Patents

Literature

59results about How to "Resume production quickly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

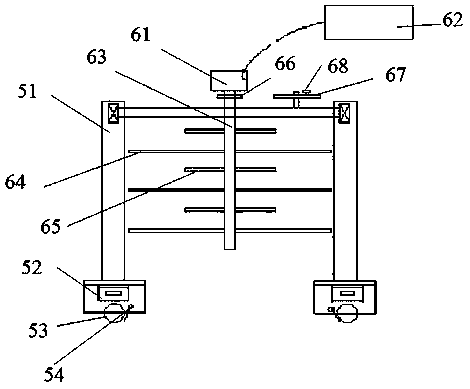

Safety monitoring system of crane

InactiveCN108002239AResume production quicklyComprehensive security monitoringSafety gearData acquisitionSmart surveillance

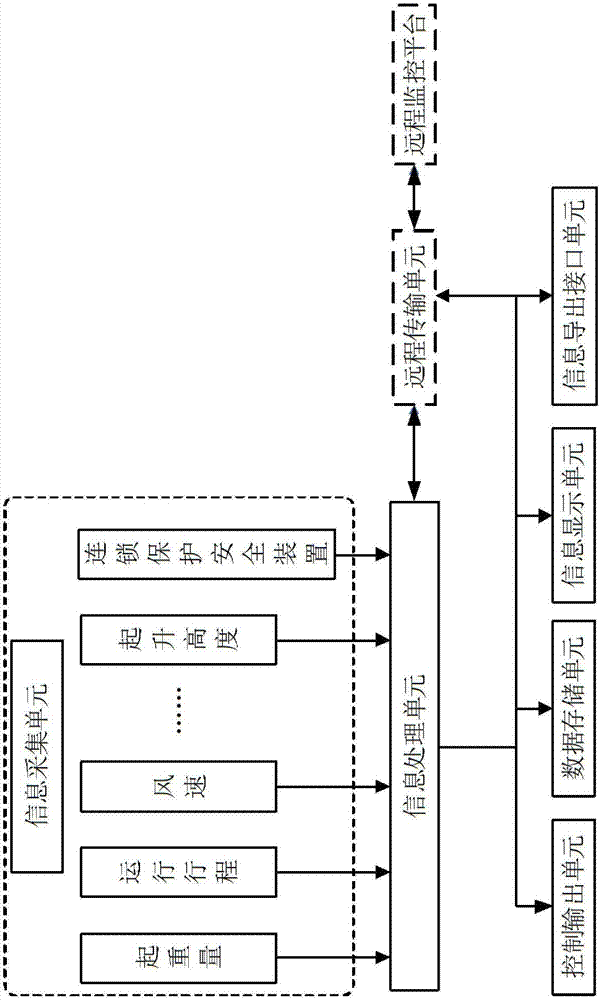

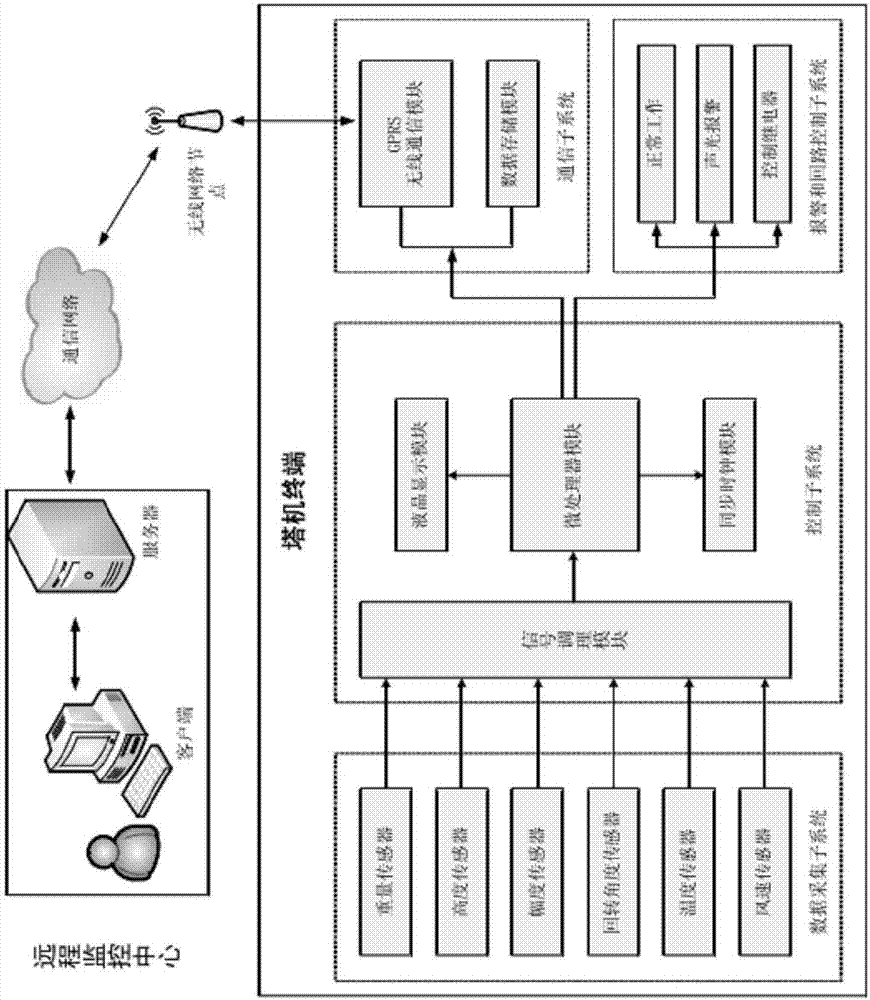

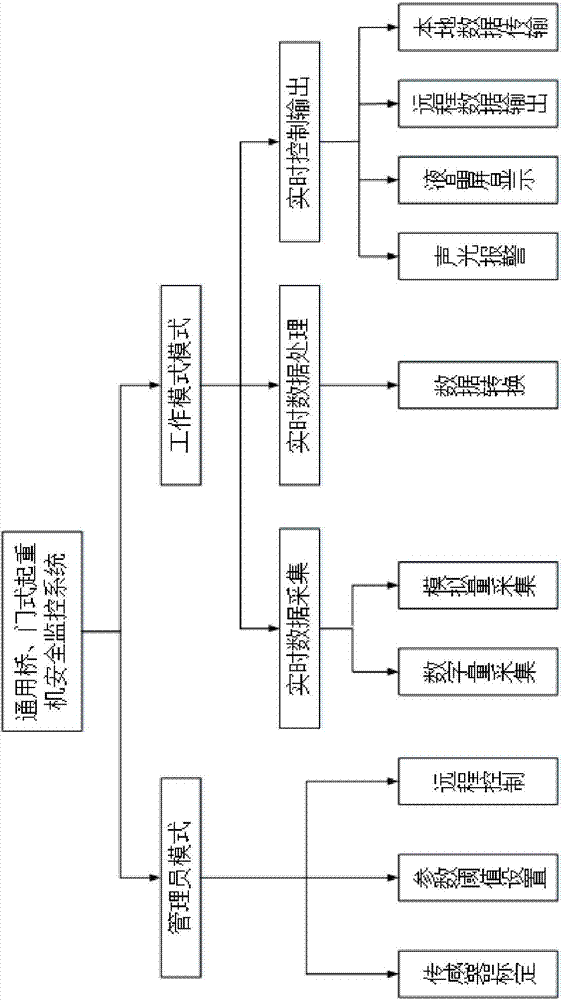

The invention provides a safety monitoring system of a crane, and belongs to the technical field of intelligent monitoring. The safety monitoring system comprises a software part and a hardware part.The hardware part comprises a data collection subsystem, a control subsystem, a control output subsystem, an information storage subsystem, an information display subsystem, an information export connector subsystem, a remote transmission subsystem and a remote monitoring center. The software part comprises an administrator mode and a working mode. The safety monitoring system has the advantages that monitoring data are comprehensive, and potential safety hazards can be reduced.

