Repairing method for broken and defected bronze ware culture relic

A repairing method and technology of bronze ware, which is applied in welding/welding/cutting items, aluminothermic welding equipment, welding equipment, etc., can solve problems such as defective bronze ware, and achieve the effect of fast repair speed, good versatility, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

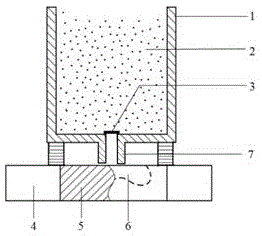

Image

Examples

Embodiment 1

[0030] The bronze artifacts to be restored are made of tin bronze, and the cylindrical support is broken.

[0031] (1) Pre-repair treatment: Perform pre-repair treatment on the area of the bronze ware to be repaired, remove surface oil and rust, and open welding grooves.

[0032] (2) Establish a restoration model: Measure the relevant dimensions of the bronze cultural relics to be restored (Y-shaped groove, gap 5mm, blunt edge 4mm), use the 3D modeling software SOLIDWORKS to establish a virtual restoration 3D model of the area, and use a 3D printer to obtain physical model;

[0033] (3) Making packaging molds: According to the physical model, use fireproof mud to make matching packaging molds, and dry the packaging molds for later use;

[0034] (4) Preparation of solder powder: Determine the solder powder formula for exothermic reaction according to the composition of the bronze cultural relics to be repaired. The mass percentage of each material is 10% Na 2 SO 4 Powder, ...

Embodiment 2

[0041] The bronze artifacts to be repaired are made of tin bronze, and the complex shape of the knife handle is partially damaged.

[0042] (1) Pre-repair treatment: Pre-repair the area of the bronze ware to be repaired to remove surface oil and rust.

[0043] (2) Establish a repair model: use a 3D scanner to directly obtain a 3D model of the area to be repaired, perform virtual repair, and use a 3D printer to obtain a solid model;

[0044] (3) Making packaging molds: According to the physical model, use fireproof mud to make matching packaging molds, and dry the packaging molds for later use;

[0045] (4) Preparation of solder powder: Determine the solder powder formula for exothermic reaction according to the composition of the bronze cultural relics to be repaired. The mass percentage of each material is 11% Na 2 SO 4 Powder, 38% Cu 2 O powder, 11% Al powder, 2% CaF 2 Powder, 1% borax, 24% Cu powder, 11.5% Sn powder, 1.00% PbO powder, 0.25% Ag powder, 0.17% As powder,...

Embodiment 3

[0052] The bronze artifacts to be restored are made of lead-tin bronze, and the complex shape is full of local defects.

[0053] (1) Pre-repair treatment: Pre-repair the area of the bronze ware to be repaired to remove surface oil and rust.

[0054] (2) Establish a repair model: use a 3D scanner to directly obtain a 3D model of the area to be repaired, perform virtual repair, and use a 3D printer to obtain a solid model;

[0055] (3) Making packaging molds: According to the physical model, use fireproof mud to make matching packaging molds, and dry the packaging molds for later use;

[0056] (4) Preparation of solder powder: Determine the solder powder formula for exothermic reaction according to the composition of the bronze cultural relics to be repaired. The mass percentage of each material is 11% Na 2 SO 4 Powder, 34% Cu 2 O powder, 10% Al powder, 1.5% CaF 2 Powder, 2% borax, 15% Cu powder, 10% Sn powder, 18% Pb powder, 0.3% Ag powder, 0.15% As powder, 0.05% Sb powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com