bridge engineering, in particular to a low pressure pouring closing method for concrete grouped cracks. The method comprises the following steps: processing a proper template according to a range of grouped cracks on the surface of a to-be-repaired concrete structure; cleaning the cracks; fixing the template to the surfaces of the concrete grouped cracks; mounting a glue pouring nozzle to seal the cracks; injecting glue into the cracks through the glue pouring nozzle; after life-preserving curing, removing the template; and polishing the surfaceof the glue-injected concrete to finish construction. The crack repair method is simple and convenient to operate, can repair the concrete grouped cracks well, is low in repair cost and good in repaireffect, and has extremely huge promotional value.

Owner:CCCC SECOND HARBOR ENG +1

Threaded rod compressor broken main shaft burying shaft repairing method

The invention relates to a threaded rod compressor broken main shaft burying shaft repairing method. The method comprises the steps that one section of a broken main shaft is clamped and positioned bythe P end of a positioning tool, then a connecting shaft and the positioning tool are clamped and positioned to push the Q end, so that the matching of the connecting shaft and the broken main shaftinstalled and clamped at the P end is completed; and the broken shaft and the connecting shaft joint surface are connected together by spot welding, namely, spot welding is carried out at a first spotwelding position, and when spot welding at the first spot welding position is completed, after the spot welding position is cooled to room temperature, the positioning tool at the Q end is loosened,after a positioning table Q end is pushed to an appropriate position, the other section of the broken main shaft is clamped and positioned, and then the positioning table Q end is pushed and forms assembly with the connecting shaft in a matched mode. The threaded rod compressor broken main shaft burying shaft repairing method has the beneficial effects that the reuse of the broken main shaft is realized, the loss of discarded main shafts is reduced, the costs of enterprises are saved, the repairing method is easy, the operation is convenient, the method can be completed by general mechanical processing enterprises, and the repairing cost is low.

Owner:济南德盛压缩机设备有限公司

Restoring method for soil contaminated by organophosphorus, organochlorine and pyrethroid pesticides

InactiveCN106269846AImprove adsorption capacityReduce repair costsContaminated soil reclamationAgriculture cropsSoil surface

The invention relates to the technical field of crop straw application, in particular to a restoring method for soil contaminated by organophosphorus, organochlorine and pyrethroid pesticides. After a contaminated block is shallowly ploughed, wheat straw obtained by fermentation with inoculated radioactive soil bacillus LQC-99 is applied, the fermented products are applied to the contaminated block according to a proportion of 30-50kg per mu for even blending, the soil surface is covered with straw, restoring is completed in 8-10 days, and the straw covering the soil surface is removed. The restoring cost is low, the restoring method is simple, the restoring time is short, the degradation rate of the organophosphorus, organochlorine and pyrethroid pesticides is above 91.33%, and no secondary contamination is generated by restoring.

Owner:余敏敏

Saline alkali soil remediation agent and remediation method

InactiveCN111234837AGood water contentIncrease water contentAgriculture tools and machinesOrganic fertilisersAlkali soilBiochar

The invention relates to the technical field of soil remediation, in particular to a saline alkali soil remediation agent and a remediation method. The soil remediation agent comprises a component A and a component B, wherein the component A comprises the following components in parts by weight: 60-90 parts of desulfurized gypsum, 5-20 parts of sawdust, 2-10 parts of zeolite, 5-10 parts of honeycomb briquette ash, 50-100 parts of citric acid residues, 5-10 parts of river sand, 80-100 parts of diatomite, 5-20 parts of seaweed residues, 10-30 parts of charcoal, 60-80 parts of shrimp shells and 1-5 parts of polyaluminum ferric silicate. The component B is prepared from the following components in parts by weight: 10-50 parts of humic acid powder, 10-14 parts of trace element fertilizer and 2-10 parts of microorganism mixed bacteria liquid. According to the saline alkali soil remediation method, the saline alkali soil remediation agent is added into saline alkali soil for remediation, theremediation method is simple, comprehensive remediation of the saline alkali soil can be guaranteed, and the soil activity is improved.