Owner:HUBEI UNIV OF SCI & TECH

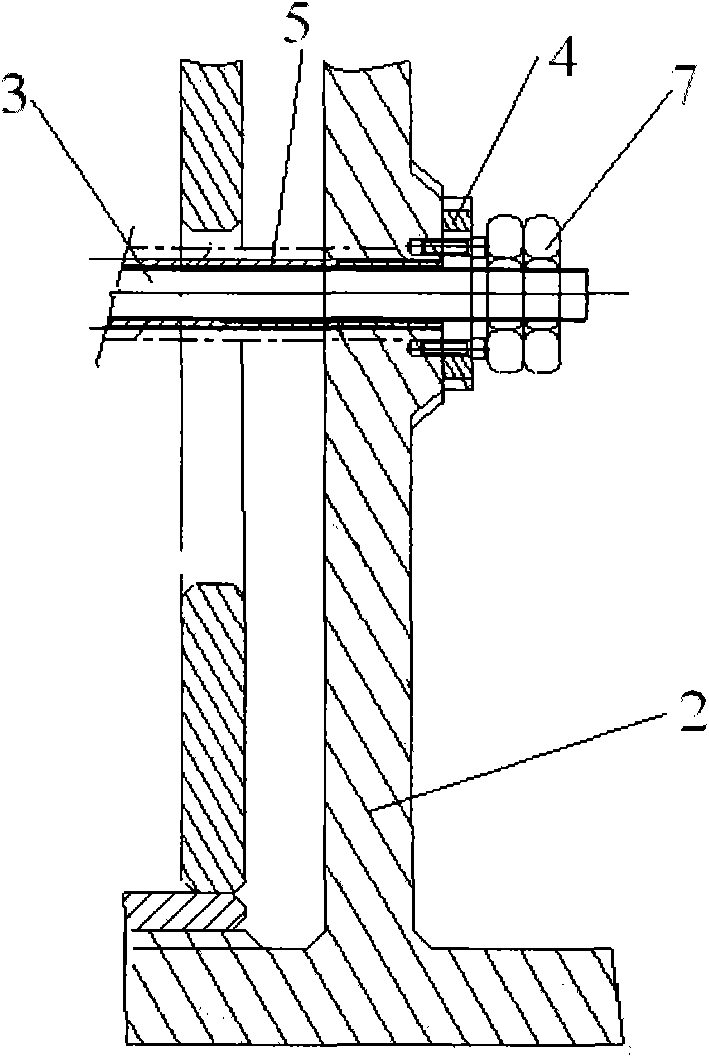

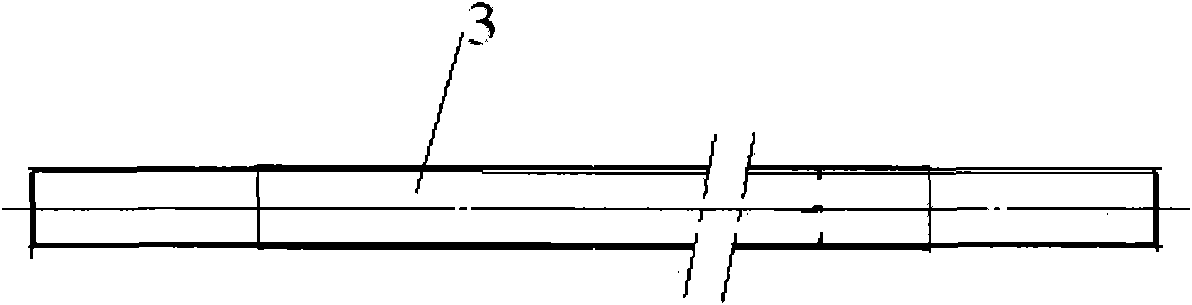

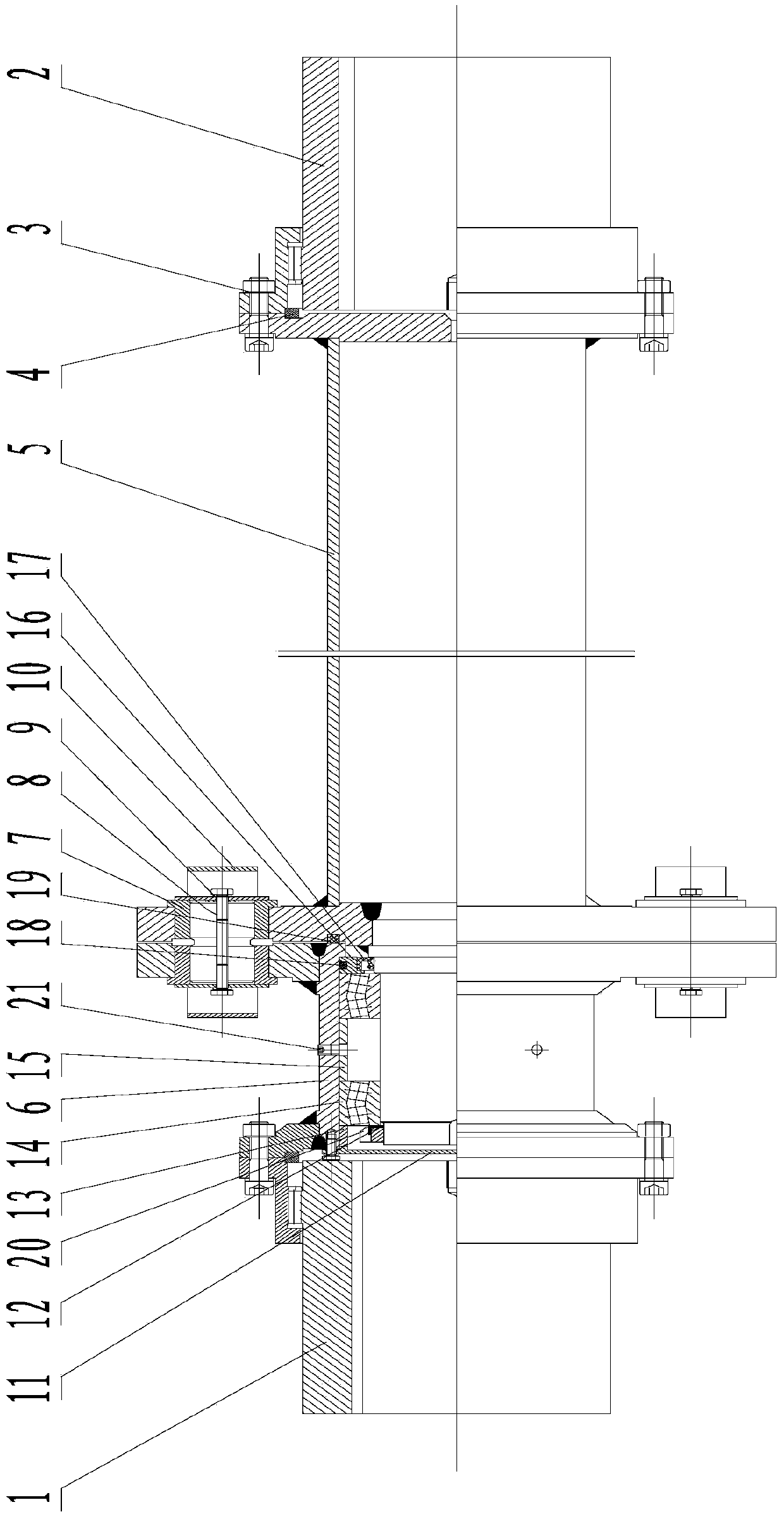

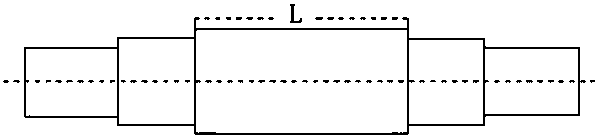

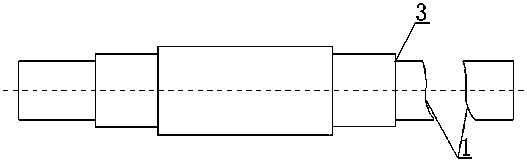

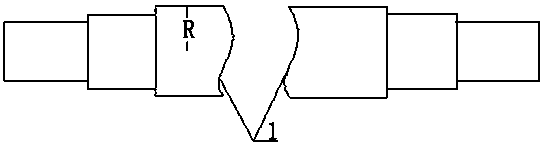

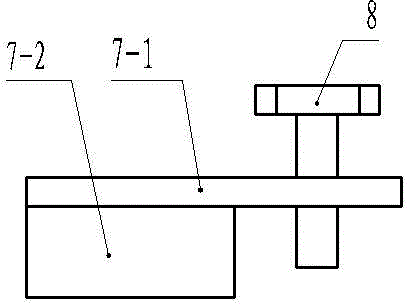

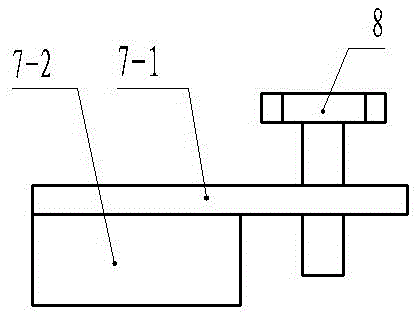

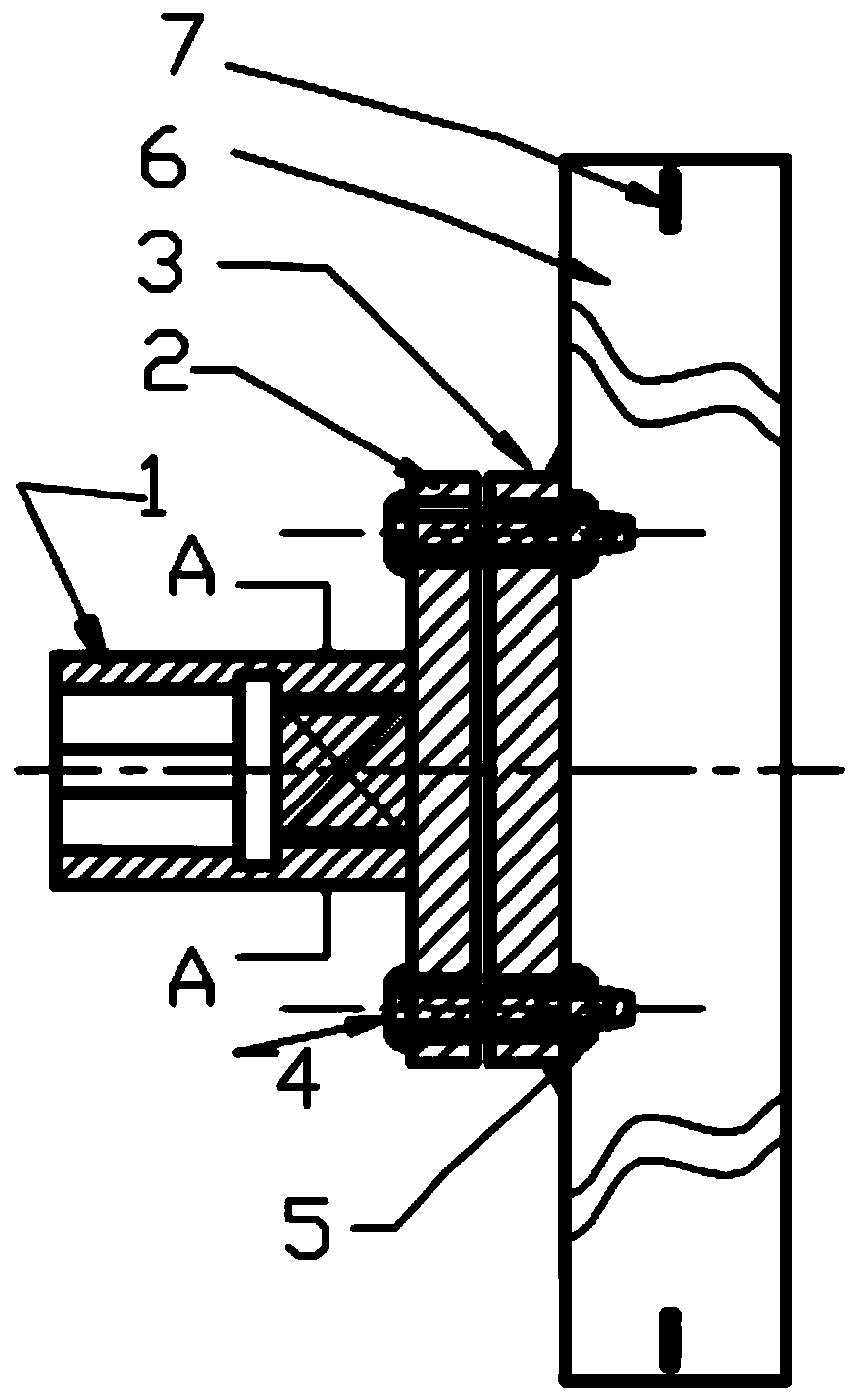

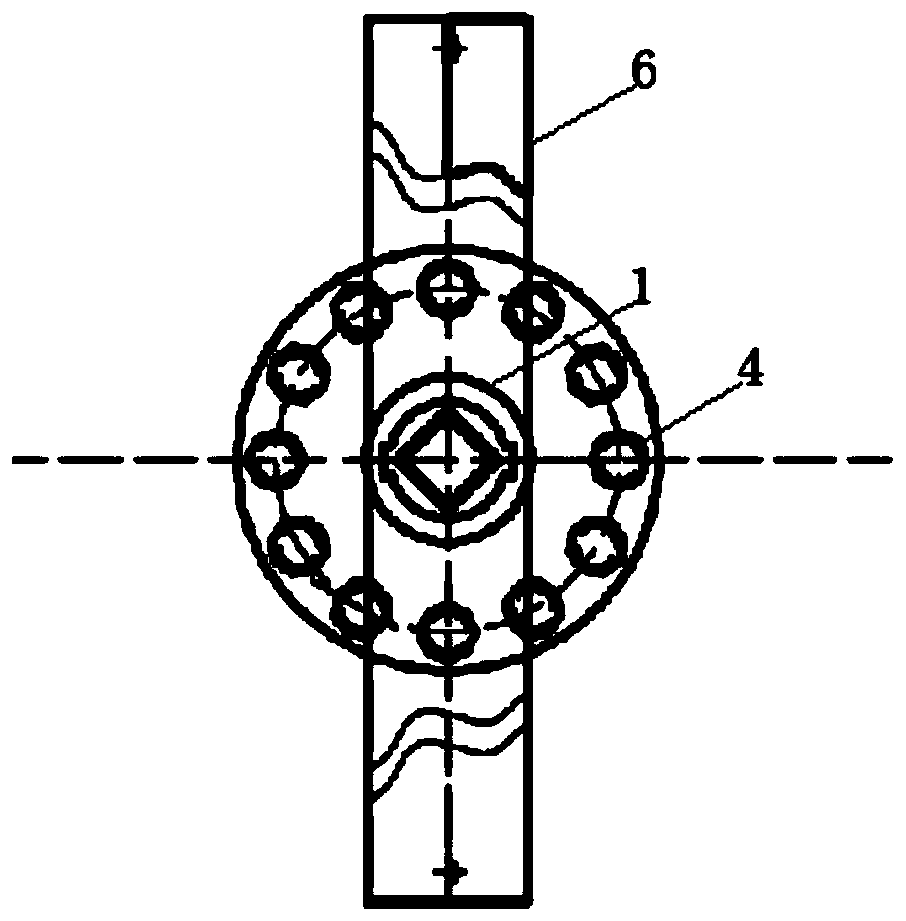

Drawing and shaping mold structure

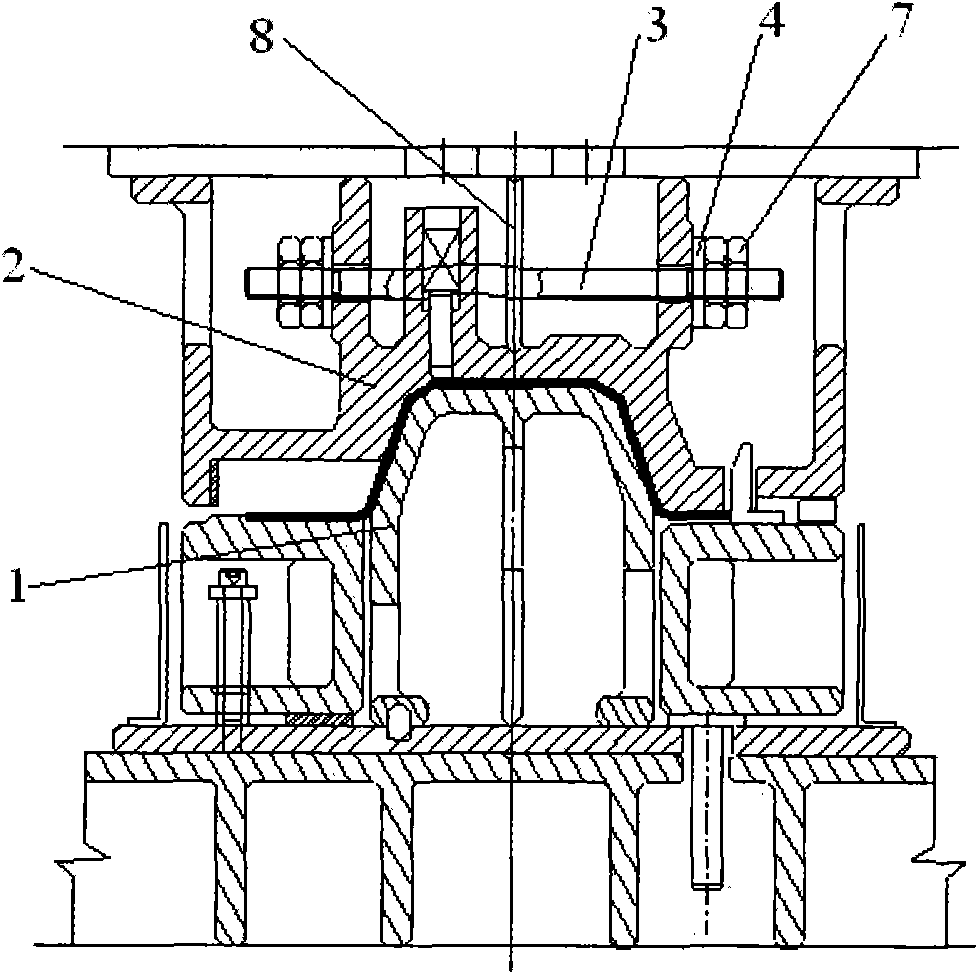

The invention discloses a drawing and shaping mold structure, which comprises a terrace die (1) and a die (2), wherein the die (2) is divided into two half moulds in a jogged structure, the combination surface of the two half molds is a die partingsurface (8), the die partingsurface (8) is vertical to the separation-combination plane of the terrace die (1) and the die (2), a fastening screw bolt (3) is arranged on the die (2), and the two half molds of the die (2) are tightly fastened and connected. When the technical scheme is adopted, the die is separated and is connected and fixed through the fastening screw bolt, the fastening screw bolt is provided with a theoretical ultimate fracture point, and the expansion crack of the die can be avoided under the risk of double-material occurrence of the mold. The invention is applicable to vertical beam type parts on automobiles, particularly U-shaped beam type parts. The damage on the die by the double materials is avoided through the fracture of the fastening screw bolt, so the risk-resistance capability of the mold can be effectively improved, the die can not be damaged even if the fracture of the fastening screw bolt occurs, and the mold production can be fast recovered.

Owner:CHERY AUTOMOBILE CO LTD

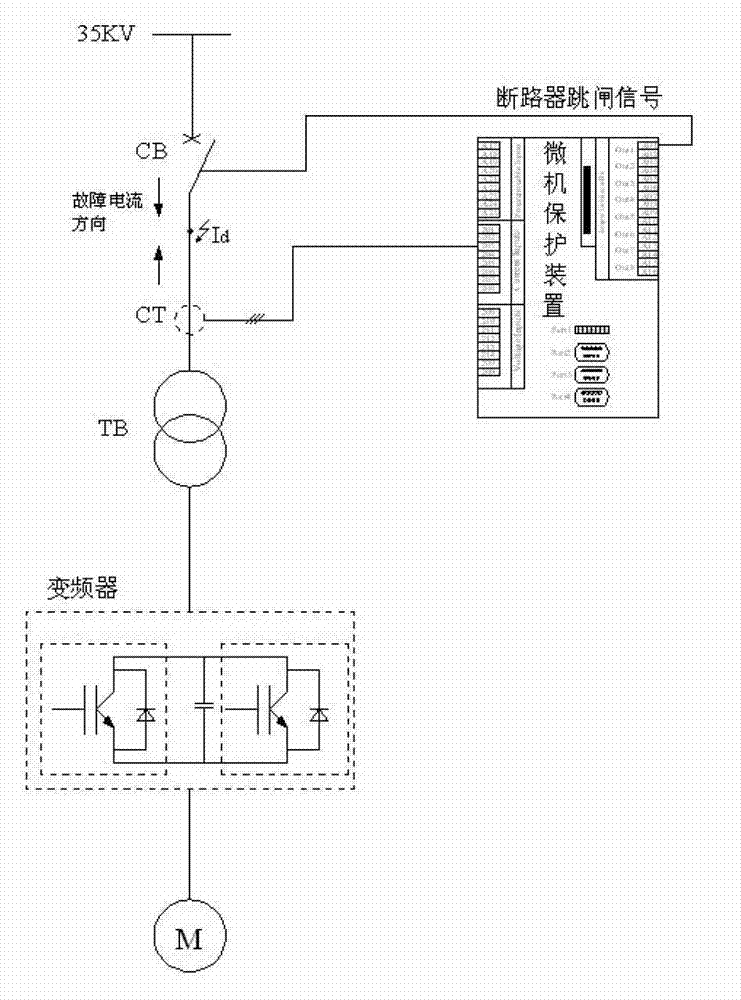

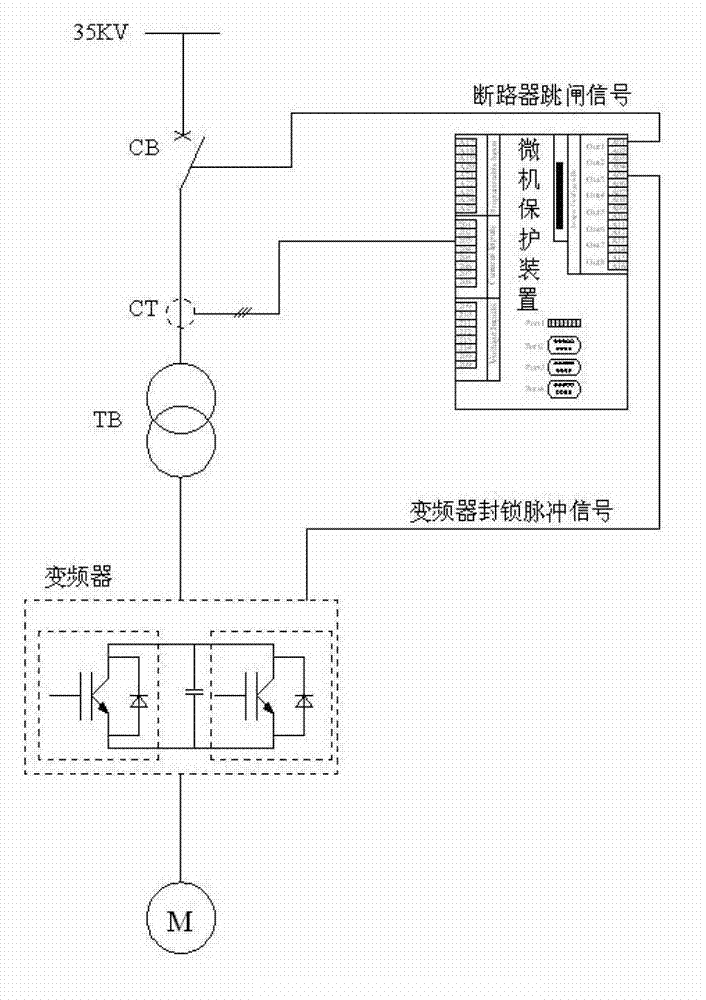

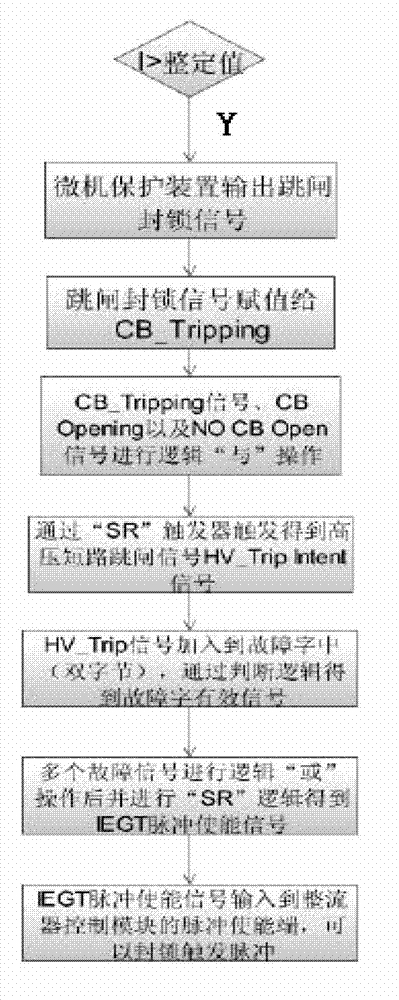

Implementing method of protecting IEGT (injection enhanced gate transistor) based on relay protection tripping signal

InactiveCN102769276AAchieve shutdownFrom shockEmergency protective circuit arrangementsMicrocomputerControl signal

The invention discloses an implementing method of protecting an IEGT (injection enhanced gate transistor) based on a relay protection tripping signal, belonging to the field of control. The implementing method comprises the steps of: introducing a 'tripping' control signal of a breaker into logic trigger conditions of a blocking IEGT triggering pulse module to form a mode of new logic trigger conditions of the blocking IEGT triggering pulse module together with original logic trigger conditions, outputting a 'blocking IEGT triggering pulse' signal through the blocking IEGT triggering pulse module after a microcomputer protection device outputs the 'tripping' control signal, before the 'tripping' mechanical action of the breaker, shielding / blocking the triggering pulse of the IEGT in a frequency convertor so as to turn off the IEGT and avoid the impact on the IEGT caused by a di / dt current mutation value impact, and to protect the IEGT. The protection action mechanism of the implementing method is cleverly set and easily achieved, and according to the protection action mechanism, the needed time of an on-site repair process is shortened greatly, the production can be resumed quickly and the production / maintenance cost can be lowered. The implementing method can be widely applied to the control / protection field of the driving system of a rolling mill set.

Owner:BAOSTEEL STAINLESS STEEL

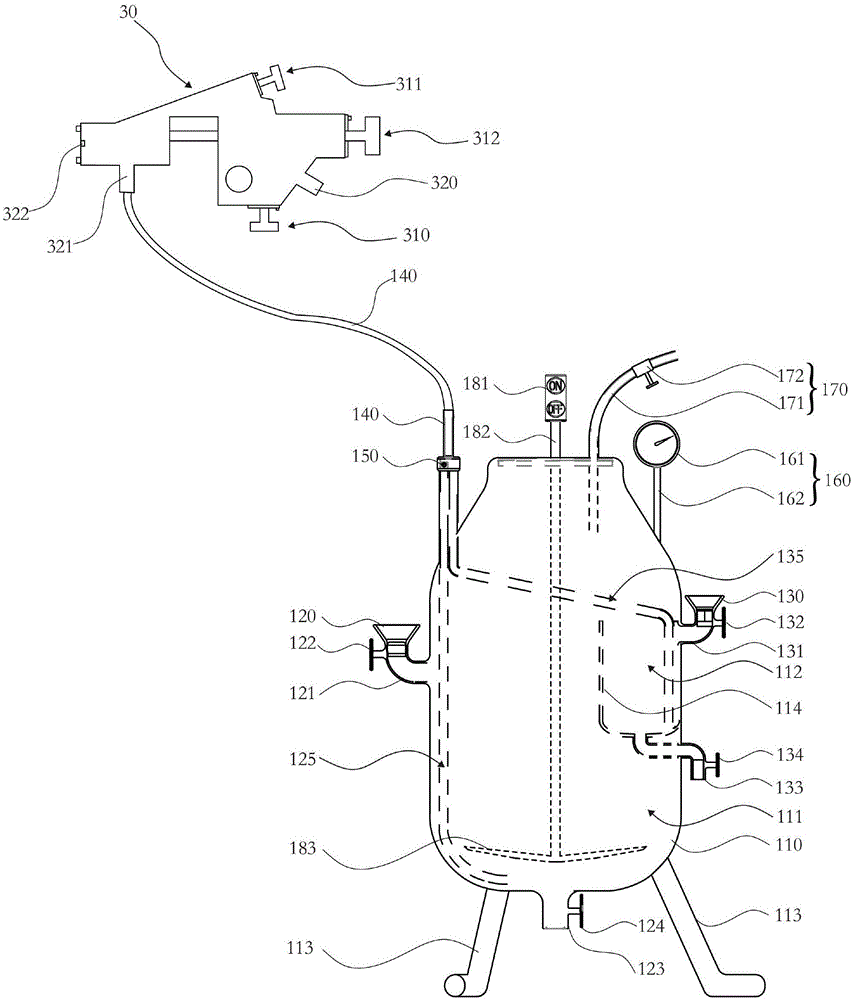

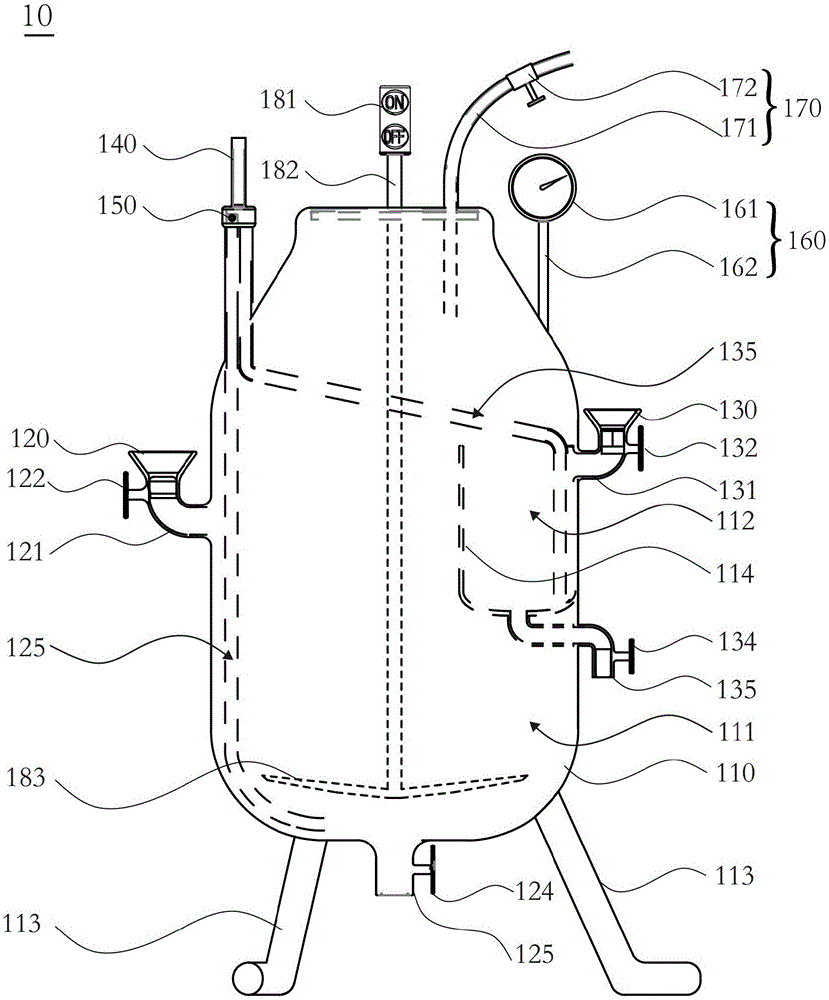

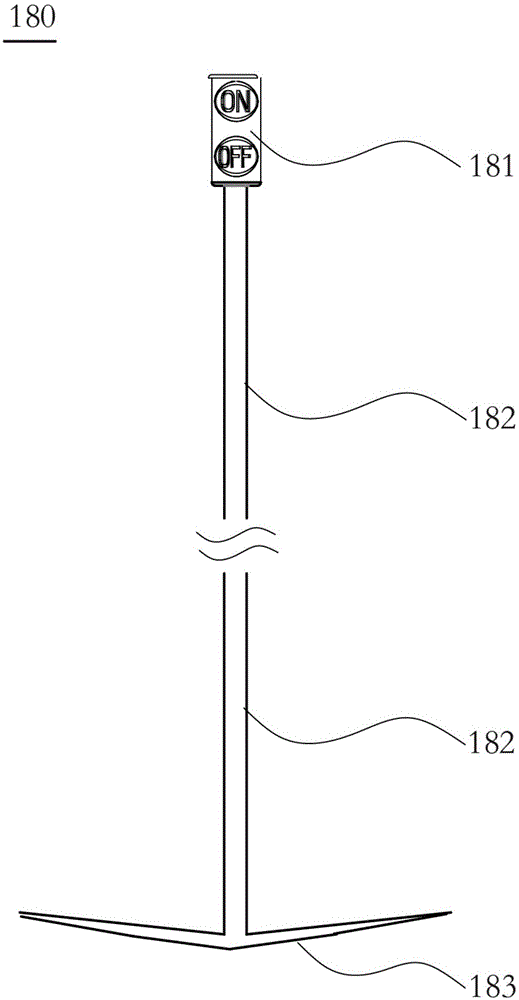

Spraying system and spraying method

InactiveCN105013641AReduce dependenceImprove accuracyLiquid spraying apparatusSpray coatingEngineering

The invention discloses a spray coating system and a spraying method. The spraying system comprises a spray gun, a paint spraying tank and a plurality of valve devices, wherein the valve devices regulate the oil discharging amount, the oil discharging angle and the gas flow of the spray gun; the paint spraying tank comprises an air inlet component, a conversion switch component, a pressure detecting component and a storage tank; the storage tank is provided with a storage cavity; the air inlet component is communicated to the storage tank and used for enabling air to enter into the storage cavity of the storage tank; the pressure detection part is connected to the storage tank; a partition board is connected to the inner part of the storage cavity; the partition board divides the storage cavity into a first storage cavity and a second storage cavity; a first spray pipe communicated with the first storage cavity, and a second spray pipe communicated with the second storage cavity are arranged at the outer part of the storage tank; the first spray pipe and the second spray pipe are communicated in parallel to the spray gun through the conversion switch component; each of the first storage cavity and the second storage cavity is communicated with a feed pipe and a discharg pipe; feed openings of the feed pipes, and discharge openings of the discharge pipes are positioned at the outer part of the storage tank. Through the adoption of the spraying system disclosed by the invention, the time is shortened, and the working efficiency is improved.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

