Soil remediation adsorption net and remediation method thereof

A technology of soil remediation and adsorption net, applied in the field of attapulgite materials, can solve the problems of slow adsorption speed, wide application limitation, low adsorption capacity, etc., achieve the effect of reducing leaching concentration, simple repair method, and repair soil pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

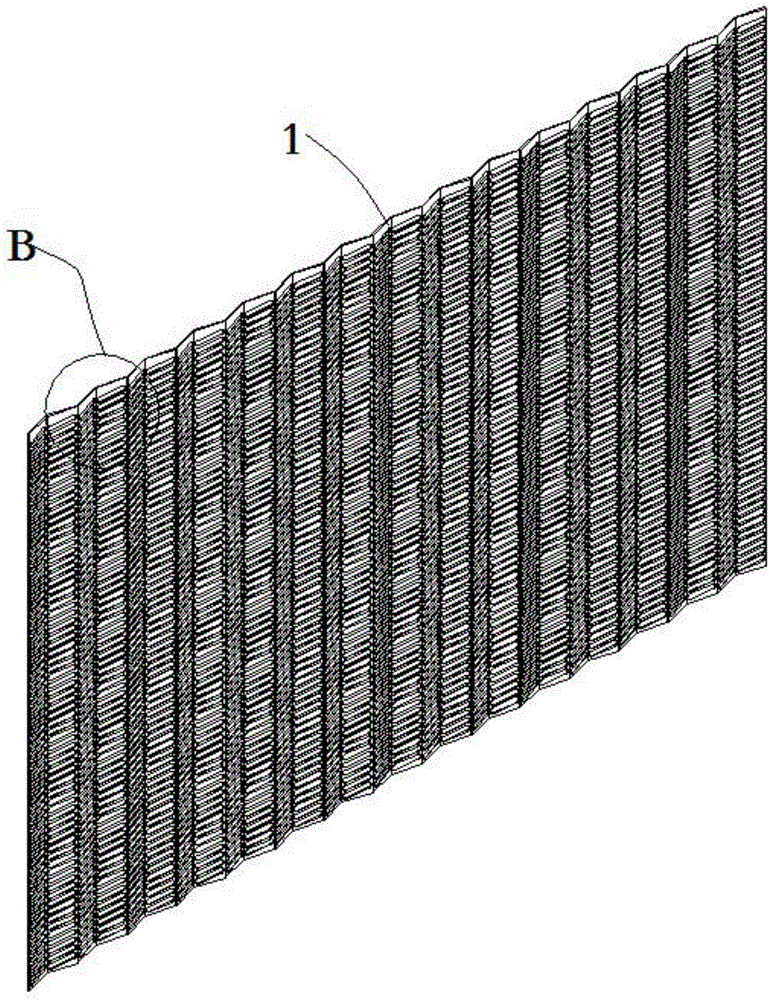

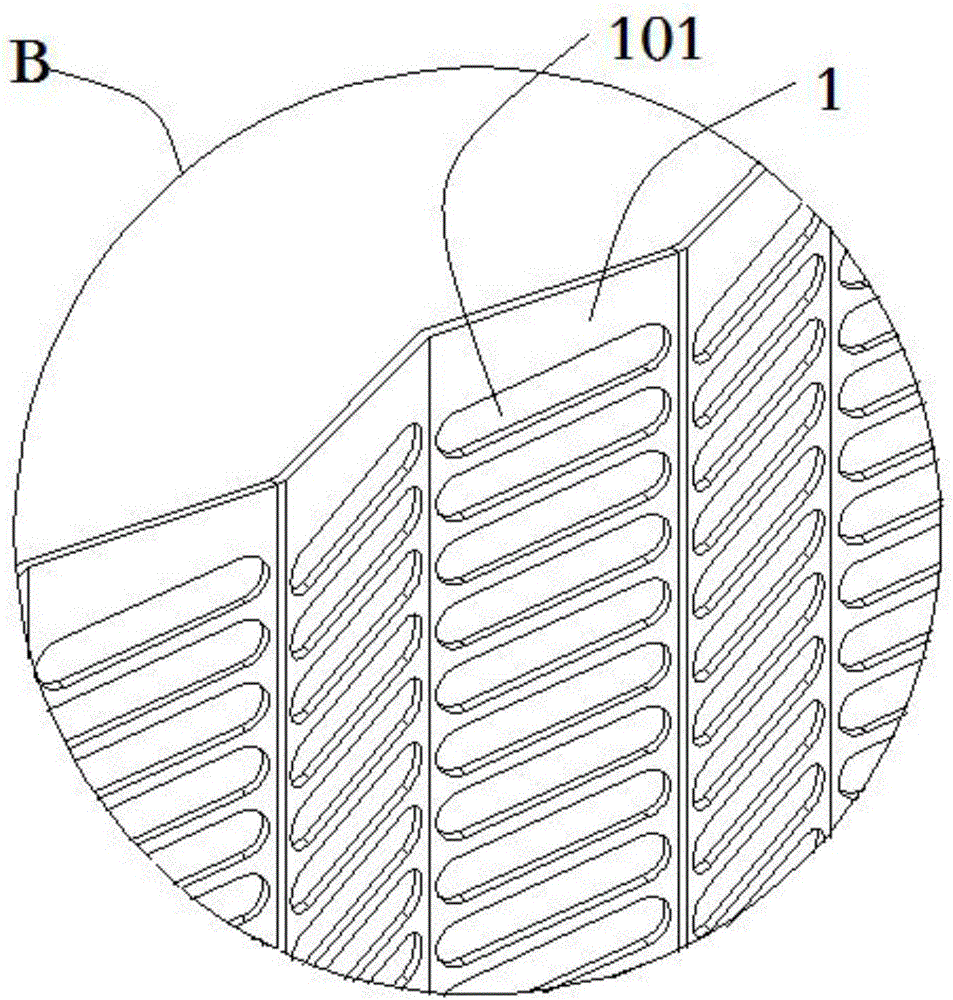

[0016] A kind of soil restoration adsorption net, see figure 1 , figure 2 , comprising a mesh plate 1, the mesh plate 1 is made into a block of 1.5m*1.5m by adsorption material, and pressed into a wave shape; the thickness of the mesh plate 1 is 5mm, and strip-shaped filter holes 101 are evenly distributed on its surface , the strip-shaped filter hole 101 forms an inclination angle of 15 degrees with the wave folding edge of the screen plate 1; the adsorption material is made by adding attapulgite powder with a particle size of 350 mm by ion exchange fiber at a weight ratio of 4:1.5;

[0017] The preparation method of ion exchange fiber is as follows: add 4.5kg of ethylene glycol and 2.5kg of ethylenediamine to 3.22kg of polyvinyl alcohol fiber in sequence, and reflux reaction for 1 hour under stirring to obtain an intermediate product; after washing the intermediate product with water, add 1.5kg of ethylenediamine A mixed solution of diol, 6.75kg of aminopyridine and 1.25kg...

Embodiment 2

[0020] A kind of adsorption net for soil restoration, comprising a net plate 1, the net plate 1 is pressed into a strip shape of 2m*1m by adsorption material; The filter hole 101 forms an inclination angle of 10 degrees with the wavy hem of the mesh plate 1; the adsorption material is made by adding the attapulgite powder into the ion exchange fiber at a weight ratio of 2:1; the preparation method of the ion exchange fiber is the same as in Example 1.

[0021] The adsorption net prepared above was buried in the soil with a depth of 15 cm for 15 days, adsorbed and exchanged, and then removed from the soil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com