Biological restoring method for contaminative soil and equipment therefor

A technology for contaminated soil and bioremediation, applied in the field of contaminated soil remediation, can solve the problems of inconvenient control, secondary pollution of the environment and groundwater, and single experimental conditions, and achieve the effect of preventing pollution, various environmental conditions, and meeting the needs of survival.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

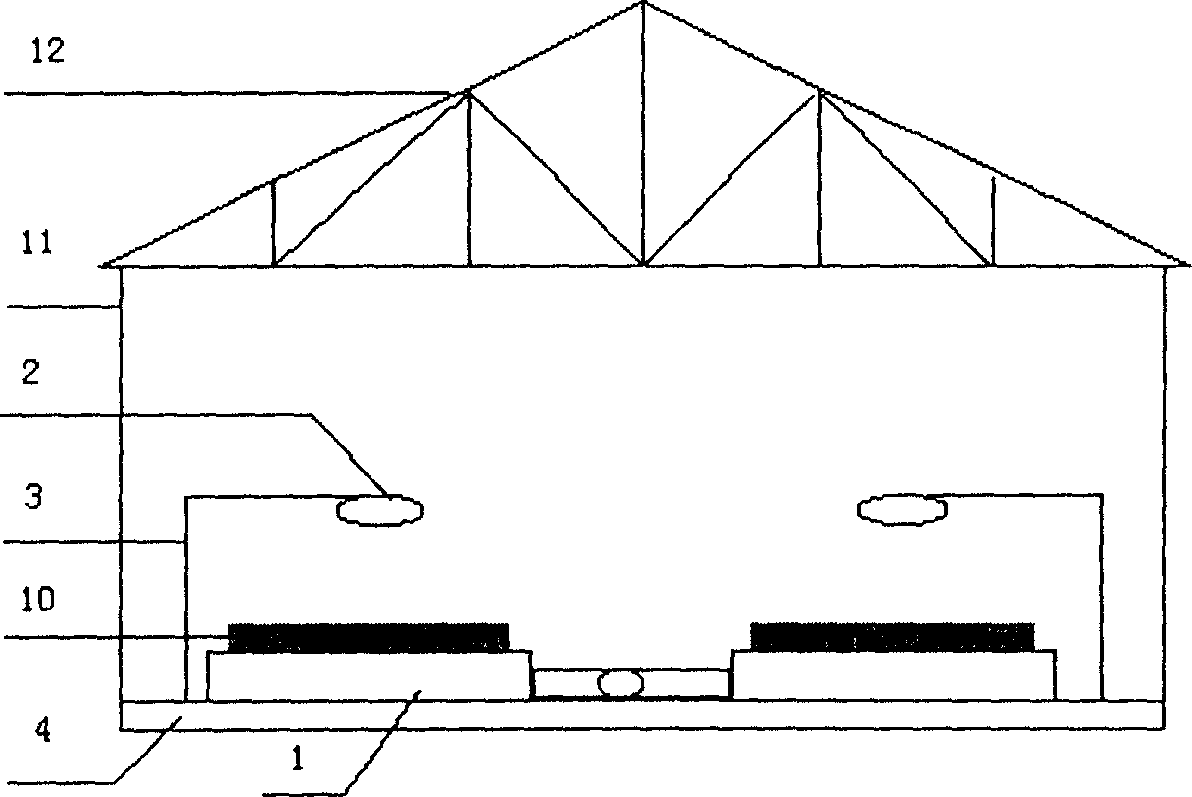

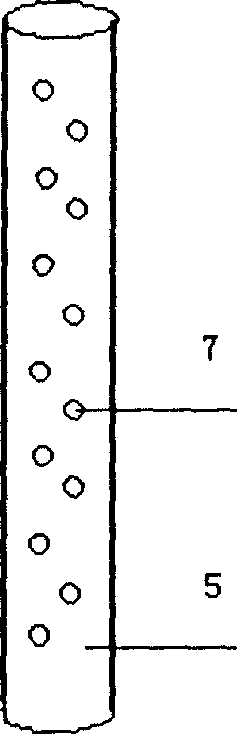

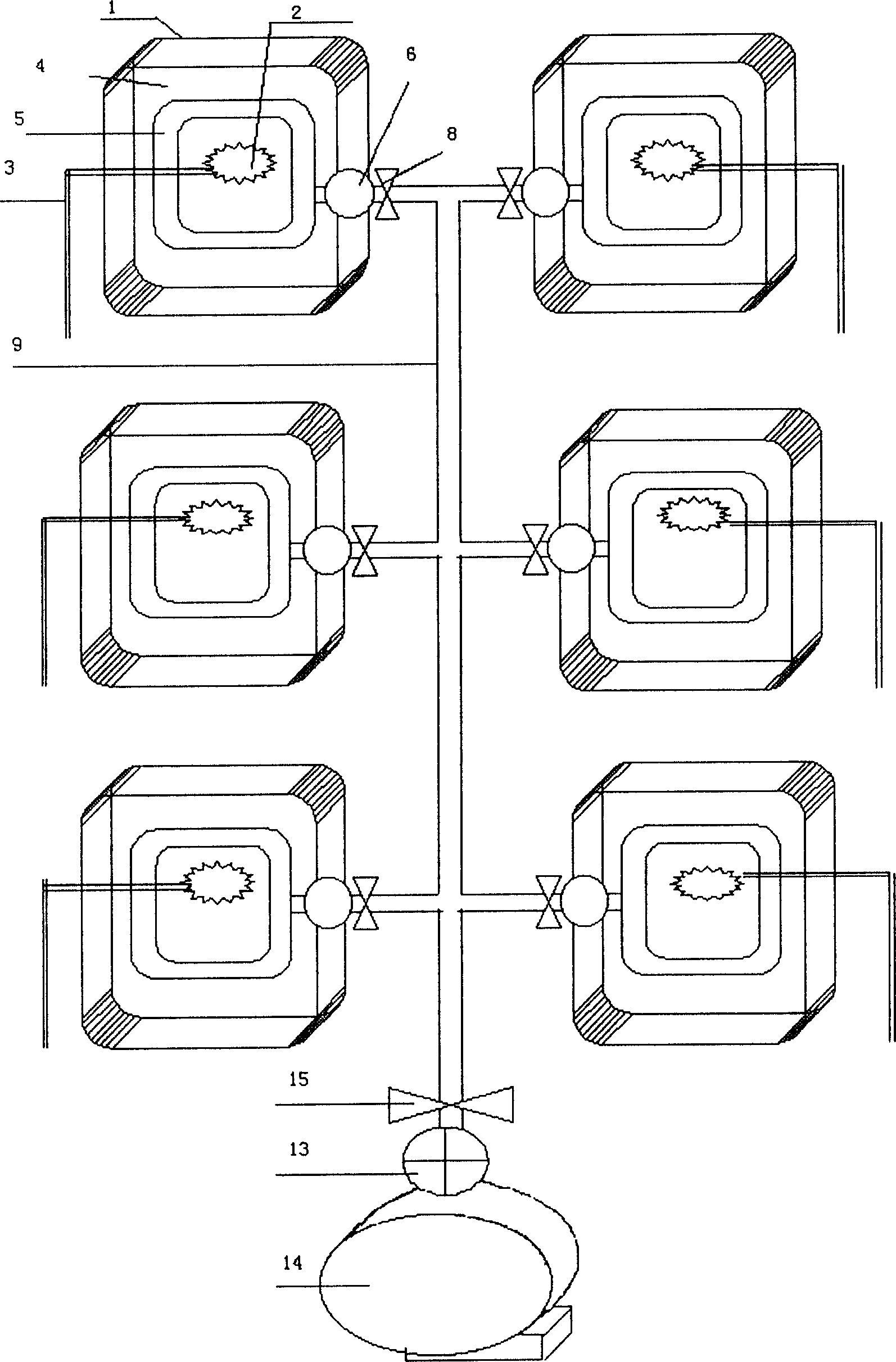

[0021] Such as figure 1 As shown, the restoration facility of the present invention is a shed-like structure consisting of a ceiling 12 and a shed wall 11, which has rainproof performance, and a heap rotting pool 1 is arranged inside, on which is a pile of contaminated soil 10, and below the heap rotting pool 1 is set Anti-seepage layer 4, sprinkler head 2 is installed through running water pipe 3 above the 1 meter high place in the center of heap rot pool 1 (it can be convenient to replenish water, and can be used for spraying water at any time according to the requirements of water content in the test), wherein there are walls covered with The ventilation pipes 5 of the ventilation holes 7 are respectively arranged in parallel to the rotting pool 1; the ceiling 12 is covered with plastic cloth, and the ventilation pipe 5 is connected to the air blower 14 through the gas pipeline 9, and the ventilation pipe 5 in each heaping rot pool 1 is connected with the air blower 14. A g...

Embodiment 2

[0049] The difference from Example 1 is that in this example, the ground crude oil near the oil well of Shuguang Oil Production Plant and the polluted soil around the oil well are used. The crude oil is heavy oil with a density of 0.97g.cm -3 , the colloid + bitumen content is 35.7%, the wax content is 6.2%, and the viscosity is 3026.5mPa.s (50°C). The guest soil is collected from the uncontaminated soil far away from the oil well in this area, which belongs to the salinized meadow soil, and is transported to the test site by truck.

[0050] Grind the large lumps of oily soil, and pass through a 5mm sieve for the oily sludge and contaminated soil. The pretreatment soil preparation is as follows:

[0051] KB: 80kg of oil-contaminated soil was added to 20kg of guest soil (comparative example 1);

[0052] CK: 80kg of oil-contaminated soil was added to 20kg of guest soil and 1.36kg of urea and 0.5kg of superphosphate were added (comparative example 2);

[0053] F: Add 20kg fore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com