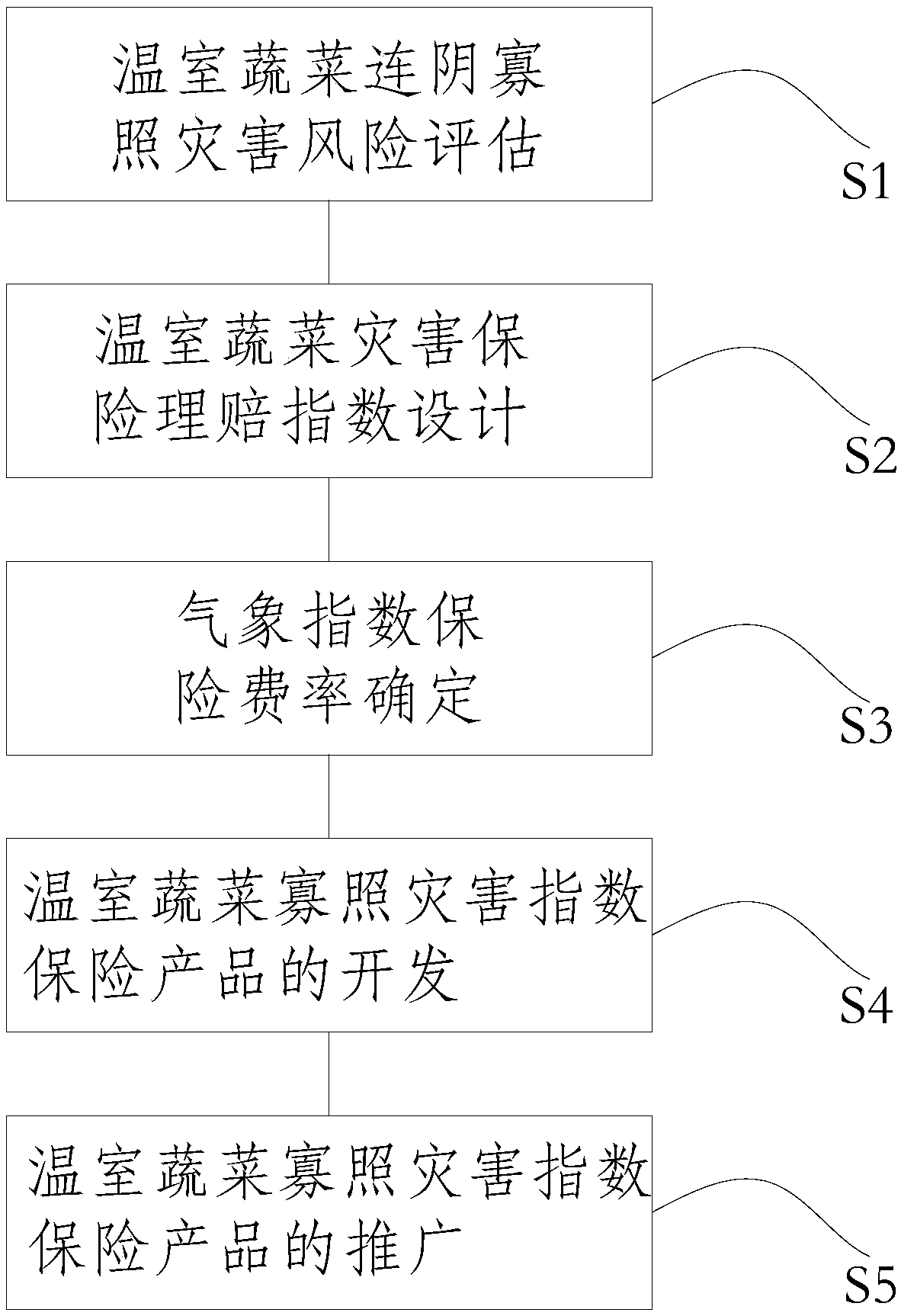

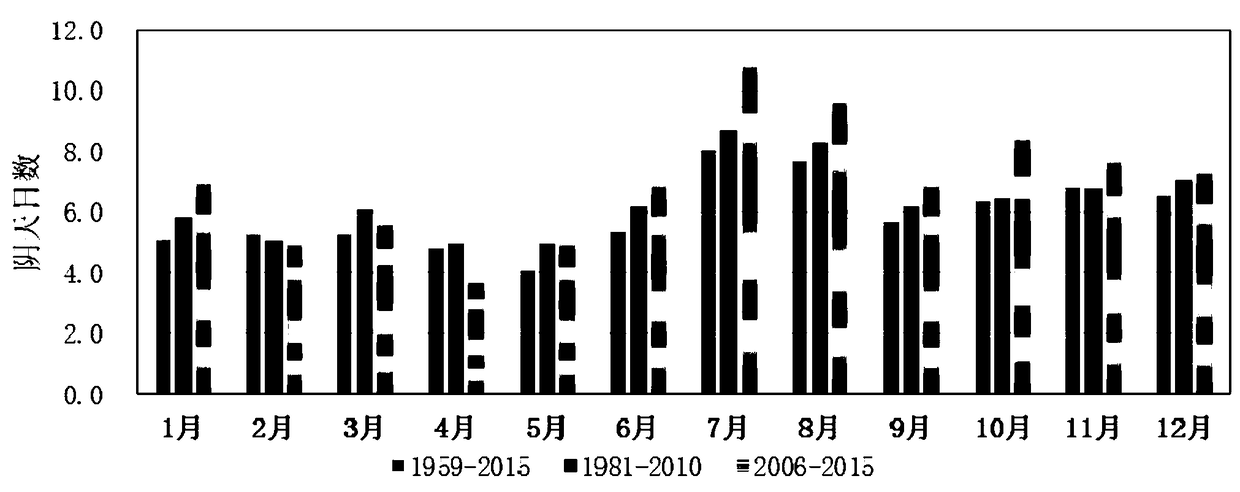

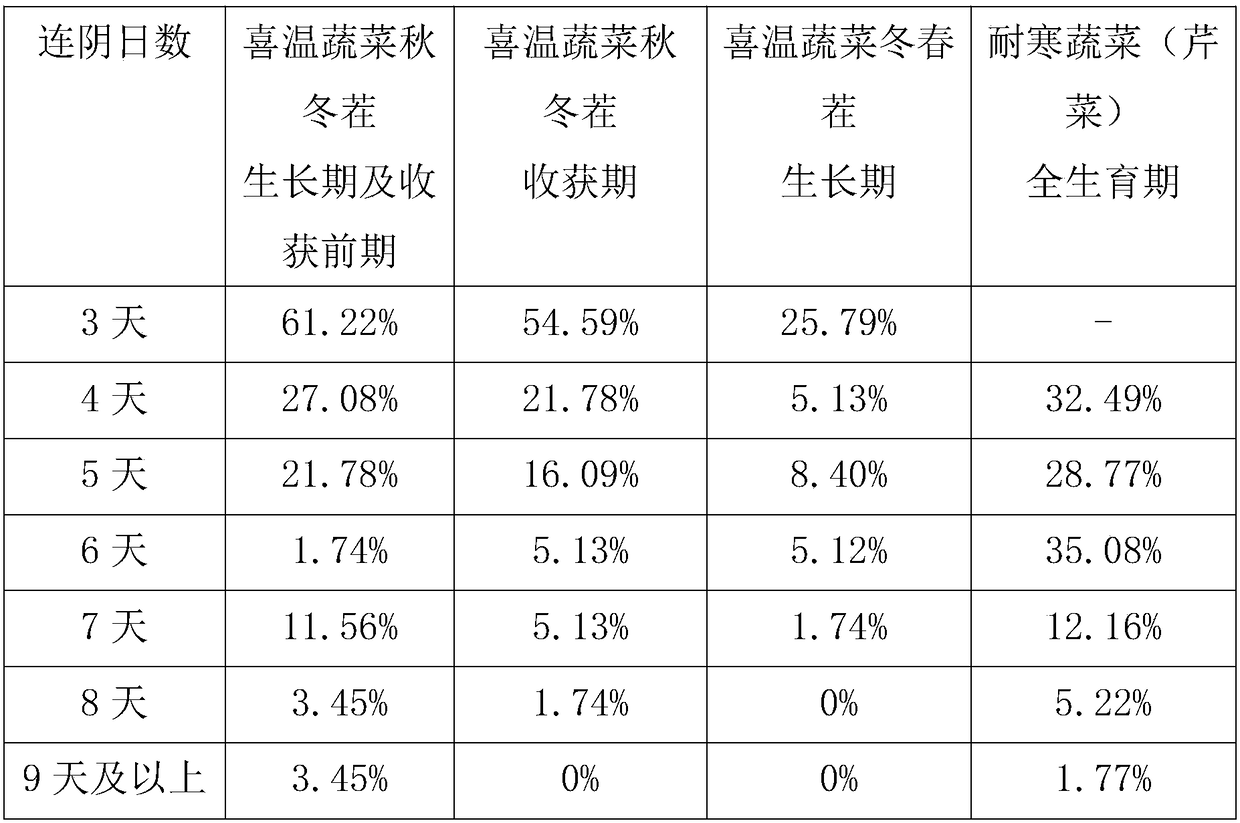

Sunlight greenhouse continuous-illumination weather index insurance method

InactiveCN108460691AExpand business areasPromote sustainable developmentFinanceClimate change adaptationWeather indexChemistry

The invention relates to a sunlight greenhouse continuous-illumination weather index insurance method. The method comprises the following steps that s1, the risk of flood disaster risk of the greenhouse vegetables is evaluated; s2, a greenhouse vegetable disaster insurance weather settlement index is designed; s3, the weather index insurance rate is determined; s4, the greenhouse vegetable oligomeric disaster index insurance product is developed; s5, the greenhouse vegetable oligomeric disaster index insurance product is popularized. The invention has the beneficial effects that the operationis simple, is high in efficiency and is stable and feasible.

Owner:杞人气象科技服务(北京)有限公司

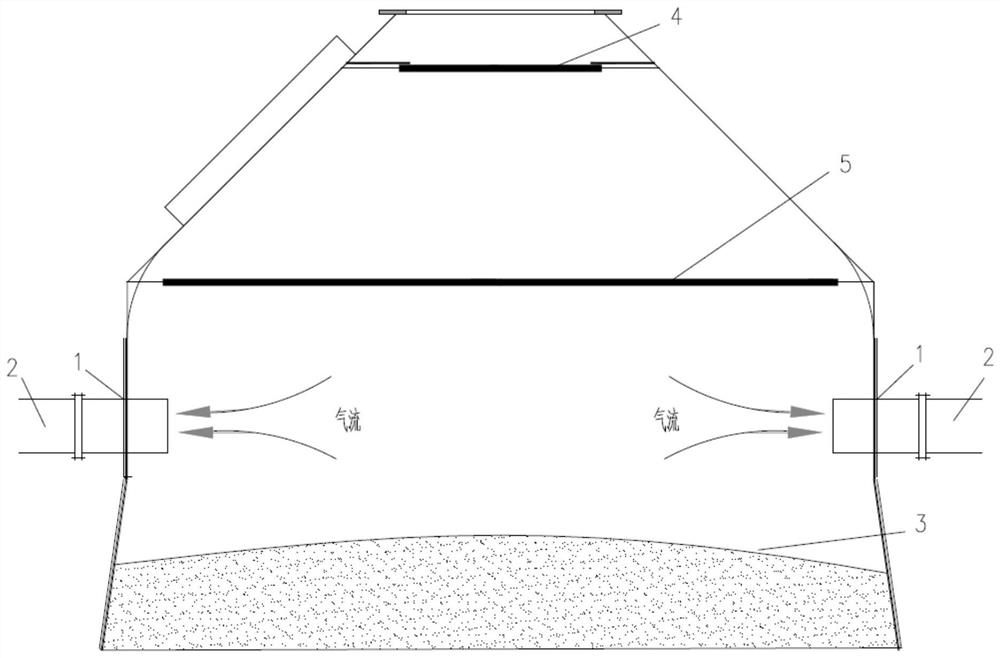

Water quality filtration and separation equipment for oil field

InactiveCN104548687AEasy to operateEasy to separateLoose filtering material filtersGravity filtersWater qualityOil sludge

The invention discloses water quality filtration and separation equipment for an oil field. In the prior art, water for the oil field is mainly water produced after dehydration of crude oil and reused for oil field operations, and the water contains more substances such as oil slick, impurities, oil sludge, silt, suspended matters and the like, so that severe pollution can be caused to pipelines, water supply equipment, water storage equipment and stratums. The water quality filtration and separation equipment for the oil field consists of a tank, a water inlet, a water outlet, a filtering filler inlet / outlet and filtering baffles, wherein a cavity is formed in the tank, and a stirrer is arranged in the cavity. The equipment has main purposes that the water produced after dehydration of the crude oil passes through the water quality filtration and separation equipment for the oil field and passes through multiple layers of filtering baffles with different specifications of holes and equipment filled with filtering filler, the filtering effect is not affected no matter how high the pressure of the pipelines of the oil field is, and the oil slick, the silt, the mechanical impurities and the oil sludge are effectively filtered out, so that the water quality is improved and optimized finally, and the water for the oil field is effectively treated.

Owner:天津市蓝海华博科技发展有限公司

Drive shaft capable of preventing overload fracture

ActiveCN103438114AImprove securitySave resourcesCouplings for rigid shaftsHeavy equipmentInternal cavity

The invention discloses a drive shaft capable of preventing overload fracture, which comprises a half-coupling 1, a half-coupling 2, a connector 1, a connector 2, a sleeve and a safety pin, wherein the left end of the half-coupling 1 is connected with a gearbox input shaft through a key; the right end of the half-coupling 2 is connected with a main motor output shaft through a key; the right side of the half-coupling 1 is fixed and connected with the connector 2 through a bolt; the left end of the connector 1 is welded with a shaft head; the shaft head can be inserted to an internal cavity on the right end of the connector 2 to be fixed axially and rotate radially; and the right end of the connector 1 is fixedly connected with the half-coupling 2 through a bolt. The drive shaft capable of preventing overload fracture can provide a substitute for a high-torque drive shaft used by flour mill equipment or other heavy equipment; and thus, the drive shaft capable of preventing overload fracture enhances the safety and reliability of the equipment, can better protect related equipment and personnel from damage, can greatly lower the maintenance cost and shorten the maintenance time, effectively enhances the production efficiency, and brings in considerable economic benefit.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

Threaded rod compressor broken main shaft burying shaft repairing method

The invention relates to a threaded rod compressor broken main shaft burying shaft repairing method. The method comprises the steps that one section of a broken main shaft is clamped and positioned bythe P end of a positioning tool, then a connecting shaft and the positioning tool are clamped and positioned to push the Q end, so that the matching of the connecting shaft and the broken main shaftinstalled and clamped at the P end is completed; and the broken shaft and the connecting shaft joint surface are connected together by spot welding, namely, spot welding is carried out at a first spotwelding position, and when spot welding at the first spot welding position is completed, after the spot welding position is cooled to room temperature, the positioning tool at the Q end is loosened,after a positioning table Q end is pushed to an appropriate position, the other section of the broken main shaft is clamped and positioned, and then the positioning table Q end is pushed and forms assembly with the connecting shaft in a matched mode. The threaded rod compressor broken main shaft burying shaft repairing method has the beneficial effects that the reuse of the broken main shaft is realized, the loss of discarded main shafts is reduced, the costs of enterprises are saved, the repairing method is easy, the operation is convenient, the method can be completed by general mechanical processing enterprises, and the repairing cost is low.

Owner:济南德盛压缩机设备有限公司

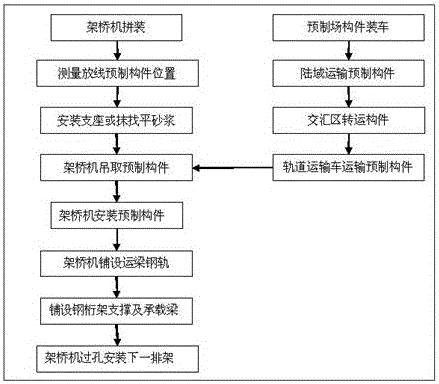

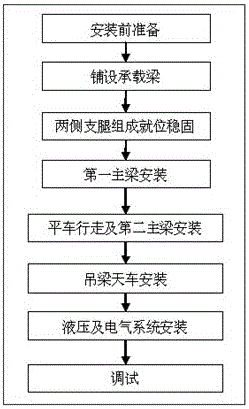

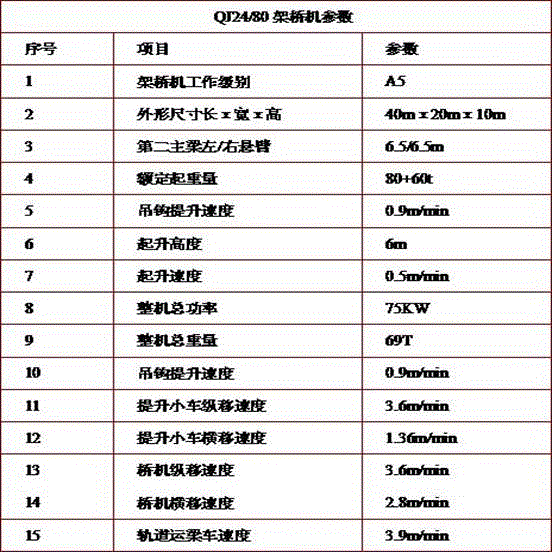

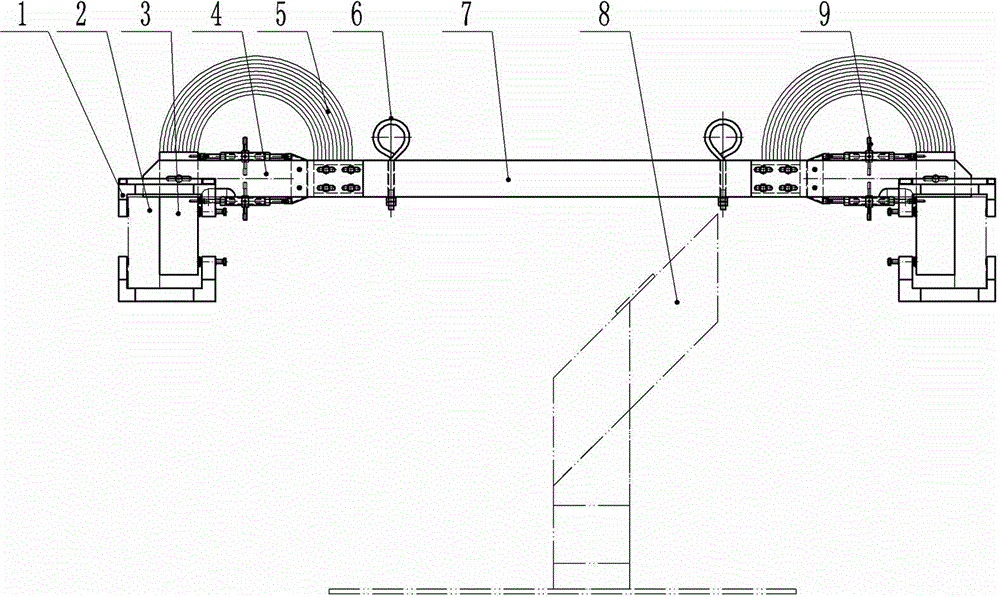

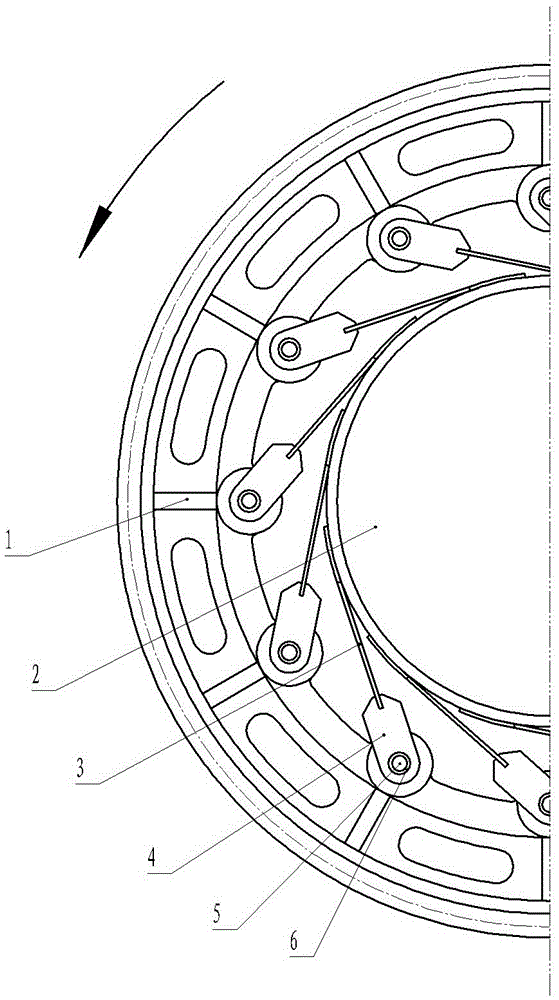

Construction method for installing precast beam slabs by adopting bridge girder erection machine

InactiveCN106320181AEasy to reinforceEasy to assembleBridge erection/assemblyMachine selectionEngineering

The invention discloses a construction method for installing precast beams and slabs by adopting a bridge girder erection machine and belongs to the field of precast beam slab construction. The construction method comprises the following steps that 1, bridge girder erection machine selection is performed: the suitable bridge girder erection machine is selected according to the hoisting weight and length of precast members; 2, the bridge girder erection machine and a transfer portal crane are spliced; 3, surveying and setting out are conducted on the positions of the precast members, supports are installed or mortar is levelled; 4, precast yard members are loaded on trucks, transported by land, transferred and transported by rail transportation carts; 5, the precast members are installed; 6, beam-transporting steel rails, steel truss supports and bearing beams are laid for the bridge girder erection machine, and via holes are set. Overwater precast member installation is performed by using the bridge girder erection machine, the bridge girder erection machine is directly fixed by using a rail clamping device and is reinforced by adopting a windproof zipper on the periphery when a typhoon reaches level 8 or above, and the bridge girder erection machine is directly dismounted when the typhoon is higher than the level 8 and is then assembled after the typhoon. Assembly and dismounting are relatively convenient, the required time is shorter, and production can be resumed in time after typhoons.