Owner:WEIFANG UNIV OF SCI & TECH

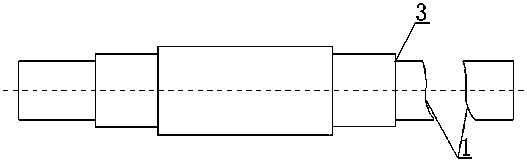

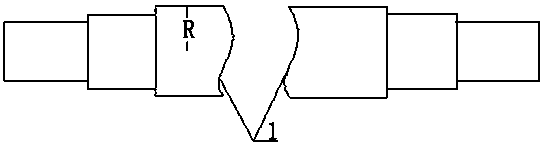

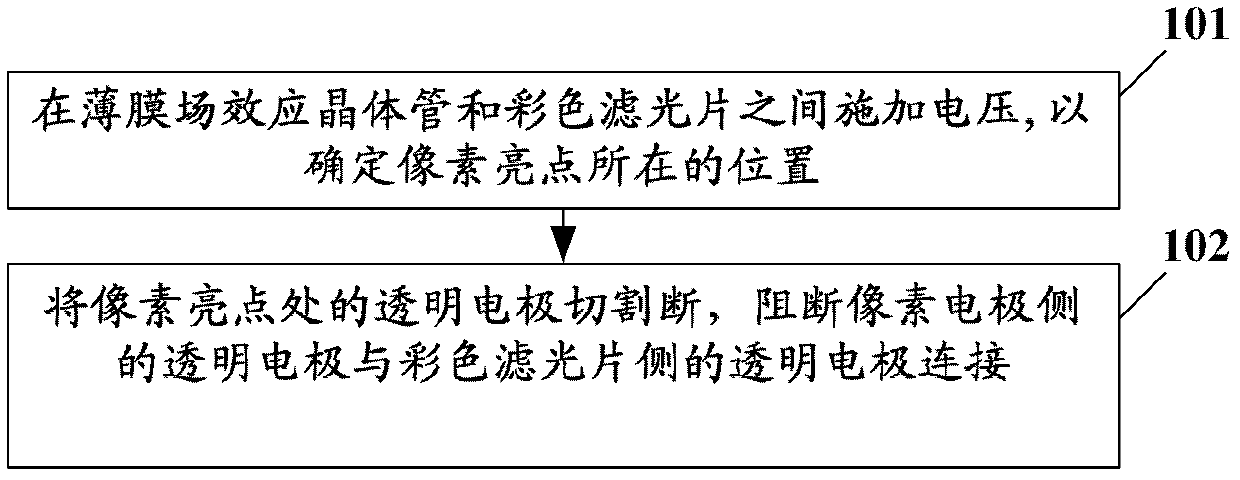

Method for repairing pixel bright spot

The invention provides a method for repairing a pixel bright spot. The method comprises the following steps of: cutting off a transparent electrode at the pixel bright spot; and cutting connection between a transparent electrode on a pixel electrode side and a transparent electrode on a color filter side. The method for repairing the pixel bright spot is simple; and the efficiency for repairing the pixel bright spot can be effectively improved.

Owner:BOE TECH GRP CO LTD +1

Nickel-contaminated soil repairing material as well as preparation method and application thereof

InactiveCN108620433ASmall particle sizeLarge specific surface areaContaminated soil reclamationOrganic fertilisersSoil remediationEnvironmental engineering

The invention belongs to the technical field of contaminated soil repairing, and particularly relates to a nickel-contaminated soil repairing material as well as a preparation method and application thereof. According to the invention, the nickel-contaminated soil repairing material is prepared by using a mineral material and a compounding material as a formula. The nickel-contaminated soil repairing material has a large specific surface area and high repairing efficiency to nickel-contaminated soil, can solidify nickel in the contaminated soil, improves an acidic environment of the contaminated soil, does not produce secondary pollution, and has advantages of low price, simple repairing method, short repairing time and easy promotion and use.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com