Touch panel and repair method thereof

A touch panel and repair wire technology, applied in the direction of instrument, electrical digital data processing, data processing input/output process, etc., can solve the problem that X sensing serial or Y sensing serial cannot operate normally, metal bridge wire Problems such as short circuit or open circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

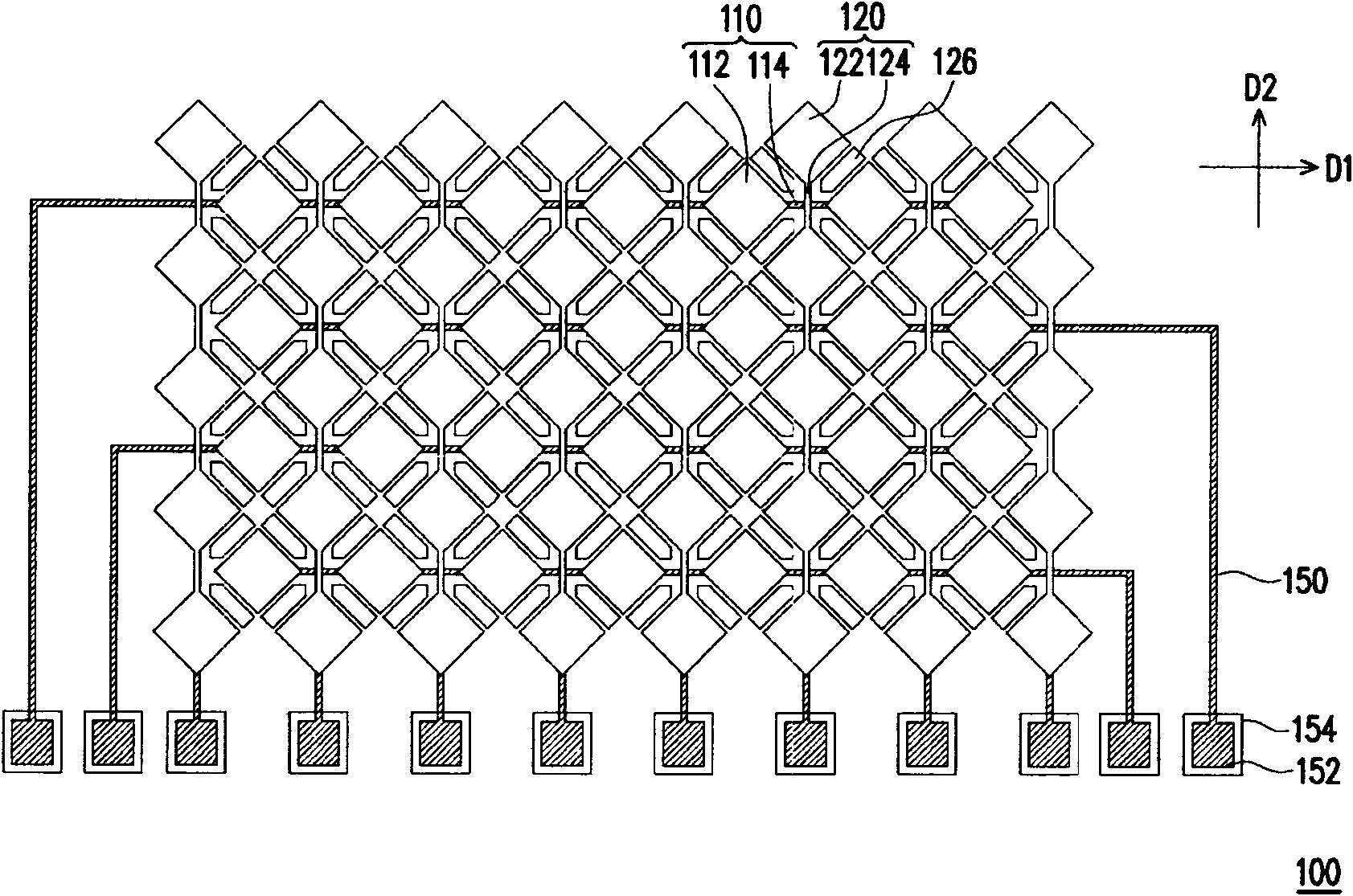

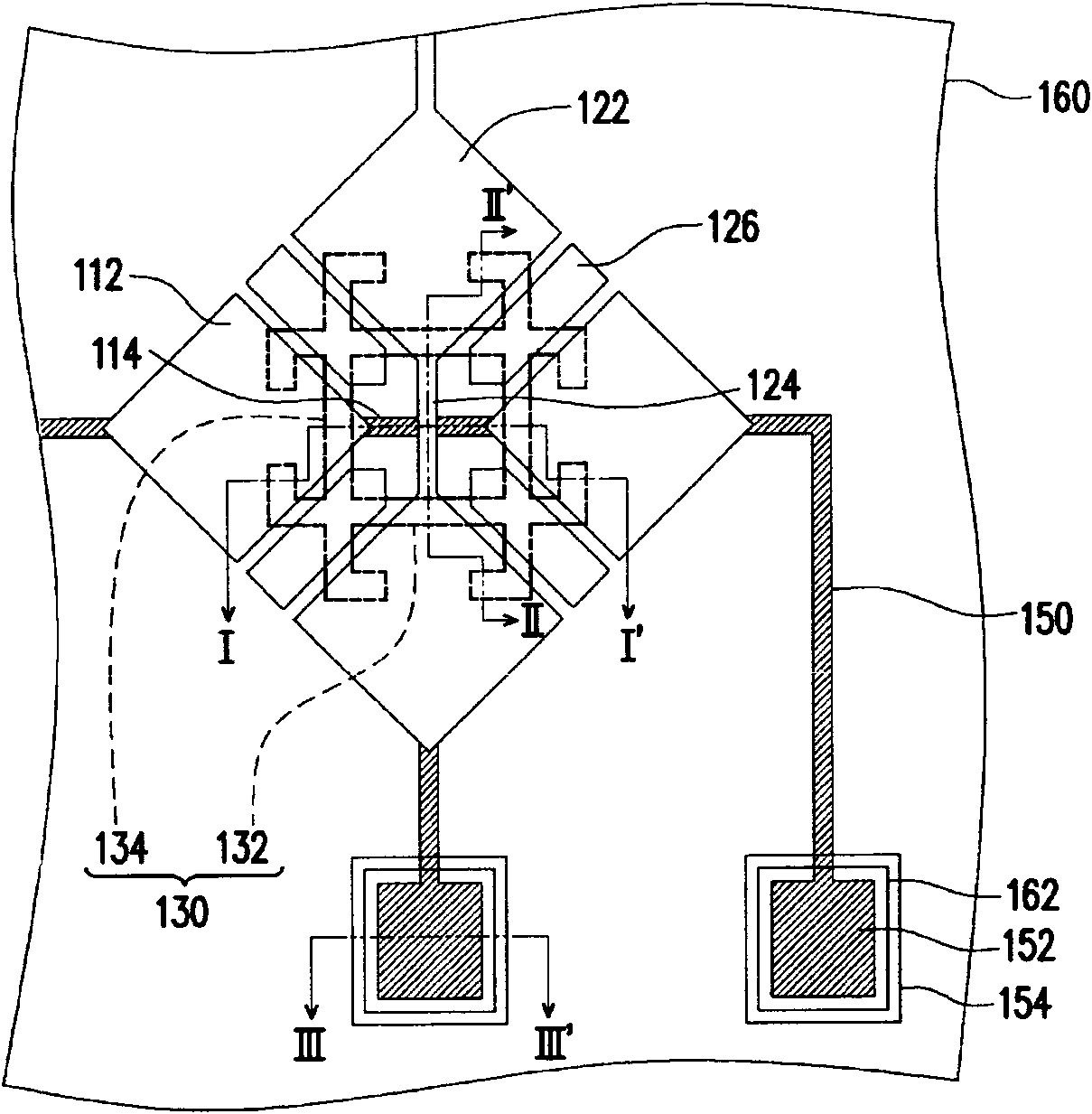

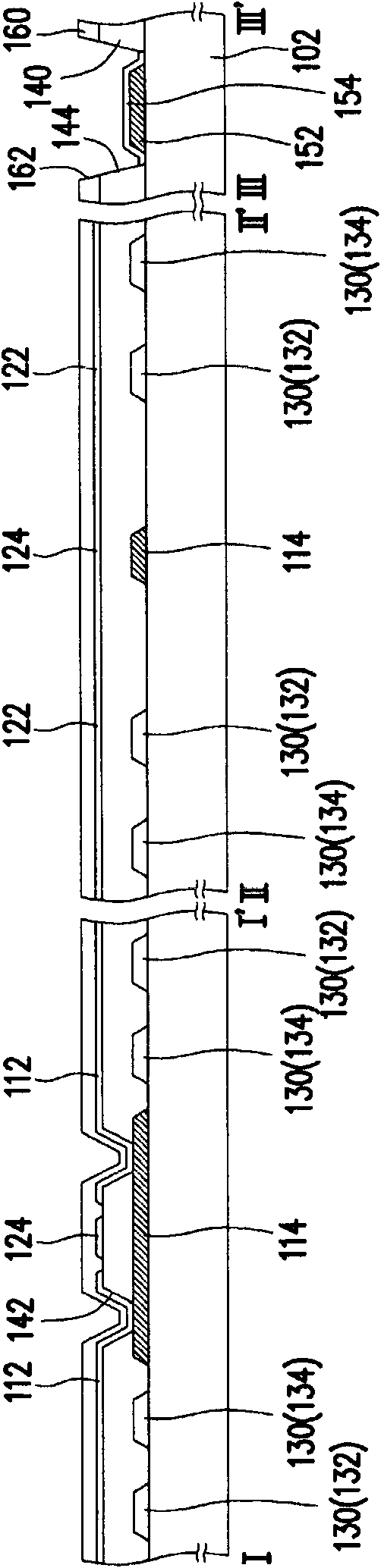

[0063] Figure 1A is a schematic top view of a touch panel according to a first embodiment of the present invention, Figure 1B for Figure 1A A partially enlarged schematic diagram of , and Figure 1C for along Figure 1B Schematic cross-sectional views of line I-I', line II-II' and line III-III'. Please also refer to Figure 