Owner:CCCC FIRST HARBOR ENG +1

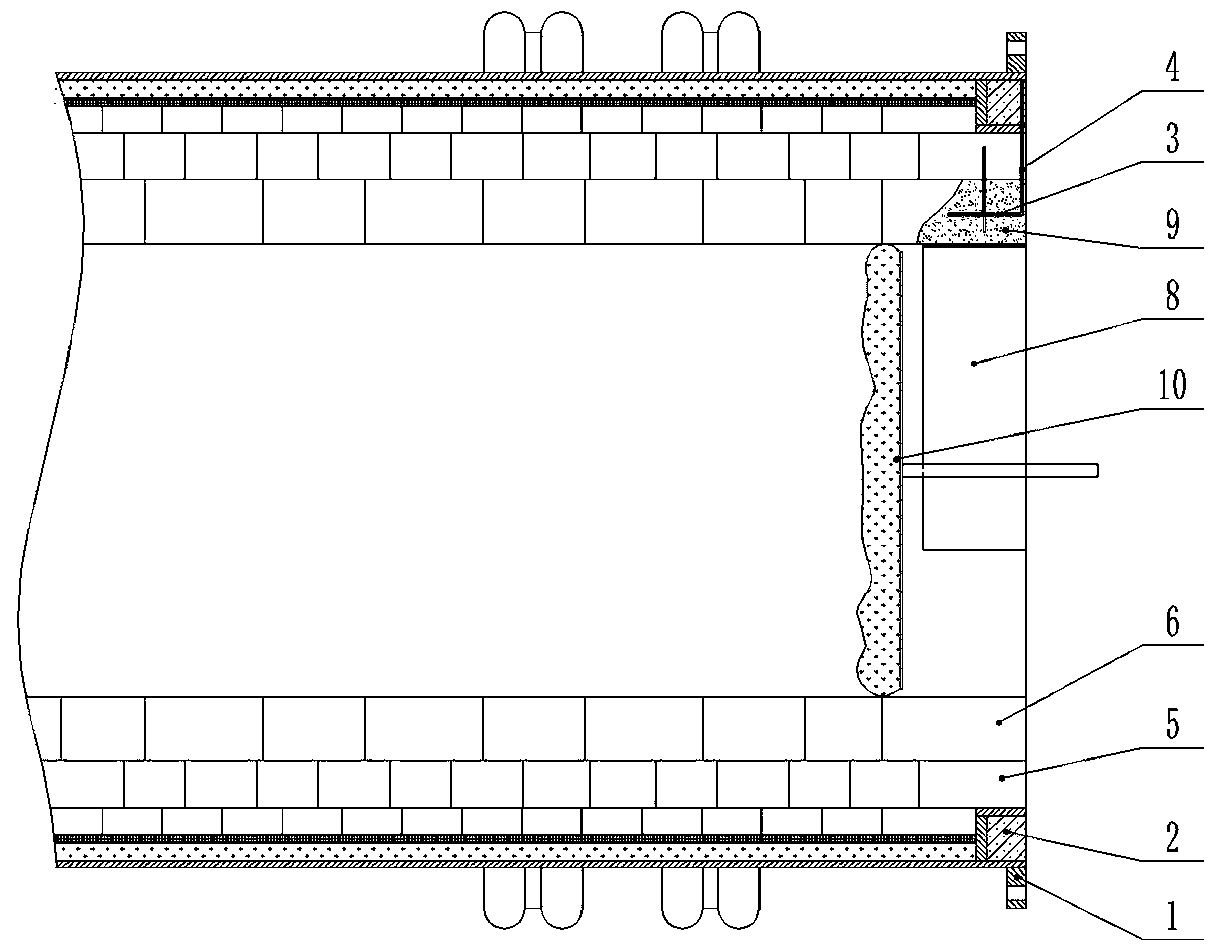

Blast furnace hot air branch pipe end hole refractory repairing method

InactiveCN110643773AMeet production environment requirementsResume production quicklyBlast furnace detailsHeating stovesFire brickRefractory

The invention relates to a blast furnace hot air branch pipe end hole refractory repairing method. The repairing method comprises the following steps that firstly, a hot air branch pipe end hole refractory damage part is thoroughly cleaned, and the part is blown by compressed air for cleaning; a pouring steel mould is manufactured according to a diameter of the inner wall of a hot air pipeline andfixed through a pouring steel mould fixing bracket; a pouring framework is manufactured and fixed; a pouring sealing plate is welded along a plane or a flange face of a original refractory end hole,and high-strength ceramic material is used for pouring; and curing, demolding and grinding are carried out on the pouring part, and the pouring part is put into use. According to the method, the hot air branch pipe end hole needing to be repaired is repaired through a principle of pouring material indefinite molding; and the pouring framework is welded and fixed to a branch pipe flange and a refractory brick seam to "take root", so that the overall stability of the pouring part is improved. The high-temperature-resistant and extrusion-resistant performance of the pouring material after solidification meets the production environment requirement of the hot air branch pipe, the heat insulation effect of the branch pipe flange is achieved, and the production requirement is met.

Owner:SGIS SONGSHAN CO LTD

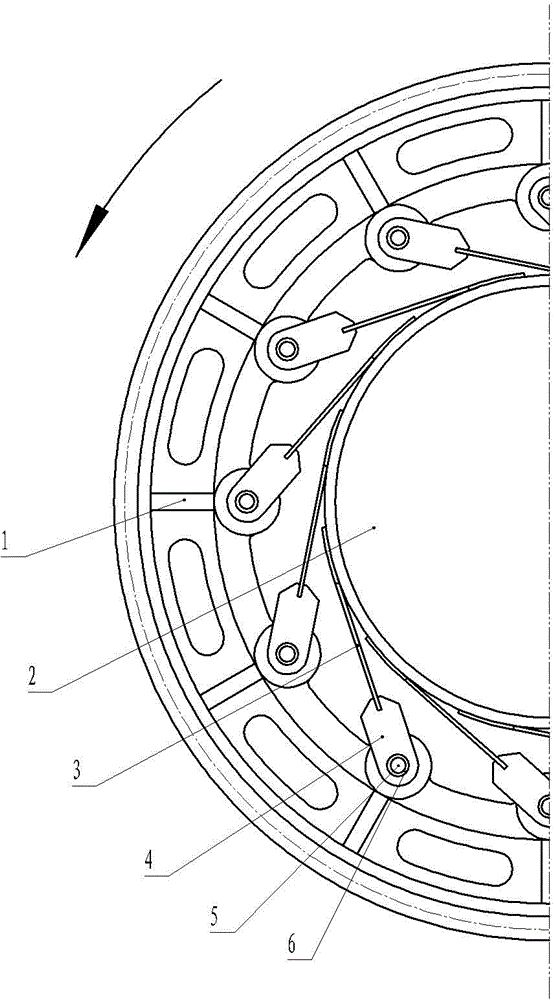

Kiln turning method for rotary kiln large-gear precise alignment

ActiveCN104390452AThe construction process is simple and fastLow costRotary drum furnacesTime efficientGear wheel

The invention discloses a kiln turning method for rotary kiln large-gear precise alignment and relates to the technical field of rotary kiln large-gear installation. A rotary kiln comprises a large gear installed outside a barrel body in a sleeving mode, wherein multiple pin holes are distributed in the inner edge position of the large gear, the large gear is in meshed connection with a small gear, and the small gear is connected with an auxiliary motor through a speed reducer. The kiln turning method comprises the following steps of (A) using multiple spring connecting plates to enable the large gear 1 and the barrel body to be connected; (B) using press wires to fix the long side edges of the spring plates to the barrel body, wherein the arc-shaped concave faces of the spring plates mutually abut against limiting blocks; (C) starting the auxiliary motor to drive the barrel body to rotate and measuring the radial and axial run-out amounts of the large gear; (D) adjusting the large gear; (E) repeating the step B and the step C till the measured radial and axial run-outs of the large gear are qualified; (F) dismounting the press wires and the limiting blocks and enabling the spring plates to be welded with the barrel body. Compared with the prior art, the kiln turning method does not need to dismount spring plates and does not need to repeatedly adjust the press wires and the limiting blocks as well when the large gear is adjusted, and the time and cost are saved.

