Full automatic V-groove cutting and edging machine

A fully automatic, edge folding machine technology, applied in the field of plate processing, can solve the problems of insufficient toughness of glue, complicated and cumbersome operation, colloid mixing, etc., and achieve the effects of strong aging resistance, good toughness, and promoting the bonding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

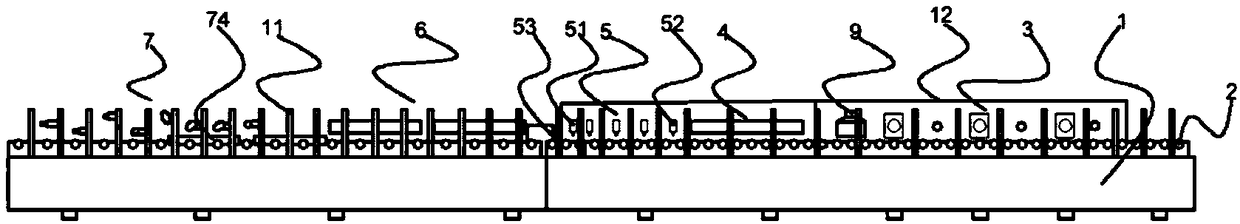

[0052] The following is attached Figure 1-9 The present invention is described in further detail.

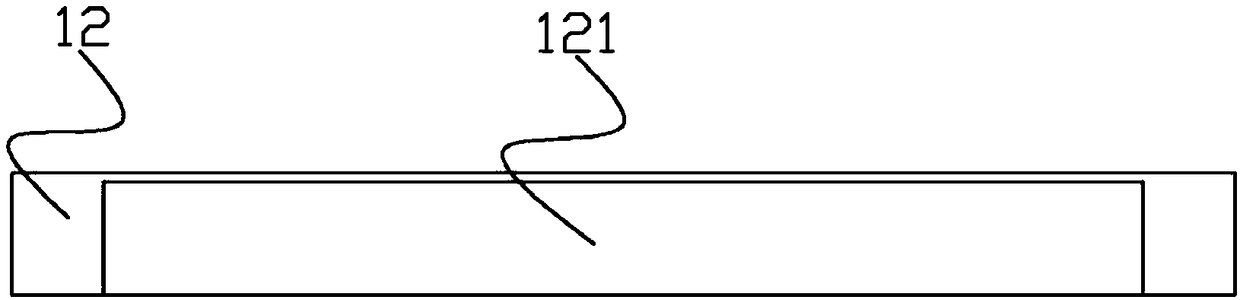

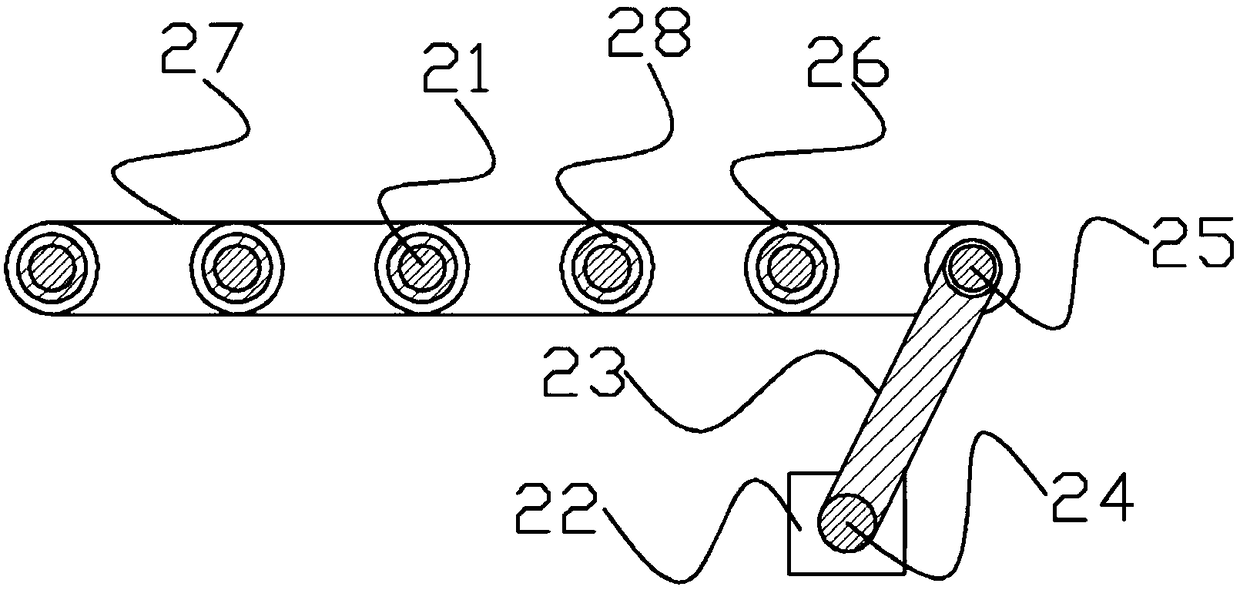

[0053] A fully automatic V-groove cutting and folding machine, such as figure 1 and figure 2 As shown, it includes the frame base 1 and the transmission device 2. The top of the frame base 1 is provided with a special placement groove, the transmission device 2 is fixed in the placement groove, and the frame base 1 is sequentially provided with three cutting machines along the length of the machine body Device 3, a preheating device 4, a dispensing device 5, two heating devices 6 and a set of hemming device 7, the preheating device 4 is fixedly connected with the frame base 1, and the preheating device 4 is set on the transmission device 2 Above, the dispensing device 5 is fixedly connected to the side of the frame base 1, the heating device 6 is fixedly connected to the frame base 1, the heating device 6 is also arranged above the transmission device 2, and the hemming devi...

Embodiment 2

[0064] The difference from Embodiment 1 is that the lower roller 28, the upper roller 34 and the fixed roller 91 are made of special materials.

[0065] Lower roller 28, upper roller 34 and fixed roller 91 are prepared by the following method:

