Construction method for installing precast beam slabs by adopting bridge girder erection machine

A bridge erecting machine and beam-slab technology, which is applied in the direction of erecting/assembling bridges, bridges, and bridge construction, etc., can solve the problems of low construction efficiency, difficult component installation and safe operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

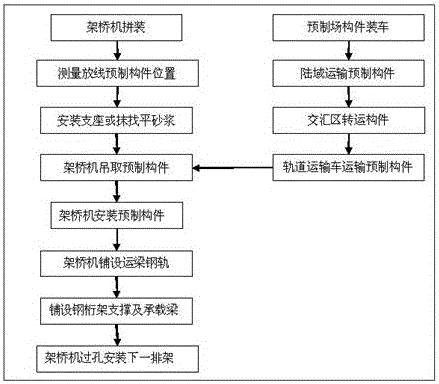

[0034] Such as figure 1 As described, a construction method for installing prefabricated beams and slabs using a bridge erecting machine includes the following steps:

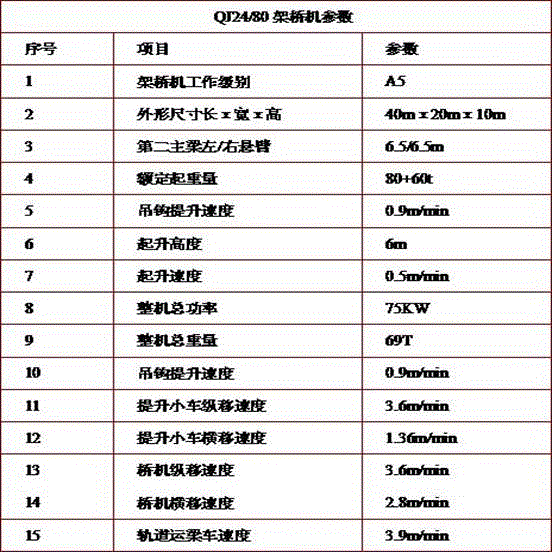

[0035] 1) Selection of bridge erecting machine: In this embodiment, according to the maximum hoisting weight of the prefabricated component is 40t, the maximum length of the prefabricated component is 11.2m, so the QJ24 / 80 type bridge erecting machine is selected to meet the construction requirements of this project;

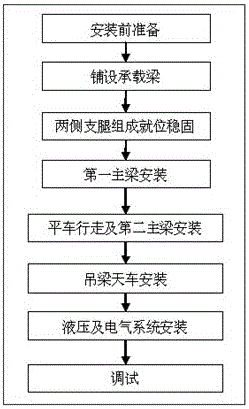

[0036] The main structure of the QJ24 / 80 bridge erecting machine consists of the first main girder, the truss crane walking assembly, the second main girder, the crane girder crane, the main support, the auxiliary support and the hydraulic system, forming a complete structural system. The bridge erecting machine has a total length of 40 meters, a maximum lifting weight of 60 tons, and a maximum beam span of 24 meters. It has the characteristics of light structure, good rigidity, strong stability,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com