Owner:GUANGXI YUFENG CEMENT

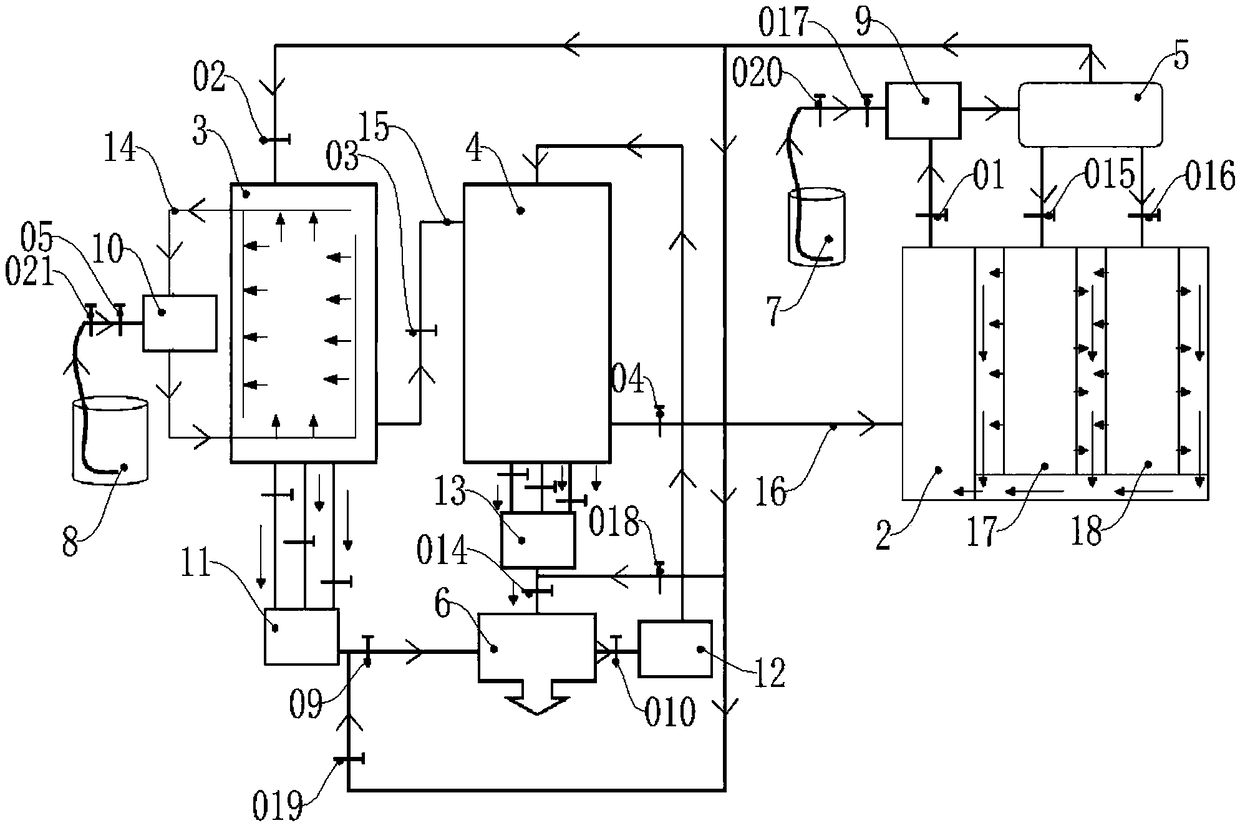

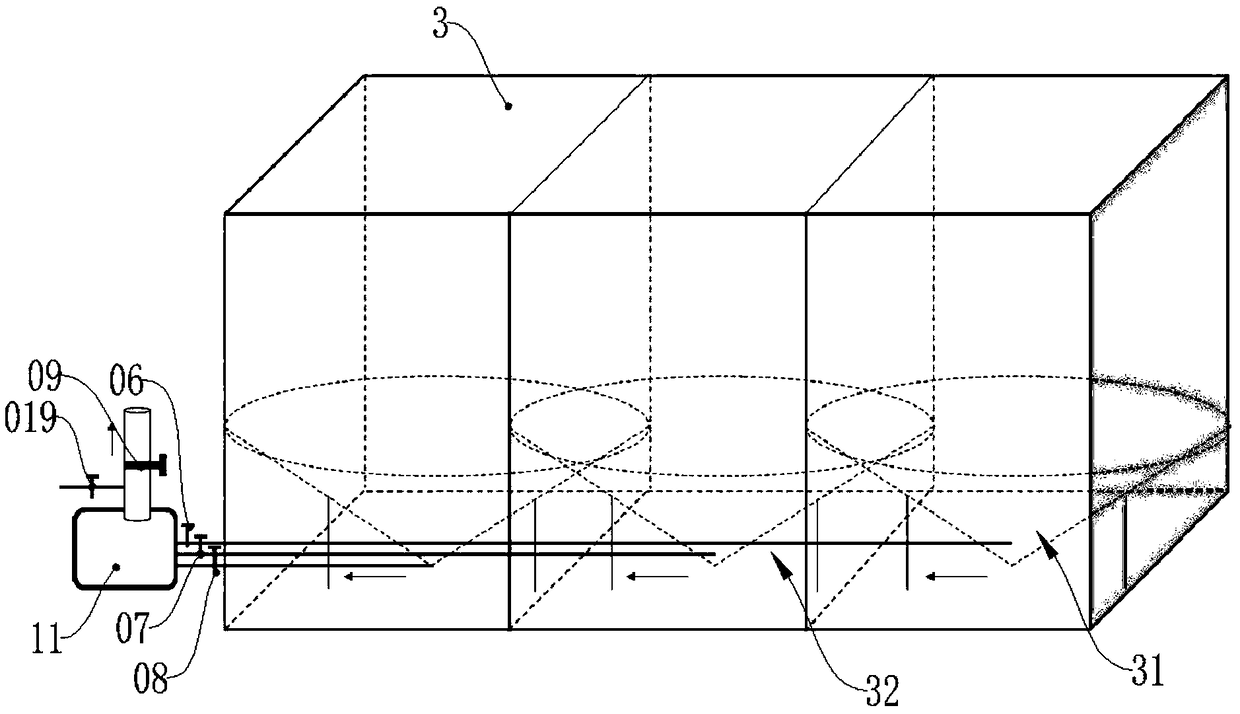

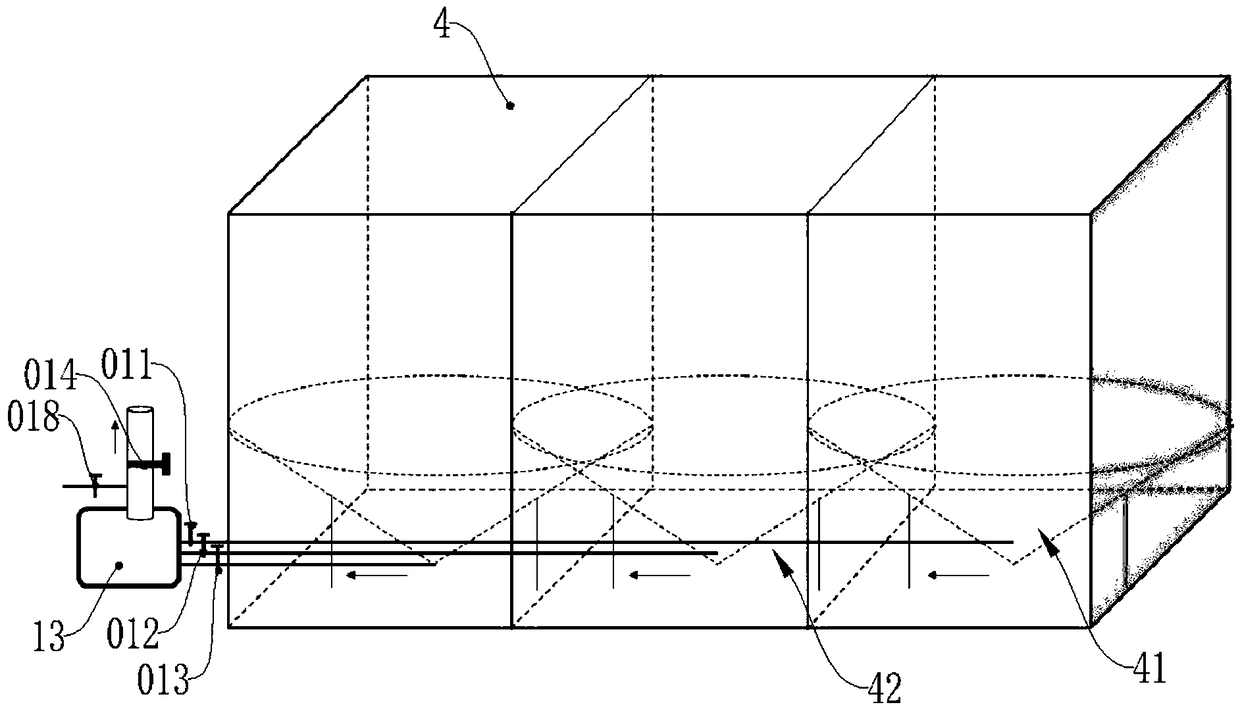

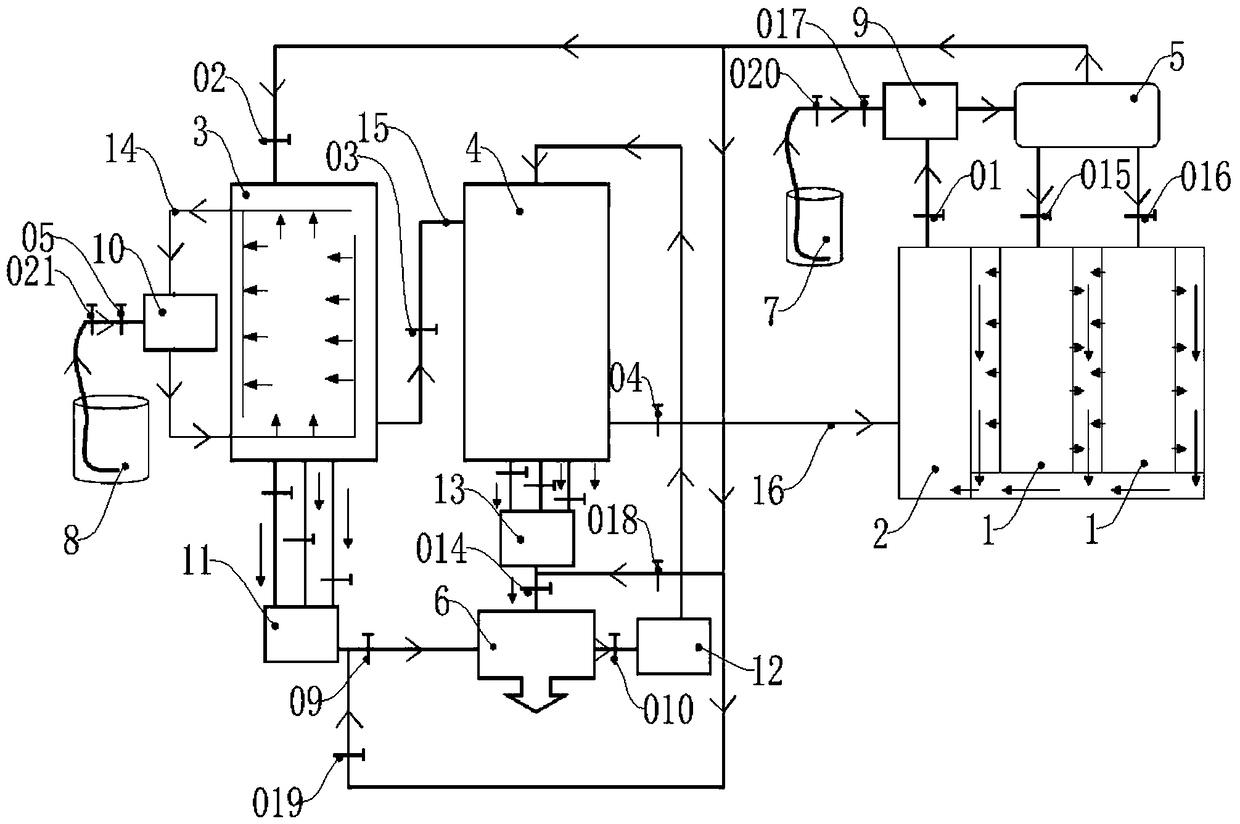

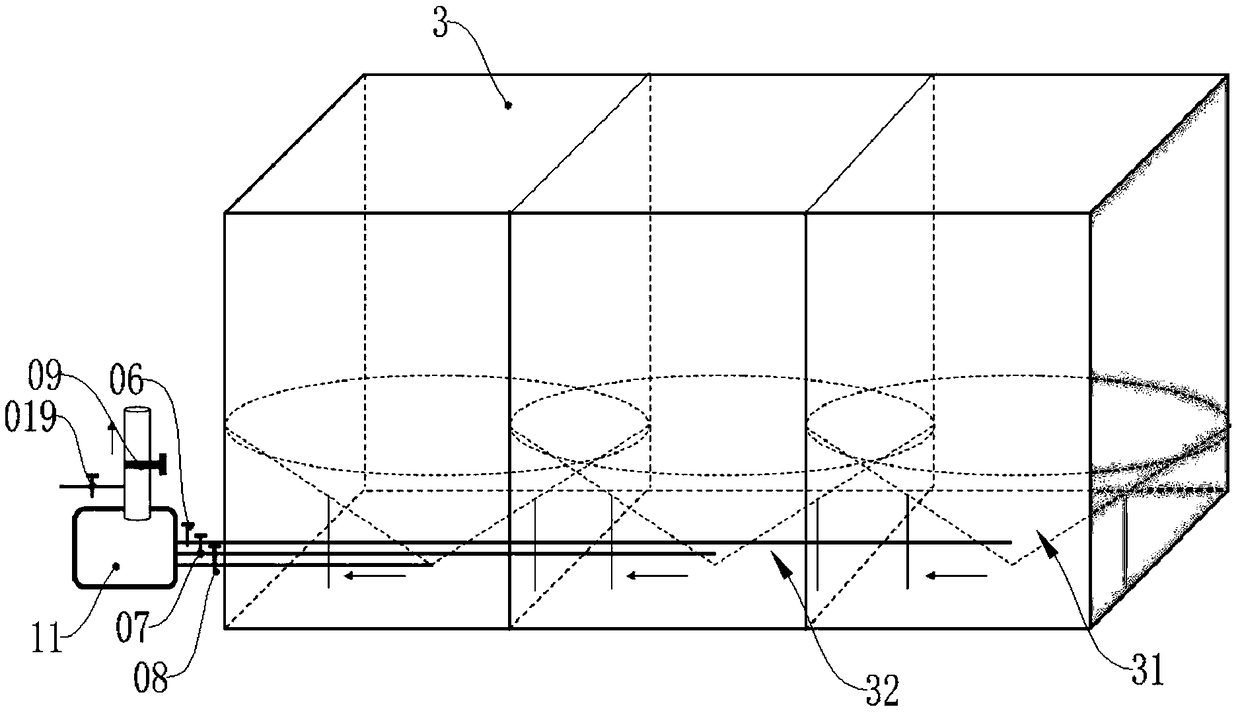

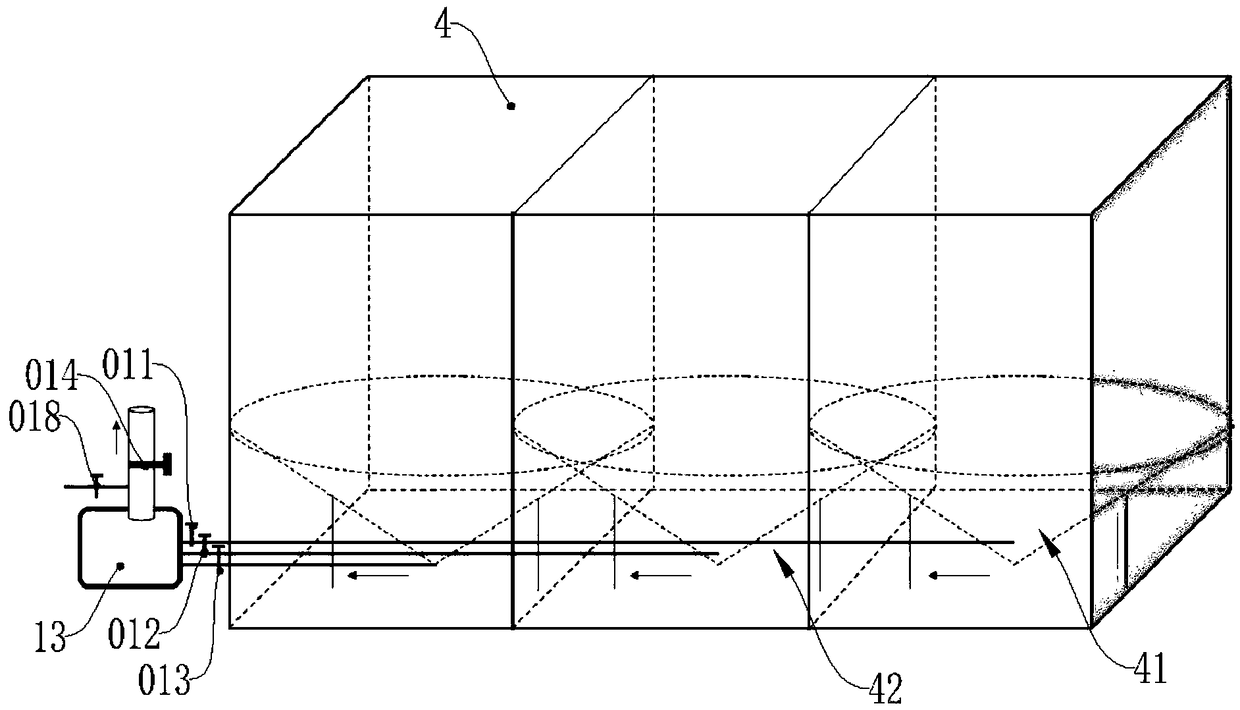

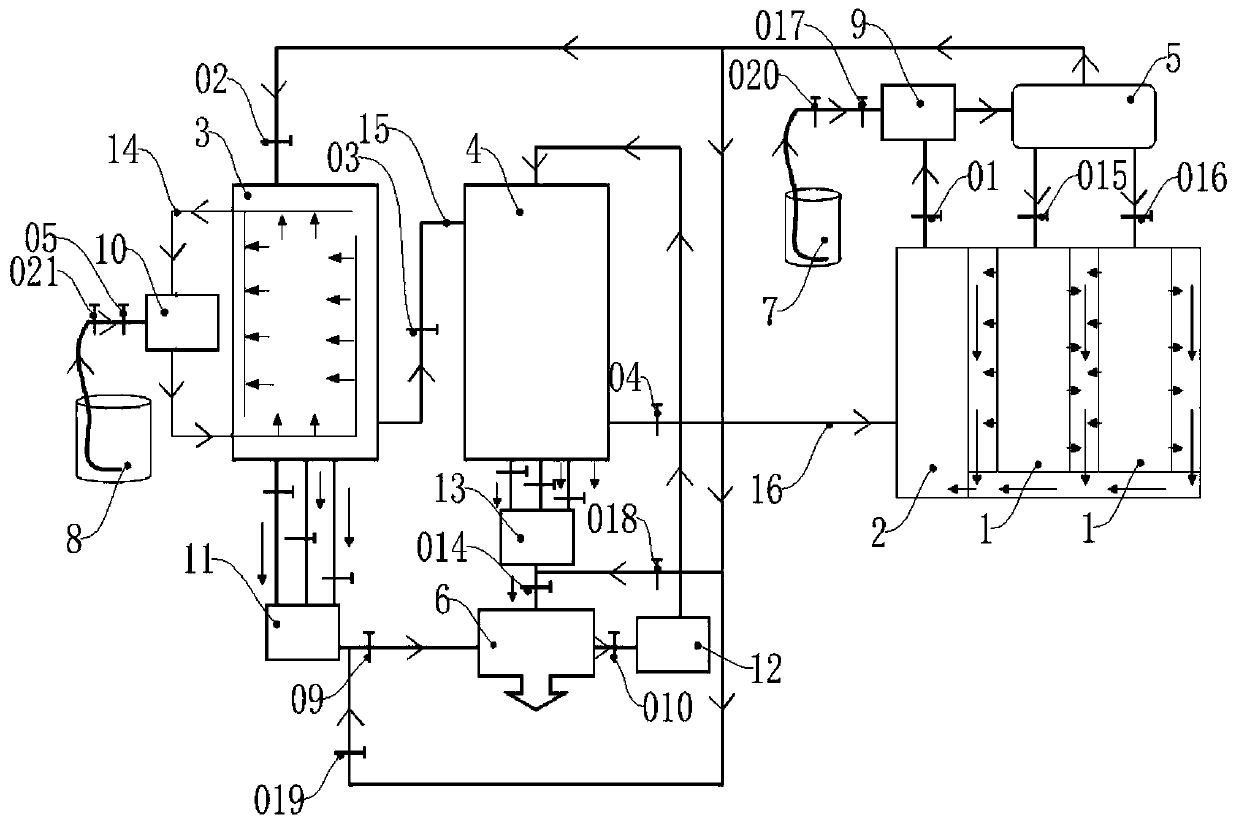

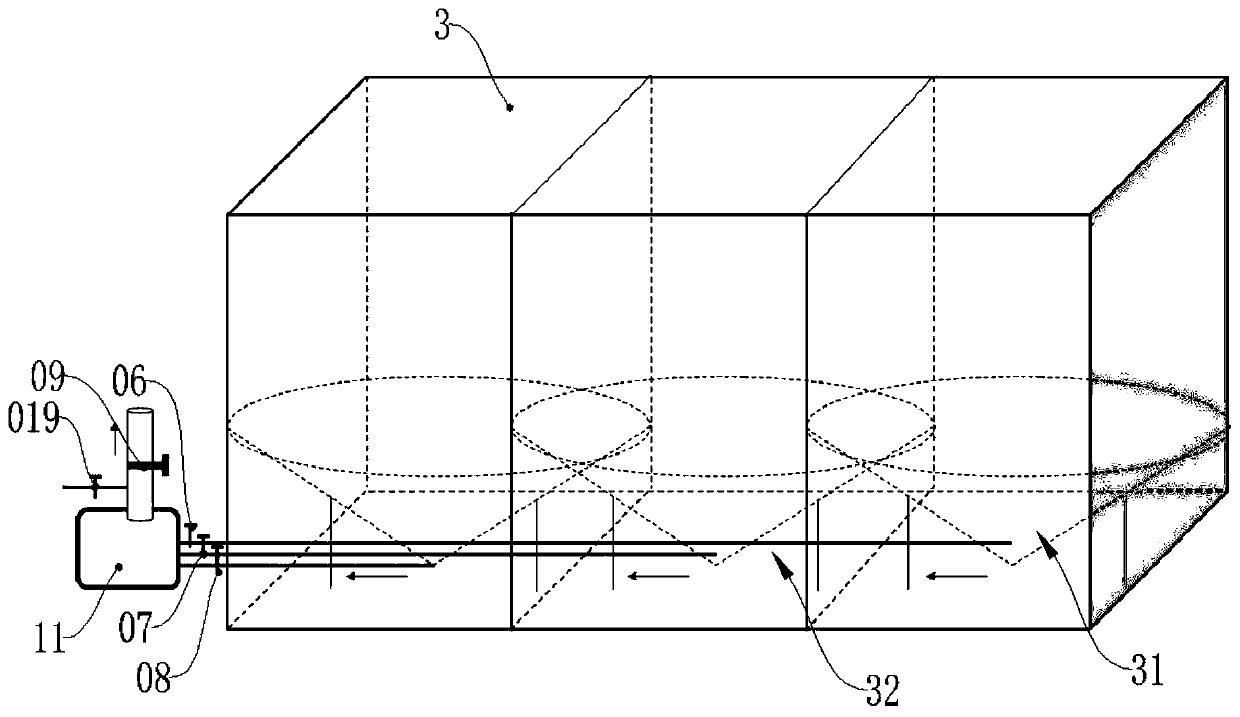

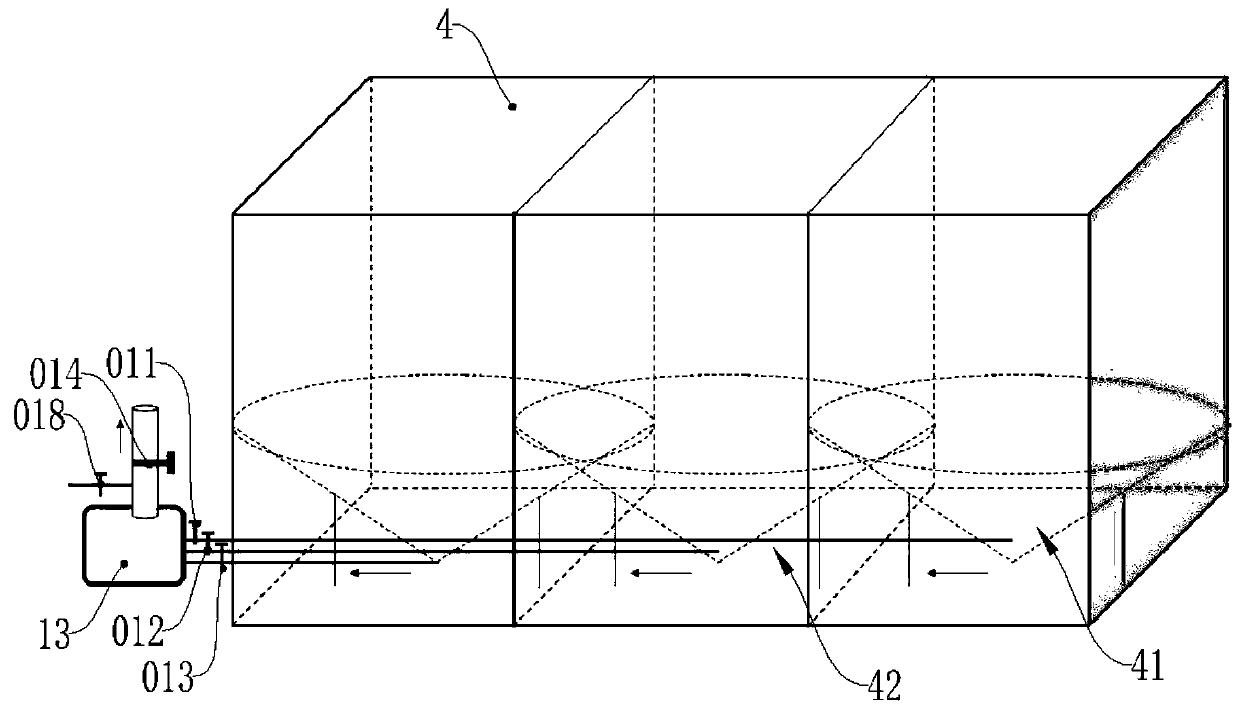

A configuration and method for recovering oxidation liquid in a transformed oxidation line and protecting a single-nickel-salt coloring tank

A configuration for recovering oxidation liquid in a transformed oxidation line and protecting a single-nickel-salt coloring tank is disclosed. The configuration includes an oxidation liquid collection system, an oxidation liquid circulating and cooling system, an oxidation liquid treatment system, an oxidation liquid separation system, an oxidation liquid recovery and recrystallization system anda single-nickel-salt coloring tank protecting system. The invention further discloses a method adopting the configuration to recover the oxidation liquid and protect the single-nickel-salt coloring tank. The method includes oxidation liquid collecting, oxidation liquid circulating and cooling, oxidation liquid treatment and separation, oxidation liquid recovery and recrystallization, and single-nickel-salt coloring tank protection steps. The configuration and method achieve on-line crystallization and separation of aluminum ions and cyclic use of the oxidation liquid, can effectively reduce resistance of the oxidation liquid, greatly reduce the risk that the single-nickel-salt coloring tank is polluted, save water and achieve low-cost high-quality production.

Owner:FOSHAN SANSHUI XIONGYING INNOVATION CENT FOR ALUMINUM SURFACE TECH

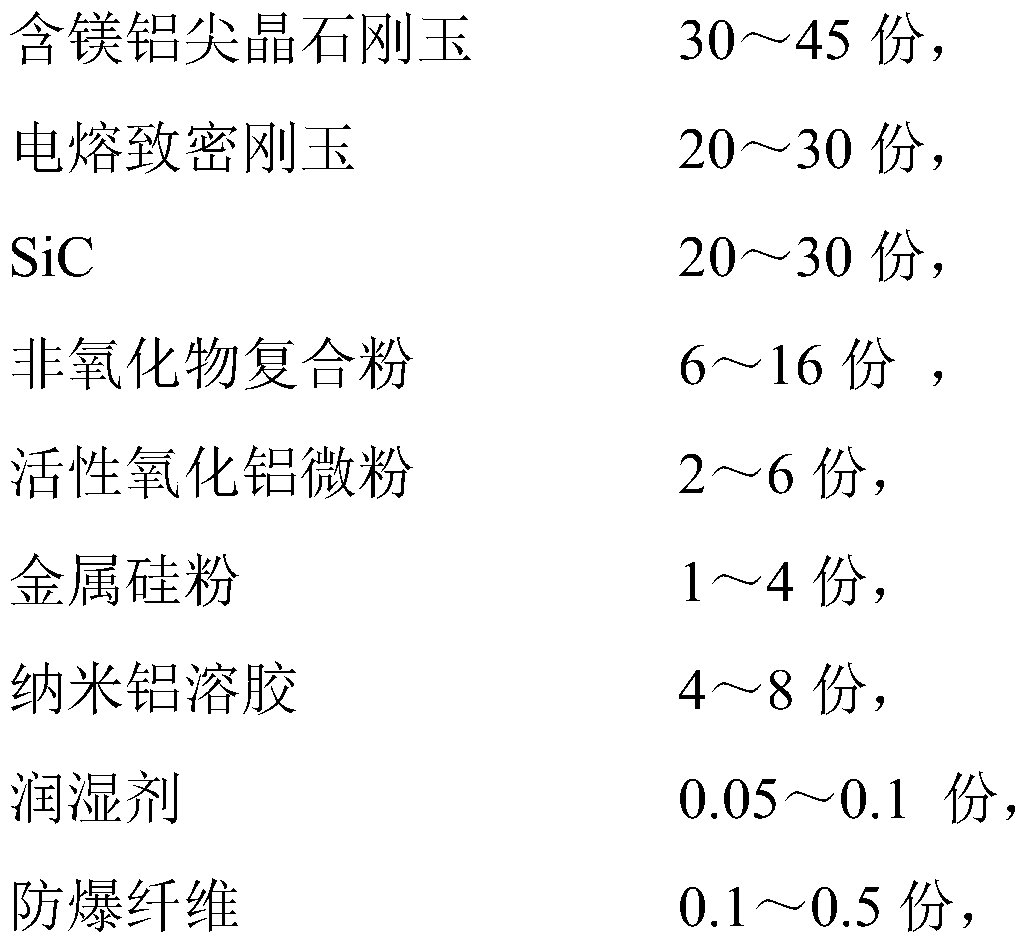

Nano-sol combined wear-resistant board used for main iron channel of blast furnace and production method and application thereof

ActiveCN109851333AImprove erosion and wear resistanceImprove thermal shock resistanceFiberWear resistant

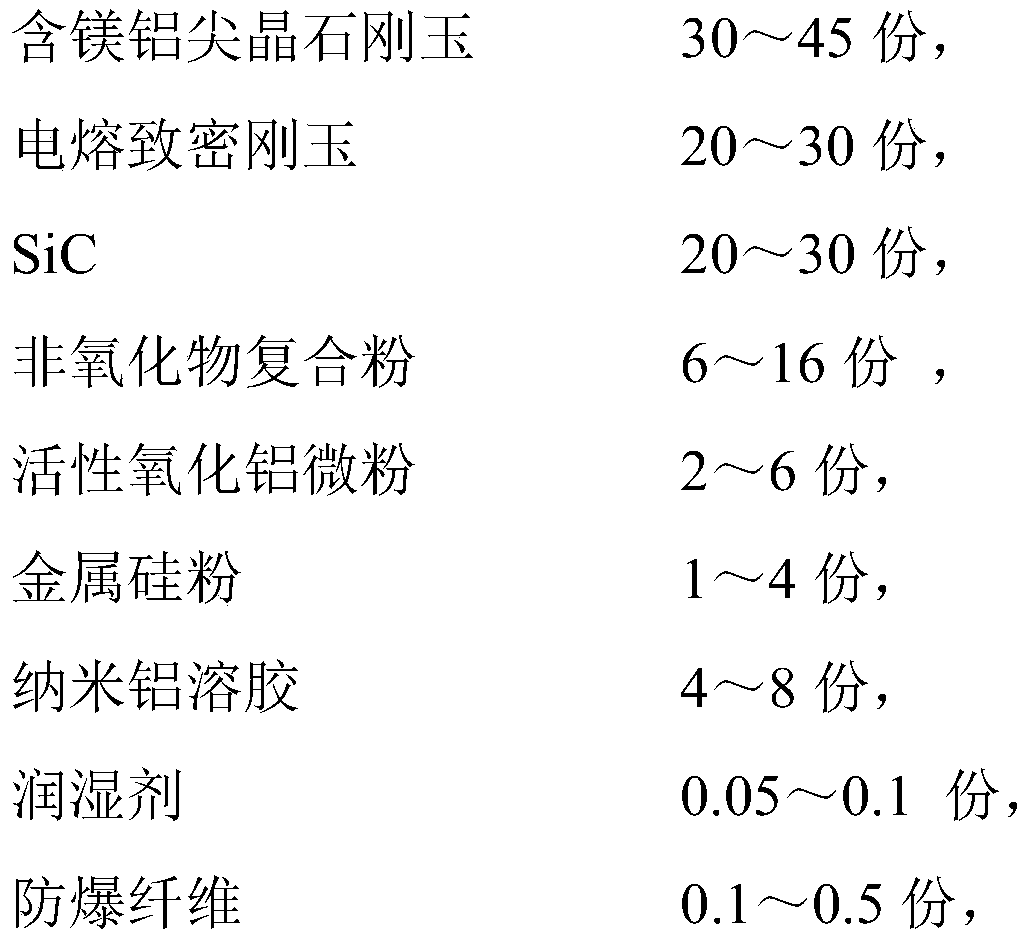

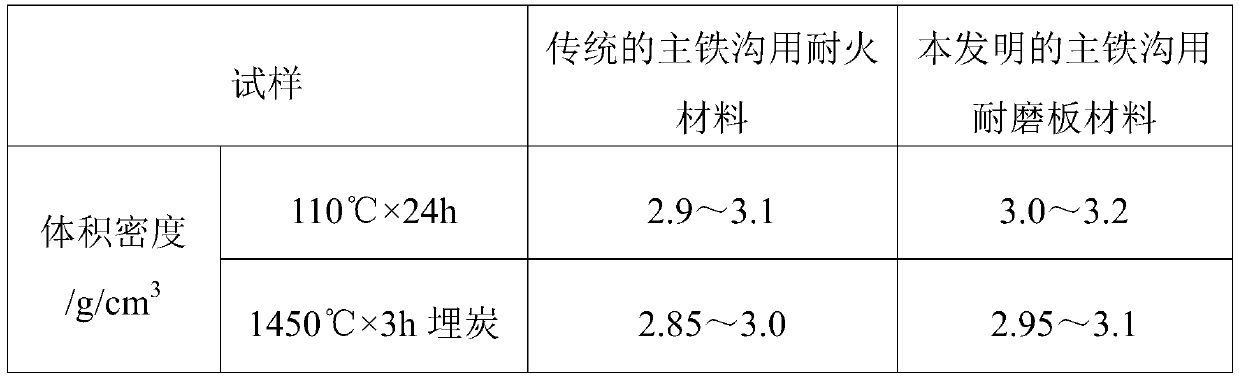

The invention discloses a nano-sol combined wear-resistant board used for a main iron channel of a blast furnace. Raw materials of the wear-resistant board comprise, in parts by weight, 30-45 parts ofmagnesium-containing aluminium-containing spinel alumina, 20-30 parts of electro-fused dense alumina, 20-30 parts of SiC, 6-16 parts of nonoxide compound powder, 2-6 parts of activated aluminium oxide micro powder, 1-4 parts of silicon metal powder, 4-8 parts of nano-aluminum sol, 0.05-0.1 part of wetting agent and 0.1-0.5 part of explosion-proof fibers, wherein the nonoxide compound powder is composed of, in parts by weight, 1-3 parts of carbon black, 2-4 parts of silicon nitride, 1-5 parts of titanium carbonitride and 2-4 parts of aluminium titanate. The invention further discloses a production method and application of the wear-resistant board. By means of the nano-sol combined wear-resistant board used for the main iron channel of the blast furnace and the production method and the application thereof, the erosion resistance, the wear resistance and the corrosion resistance of a lining material of the main iron channel can be improved, a work environment of workers can be improved, remedial work time of the main iron channel can be shortened, and the service life of the main iron channel can be prolonged.