1A to Figure 1C , in this embodiment, the touch panel 100 includes a substrate 102, a plurality of first sensing series 110, a plurality of second sensing series 120, a plurality of conductive repair pattern layers 130 and a first dielectric layer 140 . The substrate 102 is, for example, a glass substrate, a plastic substrate, a flexible substrate or other substrates. The substrate 102 can also be a printed circuit board or a display panel, such as a liquid crystal display panel, an organic display panel, an electrophoretic display panel, a plasma display panel, etc. It can be directly integrated on the display panel or in the display panel. Taking ...

no. 2 example

[0083] Figure 6A It is a schematic top view of a touch panel according to a second embodiment of the present invention, Figure 6B for Figure 6A The partially enlarged schematic diagram of , and Figure 6C for along Figure 6B Schematic cross-sectional views of line I-I', line II-II' and line III-III'. Please also refer to Figure 6A to Figure 6C , in this embodiment, the touch panel 100 includes a substrate 102, a plurality of first sensing series 110, a plurality of second sensing series 120, a plurality of conductive repair pattern layers 130, a first dielectric layer 140 , the second dielectric layer 160 and a plurality of peripheral connection lines 150 and a plurality of peripheral connection pads 152 . In this embodiment, the first dielectric layer 140 is, for example, disposed on the substrate 102 and has a plurality of vias 142 .

[0084] In this embodiment, the first sensing series 110 is disposed on the substrate 102 and extends along a first direction D1, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com