[0066] Get the following raw materials for each component by weight: 30 parts of styrene-butadiene rubber, 20 parts of natural rubber, 8 parts of zinc oxide, 6 parts of calcium carbonate, 5 parts of titanium dioxide powder, 3 parts of natural paraffin, 3 parts of styrene, stearic acid 4 parts of zinc, 2 parts of tri-n-butyl citrate, 3 parts of p-phenylenediamine and 3 parts of diethylthiourea;

[0067] S1. Put the weighed styrene-butadiene rubber and natural rubber into the mixer and stir well, it is worth mixing the materials;

[0068] S2. Put the mixed material prepared in step S1 into the internal mixer for masticating, the temperature of the internal mixer is set to 120° C., and the internal mixing time is 15 minutes to obtain the...

Embodiment 3

[0074] The difference from Example 2 is that the formulation of the lower roller 28, the upper roller 34 and the fixed roller 91 is adjusted:

[0075] Get the following components by weight for subsequent use: 40 parts of styrene-butadiene rubber, 30 parts of natural rubber, 12 parts of zinc oxide, 10 parts of calcium carbonate, 8 parts of titanium dioxide powder, 6 parts of natural paraffin, 5 parts of styrene, stearic acid 7 parts of zinc, 4 parts of tri-n-butyl citrate, 5 parts of p-phenylenediamine and 5 parts of diethylthiourea;

[0076] S1. Put the weighed styrene-butadiene rubber and natural rubber into the mixer and stir well, it is worth mixing the materials;

[0077] S2. Put the mixed material prepared in step S1 into the internal mixer for masticating, the temperature of the internal mixer is set to 120° C., and the internal mixing time is 15 minutes to obtain the internal mixing material;

[0078] S3. Mix the banburying material prepared in step S2 and weighed zin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com