Owner:CHINA JINGYE ENG TECH CO LTD +2

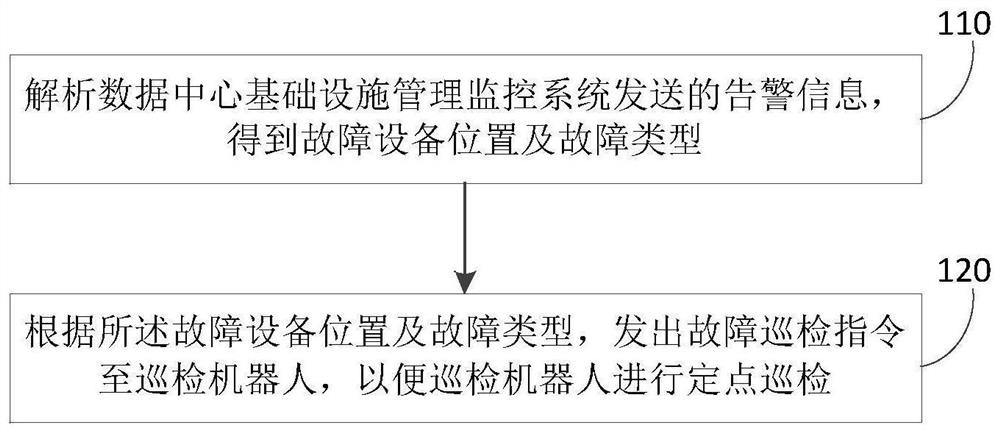

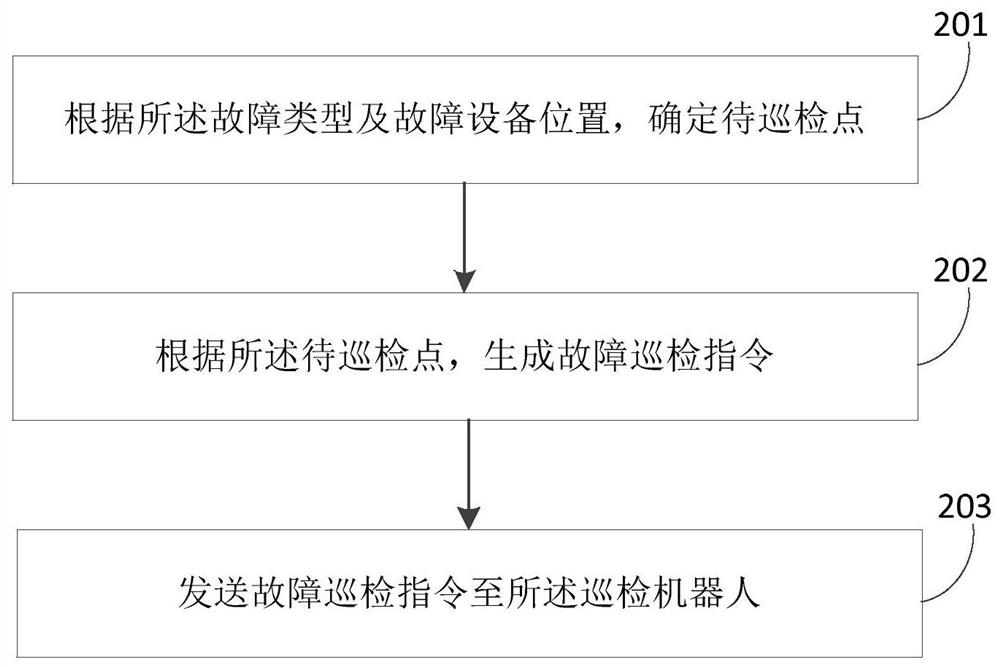

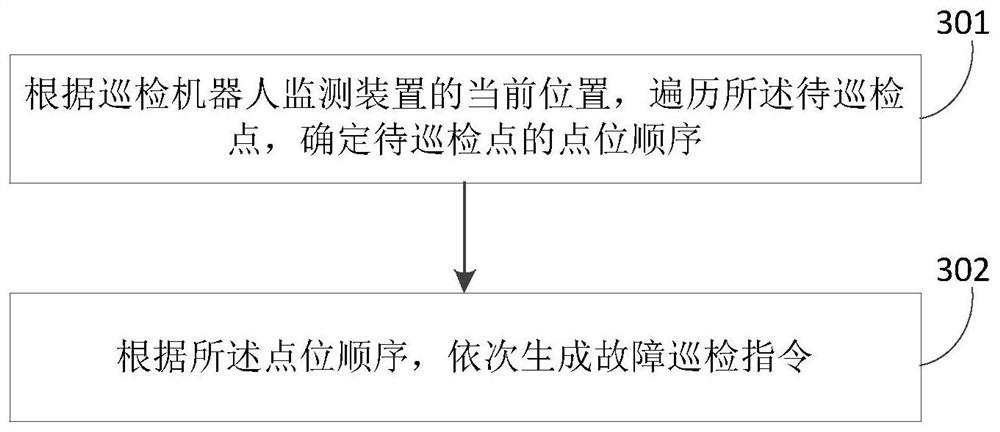

Fault inspection method and device based on alarm information linkage

PendingCN113052993AResume production quicklyRapid productionChecking time patrolsData center infrastructure managementComputer science

The invention provides a fault inspection method and device based on alarm information linkage, and the method comprises the steps: analyzing alarm information sent by a data center infrastructure management system, and obtaining the position of fault equipment and a fault type; and according to the fault equipment position and the fault type, sending a fault inspection instruction to an inspection robot, so that the inspection robot performs fixed-point inspection, thereby determining a fault reason. According to the invention, when the equipment in the data center has a fault alarm, the inspection robot can quickly perform fixed-point inspection on the fault equipment, and emergency measures are taken according to the inspection result, so that the fault processing time is shortened, and production is quickly recovered.

Owner:INDUSTRIAL AND COMMERCIAL BANK OF CHINA

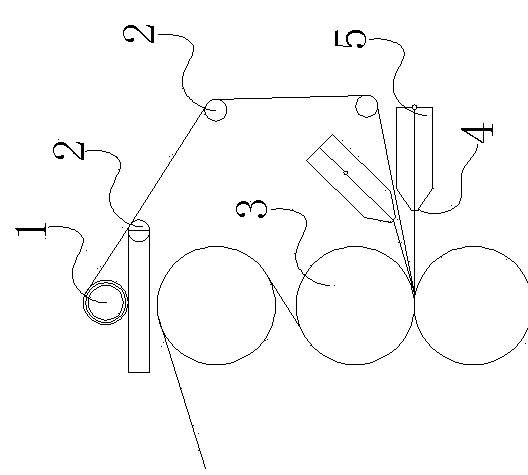

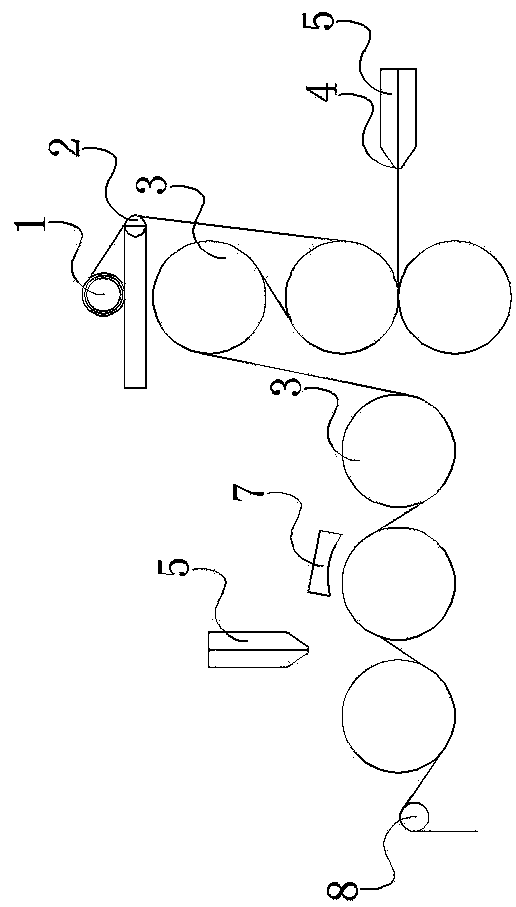

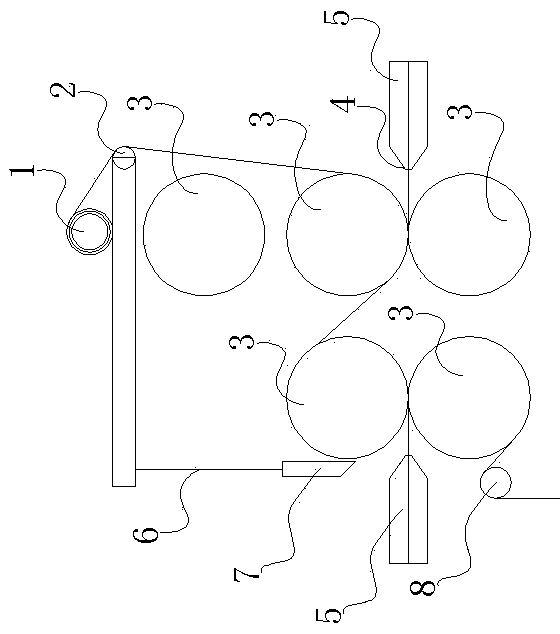

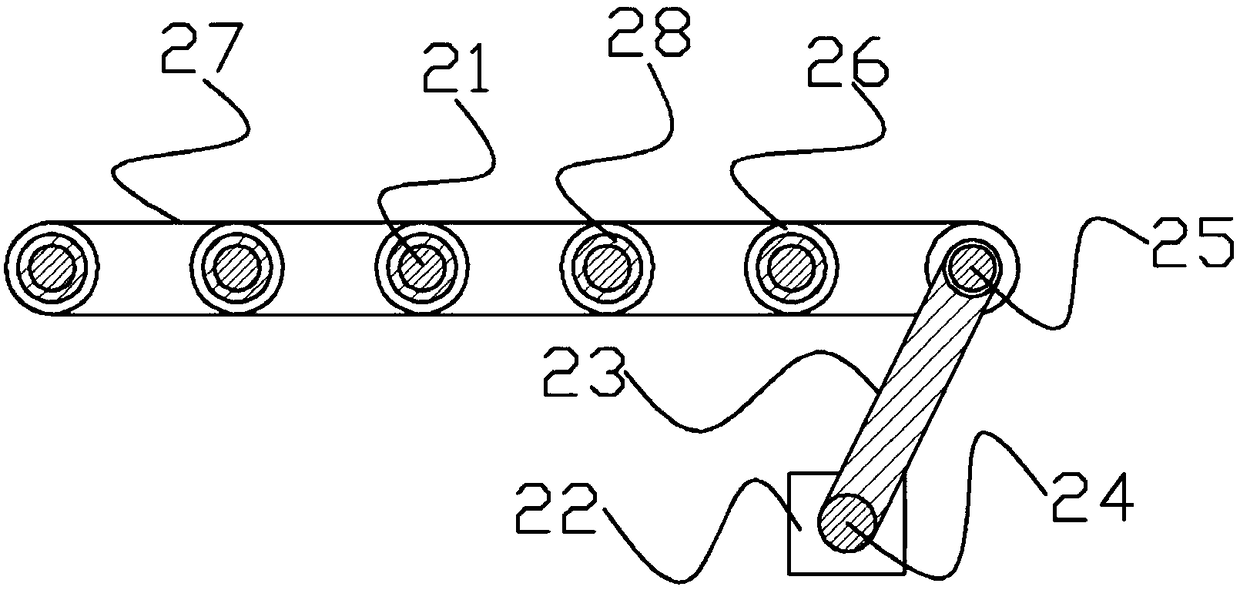

High-molecular coiled material extrusion composite device

The invention relates to a high-molecular coiled material production device, and concretely provides a high-molecular coiled material extrusion composite device. The high-molecular coiled material extrusion composite device is composed of composite rollers, high-molecular extrusion dies, regulating screws and a hot air blowing and melting machine. The two removable high-molecular extrusion dies are respectively arranged at two sides of the device. The high-molecular extrusion dies have a tapered structure. Adjusting screws are arranged at both the upper part and the lower part of each high-molecular extrusion die. At least three composite rollers are arranged at the right side of the device from up to down. At least two composite rollers are arranged at the left side of the device from up to down. A hot air blowing and melting machine is arranged at the upper part of the left side of the device and above the composite rollers. A support bar is arranged on the hot air blowing and melting machine. A wind-up roller is arranged under the left high-molecular extrusion dies. Output rollers are arranged above right composite rollers. The output rollers are connected with a grid cloth roller.

Owner:JIANGSU CANLON BUILDING MATERIALS

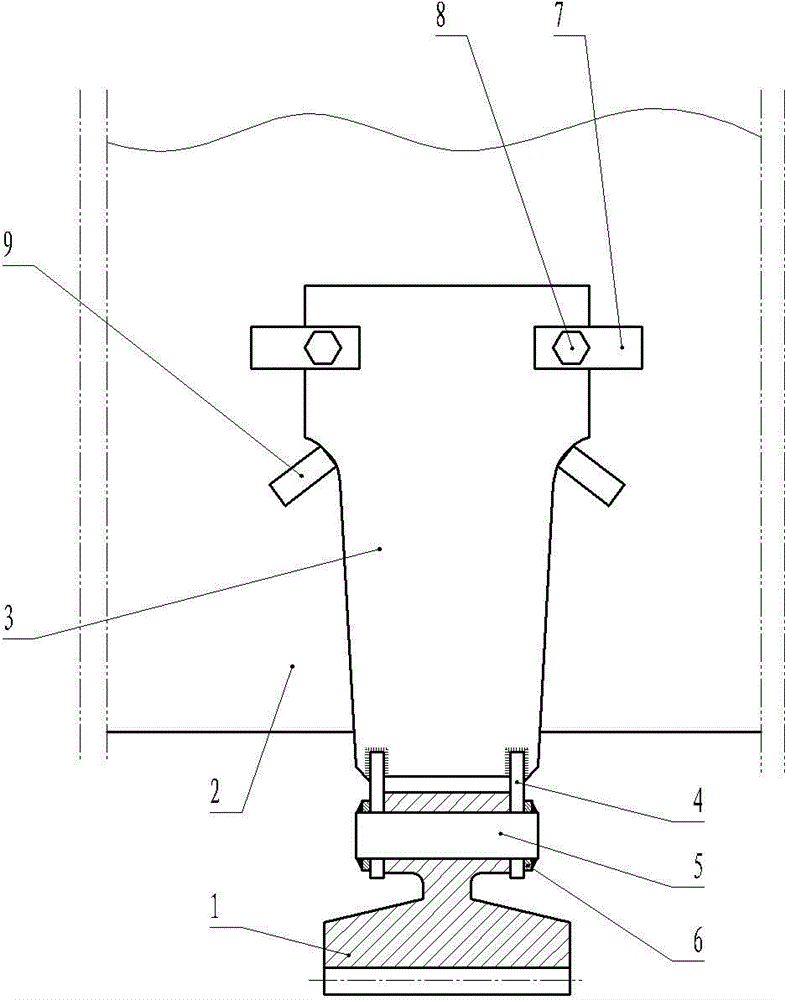

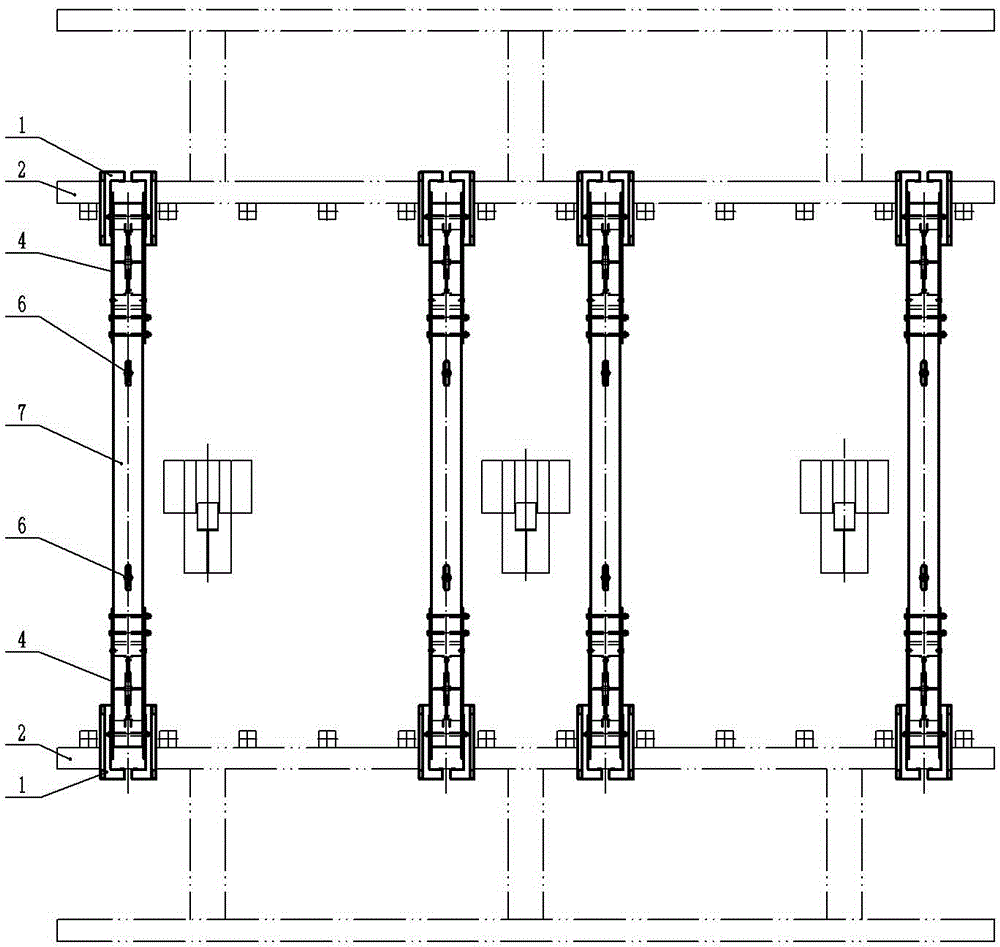

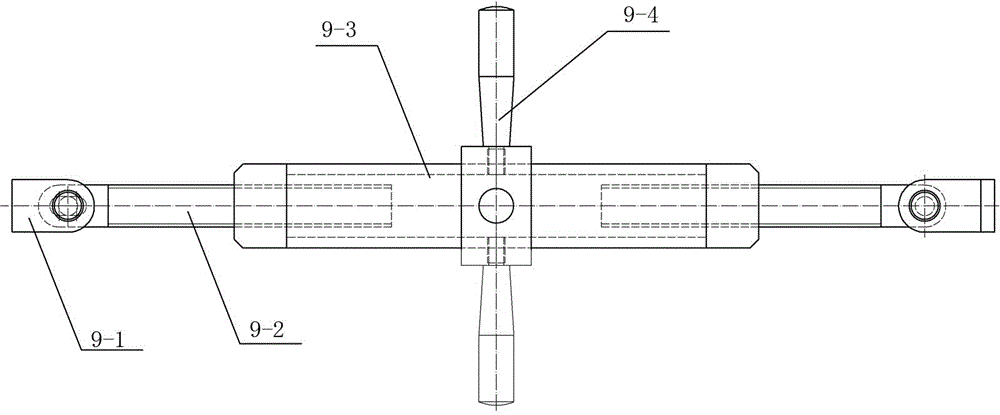

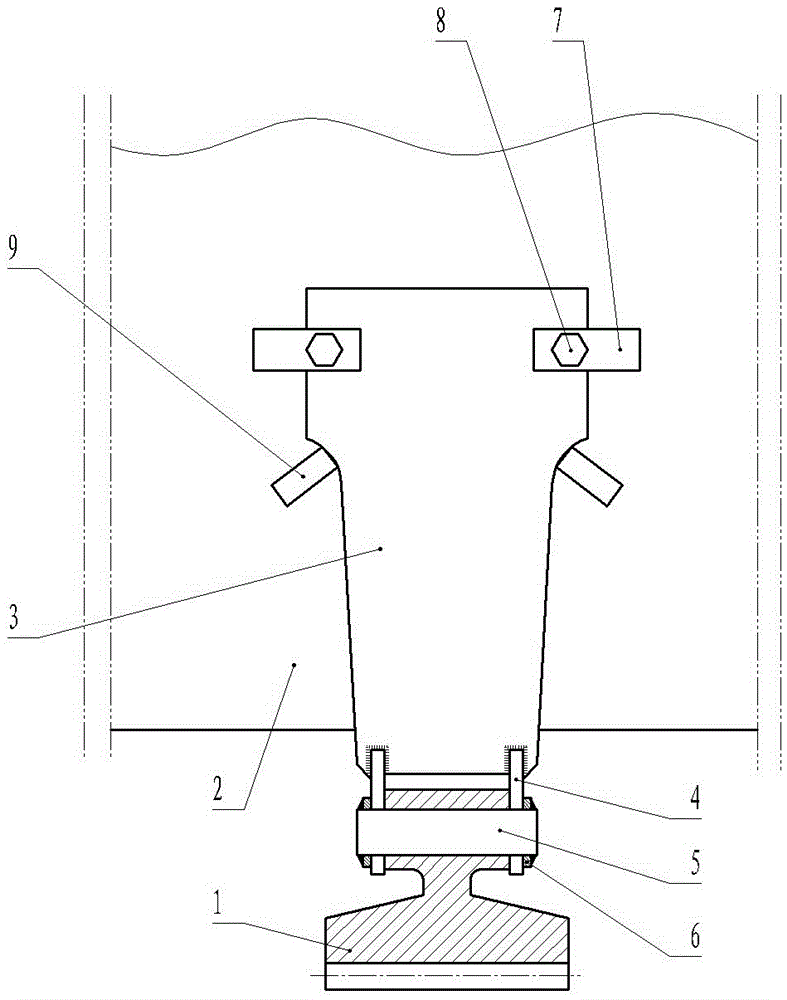

Emergency short-circuit device and method for aluminum electrolytic cell

The invention relates to the technical field of short circuit treatment of aluminum cells, and particularly relates to an emergency short circuit device and method of an aluminum cell. The emergency short circuit device disclosed by the invention comprises a guide bus, a crimping bus, a transitional soft connector and a clamp, wherein a support beam is supported and fixed together with the guide bus, the crimping bus and the transitional soft connector. The emergency short circuit device is simple in structure, convenient to install, reliable to crimp, and high in security, and can be accurately positioned. By adopting the device and the method disclosed by the invention, rapid short circuit operation of a worker is facilitated; the time is saved; the loss caused by power failure is reduced; the emergency short circuit device can be suitable for various accidents of the electrolytic cell; rapid recovery of production can be achieved; the time is saved; the connection part is easily dismantled; and the emergency short circuit device is simple to operate, fast and feasible, and has good maneuverability.

Owner:ZHENGZHOU LIGHT METAL TECH

Rotary Kiln Method for Fine Alignment of Large Gear in Rotary Kiln

ActiveCN104390452BThe construction process is simple and fastLow costRotary drum furnacesTime efficientGear wheel

The invention discloses a kiln turning method for rotary kiln large-gear precise alignment and relates to the technical field of rotary kiln large-gear installation. A rotary kiln comprises a large gear installed outside a barrel body in a sleeving mode, wherein multiple pin holes are distributed in the inner edge position of the large gear, the large gear is in meshed connection with a small gear, and the small gear is connected with an auxiliary motor through a speed reducer. The kiln turning method comprises the following steps of (A) using multiple spring connecting plates to enable the large gear 1 and the barrel body to be connected; (B) using press wires to fix the long side edges of the spring plates to the barrel body, wherein the arc-shaped concave faces of the spring plates mutually abut against limiting blocks; (C) starting the auxiliary motor to drive the barrel body to rotate and measuring the radial and axial run-out amounts of the large gear; (D) adjusting the large gear; (E) repeating the step B and the step C till the measured radial and axial run-outs of the large gear are qualified; (F) dismounting the press wires and the limiting blocks and enabling the spring plates to be welded with the barrel body. Compared with the prior art, the kiln turning method does not need to dismount spring plates and does not need to repeatedly adjust the press wires and the limiting blocks as well when the large gear is adjusted, and the time and cost are saved.

