Kiln turning method for rotary kiln large-gear precise alignment

A technology of rotary kiln and large gear, which is used in rotary drum furnaces, furnaces, lighting and heating equipment, etc., can solve problems such as repeated cutting, and achieve the effect of saving costs, shortening installation time, and restoring production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

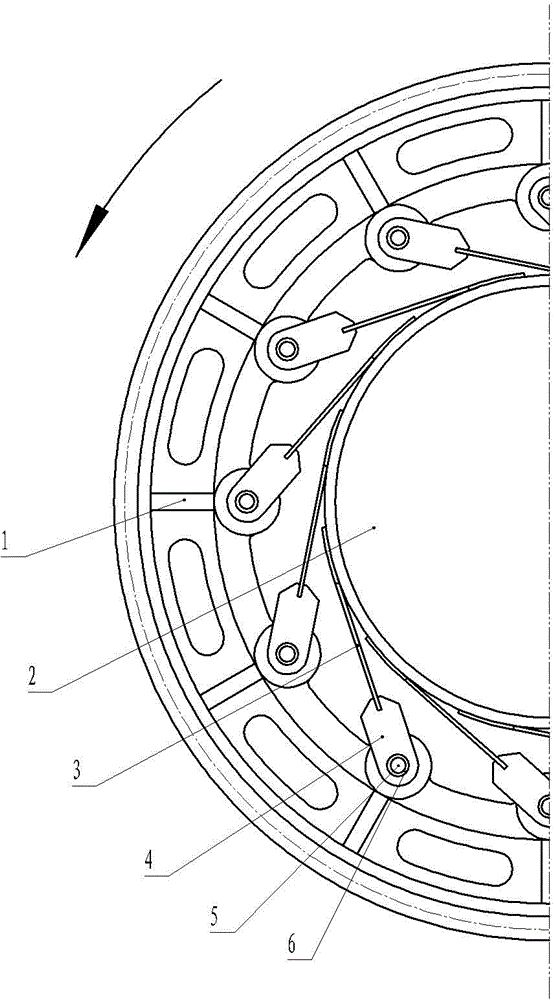

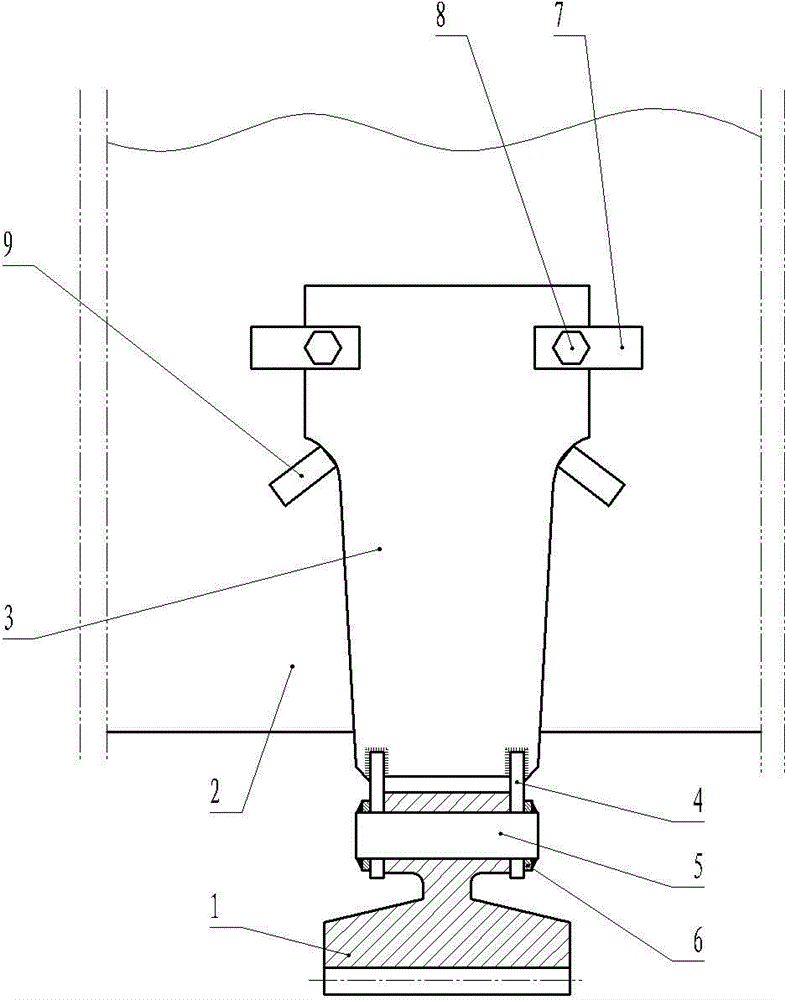

[0021] Such as figure 1 , figure 2 As shown, a rotary kiln method for fine alignment of the large gear of the rotary kiln. The rotary kiln includes a large gear 1 set outside the cylinder body 2 through the central installation hole, and the large gear 1 is circumferentially distributed near the inner edge of the central installation hole. There are twelve pin holes, the large gear 1 is meshed with the pinion, and the pinion is connected with the auxiliary motor through the reducer. The specific steps are as follows:

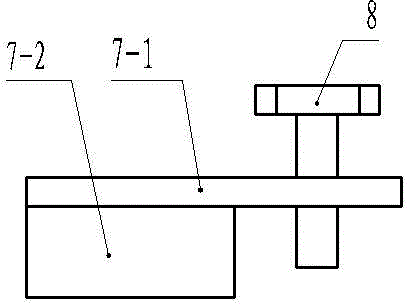

[0022] A. Use six evenly distributed spring connecting plates to connect the large gear 1 to the cylinder body 2. The spring connecting plates include a spring plate 3. The spring plate 3 includes two oppositely arranged arc-shaped sides with arc-shaped concave surfaces and respectively The long side and the short side connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com