Owner:GUANGXI YUFENG CEMENT

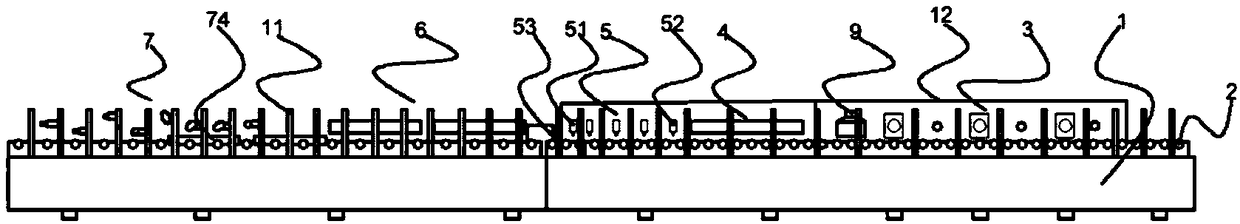

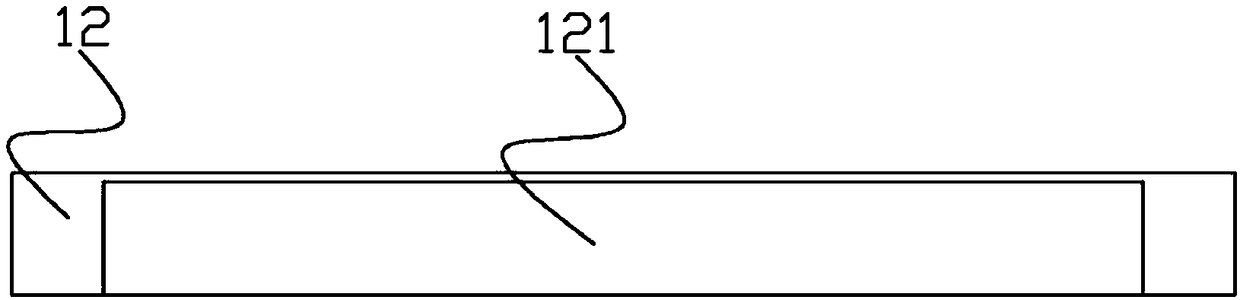

Full automatic V-groove cutting and edging machine

PendingCN109227815AGuaranteed toughnessImprove adhesionWood mortising machinesBark-zones/chip/dust/waste removalAdhesiveEngineering

The invention discloses a full automatic V-groove cutting and edging machine. The full automatic V-groove cutting and edging machine comprises a machine body base, a transmission device, a cutting device, a lifting device, a pre-heating device, an adhesive dispensing device, an edging device, a dust sucking device and a heating device, wherein the transmission device is fixedly arranged on the topof the machine body base, the cutting device, the dust sucking device, the preheating device, the adhesive dispensing device, the heating device and the edging device are fixedly arranged on the machine body base in the length direction of the machine body and arranged above the transmission device, and the lifting device is arranged on the bottom of the cutting device and fixedly connected withthe machine body base. The cutting device is used for forming a V groove; the heating device and the preheating device can heat an adhesive for adhesive dispensing; the dust sucking device is used forsucking wood chips; the lifting device is used for adjusting the depth of the cut V shape; an adhesive stirring device is arranged on the adhesive dispensing device, and the adhesive is stirred so that adhesive dispersing can be facilitated; a white adhesive gun and a yellow adhesive gun are arranged on the adhesive dispersing device so that the toughness of the adhesive can be enhanced, and a running roller prepared by using the machine is resistant to ageing, tough and long in service life.

Owner:顾银军

Configuration of improving existing oxidation tank to recover anode oxidation solution and method

ActiveCN109137034AEfficient handlingEfficient recyclingAnodisationCellsSolution treatmentAluminum Ion

The invention discloses a configuration of improving an existing oxidation tank to recover an anode oxidation solution. An oxidation solution collecting system, an oxidation solution circulation cooling system, an oxidation solution treatment system, an oxidation solution separation system and an oxidation solution recovering and recrystallizing system are included. The invention further disclosesa method for recovering the anode oxidation solution using the configuration of improving the existing oxidation tank to recover the anode oxidation solution. The method comprises the steps of oxidation solution collecting, oxidation solution circularly cooling, oxidation solution processing and separating, and oxidation solution recovery and recrystallizing. By means of the configuration and themethod, online crystal precipitation of aluminum ions and oxidation solution circular use can be achieved to effectively reduce oxidation solution resistance and achieve low-cost high-quality production.

Owner:FOSHAN SANSHUI XIONGYING INNOVATION CENT FOR ALUMINUM SURFACE TECH

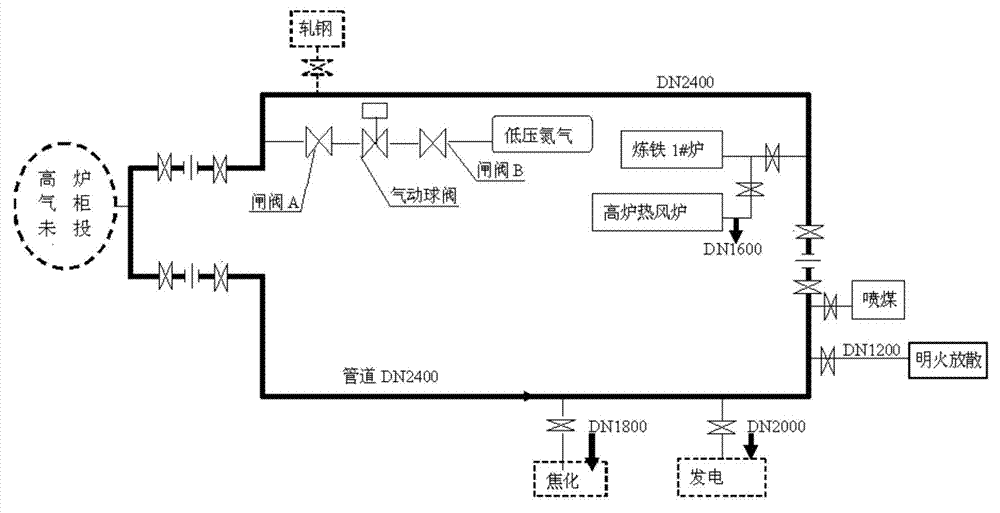

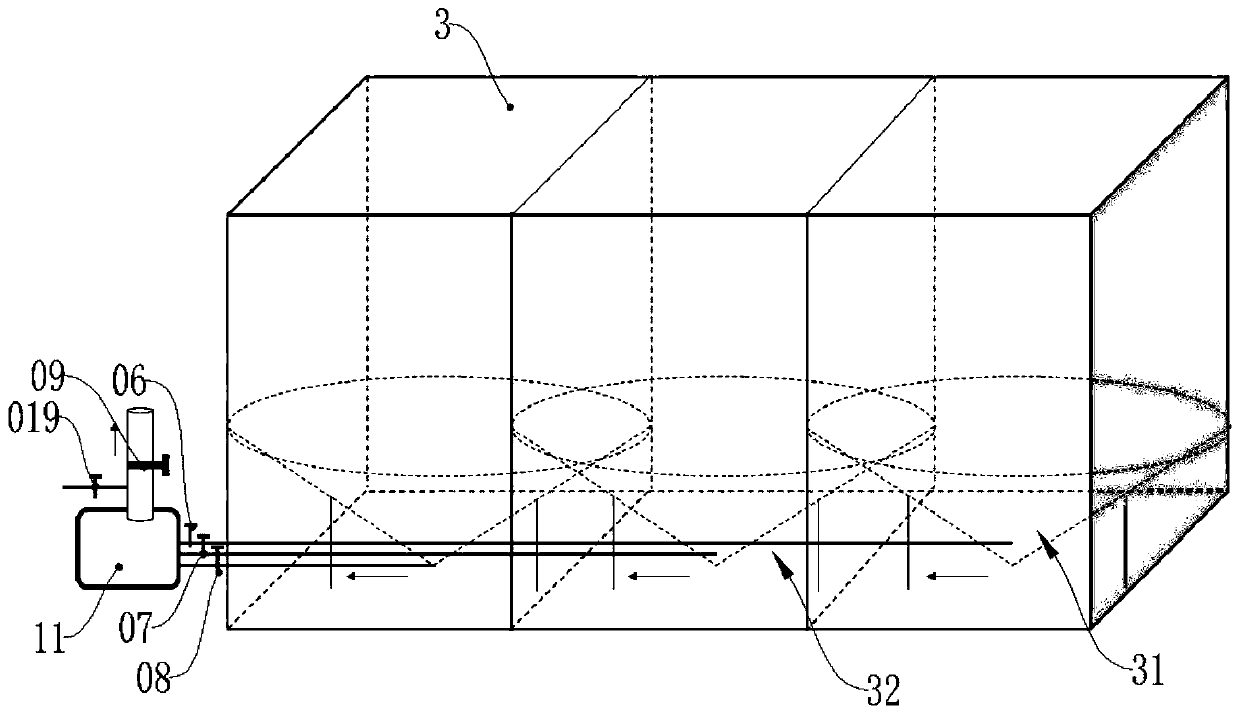

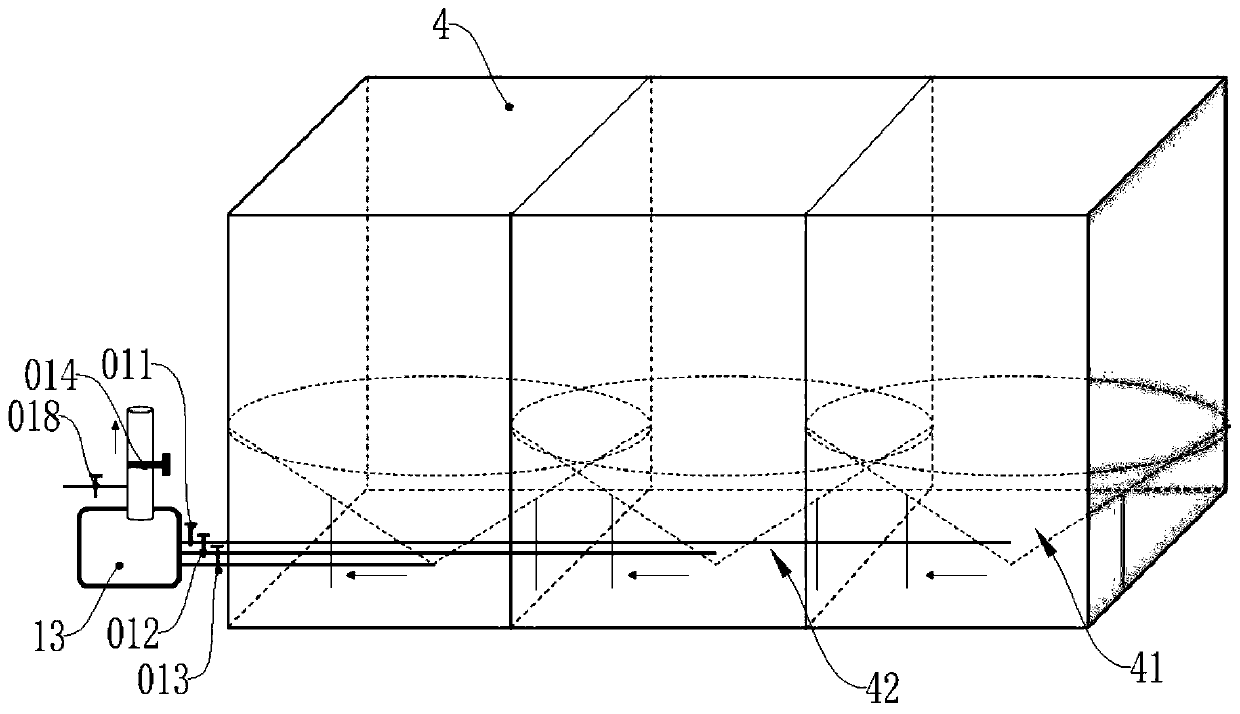

Safety operation method for gaspipe network in gasometer-free single-seated blast furnace production

ActiveCN103571985AGuaranteed positive pressureResume production quicklyBlast furnace detailsBack-firePositive pressure

The invention discloses a safety operation method for a gaspipe network in gasometer-free single-seated blast furnace production. A blast furnace is an ironmaking blast furnace; the gaspipe network is further connected with a gas consumption unit, and connected with a low-pressure nitrogen gas pipe network through a nitrogen gas pipeline. The invention further provides a safety operation method for the gaspipe network. By adopting the technical scheme, under the situation that the pipe network is in loss of pressure, gas consumption users have time to turn off a burner valve, so as to guarantee the positive pressure of the pipe network, prevent the occurrence of back fire explosion accidents and guarantee the operation safety and stability of the pipe network. After the blast furnace obtains air again, the interior of the pipeline is always in positive pressure without the entry of air, the explosion-proof tests for blast-furnace gas consumption users are qualified within short time, and users can be guaranteed to fast resume production.

Owner:WUHU XINXING DUCTILE IRON PIPES

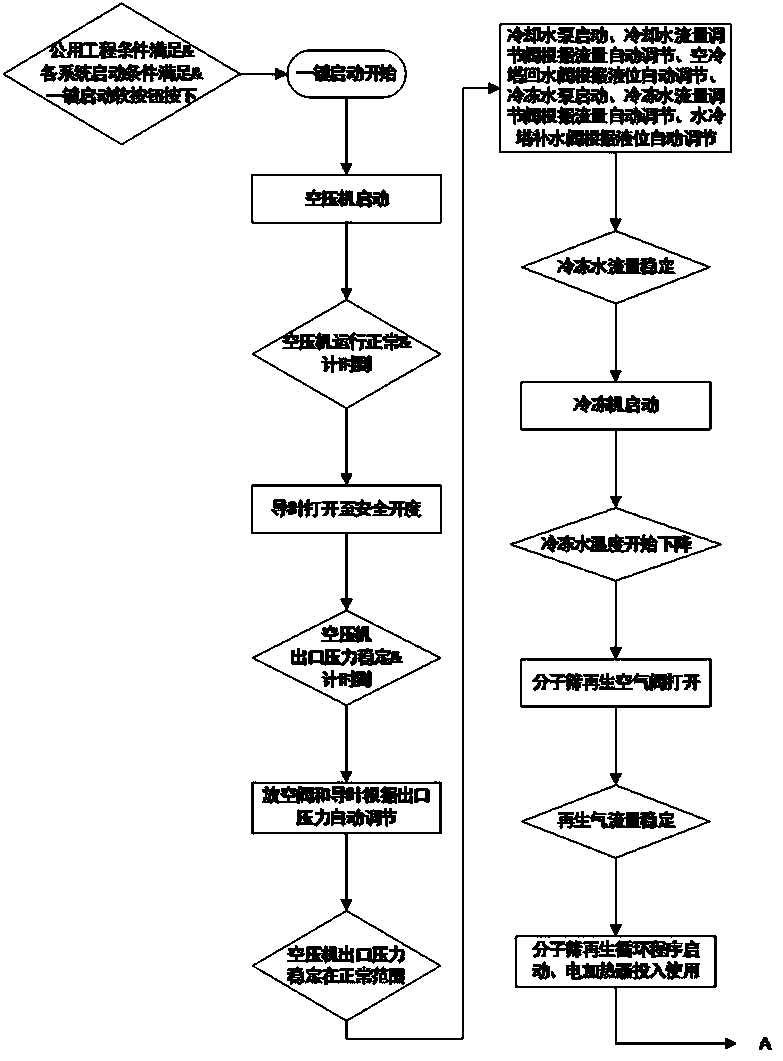

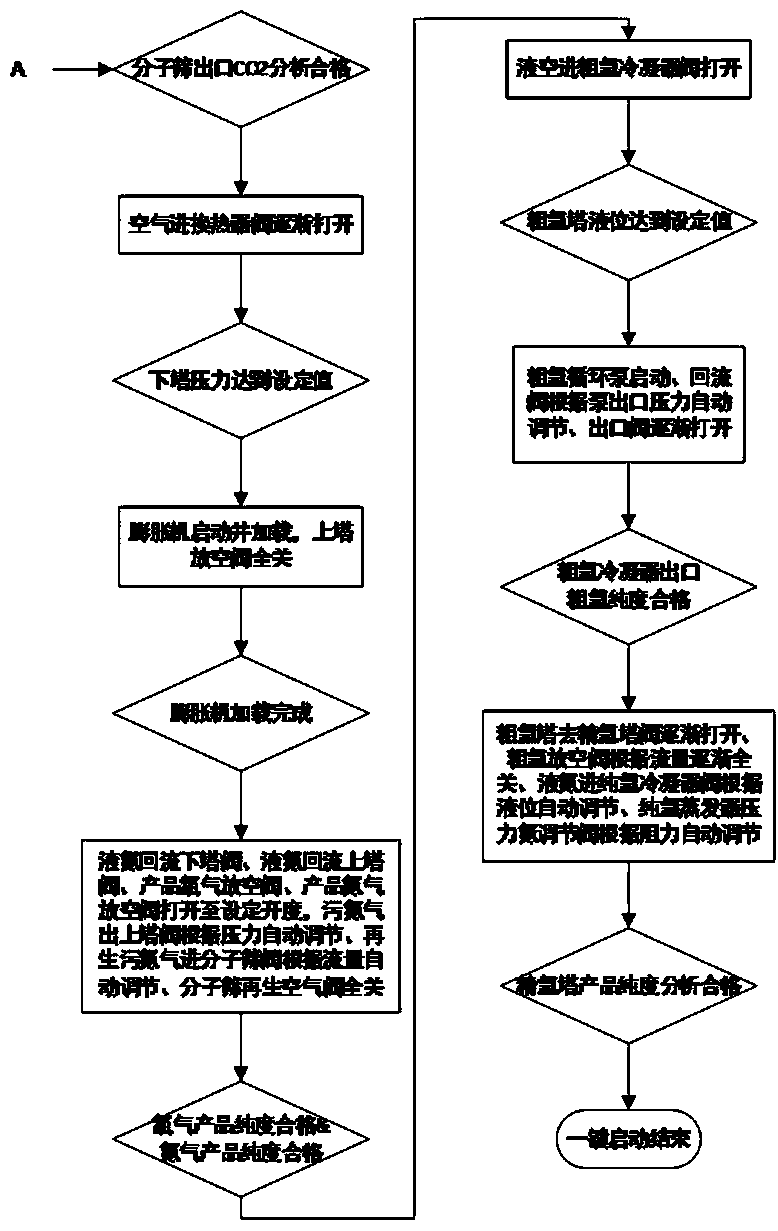

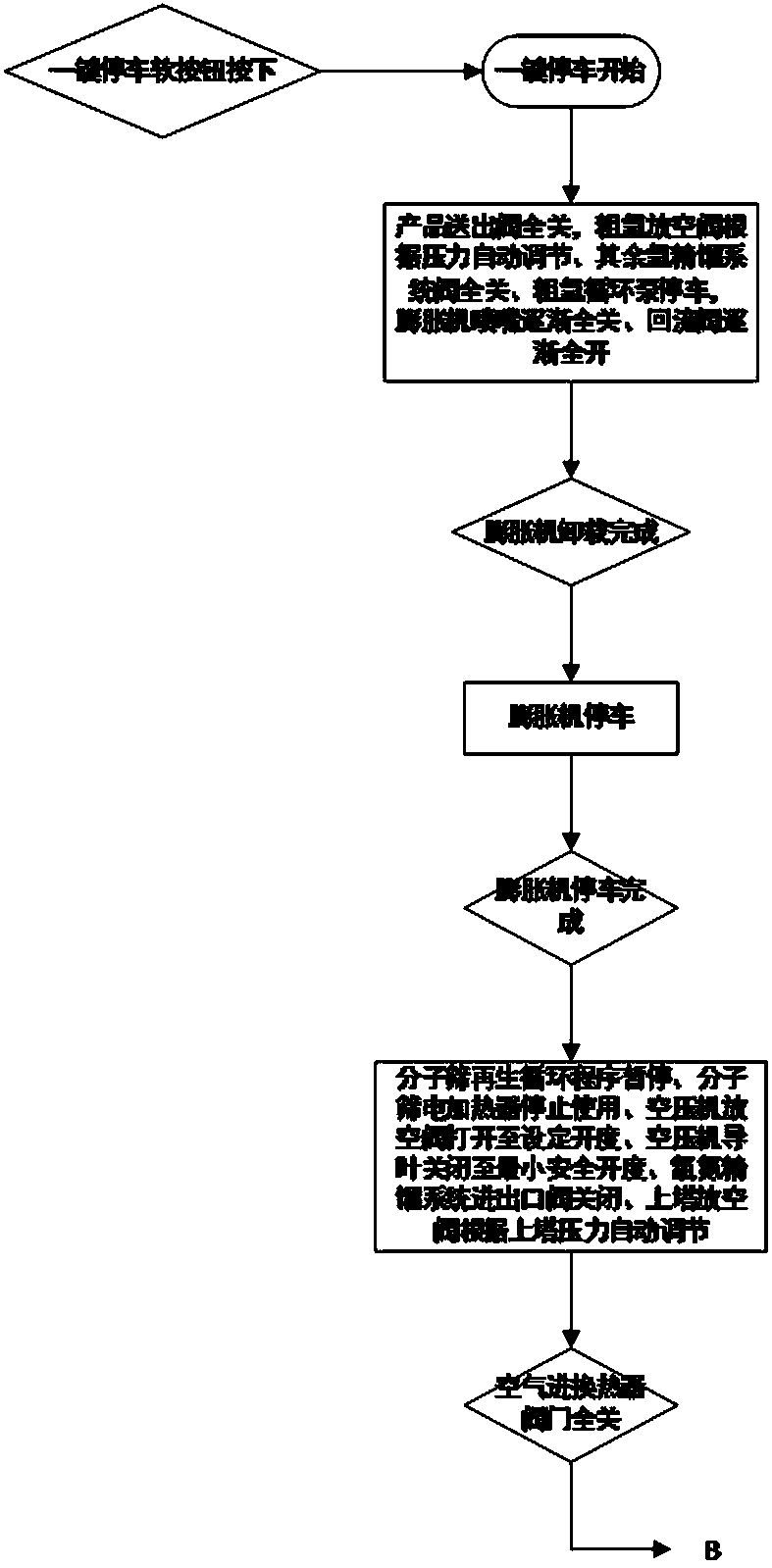

One-button start-stop control method for external compression air separation device with argon

ActiveCN111306890AReduce labor costsAvoid human errorSolidificationLiquefactionMolecular sieveStop time

The invention relates to a one-button start-stop control method for an external compression air separation device with argon, and relates to the technical field of air separation equipment automationengineering. The external compression air separation device with the argon comprises an air compressor system, an air precooling system, a molecular sieve purification system, an expander system, an oxygen nitrogen distillation system and an argon distillation system. According to the one-button start-stop control method, when an operator presses a one-button start-stop soft button, a DCS or PLC system completes the full automatic start-stop of each system of the device according to the steps, the tedious start-up and stop operation process of the external compression air separation device with the argon is simplified to one-click operation, the labor cost is effectively reduced, the start-up and stop time of the device is shortened, and production can be quickly resumed after the device bumps.

Owner:HANGZHOU HANGYANG

Allocation and Method of Retrofitting Existing Oxidation Tank to Recover Anodic Oxidation Solution

The invention discloses a configuration of improving an existing oxidation tank to recover an anode oxidation solution. An oxidation solution collecting system, an oxidation solution circulation cooling system, an oxidation solution treatment system, an oxidation solution separation system and an oxidation solution recovering and recrystallizing system are included. The invention further disclosesa method for recovering the anode oxidation solution using the configuration of improving the existing oxidation tank to recover the anode oxidation solution. The method comprises the steps of oxidation solution collecting, oxidation solution circularly cooling, oxidation solution processing and separating, and oxidation solution recovery and recrystallizing. By means of the configuration and themethod, online crystal precipitation of aluminum ions and oxidation solution circular use can be achieved to effectively reduce oxidation solution resistance and achieve low-cost high-quality production.

Owner:FOSHAN SANSHUI XIONGYING INNOVATION CENT FOR ALUMINUM SURFACE TECH

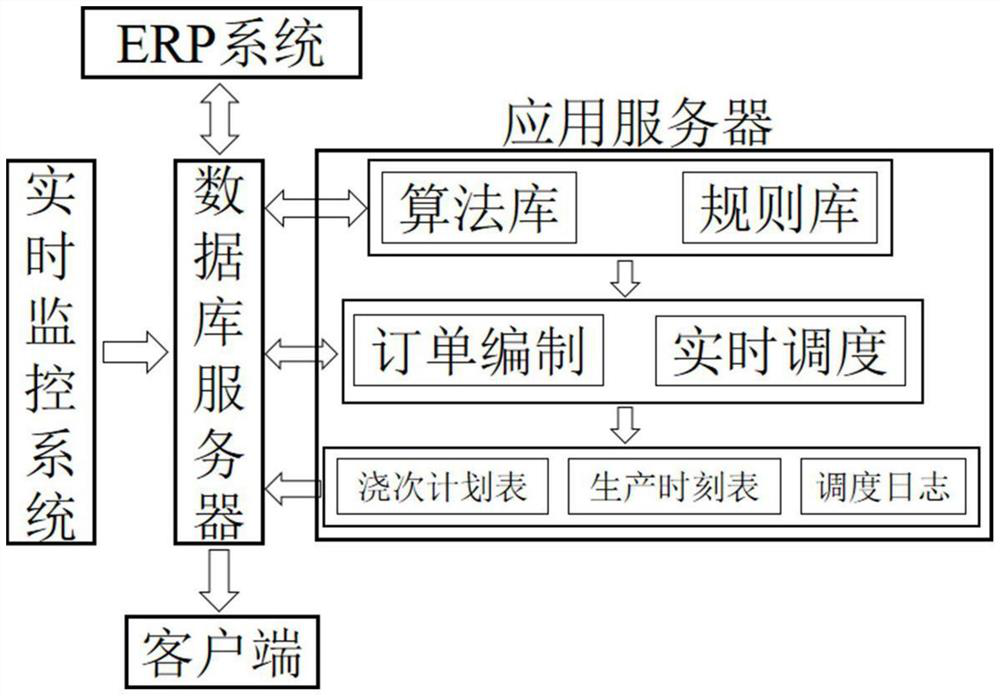

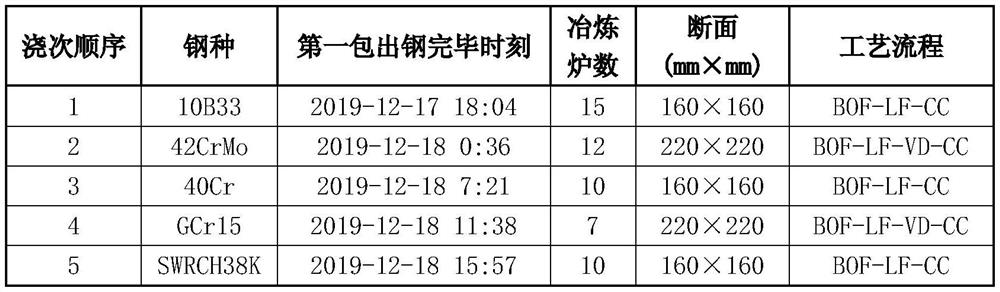

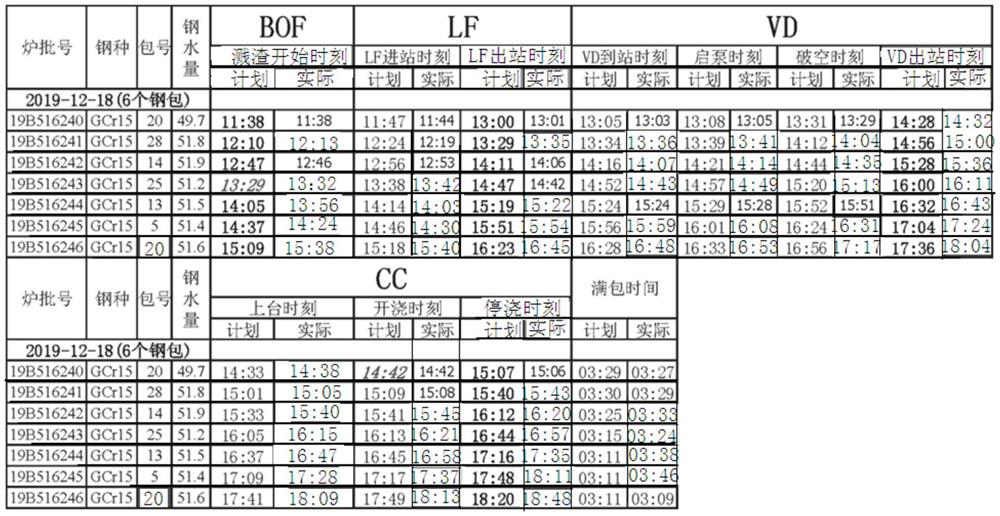

Intelligent scheduling system and method for steelmaking production process

PendingCN111898975AResume production quicklyTimely processingOffice automationResourcesApplication serverDatabase server

The invention discloses an intelligent scheduling system and method for a steelmaking production process. The scheduling system comprises an ERP system, a database server, a real-time monitoring system, a client and an application server. The ERP system is in communication connection with the database server, the output end of the real-time monitoring system is in communication connection with theinput end of the database server, the output end of the database server is in communication connection with the input end of the client, and the database server is in communication connection with the application server. According to the invention, the problems of inconsistent coordination of procedures before and after a production site and delayed mastering of real-time time information by technical management personnel are solved.

Owner:LIANFENG STEEL (ZHANGJIAGANG) CO LTD

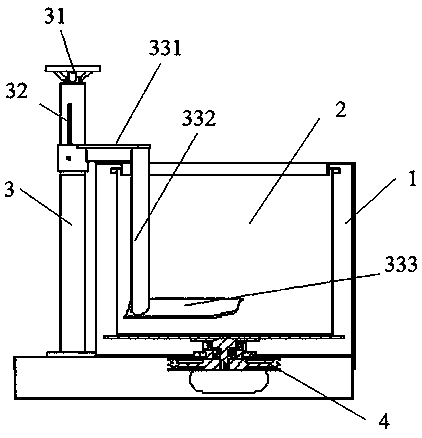

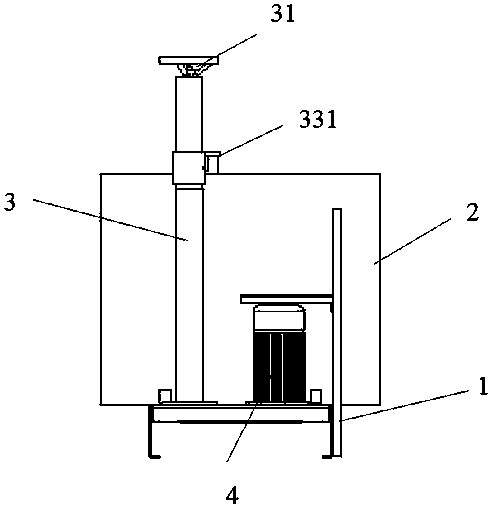

Slurry soaking device

InactiveCN107755647AAvoid lostIncrease production capacityMoulding toolsHigh resistancePulp and paper industry

The invention discloses a slurry soaking device which comprises a slurry soaking machine and a slurry soaking auxiliary machine used cooperatively with the slurry soaking machine, wherein the slurry soaking machine comprises a machine seat, a vertical column, a slurry barrel and a driving device; the slurry barrel is arranged on the machine seat; the stirring barrel is driven by the driving deviceto rotate; the vertical column is arranged on one side of the machine seat; a lifting handle, a lifting rod and a stirring device are arranged on the vertical column; the stirring device comprises alifting flat plate, a supporting column and a stirring blade; and the slurry soaking auxiliary machine comprises a bracket and an auxiliary stirrer movably arranged on the bracket, and is applied to auxiliary stirring of slurry. Compared with the prior art, the slurry soaking device disclosed by the invention makes use of the liftable stirring blade; when a fault occurs, the blade rises up to avoid an equipment accident caused by extremely high resistance during secondary stirring; the slurry soaking auxiliary machine can be applied to auxiliary stirring when equipment is faulted or power fails, so that slurry loss caused by sedimentation and solidification of slurry powder within relatively short time is avoided; and after the fault is solved, production can be quickly recovered, and theworking efficiency is improved.

Owner:东营腾云精铸设备有限责任公司

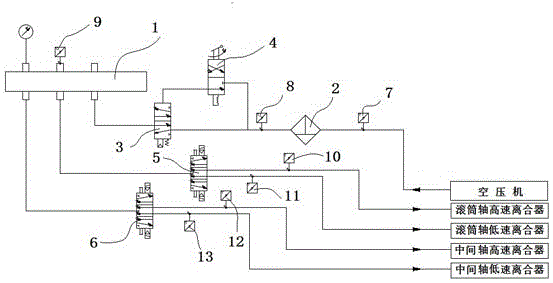

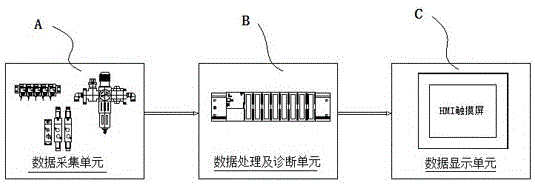

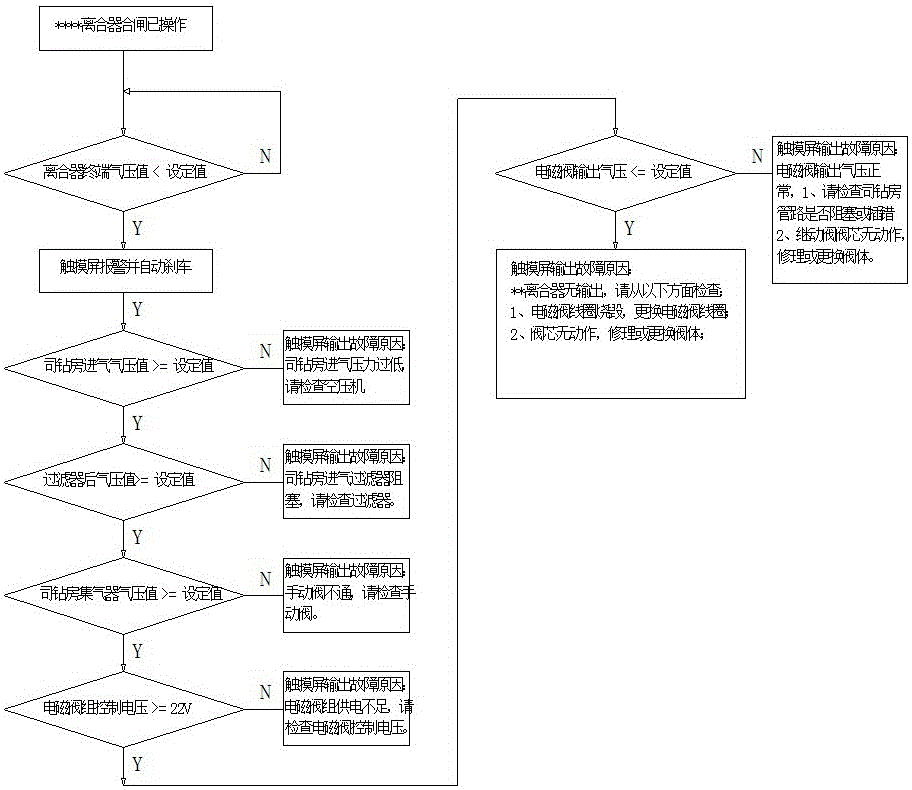

Pneumatic control fault diagnosis system of drilling machine driller room

ActiveCN105005297AReduce expertiseReduce experienceElectric testing/monitoringData displayProgrammable logic device

The invention relates to a pneumatic control fault diagnosis system of a drilling machine driller room. The system is composed of a data acquisition unit, a data processing and diagnostic unit, and a data display unit. The data acquisition unit consists of control assemblies like a gas control valve, an electronic control valve, and pressure sensors; and the data processing and diagnostic unit includes an analog input module and a programmable logic device. The pressure sensors are installed at input terminals and output terminals of the gas control valve and the electronic control valve. The data processing and diagnostic unit sends an electric signal provided by the data acquisition unit to the analog input module; and the programmable logic device carries out a logic analysis on the collected data and makes a judgment on the system equipment working state and the fault position, thereby providing data for the fault diagnosis. According to the invention, the pneumatic control fault diagnosis system can detect and display a working state of gas circuit control of a driller room timely; and when a fault occurs, a fault type and a fault point can be determined and reported timely, so that the operation and maintenance staff can solve the fault problem timely and efficiently.

Owner:ZHONGMAN GASOLINEEUM & NATURAL GAS GROUP

Allocation and method of reforming oxidation line to recover oxidizing liquid and protect single nickel salt coloring tank

A configuration for recovering oxidation liquid in a transformed oxidation line and protecting a single-nickel-salt coloring tank is disclosed. The configuration includes an oxidation liquid collection system, an oxidation liquid circulating and cooling system, an oxidation liquid treatment system, an oxidation liquid separation system, an oxidation liquid recovery and recrystallization system anda single-nickel-salt coloring tank protecting system. The invention further discloses a method adopting the configuration to recover the oxidation liquid and protect the single-nickel-salt coloring tank. The method includes oxidation liquid collecting, oxidation liquid circulating and cooling, oxidation liquid treatment and separation, oxidation liquid recovery and recrystallization, and single-nickel-salt coloring tank protection steps. The configuration and method achieve on-line crystallization and separation of aluminum ions and cyclic use of the oxidation liquid, can effectively reduce resistance of the oxidation liquid, greatly reduce the risk that the single-nickel-salt coloring tank is polluted, save water and achieve low-cost high-quality production.

Owner:FOSHAN SANSHUI XIONGYING INNOVATION CENT FOR ALUMINUM SURFACE TECH

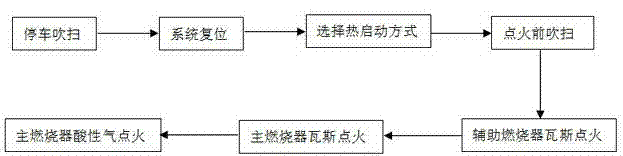

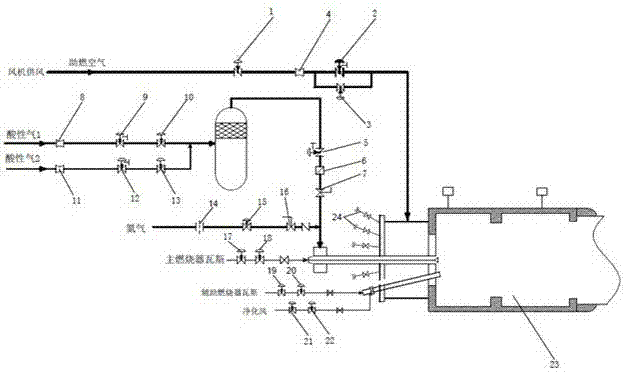

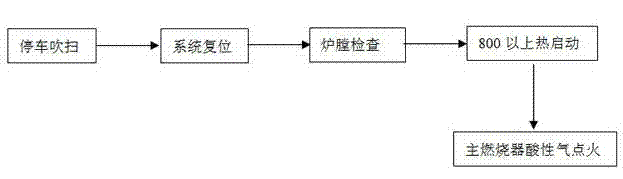

Improved thermal ignition method of combustion furnace of sulfur recovery device

ActiveCN102954489ASimplified ignition procedureReduce flareSulfur preparation/purificationCombustion ignitionThermal ignitionProcess engineering

The invention discloses an improved thermal ignition method of a combustion surface of a sulfur recovery device. The improved thermal ignition method comprises the following steps of: (1) stopping to blow; (2) replacing the system; (3) inspecting a hearth: inspecting whether the temperature in the hearth is above 800 DEG C after the system is replaced, if so, carrying out the following step, and if not, igniting according to the original ignition process; (4) carrying out hot start at temperature more than 800 DEG C: switching on a combustion air interlocking valve, and allowing to switch on an acidic gas interlocking valve; and (5) igniting main combustion acidic gas: switching on the combustion air interlocking valve, feeding combustion air into the combustion furnace, then switching on the acidic gas interlocking valve, an acidic gas control valve and an acidic gas furnace feeding ball valve, and feeding the acidic gas into the furnace, igniting, and finally canceling the hot start procedure under temperature more than 800 DEG C. By adopting the improved heating ignition method, the ignition efficiency can be improved, the torching of the acidic gas can be reduced, and the environmental pollution can be reduced.

Owner:CHINA PETROLEUM & CHEM CORP

Method for repairing tube plate of graphite heat exchanger

InactiveCN102809318AHigh bonding strengthShort timeHeat exchanger casingsPlate heat exchangerEngineering

The invention discloses a method for repairing a tube plate of a graphite heat exchanger. An original tube plate hole is enlarged, threads are formed in the tube plate hole which is enlarged, a boss is arranged at the bottom of the tube plate hole, a graphite nylon gasket is sleeved at the periphery of the boss, a screw which is matched with the threads in the tube plate hole is processed, and the screw is screwed into the tube plate hole and compresses the graphite nylon gasket for sealing. Compared with the conventional adhesion repair method, the method for repairing the tube plate of the graphite heat exchanger by using thread plug holes is high in strength and short in time, and facilitates production quick recovery of equipment, so working efficiency is improved.

Owner:NANTONG SANXIN CARBON GRAPHITE EQUIP

Special device for online opening and closing activation of large butterfly valve

InactiveCN111015596AReduce maintenance costsResume production quicklyMetal-working hand toolsProcess systemsButterfly valve

The invention discloses a special device for online opening and closing activation of a large butterfly valve. The special device comprises an activation shaft sleeve, a square-head indexing flange and an activation lever; a square hole is formed in the activation shaft sleeve; the square-head indexing flange is fixedly connected with a plane indexing flange through 12 screws; the 12 screws are equal in distance; a nut is movably hinged to one end of each screw; and a square head is arranged on one side, deviating from the plane indexing flange, of the square-head indexing flange. By the aid of the special device for online opening and closing activation of the large butterfly valve, online handling of the equipment failure of jamming of the large butterfly valve can be completed in the construction period of 3 hours, the distance between lifting rings and the top end of the activation lever is set to be longer than 5 mm, the device can be stressed by 1,000 kg or above, the device canbear the torque being 200 kn.m or above, the effects that the valve maintenance cost is reduced, a process system resumes production quickly and the running efficiency of the process system is improved substantially are achieved, and the problem of low bearing capacity of online activation machines for the large butterfly valves is solved.

Owner:湖南湘钢工程技术有限公司

Inspection and Repair Method of Blast Furnace Top Gas Cover

ActiveCN109628674BResume production quicklyIncrease productivityBlast furnace componentsBlast furnace detailsSlagDust control

The invention provides an overhauling method for a blast furnace top gas sealing cover. The overhauling method comprises the following steps that a cross-shaped temperature measuring rod of a blast furnace body is removed, a mounting hole of the cross-shaped temperature measuring rod in the blast furnace body is left, and an air pipe is installed at the mounting hole; the air pipe communicates with dust removal equipment; blowing-down materials and water pressing slag materials are loaded in a blast furnace, and the material level in the blast furnace is decreased to be below the position of the cross-shaped temperature measuring rod; a protective shed is installed in the blast furnace top gas sealing cover, so that the protective shed, the blast furnace body and the material level in theblast furnace form a relatively closed space; the dust removal equipment is used for pumping and discharging gas generated by the material level in the blast furnace from the air pipe, and the gas isprevented from being moved to the position above the protective shed. By means of the overhauling method for the blast furnace top gas sealing cover, the gas content inside the sealing cover is greatly reduced, safety inspection is achieved, maintenance time is shortened, the labor intensity of workers is reduced, and the aim of blast furnace production efficiency is improved.

Owner:BAOTOU IRON & STEEL GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com